|

|

|

|

|

|

You can see the roof sheets stacked on a section of scaffold there inside the shed to the back right corner, ready to go on when a suitable clement spell is forecast.

If I was allowed out at xmas the roof would be done but SWMBO had other plans.

|

| |

Last Edit: Feb 2, 2021 12:33:56 GMT by henspeed

|

|

|

|

melle

South West

It'll come out in the wash.

Posts: 2,010

|

|

|

|

|

Larch cladding on the whole structure will look awesome I think.

|

| |

www.saabv4.com'70 Saab 96 V4 "The Devil's Own V4" '77 Saab 95 V4 van conversion project '88 Saab 900i 8V

|

|

|

|

|

|

|

Little more progress, got the first row of boards on above the door, gives you a better idea of how it will look. Still happy enough with it, now to fill in the corners and commence with the overlap. Bloody freezing up there at night in the Highlands mind you, makes for slow work.  |

| |

Last Edit: Feb 4, 2021 8:53:48 GMT by henspeed

|

|

|

|

|

|

|

|

Thats a great garage space, the cladding is going to look really good.

|

| |

|

|

|

|

|

|

|

Thats a great garage space, the cladding is going to look really good. Cheers mate Still a whole lot more to do, but it is heading in the right direction. Only get a couple of hours at it each evening so its a hard slog |

| |

|

|

|

|

|

|

|

So Sat morning and decided to do a little, only work for a couple of hours in the morning to keep family semi happy. Filled in one corner  Next morning was greeted to whiteout conditions, cant really see well from the pic, so had to breakout the thermal covvies and gloves.  Filled in the the other side. Next to trim off the excess and begin the overlap.  |

| |

|

|

|

|

|

|

|

|

Notice the thread namechange?

I thought it was more apt to what I am doing

|

| |

|

|

|

|

|

|

|

|

It seems I may have mad ea schoolboy error in my cladding installation.

The boards I have are 6" wide, I installed them with a 2" space between, with the intention to rip the overlap boards to 3" and overlay.

I am now thinking that I the overlap of 1/2" each side wont be enough.

I think I will source some 4" boards for the overlap to give me a 1" overlap each side.

Anyone with any thoughts?

|

| |

Last Edit: Feb 8, 2021 12:57:06 GMT by henspeed

|

|

|

|

|

|

|

|

Hi, Yes good call because timber swells and contracts width ways as the seasons change so it's easy to lose that overlap altogether.

Colin

|

| |

|

|

|

|

|

|

|

|

Yep you need more overlap that that.

Id go with the 4" boards if you can get them or just continue with the 6" boards and have 2" overlap on each side.

|

| |

|

|

|

|

|

|

|

|

|

|

I agree with the above, the 2" overlap will be more weatherproof & warmer. It's amazing how much wood can shrink when it dries out.

|

| |

|

|

|

|

|

|

|

|

I guess a 2" overlap cant harm it, will just be a bit more material.

I can get the boards at the right money though, I have a contact who will sell me B grade rejects at £1.20/m which is what I have been using already. Not perfect, some gouges etc but I'm only building a garage and I stick the rough bit to the inside.

|

| |

|

|

|

|

|

|

|

|

The other 3 sides I will stick to a 6" board and a 4" gap leaving a 1" overlap, I don't think it will stand out too much, wont be seen from a passing train at least.

Pretty much made my mind up that I will clad the lot now.

That way 98% of the build will be self done, with the exception of the 2 or 3 days I had a bricklayer turn up for.

I must work out what this thing owes me now.

I'm pretty sure its still a very cheap building.

|

| |

Last Edit: Feb 8, 2021 13:59:29 GMT by henspeed

|

|

|

|

|

|

|

It seems I may have mad ea schoolboy error in my cladding installation. The boards I have are 6" wide, I installed them with a 2" space between, with the intention to rip the overlap boards to 3" and overlay. I am now thinking that I the overlap of 1/2" each side wont be enough. I think I will source some 4" boards for the overlap to give me a 1" overlap each side. Anyone with any thoughts? I would go for using 6" boards on the overlap. Don't forget that timber shrinks in the width, and not the length. What goes on as 6" wide will not stay that wide. Therefore belt and braces and use 6" wide. Cutting costs by using narrower boards may well come back to bite you. Keep on in there. |

| |

|

|

|

|

|

|

|

|

Surely the timber won’t be shrinking more than 2” across its width.

With a 6” board would leave scope for 4” shrinkage.

The BS recommends a minimum of 3/4” overlap.

|

| |

|

|

|

|

|

|

|

Surely the timber won’t be shrinking more than 2” across its width. With a 6” board would leave scope for 4” shrinkage. The BS recommends a minimum of 3/4” overlap. I installed 6' high fencing at home, using concrete 'H' posts for support. I bought 6" X 2" timber for the Arris-Rails and 6" X 1" for the upright boards. Using a piece of 5mm thick plywood as a spacer, I then screwed all of the vertical boards in place. The timber used was soaking wet having only just been pressure treated, and on being exposed to direct sunlight, I was amazed at how the width of all of the boards shrank and the 5mm spacing gap suddenly widened to close on 15mm. In the winter they have expanded back again, but not to the original 5mm gap. Whilst living in the Midlands I had several livestock sheds errected and they were clad with what was known locally as 'Yorkshire Boarding'. These are vertically mounted, wooden boards (6 X 1), with 12mm gaps on installation. They also shrank and the gap was 25mm+. Just be aware of the shrinkaage problem. It is always across the grain and not along the grain, that shrinkage will occur. |

| |

|

|

|

|

|

|

|

|

thanks for that, certainly food for thought.

I think I will stick with the 6" boards and plod on

|

| |

|

|

|

|

|

|

|

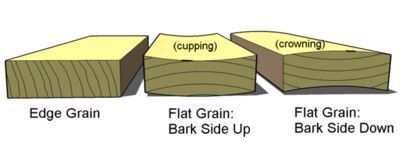

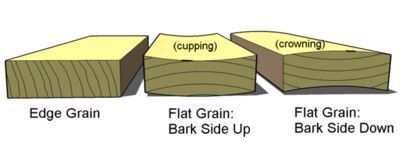

Hi, Don't forget to look at the end grain to know which way the board will cup or CROWN. you don't want the board curling away and getting draughts from the gaps.  Colin |

| |

|

|

|

|

|

|

|

|

there are a lot of sturdy fixings holding it in place, hopefully that wont be an issue.

|

| |

|

|

|

|

|

|

|

|

Not much to add for tonight

Spent the evening hacking branches off my trees to save my eyes then fixing battens at the back wall ready to accept the cladding.

A bit chilly but job done.

No pics too dark for that.

Ready to start cladding the rear now

|

| |

|

|

|

|