2020-05-30 & 31

Hi RR!

I've been busy this weekend doing rear end stuff. Actually for the first time in several weeks got time to dedicate to this. Which feels really good!

It was a lot of work though, mainly due to the center pivot pin/axle which holds the "horn" in the boot on my "new-to-me" axle was so stuck that after 2 days of gentle bashing it would not budge.

So that was a waste of time and an opportunity to cut it instead even though I honestly wanted to save a lot of parts "just-in-case".

The main reason was that the pivot pin/axle had fused with the "horn" and thus wouldn't move at all, second reason could be that the metal bearings was worn due to lack of lubrication.

I guess this isn't an issue on modern cars since I've not seen a nipple to refill grease on anything made after -89..

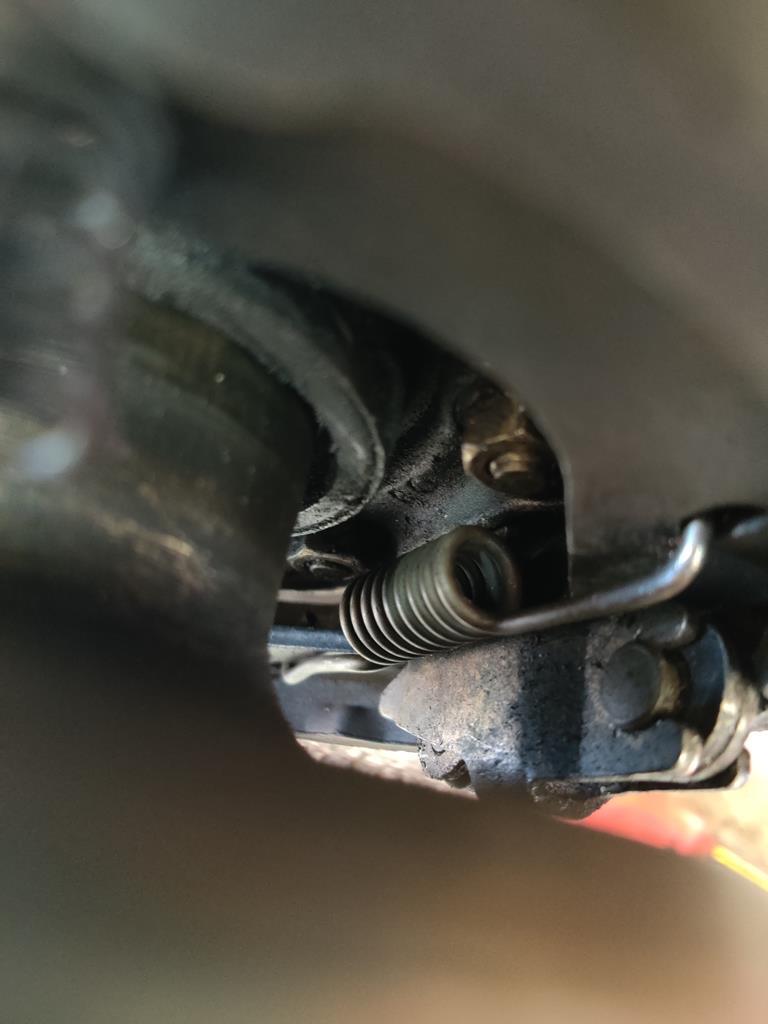

Another issue was to remove the handbrake cables from the car and axle, they are totally stuck to the knuckle and also was severely stuck to the car as well. Only removing them from the car took 45 minutes! Now I have an issue as of where to find new ones which are not too expensive or be able to remove the ones I got.

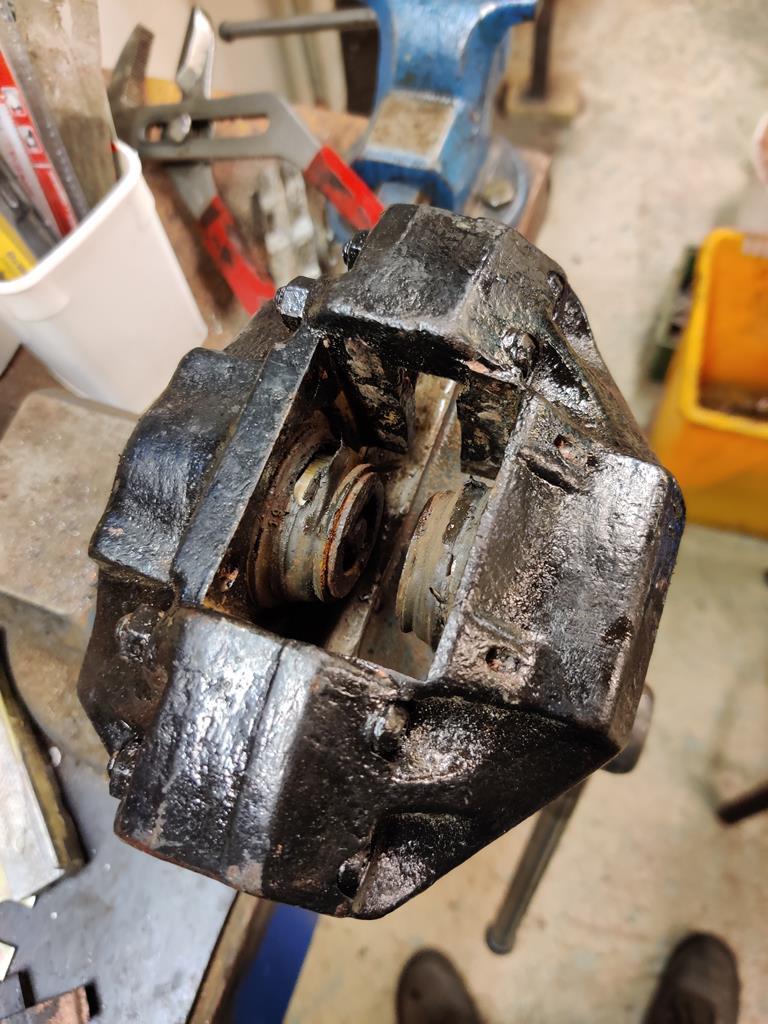

So after around 16-20 hours of work I got the new axle almost good to mount! Except some transfer of rubber bushes and handbrake wires, restoring and mounting brake calipers and so on. Just small stuff.

At first I had to remove the handbrakes at each side, which in itself isn't my favorite thing to do, handbrakes that is.

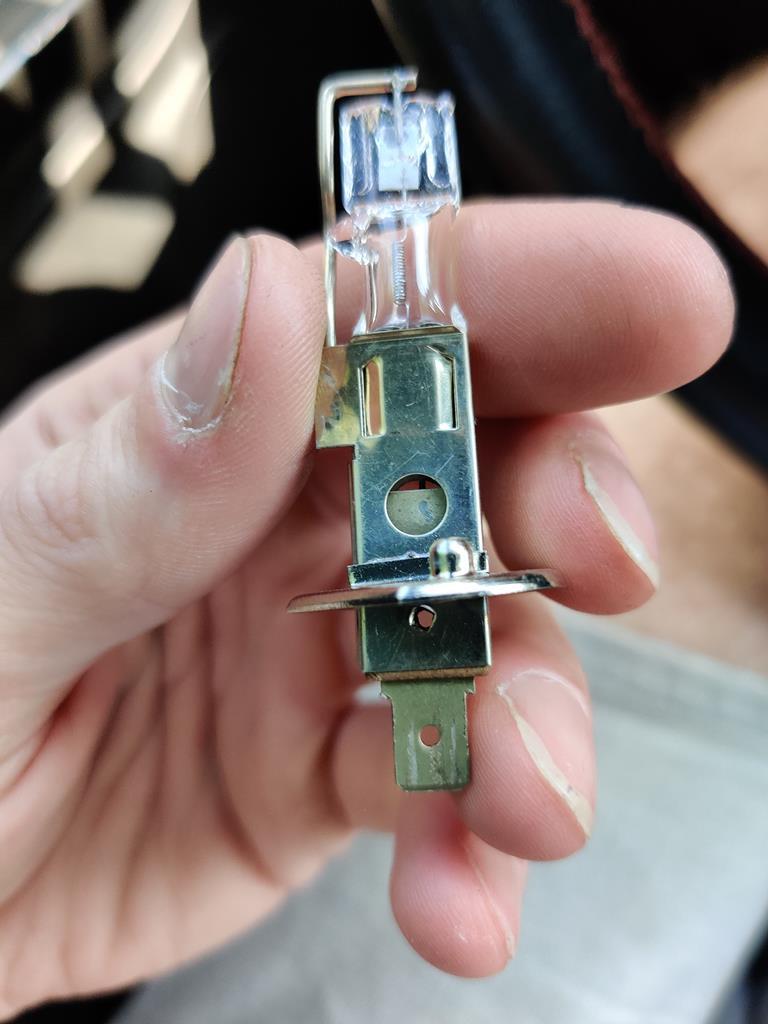

Then I had to mount some smaller wheel to be able to drag the axle out, which fortunately my mum found some 14" Bundts in the attic which I didn't even knew existed. So maybe I'll refurbish them and use them later, what do you think? Before I put some axle-stands and removed the brakelines, handbrakecables, undid the 4 nuts and bolts (3 tiny 13/15mm and 1 big 19/21mm somewhere around that size) from the L&R trailing arms and put a jack under the diff. Unscrewed the rubberbushing in the trunk for the "horn" and removed the rear shocks and finally removed the input shaft from the gearbox.

But, indeed the things that didn't go as planned were, handbrakewires, stuck everywhere but finally decided to leave the body of the car, rubberbushing in the trunk was stuck as all hell! That one alone took around 30 minutes to release, but seems to be in excellent plyable shape and no cracks, so that's a win!

After that just drop and wiggle the jack until everything is on the floor.

Since I already had the axle apart it went very smoothly to remove the hydro pneumatic compensator, pivot axle and horn, including spilling oil everywhere of course ( I had thought everything already leaked out, but of course that wasn't the case.)

After a good scrub, sanding and painting the horn turned out really okay! Will just scotchbrite the rust and lightly grease on the top of the rubbermount to ensure smooth connection later.

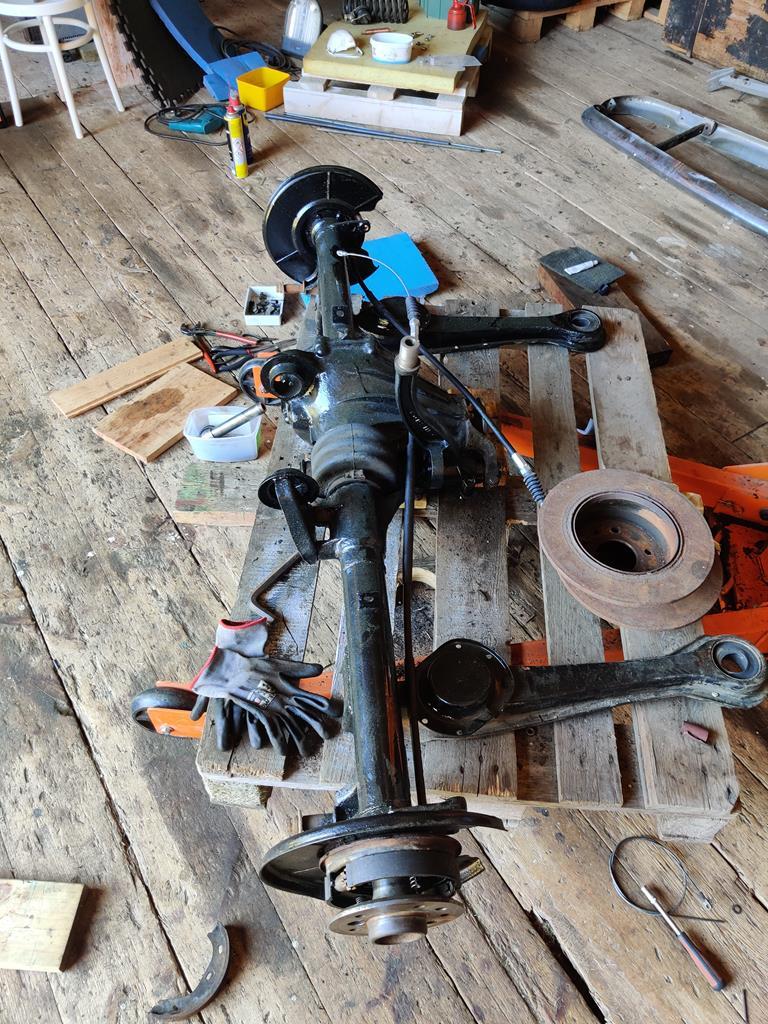

After all that hassle I did sand the whole "new" axle down and painted it, if you look closely in the middle you can see that the P-O of this axle cut the horn off.

Also the eagle-eyed have noticed some differences between this axle and the one from my car.

The differences being that the "New" axle is from a I6, 280 SE 1968

Which means it lacks the following features in comparison;

* No recirculated vent in the diff

* No relocation of the axle-to-air vent

Possible issues that might occur is as simple as follows, if I step on it from standstill too many times in a row, pressure will build up and oil might start to foam. Which will of course clog the "axle-to-air" vent in the side tube (as instead of the top in the 3.5 axle, hence why the bigger tube goes to the top vent) and that might push some seals out at the end of the axles and cause an oil leak.

So conclusion, do not floor it too much from standstill. Just hoon around 3/7 of the time instead of 8/7 times. OK.. I might add a vent later as intended if I start to push seals around.

On my way to remove the old broken horn I had to use the following stuff; a brass bar 26mm dia, a tiny sledgehammer, angle-grinder, hacksaw and almost all of my vocabulary.

After 2 hours or more of fiddling I got it to come apart and I was actually feeling satisfied and happy.

After a short break and maybe 15 minutes of fiddling I got it all back together with the freshly refurbished "horn" and bushings. So easy it is when everything is fresh!

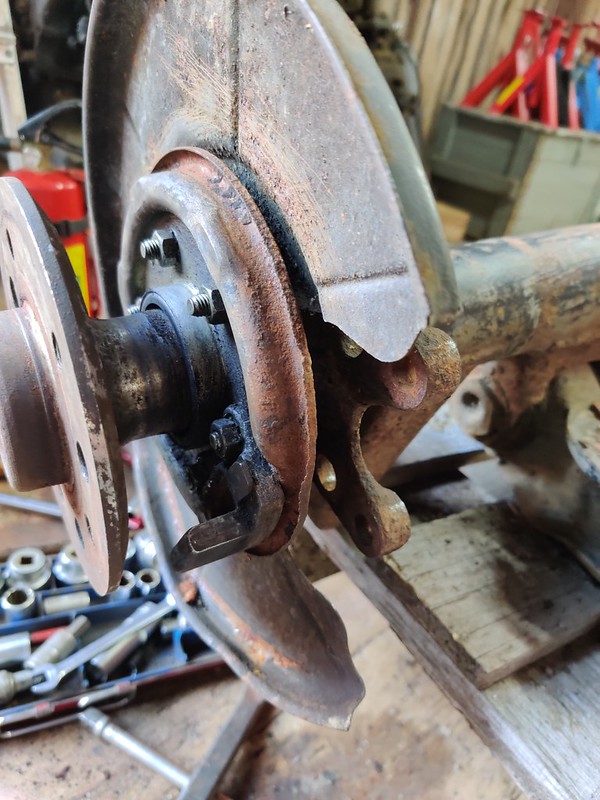

After that I started to tackle the R-side rear brake with sandpaper and paint, it's original black so why not continue a good trend when I got some heat-resistant paint left over?

That's all for now! I might be able to another update in 3 weeks, depending on how quickly I can get my hands on parts and time!

Also should I have Bundts as shown above? I am thinking about a darker/gun metal/brakedust grey, instead of the silver ones IF I intend to use them!

Best regards,

mrEA