All righty…

Having said that a bit of heavy work kept my back strong and mobile I completely over did it with a lawn mower in February and trashed it. It was recovering reasonably nicely and then I pulled it again about 3 weeks ago. This time it’s taking a lot longer to come good. Clearly it’s royally hacked off with me. As I speak my back is reasonably ok but I can’t stand or walk for long. I’m pretty sure I’ve got a trapped nerve ‘cos I frequently ache down the inside of my right leg which is really annoying. Especially when the ache extends into the “gentleman’s region”. Then it’s really REALLY annoying and makes a chap walk with a limp. Too much information? Fair enough.

Anyway, about a week after I knackered it for the second time Ian came down for a day with GKE. This caused me a dilemma as I really needed to keep pushing my back to get it moving again but an 80 year old bus may just be stupid. And I was flying to Iceland for a holiday the following morning so I really couldn’t afford to cripple myself. The sensible thing do was to say “sorry, but I’m just not fit”.

Sensible’s over rated…

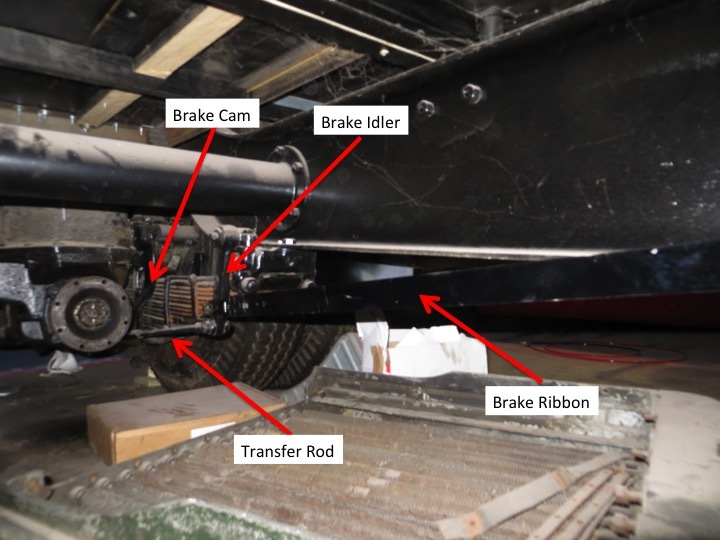

Remember the brake ribbons that run along the length of the bus to the rear wheels? They had suffered some rust pitting and as a safety critical item ‘The Friends’ had them tested and ordered some suitable high carbon steel to replace them with. We took the old ribbons off last time out.

Ian took them away and had them rebuilt.

The shackle ends were removed from the old ribbons and riveted onto the new steel. New ones on the left, old ones on the right.

You may also remember that one of the ends had been thumped at some point. Probably when the the body was removed or replaced.

Ian wasn’t happy to try and bend this back in case it weakened it, and also the chances are that the threads wouldn’t line up so you wouldn’t be able to adjust it. Luckily he had a spare at home… Yeah, I don’t know either. I guess in the same way that I have a garage full of random rubbish to do with cars, he has piles of stuff he’s rescued off buses. Just in case he might need it, you understand… Yeah, you understand, we are all alike just with different stuff.

From the left, the bent one, the spare, and the good original from GKE.

I do like the way Bristol thickened the ends of the bands with the nicely shaped packing bits. Very pretty. I guess they are there to add some support and strain relief to the end of the ribbon - to stop it work hardening and breaking at the end of the shackle.

So here they are, nicely painted.

We spent a bit of time making sure they were the same length and then our job was to fit them back on the bus. Easy eh? Right…

A couple of problems.

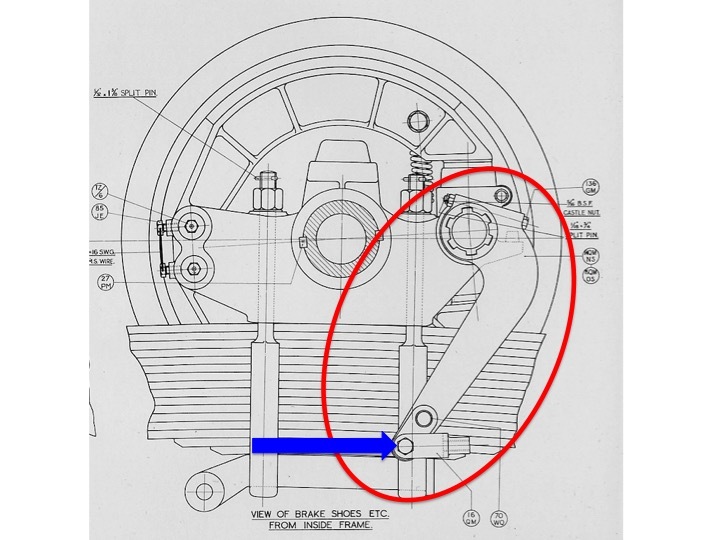

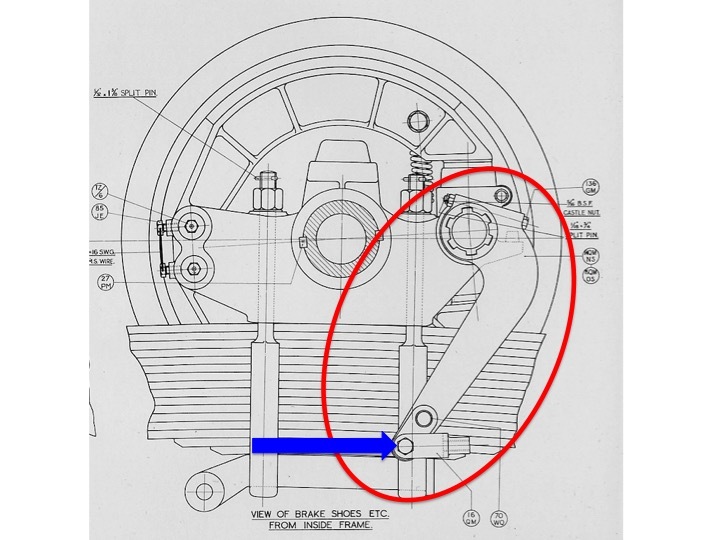

This is a drawing of the actuating cam (circled in red) and the connection point (in blue).

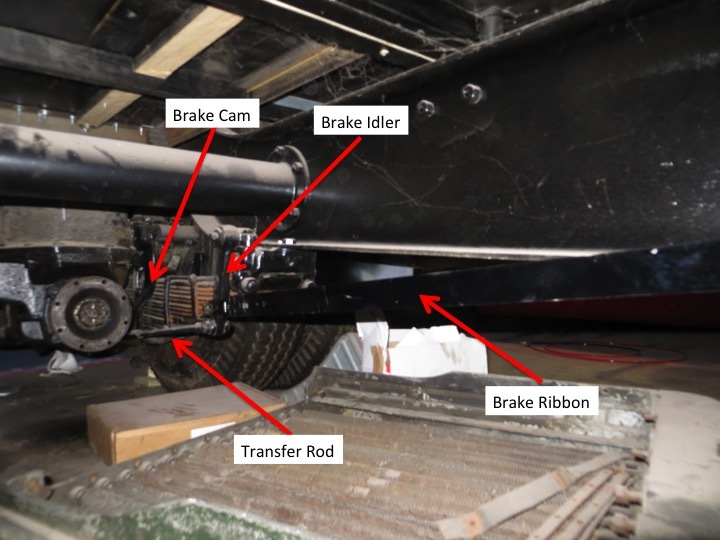

Actually the brake ribbon doesn’t join directly to the cam. There is an idler arm at the front leaf spring shackle. You can see it in this photo…

Sorry some of the photos aren’t sharp. My little work camera is struggling to focus under the bus where it’s a bit dark and everything is painted black.

At all the connection points there is a shouldered bolt and a bush, all of which are fine, except one on the right side. (Sorry again… Didn’t get a photo.)

Ian removed the bolt and the bush and will get new ones made.

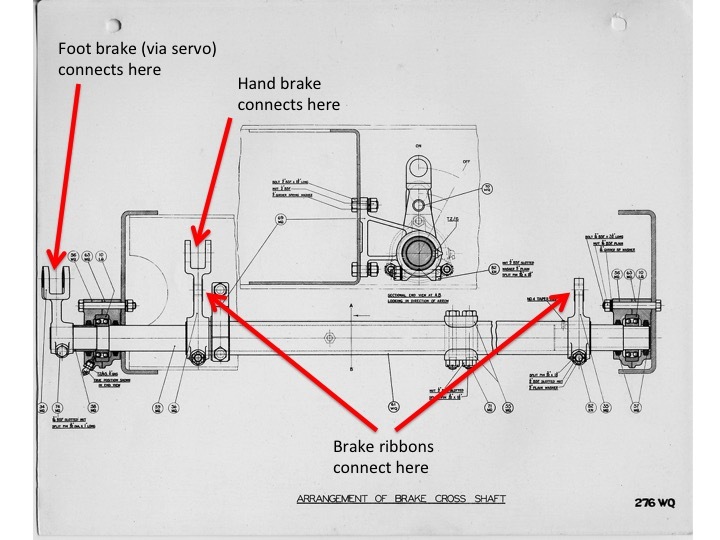

The other problem was with the brake cross shaft about a 3rd of the way down.

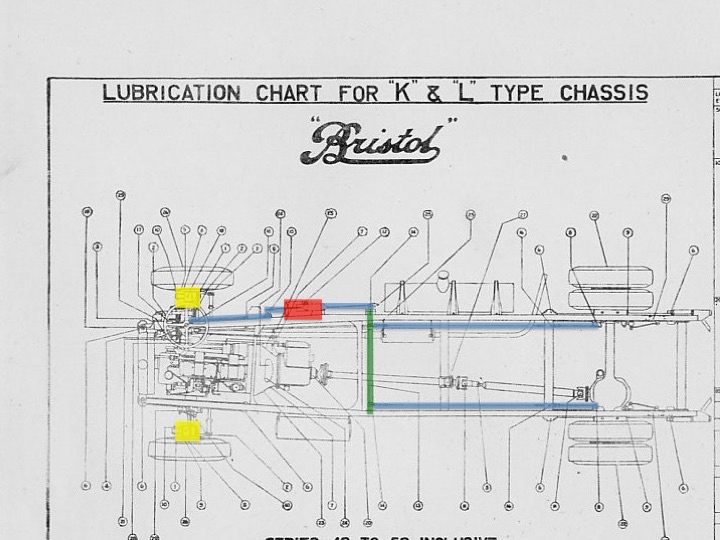

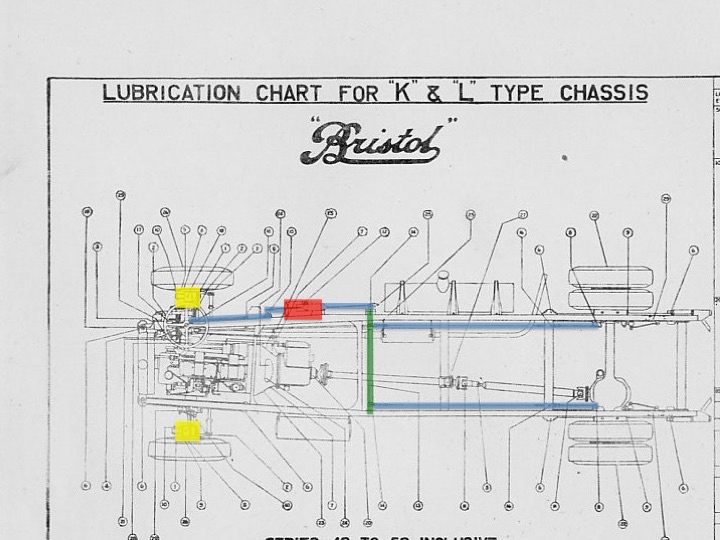

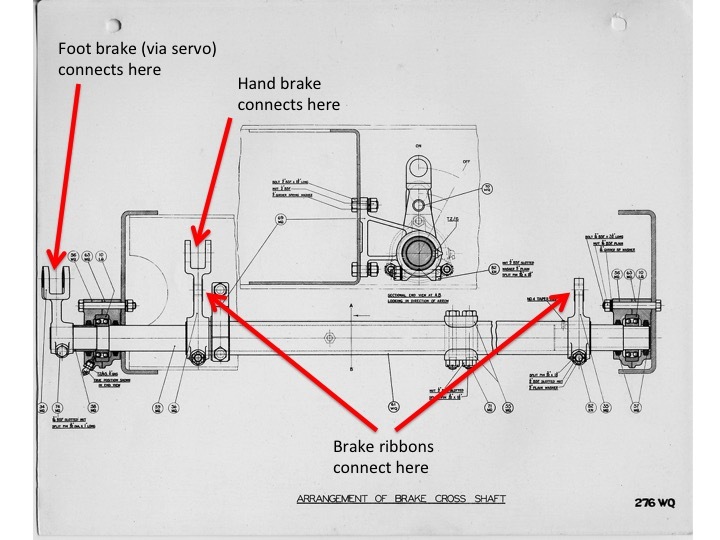

The cross shaft is the green bit in the drawing below.

It’s purpose in life is to connect the foot brake (via the brake servo) and the handbrake to the two brake ribbons running to the rear wheels.

This drawing is looking from the front towards back.

It’s an interesting bit of engineering in its own right. The foot brake connects to a bar that turns in bearings at each side of the chassis. Then there is a concentric tube that has the brake ribbons connected to each end. The bar and concentric tube are bolted together in the middle. This means that if the rear brakes aren’t quite evenly adjusted the tube can flex slightly so they operate on both sides. Eventually wear in the linings will even everything up.

This is probably another reason why these old buses were difficult to get through the modern MOT.

So what!?

Remember this?

What do you mean “no”!? Good grief Penfold! It was only 5 minutes ago!

Well it was connected to the right side of the cross shaft and looking through an inspection hatch in the floor of the saloon…

We see that the boss that the hand brake would connect to is squint with respect to the cross shaft below it.

In this photo from below it’s even more obvious.

But the question is…

Did this get bent when the clevis got lamped or is it supposed to look like this?

Sure as hell looks bent to me. But the only way to make sure was to use some rods to line up the holes to see if they pointed at their destinations. Now, because I’ve done my back in I didn’t take any tools or my Kindle with the Bristol K5G manual on it. And that meant that the first job was to work out if that boss in the picture above connected to the handbrake or the foot brake. And that meant digging the brake servo out to try and work out which side of the chassis rail it fitted to.

Anyway, some considerable time later we concluded that the photo shows the handbrake connection and that it is indeed bent.

What to do about it?

Ian had the biggest set of Stilsons that I’ve ever seen so we thought we’d gently try and pull it back into shape. If that didn’t work the cross shaft was going to have to come off and heat would have to be applied to the arm.

After a fair bit of pulling and pushing we eventually got it so it all lined up nicely.

Doesn’t look like much but it makes a hell of a difference over the distances involved.

Half way down the brake ribbons there is a hanger to stop the ribbons flapping around. They are lined with some sort of webbing which needs replacing.

Ian’s gone to mull that over too.

And then, because my back ached, we called it a day. But before I sign off…

This is a brake servo from a 1939 Bristol.

Which I’d imagine we’ll meet again in the future. It’s aluminium and surprisingly light.

Because you’ve all been so good reading all this drivel you can have a free picture of a 5 cylinder Gardner.

Sweet isn’t it? I imagine there’s about 80 or 90 BHP in there somewhere.

The cab has been painted by the good folks at SEC.

You see the two big holes in the floor behind the pedals? The one on the right is for the handbrake - a long handle with a release lever on the top - very old school style, and the one on the left is for the gear stick - which actually bolts to the side of the engine block.

We might need a drivers seat. A racing style thing would be appropriate for a bus with 10 or 15 BHP per ton…

Hmmm. The newness has worn off that.

It is, however, a proper, light weight racing seat…

…Because the woodworm have eaten most of it.

Nighty night!

James

PS, Thanks to Ian for a couple of the photos in this post.

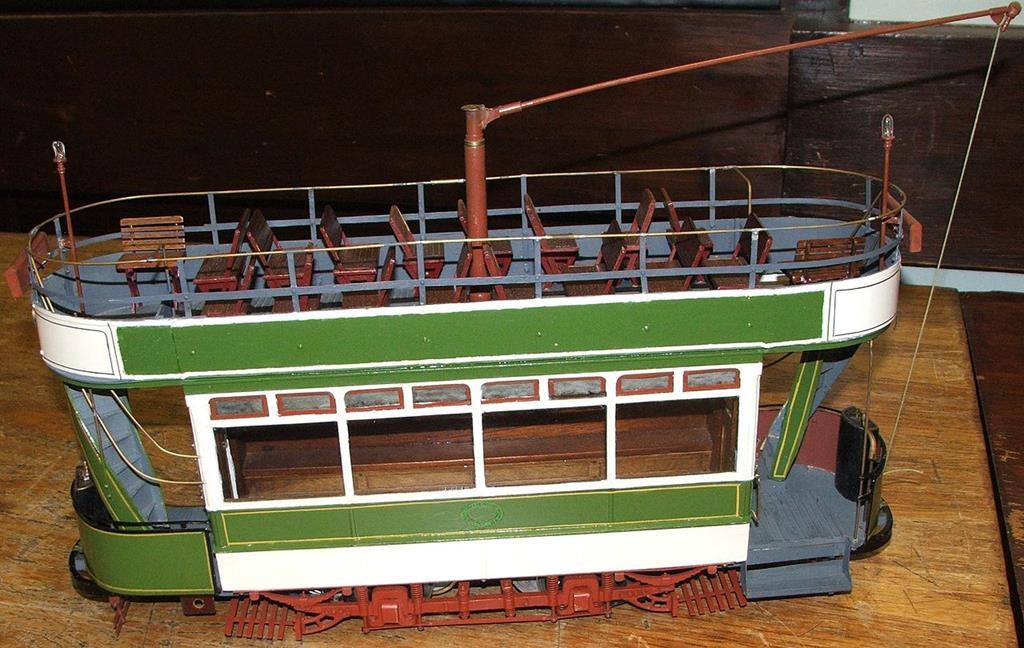

if she were alive would no doubt reveal the mystery paint scheme in the same ease as we can remember the words to a song weve not heard in 30 years.

if she were alive would no doubt reveal the mystery paint scheme in the same ease as we can remember the words to a song weve not heard in 30 years.