glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

Apr 23, 2023 12:18:49 GMT

|

I went to leave for work yesterday and, whilst manoeuvring on the drive the brakes were definitely sub optimal. A quick check of the reservoir revealed:  That ain’t great. ☹️ It was raining, and I was in my work uniform, so a quick peer underneath was all I could manage…  Yep. That’s the same wheel cylinder that’s let go. 🙄 I hadn’t got around to making a “next order” to add a pair of wheel cylinders to, so I put one in last night. I used Delphi ones last time as they’ve been a good compromise between cost and longevity for me in the past, but these ones have barely been on two years and 10,000 miles; so I’ve ordered the Lucas/TRW ones this time (which are twice the price) in the hopes that they’ll last longer. Looks like I’m walking to work for a couple of days. I’m off Wednesday and Thursday, so with luck the bits will be here by then and it won’t be raining. I think I’m going to fit a fluid level warning light too. |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Apr 23, 2023 13:20:04 GMT

|

|

I’m trying to imagine what your work uniform is like and all I can see is a cheerleader with big frilly pom-poms.

It does look a bit odd with that tin hat though…

|

| |

|

|

|

|

|

Apr 23, 2023 17:50:28 GMT

|

|

Liked for the update, not so much the crappy parts.

Imagine if you had issues like that on a new car, parts failing every 10k (and brake components at that.)

I would happily pay more for parts that are better quality, but not for a brand and I think is good but is actually ECP own brand now.

Anyway, bloody love this Landy, and your ethos of sympathetic improvement.

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

Apr 23, 2023 18:42:27 GMT

|

|

Thanks. 😃👍

I’ve actually begun to think that I should have bitten the bullet and converted to discs all around, but the cost of doing that properly is truly eye watering. Hopefully the Lucas cylinders give better service.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Apr 23, 2023 18:53:17 GMT

|

|

Glenn, saying this with humor/humour, but there’s some irony when one is looking at Lucas as the optimal quality part available. I hope you’ll be back on the road ASAP and not having to keep spending hard-earned dosh on the same bloomin’ parts.

Best, John

|

| |

|

|

|

|

|

Apr 23, 2023 19:47:20 GMT

|

|

When I had a series 2 which I used most days, brake cylinders were regularly failing, none seemed up to much, I begun to wonder if they were all made in the same Chinese factory and put in diferent boxes....

I ended up fitting some old stock genuine Landrover seals to whatever cylinders were in there they seemed to last OK.

I've also fitted a level switch to all my old single circuit cars, does give plenty of warning when leaks first start.

|

| |

|

|

|

|

|

Apr 23, 2023 21:26:28 GMT

|

It does look a bit odd with that tin hat though… I'm not sure the tin hat is certified for main line running? Alas, another sign of 'broken Britain.' There was a time when an engine driver would think nothing of a bit of grease and muck on his uniform. So much so he would happily roll about under a Land Rover to break in clean overalls. Then eat a breakfast that had been cooked on a filthy shovel.  These youngsters these days, all wanting to go to work in a pin striped suit...  |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

May 10, 2023 15:18:36 GMT

|

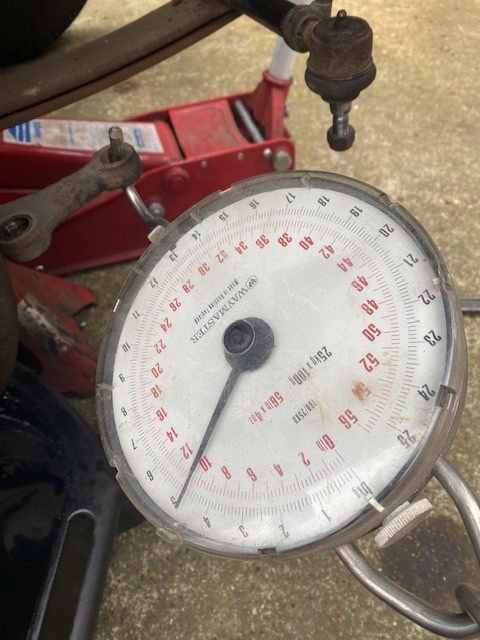

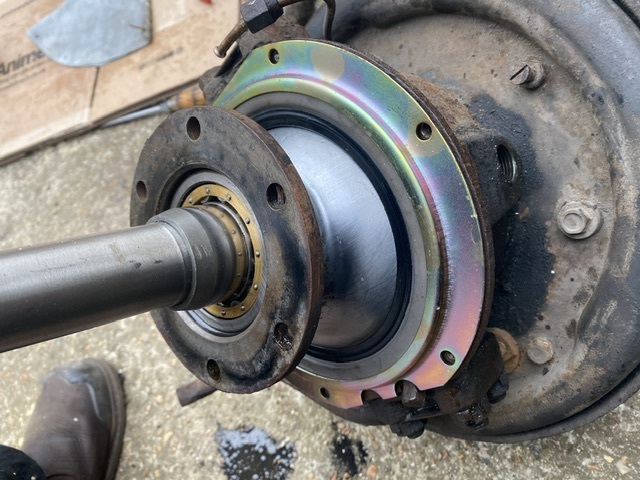

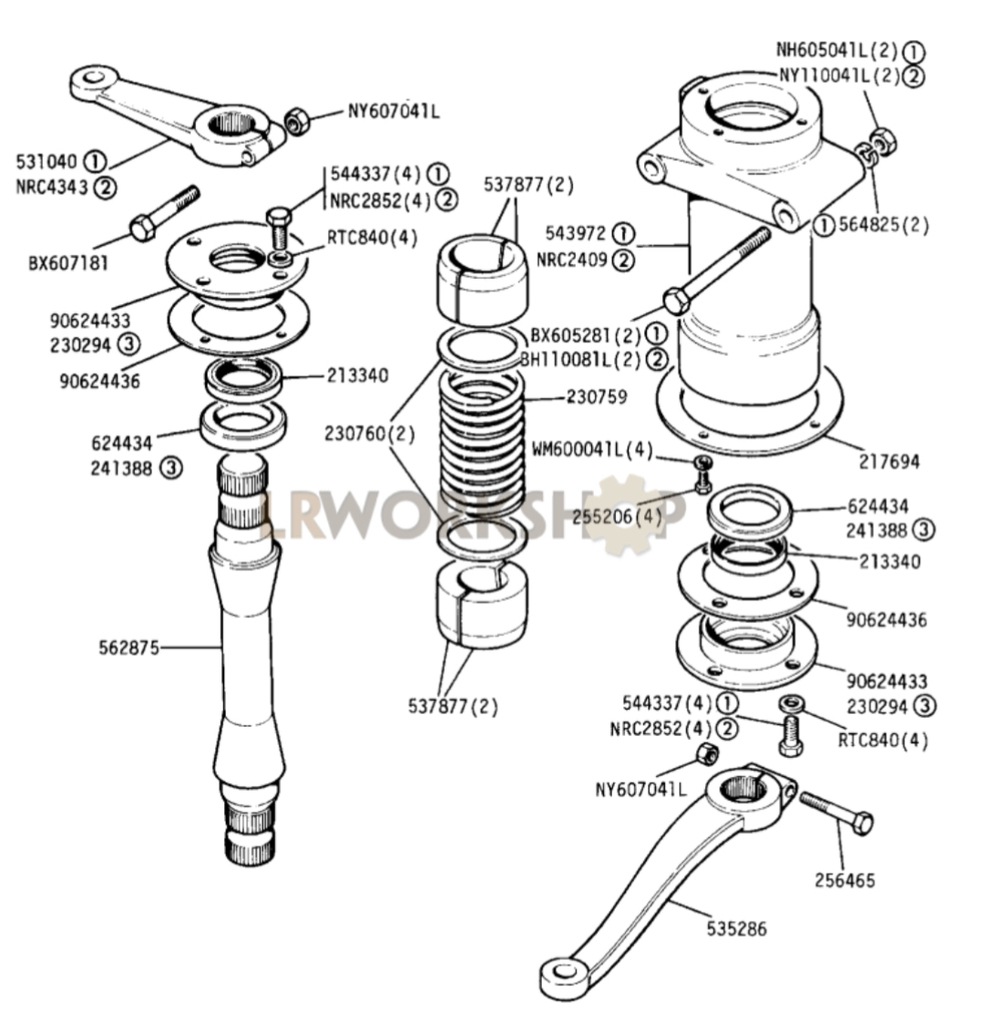

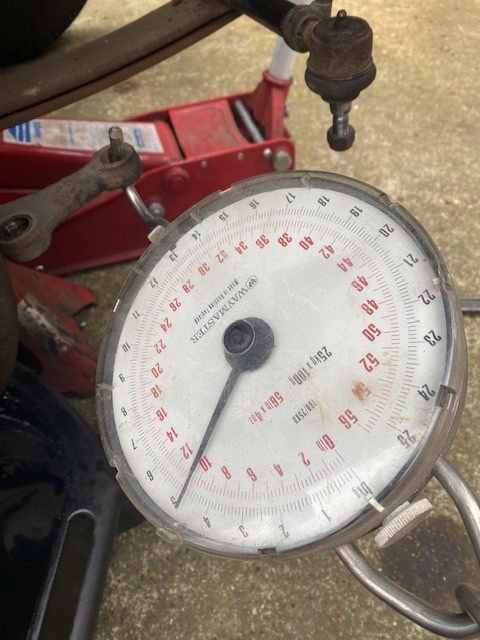

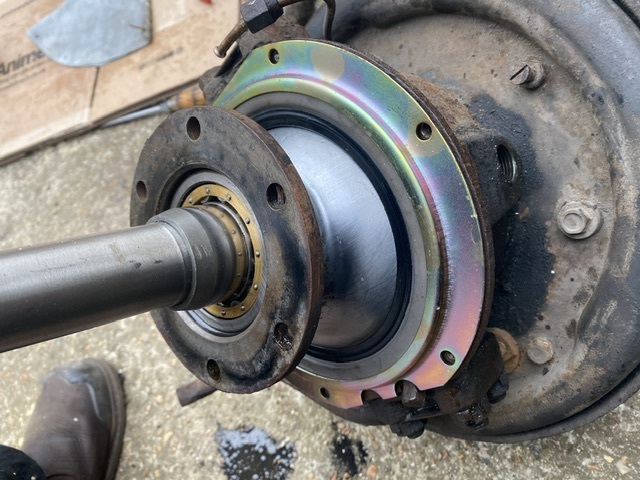

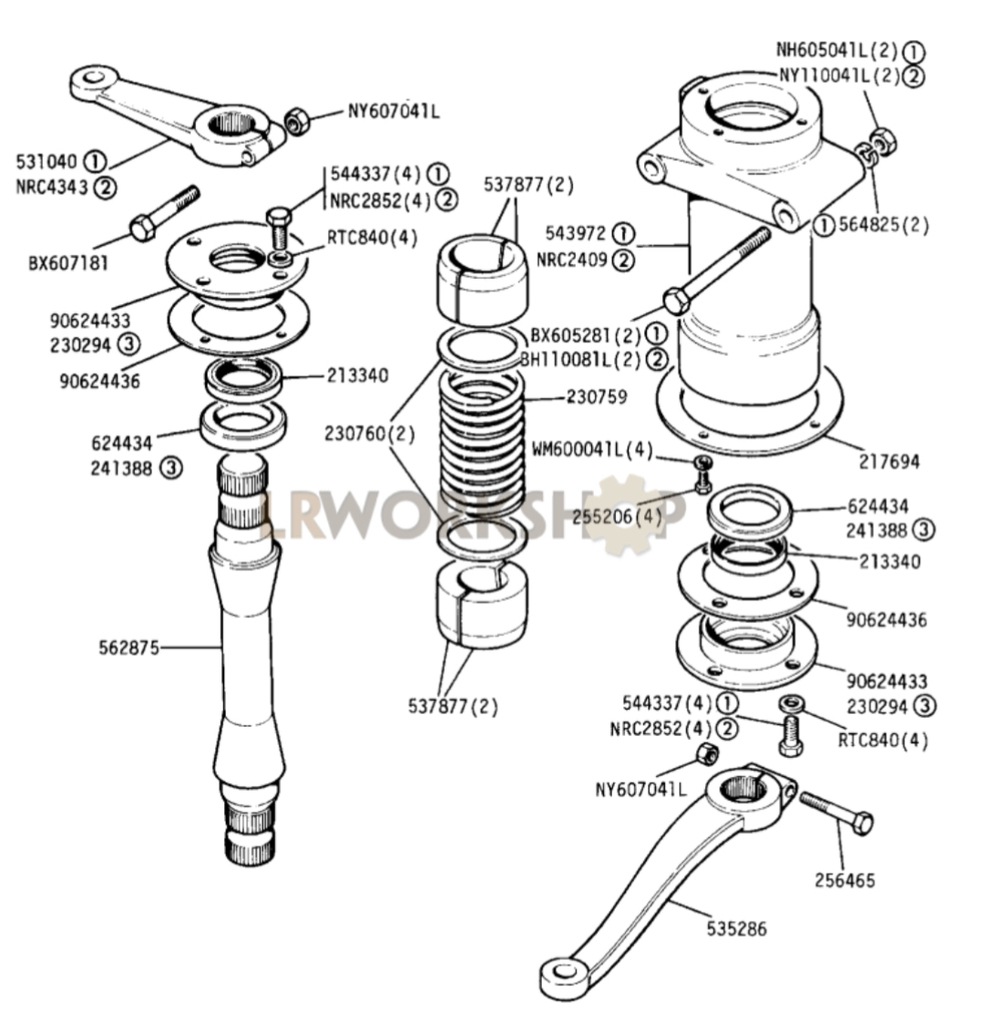

Ok, update time.  New cylinders arrived, along with a couple of days off work that weren’t rainy.  Drum off:  Yuk. Still, I knew I was on borrowed time with that cylinder; even though I’d hoped to borrow a little more time than two months. 🤣 With it all stripped, cleaned, new cylinder (seal areas liberally smeared inside with red grease). I had a dog end of black paint in a tin, so I threw that around too.🤣  Rather than risk it, I swapped out the other side too. Typically, my otherwise perfect brake pipe had seized on the tube nut, so I had to replace that too. 🙄  I splashed out a whole £9-something on a reservoir cap with a built in level switch.  This matched the thread on the reservoir perfectly. Yay. 😃 But the float bit wouldn’t fit into the reservoir because of this baffle. Boo. ☹️  The baffle separates the two circuits’ supplies, so I didn’t want to just cut it away. Further thought is required, and maybe a different reservoir. For the time being I’m going back to the previous warning system of finding out there’s a problem when the brakes stop working; after all, it’s how I have managed up until now. 🤣🤣 With the brakes reassembled, bled, adjusted and tested, I got all carried away and changed the rear differential oil too. Then it was time to look at another area that had been getting steadily less tolerable over the last year or so… Land-Rover steering isn’t known for its precision. An old fashioned steering box, a drag link, a relay, another drag link and a track rod (six balljoints) connecting two big swivel housings each with a plain bush friction damper and a hefty wiper seal, all mean loads of potential backlash points and loads of friction. My steering had been getting stiffer which, when combined with a bit of play in the box, meant it was getting a bit more wandery than normal; time to do something about it. I have always had some form of gaiter on my swivels since buying a secondhand axle for pennies (literally 50p plus 10% buyer’s commission) at an auction back in about 1994 that, despite looking like it had spent a decade in a swamp, had absolutely perfect swivels underneath the really crusty leather gaiters. Although the leather ones work really well, they’re messy and fiddly to fit, so when I fitted the current axle I installed some super-dooper expensive rubber ones that came moulded onto the seal retainers. Apparently they were Belgian Army spec. Well, they looked great, but didn’t last very long at all. After about five years they were in tatters. My next attempt was with the split rubber type that you glue together. They also looked smart for a brief while, but didn’t last. They were an MoT advise for ages, and then when I no longer needed to MoT it, I kind of just left them.  More ick. Despite the “leak”, and me genuinely not being able to tell you when I last changed or topped up the oil, the levels both sides were bang on. Now, part of my stiff steering could be the top bush in the swivel, so the first thing to do is pop the balljoint and seal off, and measure the resistance to movement with a balance.  Somewhat to my astonishment, that’s pretty much bang on. Given that there was no discernible play in the assembly there was no point in dismantling it further. Instead, in order to fit a new wiper seal I removed the whole lump as one (heavy) piece. It’s “only” six bolts. 🤣  With it off, I changed the seal at the end of the axle tube.  And then cleaned the swivel ball, and fitted a new wiper seal and retainer.  No in-progress shots of the next bit as it was just too messy to be taking any. The leather gaiter needs to be first thoroughly impregnated with Vaseline both sides, which makes it a revolting slippery mess. Then it needs stitching together; this is something that is just about possible to do in-situ, but it’s really awkward, which is why I have put off doing it for so long. However, with the swivel assembly off, you can stitch it together on the bench, then fit it afterwards. With it all back together it looks like this:  I then checked the track rod end, which also turned out to be fine, so I whacked back on and moved to the other side. This was pretty much exactly the same. All basically fine, but in need of a new seal and gaiter. The only other thing to look at that side was a slight weep from the hub cap.  Which turned out to be a slack nut on the end of the driveshaft. Easily sorted, but I put a new felt seal behind it rather than just tightening it up.  Cap back on and all cleaned up.  If you have one, the big hub nut socket makes an ideal drift for refitting the caps.  With that lot back on, oils replaced (including the diff), and the brakes bled, the next items to check were the TREs for the drag link to the relay. As they were new at the same time as the track rod ones, maybe unsurprisingly, they were ok too. 😃 Then to the relay. Aah, I have found the culprit. So stiff I could barely move it by hand. Sadly, time was against me by this point and I didn’t pause to clean up and take pictures, but this is the little so-and-so.  I fitted this in a hurry about five years ago, after damaging its predecessor hitting a stump late one night. I would swear blind that I had filled it with oil, but when I pulled it out and investigated, there was precious little in it, and no signs of any leaks. Anyway, other than being almost dry inside, there was no visible damage, so I reassembled it, filled it with oil, and lo and behold, I could move it by hand again. 😃👍 The final two TREs also checked out ok, so the final task was to top up the steering box with oil, then adjust the slack out of it. Test drive, just in time to collect SWMBO from the station, went without a hitch. Steering and braking were restored to pretty much as good as possible, so that’s a relief. 👍👍 |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

May 10, 2023 16:08:43 GMT

|

Oh, I almost forgot, as a finishing flourish I slapped on a new pair of windscreen wiper blades.  A huge expense at £1 each. They’d better be good. 🤣👍👍 |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

May 10, 2023 22:00:24 GMT

|

Ooh, that's doubled the value of it, lol!  |

| |

|

|

|

|

jamesd1972

Club Retro Rides Member

Posts: 2,921  Club RR Member Number: 40

Club RR Member Number: 40

|

|

|

|

|

Get you with your “I pulled it out and inspected it “ on your relay. Pretty sure you would need a gas axe to get ours out!

Ours leaks like a sieve so some swivel grease has found a new home…

Ours is probably due a service, new back springs 1/4 chassis plus whatever else falls off but not feeling too keen at the moment!

Onwards

James

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

|

|

Get you with your “I pulled it out and inspected it “ on your relay. Pretty sure you would need a gas axe to get ours out! Ours leaks like a sieve so some swivel grease has found a new home… Ours is probably due a service, new back springs 1/4 chassis plus whatever else falls off but not feeling too keen at the moment! Onwards James They are often very hard to remove from original chassis’. Because mine is an aftermarket galvanised one the hole for the relay is a little more generous than stock, as well as being less prone to rusting up. You can strip and rebuild the relay in-situ though, and that’s often the best way to do it when they’re properly stuck. |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

Jun 12, 2023 12:24:14 GMT

|

I did a bit of a road trip the other weekend. Up to Kettering in Northamptonshire for a few days at a mate’s. The relatively high speed run showed up that the steering was still a bit wandery around the straight ahead position, so as I knew everything else was good I had my mate wiggle the wheel while I had my head under the bonnet looking for lost motion. The culprit was soon identified. The four bolts securing the steering box were loose. Not falling out loose, and they took very little to nip up, but it’s not the first time this has happened over the years. I think it must have been a known issue, as Land-Rover increased the size of the mounting bolts from 5/16” up to 3/8” during the 60s. If I am honest, there’s a distinct possibility that I have a mashup of mounting hardware that has 3/8” holes in them, combined with the early steering box with the smaller bolts. So I thought I’d better do something about it. Or, at least, start doing something about it. I had a rumble through my collection of knackered steering boxes. Two more early ones with small fittings, and a Series 3 one with the later size. Ideal. It sounded and felt awful though, unsurprisingly as I had been given it for free several years ago. I have just realised that I didn’t take many pictures, because oily hands. Bear with me, I’ll take some and post them later. So. With a suitable candidate for rebuilding identified, the first of my OCD based issues raised its head. 😱 My current steering wheel is the early “banjo” version.  I quite like it, and it’s one of the very few original parts of the vehicle as-bought in 1993, but it is very worn underneath the cover, and the professional restoration it really needs will run to several hundred pounds I can’t justify at the moment. That, plus the fact that I am unconvinced that “restoration”, despite costing so much, will amount to more than a cosmetic uplift that won’t last long given that the vehicle is a daily, not a cosseted pet never driven with dirty hands. The early wheel is held on by a pinch bolt, and requires a corresponding column. One of the other things that I have been slowly working towards over the years is to replace the indicator switch with the modern type that incorporates a reliable self cancelling mechanism, as well as dipswitch and horn functions; combined with a column mounted wiper/washer one. This complicates matters as the early column will need shortening to accommodate the switch; not impossible, but not really a route I want to take. The early columns use a plain tufnol bush at the wheel end, bearing directly on the inner column, and the end of the outer one would need boring internally to make it fit and it’s a whole lot of faff dismantling the casting off the other end to get the tube in the lathe. Fortunately, the series 3 column is already shorter, because they have different switchgear, and the steering box end of the outer tube is simply held on to the cast end with a pinch bolt. Sticking that in the lathe to turn the end down to accept the later switches was straightforward.  Most unusually, stripping the Series 3 box completely revealed that it was in fine condition internally. Only a tiny amount of spalling on the replaceable outer race of the bottom bearing, and the inner races on the inner shaft, which are not replaceable and usually utterly knackered, were perfect. The graunchiness was all down to a manky top column bearing, which is cheap and easy to replace. So, I have a steering box that will rebuild for minimal outlay, but I need to make a decision on wheels. I can use an early inner column I think, but I will have to modify it to take the later top bearing. I’ll have to buy a new one of those too, which is another hundred and fifty quid to add to the cost of having the wheel refurbished. I do have a very good later wheel that I bought NOS a couple of decades ago, and used very briefly on another Land-Rover.  The centre horn push will be redundant. I can just use the standard Series 3 cover, or I could take the centre badge out of an old P4 wheel I found in the back of the stores…  Actually, looking at it, I could maybe mount the whole thing if I made up a suitable boss in the lathe…  What does the collective think? Using the bits I already have involves a bit of my time, but little further outlay, and would mean that a future replacement steering box would be a standard S3 item, with just the easily swapped outer column to change. The original S2 box and wheel could either be put aside incase I ever wanted to go back to stock, or sold on. Using the earlier wheel means probably buying a new inner column, unless one of the donor boxes yields a useable one (unlikely), plus will then meaning I’ll want to get the wheel refurbished, and I’ll have a hybrid box that will need replicating whenever it comes time to revisit the issue… …first world problems I know, but the wheel is one of the things that you spend most time physically and visually in contact with. It needs to be right. Another reason for keeping the older wheel is that the spokes are arranged in a Y-shape, which makes seeing the additional instruments much easier. The later wheel having T-shaped spokes puts the cross straight through the line of sight for them. I need a bit more thinking time. 🤣 In other news, now that I have almost sorted the wandery steering, and have fitted the 300tdi manifolds, I’m getting close to fitting the power steering kit. The last part of that particular jigsaw, bizarrely, is a dipstick. I currently have a mildly contorted Defender one fitted, but it’s too short to easily reach through the intercooler pipework. The 200 Discovery version won’t work with the later manifold as it wants to go straight through the middle of the exhaust:  I could carefully reshape it, but it’s a little long, and the outer tubes are NLA… The standard 300 one works better, but it is a push fit rather than tube nut and olive:   The push fit issue got solved by boring out a tube nut to suit:   Comparison of the inners showed the max/min marks were in the same relative places, despite the other visual differences. However, the next issue is that the mounting tag doesn’t align with anything on the 200 engine. It’s about 1/2” too high and 1/2” too far away from the alternator bracket mounting bolt though, so that’s where I thought I’d aim for. My initial attempt at tightening the two bends in the tube to get the desired effect ended in failure, as the stiff stainless just kinked. Fortunately, these later tubes are still available, and cheap, so £10 lighter I had another go.   This time around I carefully freed up the bracket, by slicing through it, and then re-shaped it to fit. The next step will be to tack it in place, but that means a bit of practice on my TIG welder first, and I really want to get the steering box issue sorted before I do anything else. |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Jun 12, 2023 13:52:04 GMT

|

|

I had a similar conundrum on my series 2, Initially it had the series 3 wheel (which I still have if it's any use to you) but then I found a 50s ford zodiac one with the wire spokes which fitted on the series 3 splines, wasn't in the Y shape but looked more the part.

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

Jun 12, 2023 23:11:51 GMT

|

Took a couple more pictures after work… One minty mint inner column. I don’t think I have ever pulled a Land-Rover box to bits and found one this good before.  This is the tufnol bush that acts as the top bearing on the early boxes:  And this is the later ball bearing that does the same job on later ones. They are often a bit crispy, and can make the steering feel really horrible when they’re full of muck. They also won’t fit the earlier shafts. Early shafts measure up 22.7mm diameter, later ones 22.0mm.  Early column on the left, and later on the right:  This fixed end on the early outer column is what makes modifying the other end of it in the lathe somewhat awkward. Unless you have a massive lathe, or are prepared to remove then refit the casting.  Series 3 ones though, that end just clamps on and is easily removed:  Finally, the reasons why the two early boxes are in my “rebuild” pile, not my “use” one… This one gives some insight into why Land-Rover revised the sizes of the mounting hardware:  And this is why I think column mounted power steering conversions aren’t necessarily a good idea:  |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

|

|

|

I’d do the S3 conversion because it’s presumably better but also because you already have most everything to hand. I too don’t buy that such a wheel can be durably restored.

Best, John

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

Jun 13, 2023 20:54:24 GMT

|

|

Hi John,

Having gone around in ever decreasing circles with this for the last week or so, I think you're right.

Maybe if I'd been faced with spending out for a new Series 3 inner column it might have swung it the other way, but luck is on my side for once, and I do appear to have all the necessary bits to do the job here already long paid for. My current finances are a little stretched, and the job is important enough that I don't want to put it off for an indefinite period of time, or make myself a load of uneccesary work building a hybrid steering box either.

I also fancy fitting a column mounted ignition switch and steering lock, and the Series 3 column has the facility for one already, wheras the Series 2 one would need yet another modification...

It also occurs to me that I do know that the box currently fitted should be ok internally, as I rebuilt it a few years ago with a new inner shaft and nut. There's nothing stopping me making a hybrid box at a later date if I decide I can't live with the later wheel.

I am just going to crack on with rebuilding the Series 3 box and get it ready to fit. There's another couple of tweaks needed on the outer tube first though, and it gives me an excuse to fire up the milling machine.

Once I have got it all done and working then I'll do some proper research on wheel restoration costs and the durability of the finished result. Hopefully that will make a final decision clearer, and at that point I will do some rationalising and either make an identical spare Series 3 box to put in to store, and sell on all the redundant Series 2 stuff (much like I did the other year with the excess gearbox bits I had cluttering up the place), or I'll make up two hybrid boxes instead.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Jun 13, 2023 21:10:33 GMT

|

Whilst I loathe all series and defender LR's to drive due to a vehicle designed for 1940's sized people with a dreadful ride, poor ergonomics and ear drum busting noise, I do admire the fortitude of owners who are happy to continually work on their trigger's broom' vehicles. Automotive masochism at its extreme. Keep going as its entertaining mainly because its not me  |

| |

Needs a bigger hammer mate.......

|

|

|

|

|

Jun 13, 2023 21:46:43 GMT

|

|

Whilst all that ^^^ is true, I still really want one, I had a Series 3 but haven't got it out of my system yet.

The ergonomics aren't too bad, unless it's raining and you don't want to stick your elbow out the window.

|

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,353

Club RR Member Number: 64

|

|

Jun 13, 2023 21:52:56 GMT

|

Whilst I loathe all series and defender LR's to drive due to a vehicle designed for 1940's sized people with a dreadful ride, poor ergonomics and ear drum busting noise, I do admire the fortitude of owners who are happy to continually work on their trigger's broom' vehicles. Automotive masochism at its extreme. Keep going as its entertaining mainly because its not me  Sorry, what was that? I'm a little deaf you know...  I am quite fortunate that at 5' 8" I fit the ergonomics of a Series Land-Rover pretty well. My mate Martin is 6' 5" and built like the proverbial brick outhouse; watching him get out of his 110 after a long drive makes me very glad to need steps to change lightbulbs. |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|