It’s a couple of weeks ago now but, hot on the heals of the last visit to GKE Ian and I had another trip.

My first little job was to clamp the speedo cable to the saloon floor rather than tie wrapping it to the brake rod which is how I left it last time.

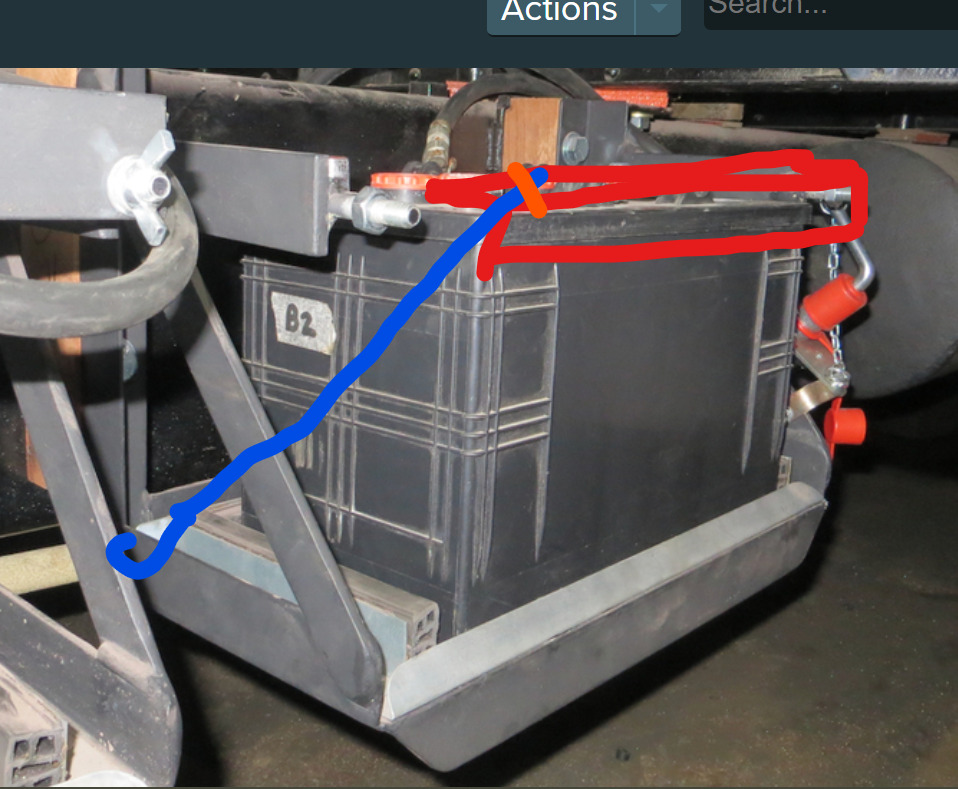

The speedo cable is this doofer which, by some fluke, has 3 red arrows attached to it.

No idea what the red arrows are for. Apart from being an aerobatic display team.

This job involved drilling a couple of holes in the floor rail. Unfortunately the visit was a bit ‘last minute’ and I had been in London the day before and didn’t get chance to load the car until Friday morning when I was a bit rushed.

The upshot is that I forgot to take a battery drill. Ian did take one but hadn’t charged the battery. He also had a mains drill but neither of us remembered to bring an extension cable.

Bum hats. How am I going to drill holes in the floor rail now? Glare at it until a hole forms?

Oh hang on… There is an air drill in the cupboard.

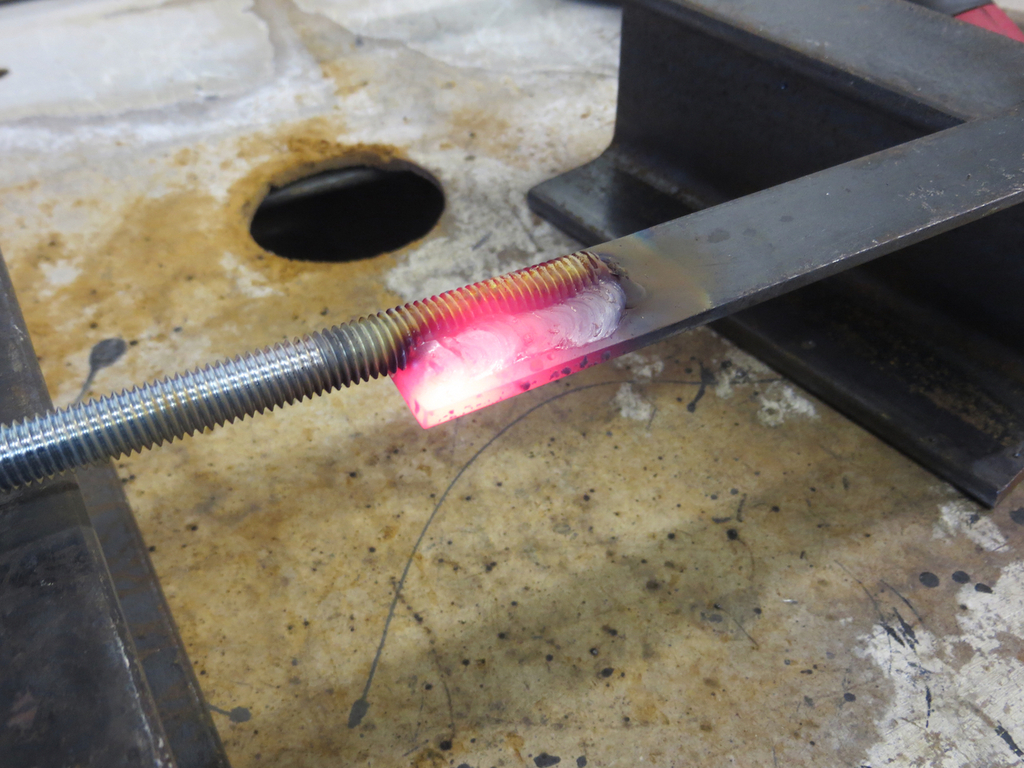

Doesn’t that look sexy in the light and shadows?

Unfortunately I had to deal with the garage airline again. I hate that airline. I don’t know what pressure they run it at but it’s a lot higher than mine at home. It’s a monster of a thing. I’m always slightly scared that the quick connects will come off and leave the end of the hose flailing around. There is something I just don’t trust about it.

Worse still the main pipe runs round the top of the garage wall and there is a drop pipe down the wall that we can plug into. That drop pipe rarely gets used so it acts as a water trap. When you try to plug into it it blows a bucket full of water in your face. And of course you have to deal with the water before plugging the tool in or it’s going to hydro lock the motor. You’re going to get very wet. And I did.

Sometime later, after I’d dried out, the job is done and the speedo cable is secure.

That’s another job off the list. Or it would be if we actually had a list.

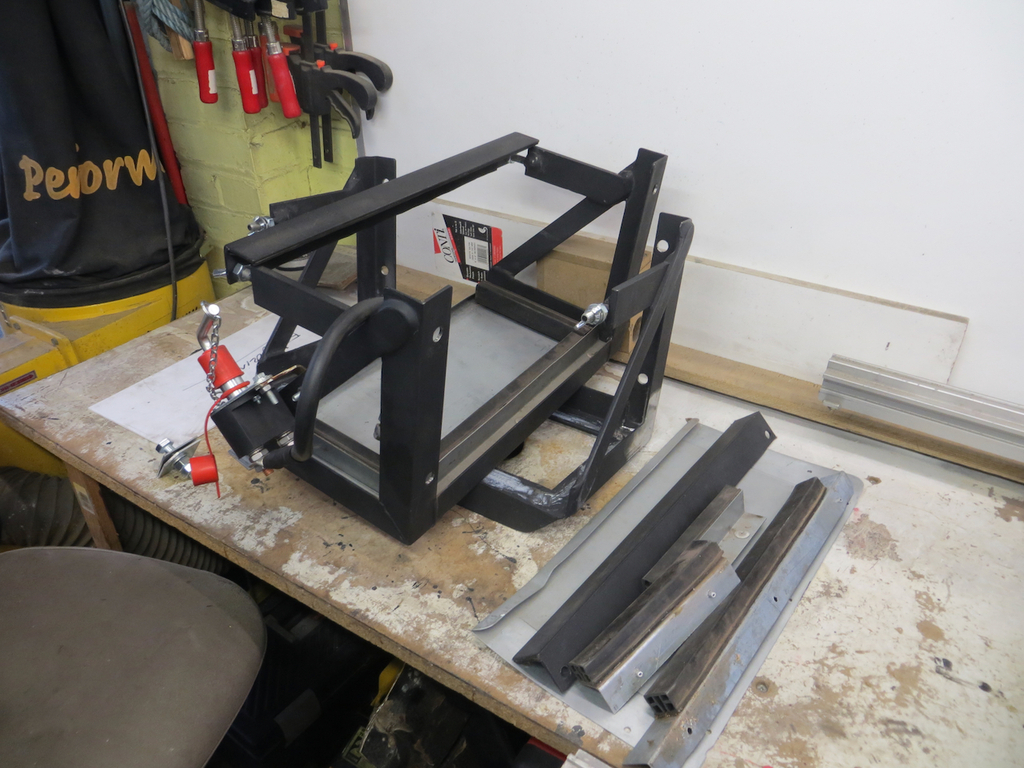

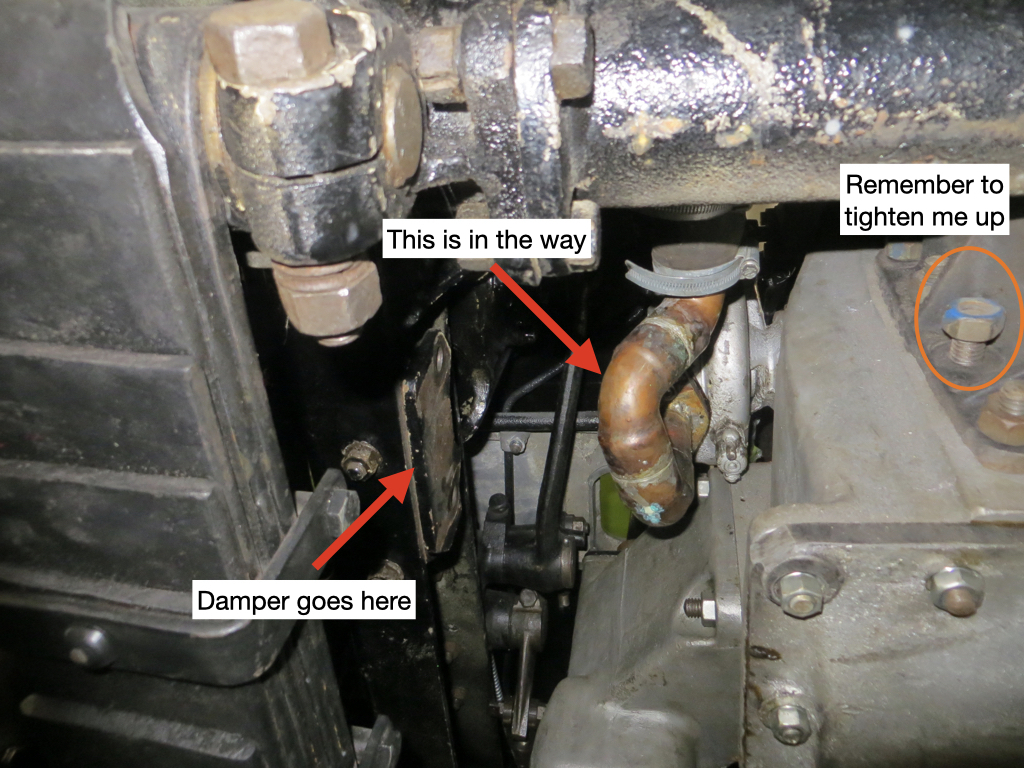

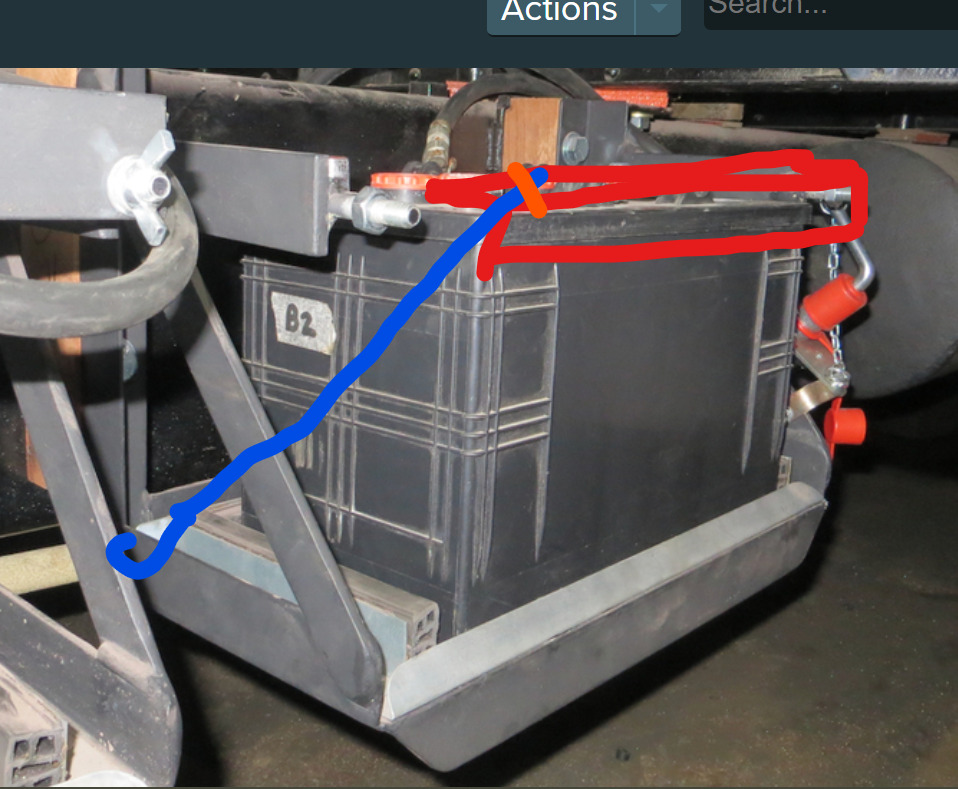

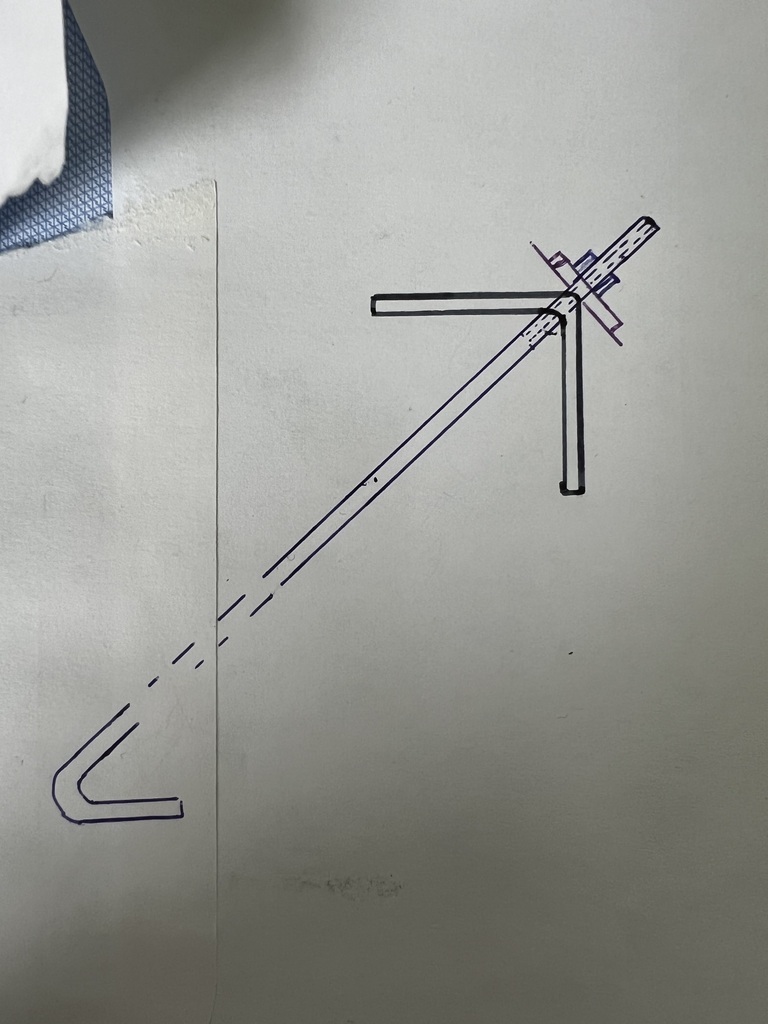

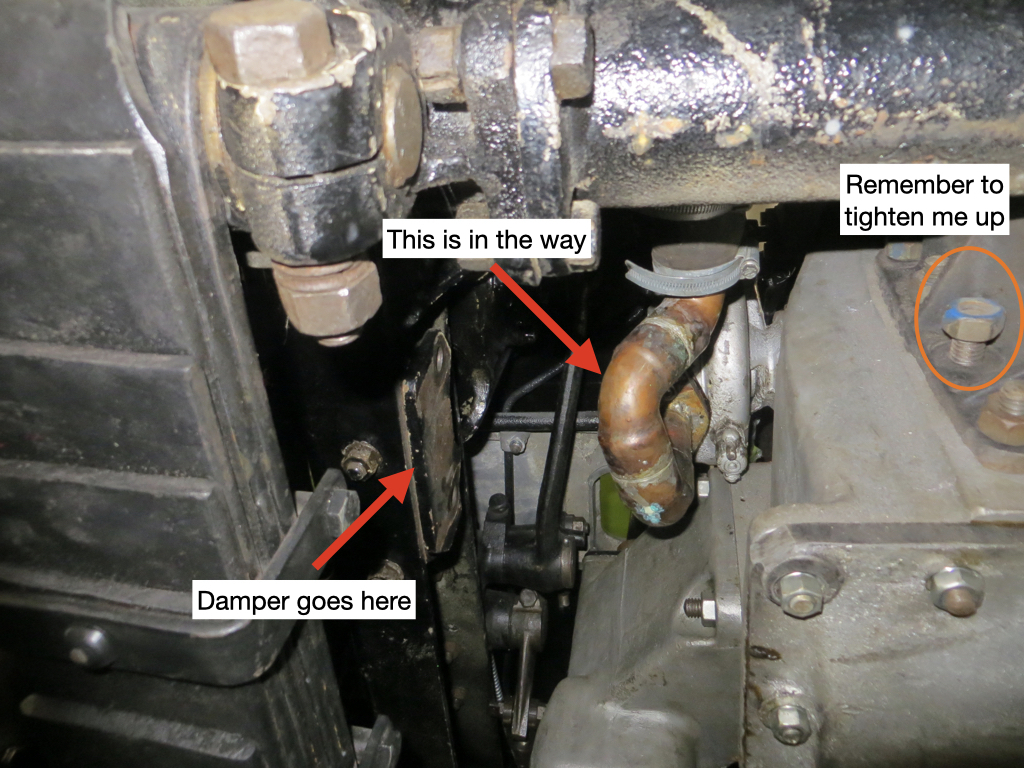

Meanwhile Ian was trying to fit the other suspension damper to the drivers side front. It bolts to the chassis here…

Hold on, what’s that nut on the nose of the engine that’s barely hanging on? Good grief Penfold! I only noticed this in the photo. We’d best tighten them all up next time we visit. I’ll put it on the list. Or I would if we actually had a list.

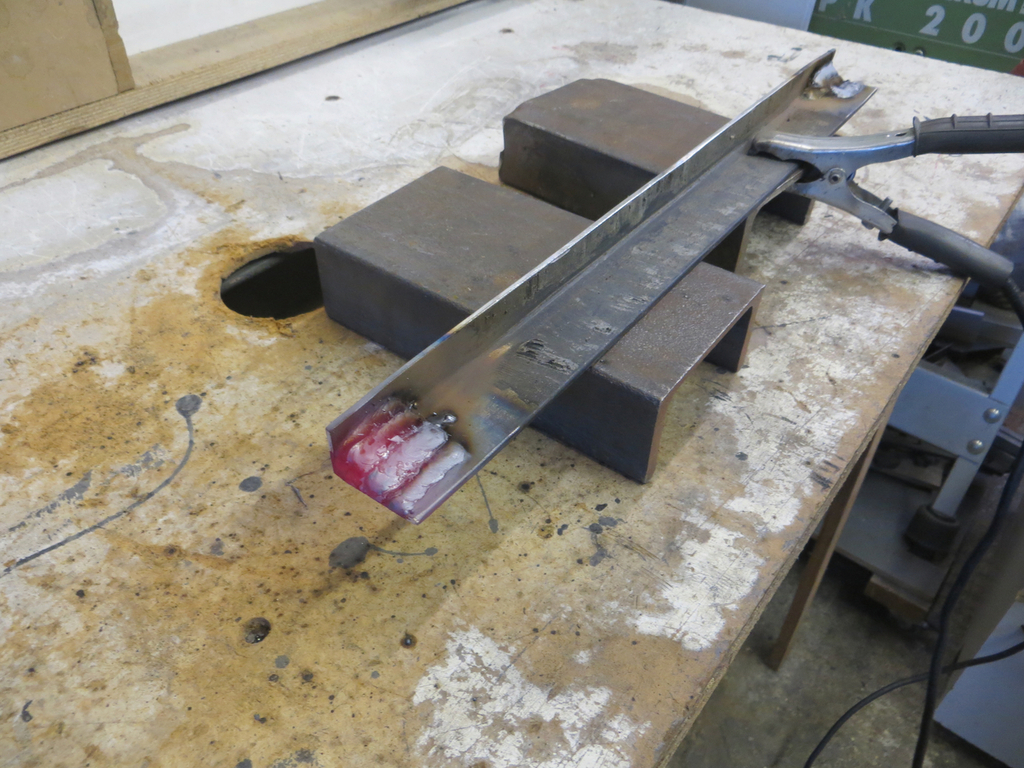

Anyway, Ian made a pipe to connect the water pump to the bottom of the radiator some time ago. It kinks slightly towards the chassis rail, Well that’s not a problem because there is endless amounts of room there. Er… Nope. It’s in the way of the damper.

There is no water in the engine, Ian drained it just in case it froze in the winter. (Cold weather in the south east? This winter? Yeah right.) So the pipe came off and the damper went on.

The errant coolant pipe will need to be reimagined into something that doesn’t try and share the same space as the damper.

Shouldn’t be too hard.

Since we filled the engine, gearbox, and axle with oil GKE has been doing its best to create a modern art work on the garage floor. I’m more at home with relatively modern cars so I’m uncomfortable with the concept that some vehicles are allowed to let their fluids out. Apart form anything else when I’ve been working under the bus I get covered in the oil that it’s dumped on the floor. Then when I get home Mrs Sweetpea makes me undress in the garden before being allowed in the house. It’s only a matter of time before she gets the jet wash out.

So I took a can of brake clean and wiped down all the sumps in a hope that we might find the source of the escaping oil.

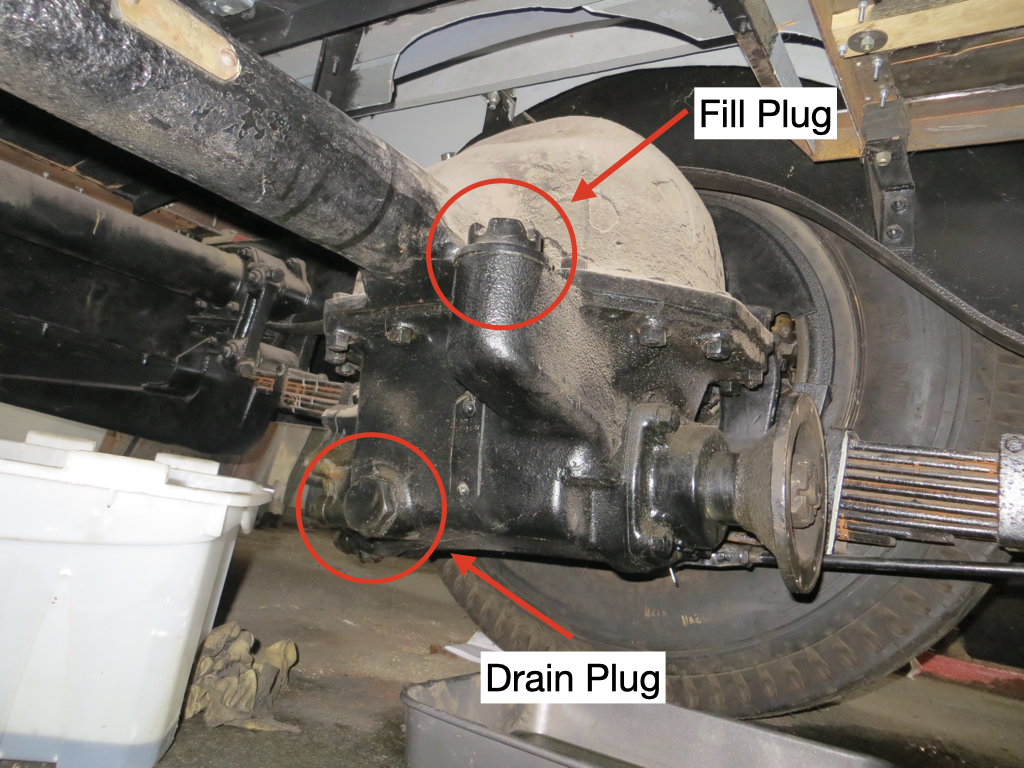

Of particular interest is the rear axle which has created something of an oil slick from what we think is the pinion oil seal.

There is a big puddle on the floor and a fair amount in that tin tray.

Just a few minutes after wiping it down oil is running out from the input shaft.

Well that was expected.

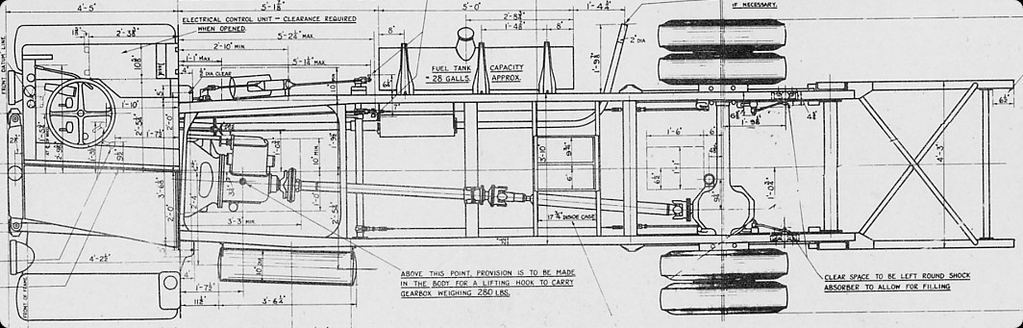

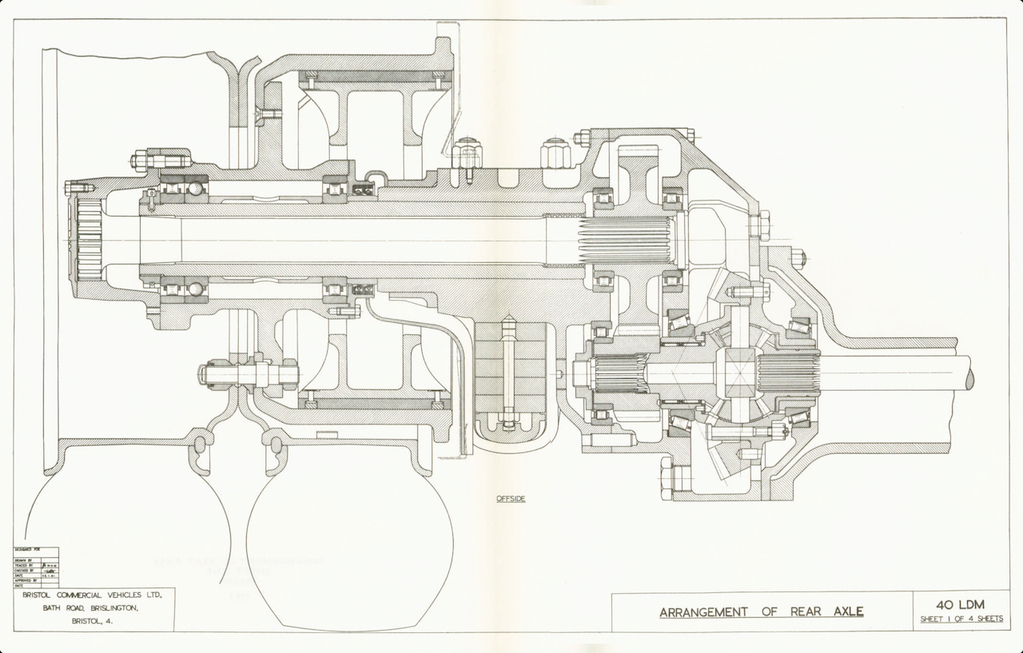

In my last post I included a drawing of the axle and was pondering what the oils seal actually was. Shortly after that I got a private message from a chap that I believe is called Neil. He also got in touch with Richard (the Chairman of the Friends).

Neil said that the drawing was not the one for this axle. Now that isn’t a shock, I’d be more surprised if it was the one for this bus. But, I believe from talking to Richard, Neil also thinks the axle is actually off a later vehicle.

Neil had joined the forum to post in this thread but found he couldn’t which is why he messaged me. I suspect his account needed to be authorised by an Admin before he could post.

Neil, if you are still out there, please try and post again. I’d like to know what the differences are and why you think this is a later axle.

Ian had a look to see if he could get the drive flange nut off but doesn’t have a socket big enough.

My last job was to fit the vacuum hose to the front near side brake cylinder.

Ian did the other side last visit but ran out of clamps. It’s vacuum so the hose isn’t exactly going to get sucked o….. I’ll rephrase that. Ah, you know what I mean.

I think that means the vacuum system is complete so next time we start the engine it should pull a vacuum and lift the gauge off the back stop.

James

if you turned it upside down then the fill/drain would still work in but in reverse

if you turned it upside down then the fill/drain would still work in but in reverse