Edit: I've shifted my other cars out to their own threads as this one was getting a bit messy. Spitfire content stops at page 2, blips back into activity on pages 3, 4, 8, 9 and 10, and then back to just Spitfire on page 13.

Seeing as my old Triumph forum haunts are a little less active these days I thought it would be a good idea to broaden my horizons a little and share my project(s) with you lovely people

We'll start with the big one. My Triumph Spitfire 6. AKA 'Patchwork' (alternatively titled: 'Project Scope Creep').

Back in 2012, just out of university, I thought 'man I want one of those classic car things' and promptly bought myself a bit of a rust-bucket Spitfire for the princely sum of £1000. Bear with me, this might be a bit of a long intro...

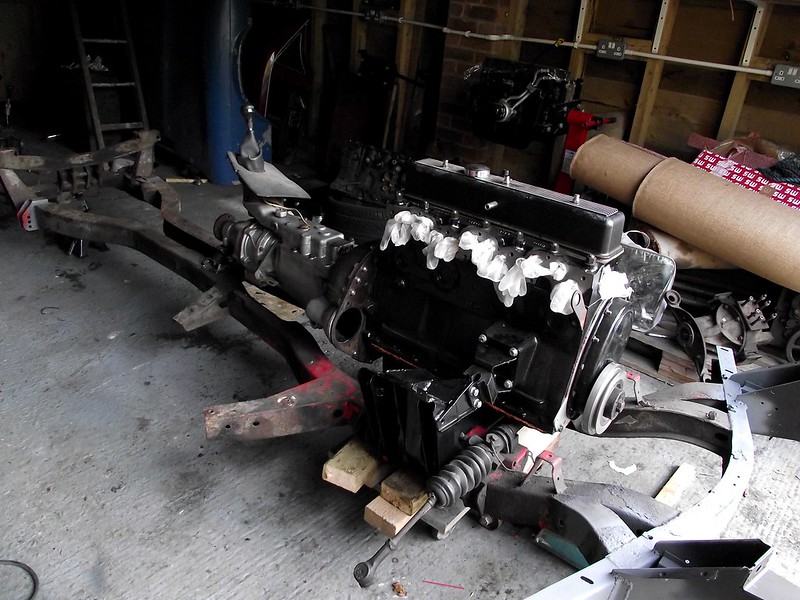

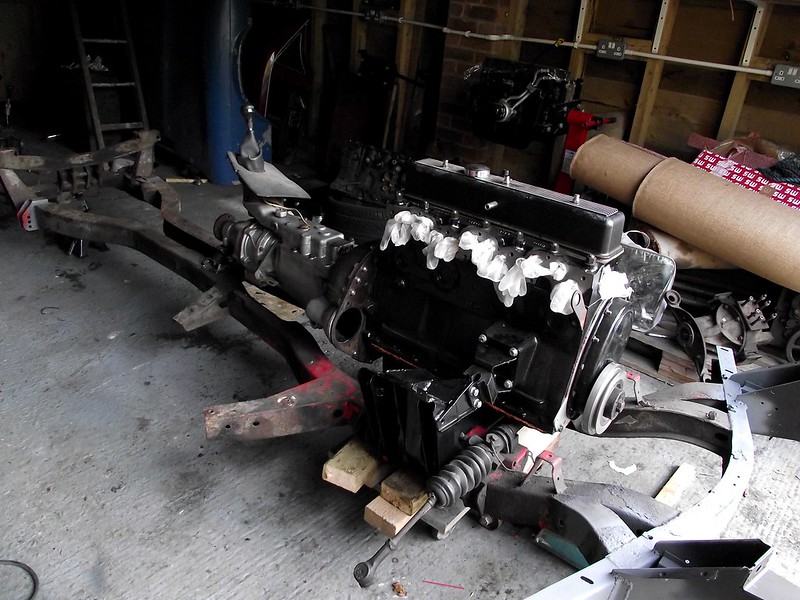

I intended to do a bit of a rolling resto, but it turned out to be a far cry from the 'light project' it was billed to be. A fair amount of rust, and the engine wouldn't rev past 3500 without backfiring through the carbs. A fortnight or so of fettling didn't improve this at all, and a quick glance over eBay heralded this:

And the scope creep begins...

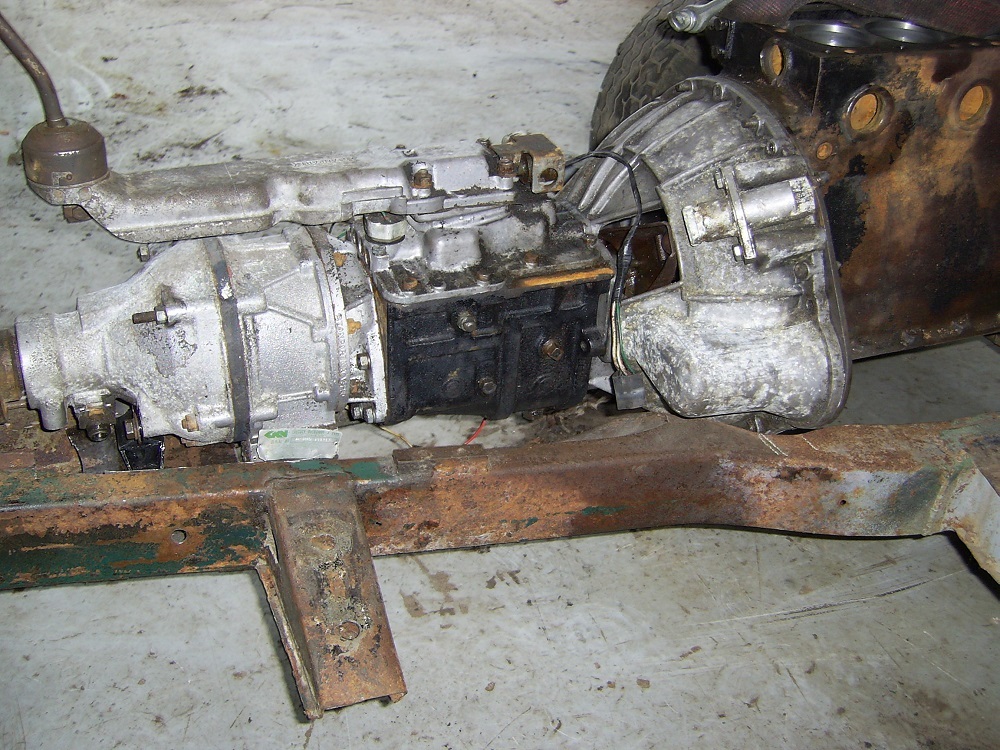

That's the mechanical fuel-injected I6 from a TR6 and associated overdrive gearbox. Rebuild, fix rust, swap in with GT6 bits, drive. Easy.

But hang on. I6-engined Spitfires are front-heavy beasts. Surely we can do something to fix that. The purchase of a £50 fibreglass bonnet turned out to be the tip of the iceberg we'll soon be uncovering. Might as well get a fibreglass hardtop too to replace the holed soft top.

Okedoke. Lets have a poke around the rest of the body for rusty bits. Bit of rust we know about, but can't be that bad.

Oh...

Okedoke then. Better learn to weld

The other side was a similar story, although the wheel arch inner had gone as well. Discovered that compound curves are pretty tricky to bend out of sheet steel, but cutting lots of little tabs and then stitching them together once bent works quite nicely

At this point in my old thread, I coin the phrase 'I'd like to do as little welding as possible to fix the rust and get it on the road', which is probably the biggest lie I've told to date...

And a little glamour shot of the garage and stable at the time parents place, and dead lucky to have such a good working space. Alfa is a V6 and has been my on and off daily for donkey's years (GTA Sportwagon ARBs and a stainless exhaust but little else). The Jag I bought from my uncle for the princely sum of £60 and pulled it out of his field. It was running but not MoT'd at this point, but sadly meets a rather sticky end...

parents place, and dead lucky to have such a good working space. Alfa is a V6 and has been my on and off daily for donkey's years (GTA Sportwagon ARBs and a stainless exhaust but little else). The Jag I bought from my uncle for the princely sum of £60 and pulled it out of his field. It was running but not MoT'd at this point, but sadly meets a rather sticky end...

More chopping, more welding:

At this point, the members of Club Triumph inform me of all the various alloy and lightweight bits and pieces you can get for the Triumph I6, so the shopping list grows oncemore. Estimated that you can cut about 30kg from the front end with the bells and whistles, and 61kg from the front including the fibreglass bonnet, ditching the bumpers and relocating the battery.

Straightened out the fibreglass bonnet and looks like we might have a bit of a tweaked chassis. A bit of closer inspection showed a little crease just aft of the very front, so hopefully no damage to the suspension mounting points.

House moved, interior stripped, body winched to the roof of the garage, engine removed:

PI engine teardown...

But 141bhp isn't particularly impressive in today's day and age, even with sod all weight to shift. Why not blow some money on a ported head?

Purdy

Balanced and reground crank...

...honed bores as they were still in spec...

...alloy engine plates and rebuilt decided on a target weight of 750kg after the swap, which seems ambitious but doable

decided on a target weight of 750kg after the swap, which seems ambitious but doable

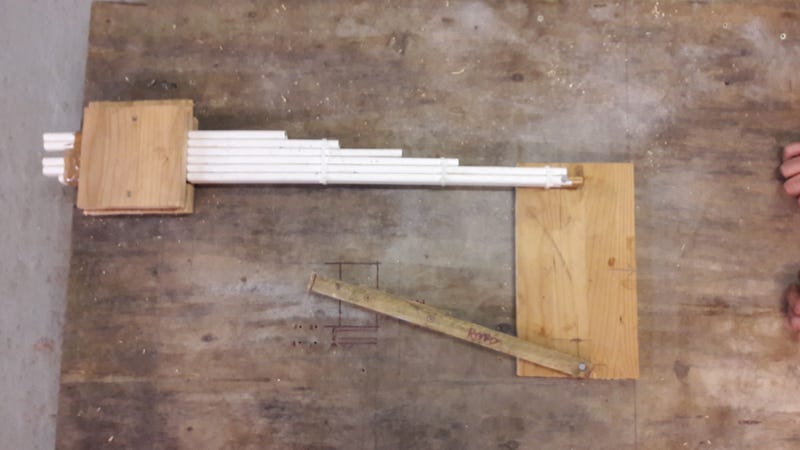

To clear the long-throw crank of the 2.5l using a GT6 sump you have to knock some channels into the shallow section. While I was there, I thought I might as well make a baffle to try and control the oil flow a little. Did a whole load of research into clever stuff like gated baffles, but having little fastening rattling around in the sump ready to come off and get stuck in moving bits didn't sound like a good idea to me. This is what I ended up with:

Outriggers off...

...rust fixed...

...and new outriggers on

A little trip to eBay and hole punch all the things!

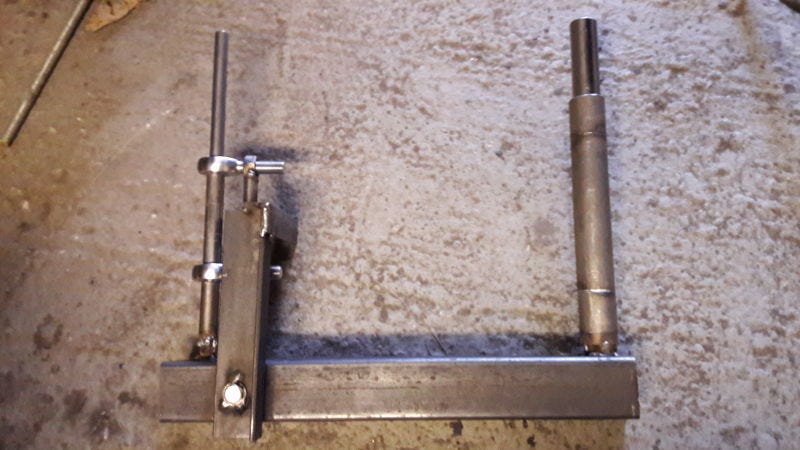

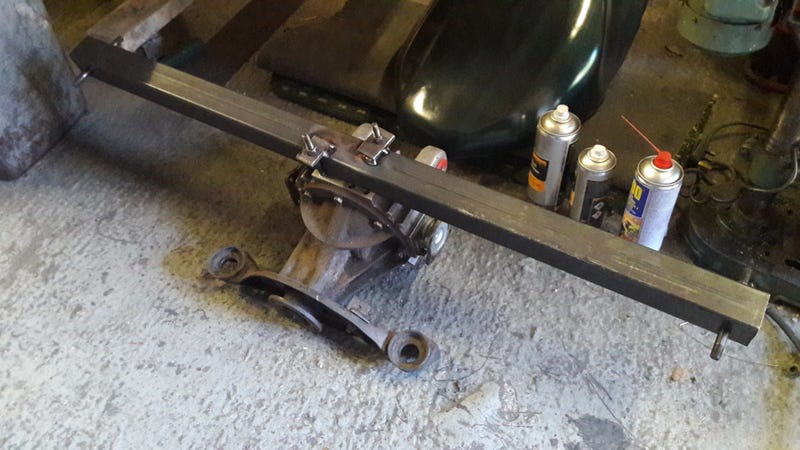

First proper fabrication job of making some gearbox mounts for the bigger saloon gearbox (if you're thinking of doing a similar thing, don't use this design. It fouled on the seats.)

Looked good though

Bodyshell back down to check clearance (and some more rust discovered and repaired)

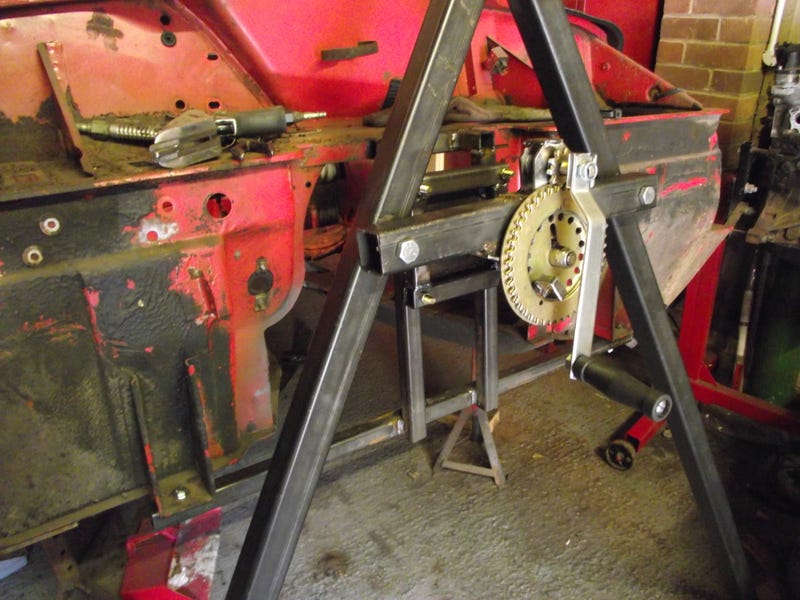

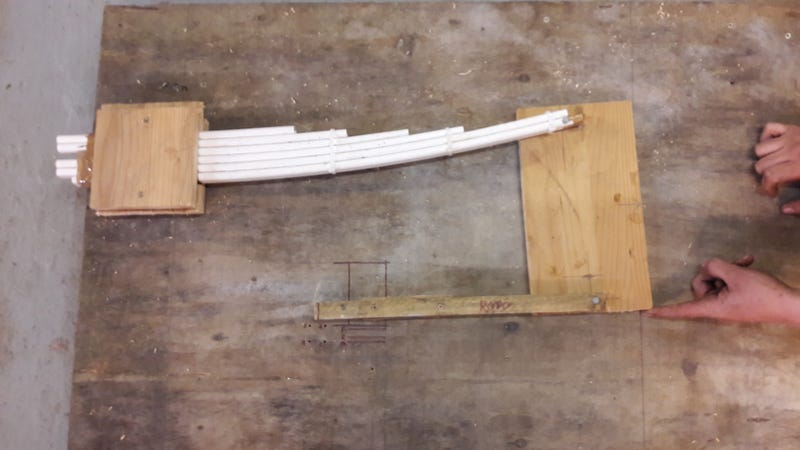

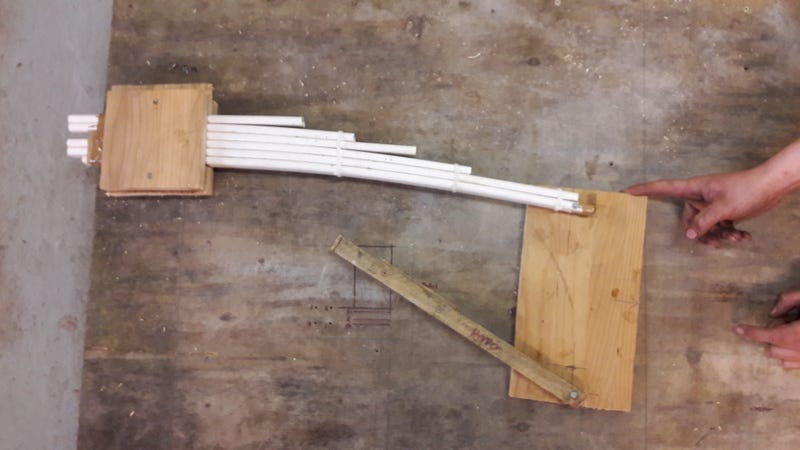

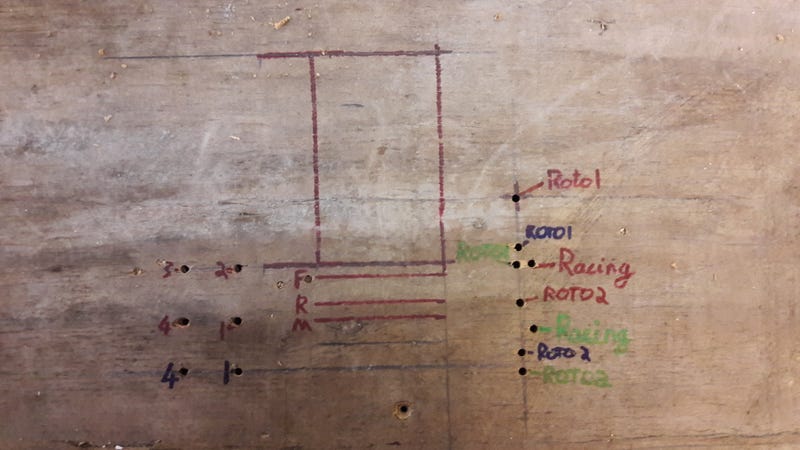

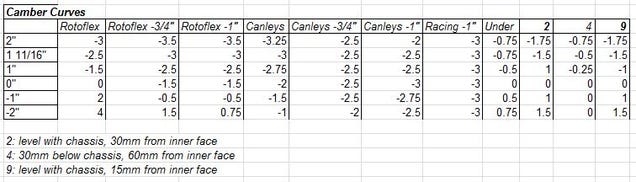

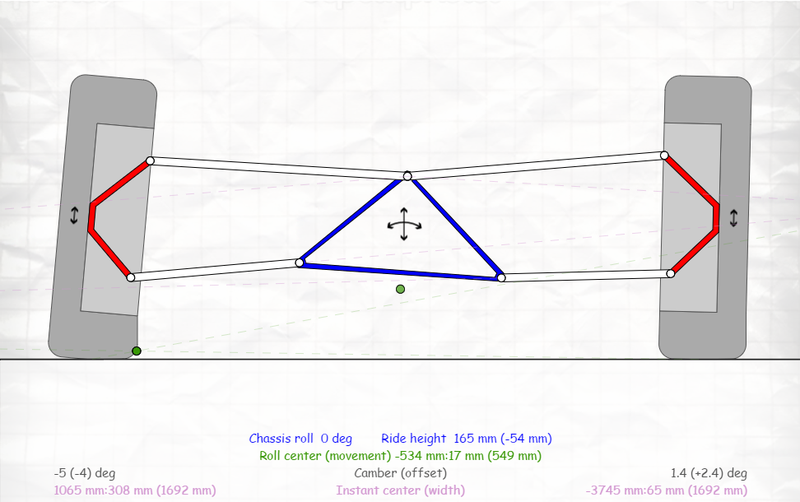

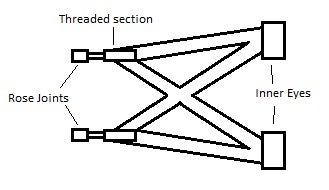

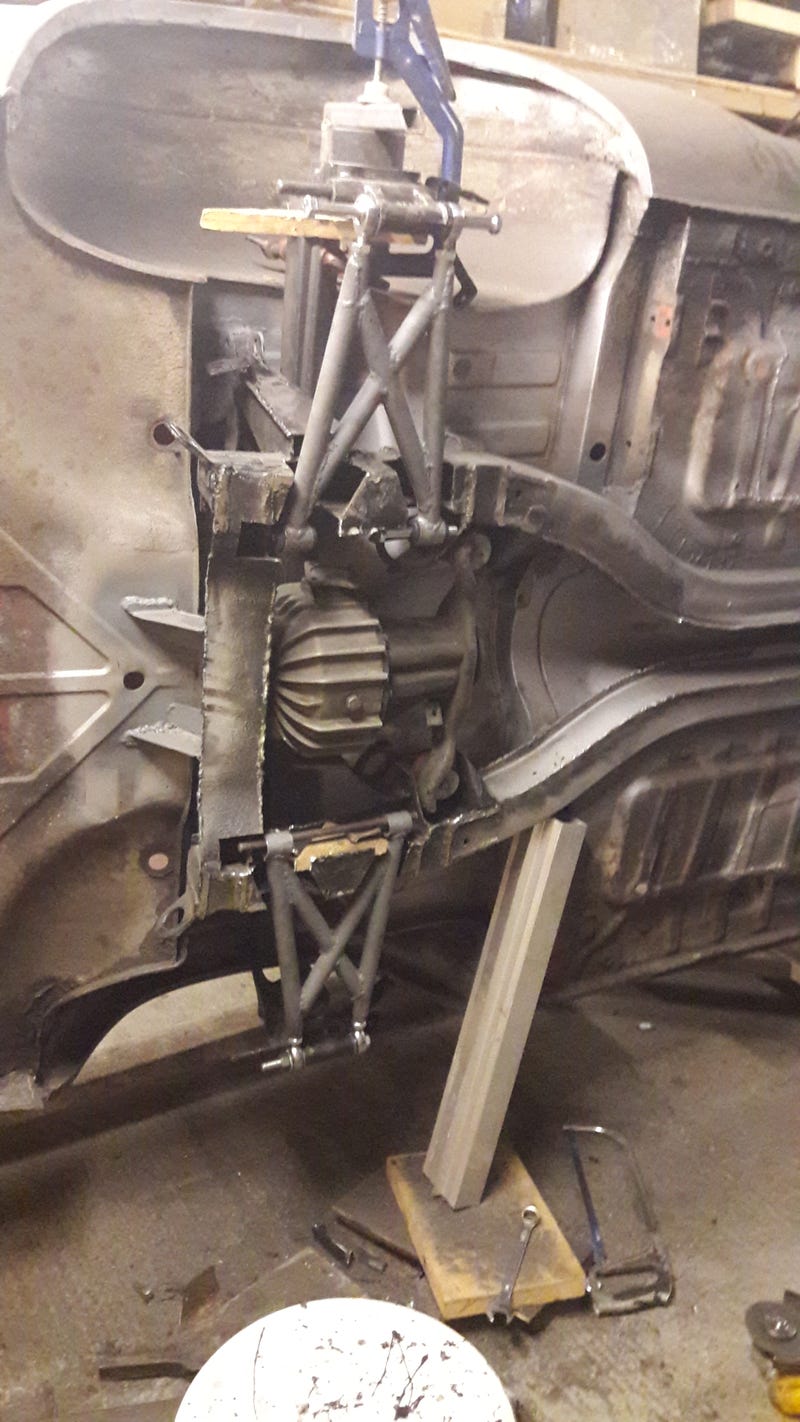

More weight reduction and spangly expensive bits oh, and decided I should probably do away with the swing axles and bought the bits for a rotoflex (GT6 mk2/early mk3 suspension) conversion

oh, and decided I should probably do away with the swing axles and bought the bits for a rotoflex (GT6 mk2/early mk3 suspension) conversion  GT6 fuel tank in the boot should help shift weight back too

GT6 fuel tank in the boot should help shift weight back too

This seems like as good a point as any to take a small break. Everything so far had been pretty straight forward as far as Spitfire 6 builds go.

If it was that, I'd have been finished by now...

Seeing as my old Triumph forum haunts are a little less active these days I thought it would be a good idea to broaden my horizons a little and share my project(s) with you lovely people

We'll start with the big one. My Triumph Spitfire 6. AKA 'Patchwork' (alternatively titled: 'Project Scope Creep').

Back in 2012, just out of university, I thought 'man I want one of those classic car things' and promptly bought myself a bit of a rust-bucket Spitfire for the princely sum of £1000. Bear with me, this might be a bit of a long intro...

I intended to do a bit of a rolling resto, but it turned out to be a far cry from the 'light project' it was billed to be. A fair amount of rust, and the engine wouldn't rev past 3500 without backfiring through the carbs. A fortnight or so of fettling didn't improve this at all, and a quick glance over eBay heralded this:

And the scope creep begins...

That's the mechanical fuel-injected I6 from a TR6 and associated overdrive gearbox. Rebuild, fix rust, swap in with GT6 bits, drive. Easy.

But hang on. I6-engined Spitfires are front-heavy beasts. Surely we can do something to fix that. The purchase of a £50 fibreglass bonnet turned out to be the tip of the iceberg we'll soon be uncovering. Might as well get a fibreglass hardtop too to replace the holed soft top.

Okedoke. Lets have a poke around the rest of the body for rusty bits. Bit of rust we know about, but can't be that bad.

Oh...

Okedoke then. Better learn to weld

The other side was a similar story, although the wheel arch inner had gone as well. Discovered that compound curves are pretty tricky to bend out of sheet steel, but cutting lots of little tabs and then stitching them together once bent works quite nicely

At this point in my old thread, I coin the phrase 'I'd like to do as little welding as possible to fix the rust and get it on the road', which is probably the biggest lie I've told to date...

And a little glamour shot of the garage and stable at the time

parents place, and dead lucky to have such a good working space. Alfa is a V6 and has been my on and off daily for donkey's years (GTA Sportwagon ARBs and a stainless exhaust but little else). The Jag I bought from my uncle for the princely sum of £60 and pulled it out of his field. It was running but not MoT'd at this point, but sadly meets a rather sticky end...

parents place, and dead lucky to have such a good working space. Alfa is a V6 and has been my on and off daily for donkey's years (GTA Sportwagon ARBs and a stainless exhaust but little else). The Jag I bought from my uncle for the princely sum of £60 and pulled it out of his field. It was running but not MoT'd at this point, but sadly meets a rather sticky end...

More chopping, more welding:

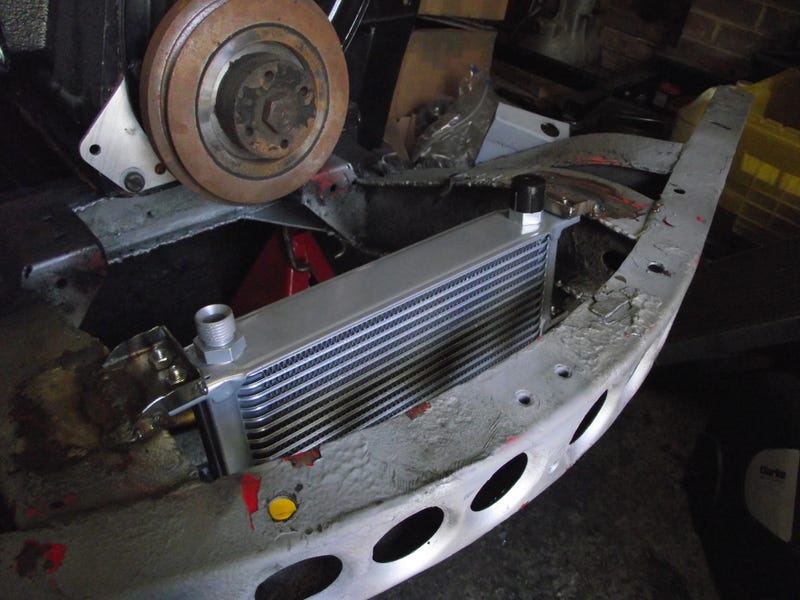

At this point, the members of Club Triumph inform me of all the various alloy and lightweight bits and pieces you can get for the Triumph I6, so the shopping list grows oncemore. Estimated that you can cut about 30kg from the front end with the bells and whistles, and 61kg from the front including the fibreglass bonnet, ditching the bumpers and relocating the battery.

Straightened out the fibreglass bonnet and looks like we might have a bit of a tweaked chassis. A bit of closer inspection showed a little crease just aft of the very front, so hopefully no damage to the suspension mounting points.

House moved, interior stripped, body winched to the roof of the garage, engine removed:

PI engine teardown...

But 141bhp isn't particularly impressive in today's day and age, even with sod all weight to shift. Why not blow some money on a ported head?

Purdy

Balanced and reground crank...

...honed bores as they were still in spec...

...alloy engine plates and rebuilt

decided on a target weight of 750kg after the swap, which seems ambitious but doable

decided on a target weight of 750kg after the swap, which seems ambitious but doable

To clear the long-throw crank of the 2.5l using a GT6 sump you have to knock some channels into the shallow section. While I was there, I thought I might as well make a baffle to try and control the oil flow a little. Did a whole load of research into clever stuff like gated baffles, but having little fastening rattling around in the sump ready to come off and get stuck in moving bits didn't sound like a good idea to me. This is what I ended up with:

Outriggers off...

...rust fixed...

...and new outriggers on

A little trip to eBay and hole punch all the things!

First proper fabrication job of making some gearbox mounts for the bigger saloon gearbox (if you're thinking of doing a similar thing, don't use this design. It fouled on the seats.)

Looked good though

Bodyshell back down to check clearance (and some more rust discovered and repaired)

More weight reduction and spangly expensive bits

oh, and decided I should probably do away with the swing axles and bought the bits for a rotoflex (GT6 mk2/early mk3 suspension) conversion

oh, and decided I should probably do away with the swing axles and bought the bits for a rotoflex (GT6 mk2/early mk3 suspension) conversion  GT6 fuel tank in the boot should help shift weight back too

GT6 fuel tank in the boot should help shift weight back too

This seems like as good a point as any to take a small break. Everything so far had been pretty straight forward as far as Spitfire 6 builds go.

If it was that, I'd have been finished by now...

but so far enjoying the Spitfire story!

but so far enjoying the Spitfire story!