It’s been an uneventful few months… both in terms of getting anything done, and also with regards to anything else dropping off.

However.

Whilst driving to work the other day, it became apparent that there was something amiss yet again in the braking department. First push of the pedal almost to the floor and not much retardation, second push and all as it should be.

Hmmmmm 🤨

This behaviour is normally indicative of brakes being way out of adjustment after lots of miles. Except that I haven’t done lots of miles; and it came on suddenly, not gradually like it would do from wear…

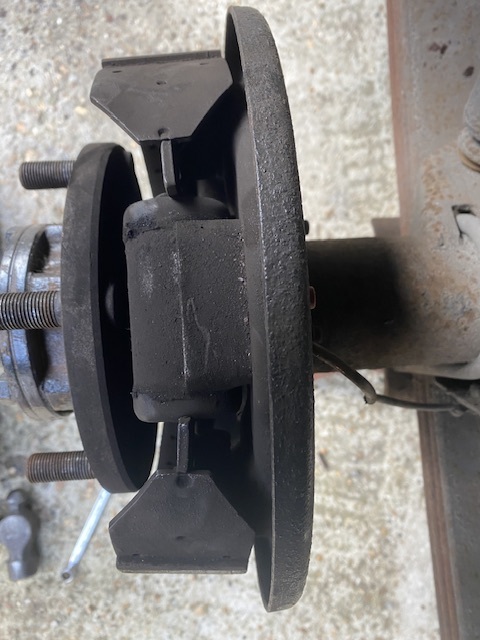

So, after a few days of driving around the issue hoping it would cure itself, I decided to get underneath and see if I could work it out. Front brakes’ adjusters all ok, but the nearside rear had one that was just spinning. Well, that seemed like the best place to start…

The adjusters are simple snail cams, and it’s not uncommon for them to fall off the end of their shafts, and that’s what I was expecting to find. Wheel off, drum off, and no, adjuster is fine, but the shoe has slid off it and the return springs have fully compressed the piston back into the cylinder.

How’s that happened? Well, the muppet that fitted them (yours truly), had put one of the return springs on the wrong side of the shoes.

So instead of pulling the shoes back against the backplate, it was pulling it away. Doh.

Anyway. An easy fix, and a reminder that none of us is exempt from making simple mistakes, no matter how familiar we are with our equipment.

With the offending spring reoriented, I thought it best to check the offside and, yes, I’d made the same mistake there too. 🙄

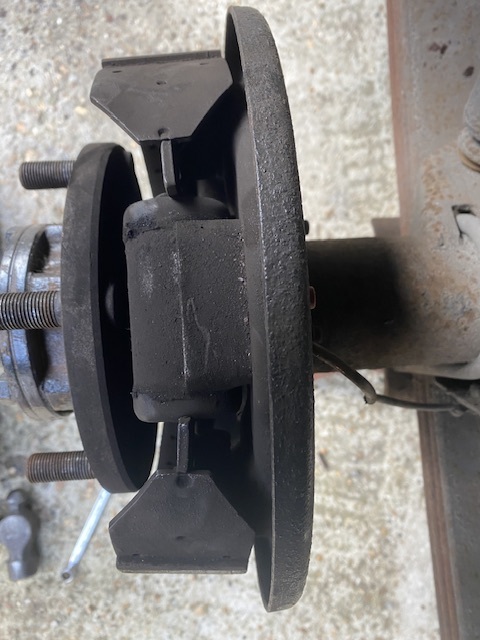

As the Land-Rover was sat there with the rear wheels off, I thought I’d take the opportunity to do another little job I’d been putting off.

I have what are known as “Wolf” wheels on the wagon, which are heavy duty 6.5J tubeless ones, and they have a thicker nave (the bit in the middle) than standard ones. This means having to use longer wheel studs. The longer wheel studs are actually about 6-7mm longer than they need to be, and they poke out of the nuts quite a bit.

This irks me.

I have thought about shortening the studs, but removing, turning down and then replacing 20 of them doesn’t appeal.

And it would be madness really, even by my own standards. 🤣

So I have just put up with it for years.

Anyway, I have a friend that works at a laser cutting company, who offered to cut me some spacers if I gave him the dimensions. Earlier this year I finally got around to doing that, and these were the result:

Four perfect discs/spacers in 6mm mild steel.

They bring the wheels out just the right amount.

Still inside the arches though, which is good. 👍

I did have a minor moment thinking that they were too thick, but it was actually that some of my wheel nuts were slightly thicker than the rest. A rumble through the stores turned out enough to get them all matching.

We will have to wait and see whether a 12mm extra track makes any noticeable impact on high speed handling… somehow I doubt that I’ll detect any difference. 🤣

The only other thing I have had to do this week was to put the batteries on charge. All the short runs I do are obviously not enough for the alternator to keep up with charging them both. I might investigate higher output alternatives when I finally get around to revisiting the whole alternator/power steering pump mounting issue, but it’s probably just as easy to whack the charger on from time to time..

However.

Whilst driving to work the other day, it became apparent that there was something amiss yet again in the braking department. First push of the pedal almost to the floor and not much retardation, second push and all as it should be.

Hmmmmm 🤨

This behaviour is normally indicative of brakes being way out of adjustment after lots of miles. Except that I haven’t done lots of miles; and it came on suddenly, not gradually like it would do from wear…

So, after a few days of driving around the issue hoping it would cure itself, I decided to get underneath and see if I could work it out. Front brakes’ adjusters all ok, but the nearside rear had one that was just spinning. Well, that seemed like the best place to start…

The adjusters are simple snail cams, and it’s not uncommon for them to fall off the end of their shafts, and that’s what I was expecting to find. Wheel off, drum off, and no, adjuster is fine, but the shoe has slid off it and the return springs have fully compressed the piston back into the cylinder.

How’s that happened? Well, the muppet that fitted them (yours truly), had put one of the return springs on the wrong side of the shoes.

So instead of pulling the shoes back against the backplate, it was pulling it away. Doh.

Anyway. An easy fix, and a reminder that none of us is exempt from making simple mistakes, no matter how familiar we are with our equipment.

With the offending spring reoriented, I thought it best to check the offside and, yes, I’d made the same mistake there too. 🙄

As the Land-Rover was sat there with the rear wheels off, I thought I’d take the opportunity to do another little job I’d been putting off.

I have what are known as “Wolf” wheels on the wagon, which are heavy duty 6.5J tubeless ones, and they have a thicker nave (the bit in the middle) than standard ones. This means having to use longer wheel studs. The longer wheel studs are actually about 6-7mm longer than they need to be, and they poke out of the nuts quite a bit.

This irks me.

I have thought about shortening the studs, but removing, turning down and then replacing 20 of them doesn’t appeal.

And it would be madness really, even by my own standards. 🤣

So I have just put up with it for years.

Anyway, I have a friend that works at a laser cutting company, who offered to cut me some spacers if I gave him the dimensions. Earlier this year I finally got around to doing that, and these were the result:

Four perfect discs/spacers in 6mm mild steel.

They bring the wheels out just the right amount.

Still inside the arches though, which is good. 👍

I did have a minor moment thinking that they were too thick, but it was actually that some of my wheel nuts were slightly thicker than the rest. A rumble through the stores turned out enough to get them all matching.

We will have to wait and see whether a 12mm extra track makes any noticeable impact on high speed handling… somehow I doubt that I’ll detect any difference. 🤣

The only other thing I have had to do this week was to put the batteries on charge. All the short runs I do are obviously not enough for the alternator to keep up with charging them both. I might investigate higher output alternatives when I finally get around to revisiting the whole alternator/power steering pump mounting issue, but it’s probably just as easy to whack the charger on from time to time..