|

|

|

|

|

|

now youve plotted it stage by stage it makes you wonder why more people havent done it (asside from the lack of lathe and ingenuity)

early coilers had railco bush at the top and taper bearing at the bottom same as series 3 (not sahing parts are same just same architecture) so the coil spring swivel housing was just bigger, to get larger internal area to clear larger outside dimeter of the CV joint ?

i don't think i ever went as deep as the axle tube on my ninety, but is that right they had no bearing/carrier in the end of the axle tube like series, the weight of the shaft just carried by the cv itself ? you gonna carry that method over or have series 3 setup with seal and bearing (since you are having custom shafts anyway) ?

|

| |

Last Edit: Dec 2, 2018 21:00:31 GMT by darrenh

|

|

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

|

|

Going step by step it does sound easy! I'd guess the main reason more don't do it is the cost of having bespoke shafts made. I'm anticipating to be paying somewhere around £450 for a pair of custom inner shafts, and on top of that I'll have to buy a 24 spline diff, the Ashcroft 4 pin centre which I want won't turn up on the doorstep for any less than £340! I've got a donor early 110 axle which I did have fitted to my 88 but just couldn't get my head round how to get the steering working without it being a monumental bodge up so pulled it all apart and dumped it in the shed. That has the top railko and bottom roller bearing, and as you say, they're dimensionally different. Side by side I'd say the coiler axle parts are generally a lot smaller than the series parts. The series chrome ball dwarfs the coiler chrome ball, it has a larger base flange, thicker neck, and generally appears thicker material. The coiler chrome ball seems to be a lot thinner material, and although the neck is smaller, it is almost solid apart from having a 32mm hole for the driveshaft hole through it. The stub axles are largely the same as post 1980 with the same wheel bearings and the hubs are interchangeable between the late series 3 and coiler axles, down to the wheel face being the same position. I do wonder why they didn't make more interchangeable parts between the coil sprung and leaf sprung axles with the start of the Range Rover, unless it's all down to shrinking the swivel housings enough to fit the disc brakes over the top? You're right in that the inner shaft is entirely free floating on the coiler axles only supported by the diff and the CV, which is supported by the hub drive flange and a bush on the stub axle. Whereas the older series axles have a large roller bearing in the base of the chrome ball to support the inner shaft, and the outer shaft free floating to the hub drive flange. After a lot of thought and looking at how both setups are made I've decided to use the later method of the CV completely supported by the hub and stub axle, and the inner shaft fully floating. There is precedence for it being done this way, so I'm hoping that the drawings will still be on record for when I'm ready to order. I just need to find a large block of metal (swaying towards aluminium as it'll be so much easier to machine) to make into the oil seal retainer in the base of the chrome ball. Today I stripped down a spare series axle for the chrome  balls to start mocking up the fitment of the CV joint and figure out how much material needed removing and what other mods are required to fit it inside   To my suprise the chrome ball went straight on over the CV with top and bottom pins fitted, but unsuprisingly wouldn't turn more than a few degrees! Some gentle massaging of the internal surface by the top railko bush and bottom roller bearing with the powerfile has the chrome ball moving fully lock to lock. Now what really suprises me is contrary to what I've been told, the CV clears the top pin, so it appears I won't need to replace the top pin with a custom part or re-machine it to take a roller bearing! I still need to conclusively verify that the centreline of the CV joint is inline with the centreline of the top and bottom swivel pins, but first impressions are that it all lines up and should work with the 110 stub axles on the series swivel housing needing no more machining? |

| |

|

|

|

|

|

|

|

|

If it's that easy to do a CV joint conversion with what appears to be very little asides a little clearancing and a set of custom shafts, I can imagine it's something that could end up a popular conversion.

|

| |

|

|

|

|

|

|

|

|

i still cant get my head round how coil spring swivel balls are smaller, but the joint inside is bigger. must just be more compact in total (clearance for misalignment is smaller on cv)

|

| |

Last Edit: Dec 4, 2018 15:01:26 GMT by darrenh

|

|

|

|

|

|

|

|

I don't have a clue on all the different Land Rover variations but its great to see workings of it all, seeing how complex some of this stuff is I'm amazed they haven't all fallen to bits with lack of maintenance, or is it not really that complex?

|

| |

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

|

|

If it's that easy to do a CV joint conversion with what appears to be very little asides a little clearancing and a set of custom shafts, I can imagine it's something that could end up a popular conversion. Cost will put most off, and to be honest it's not essential. I've done over 6000 miles with a standard series axle on permanent 4wd with u/j's in the ends and not had a failure (yet). I've put plenty of power through it and not had the cataclysmic failures most will claim they'll suffer. I reckon it's because of the 3.54 ratio diffs, they require more effort from the engine and transmission to drive, and are not like the torque multiplier of the standard series 4.7 ratio diffs. I can just about feel the driveshaft oscillations from the u/j's near hard lock with some power applied, and the CV's will eliminate that. Here's the inside of the two trial swivel balls I've started work with, before on the left, after on the right. So far all I've needed to do is blend out some of the metal at the edges of the machined faces inside. Once I've checked that the CV is set at the correct height in relation to the centreline of the swivel housing I'll know for sure exactly how much needs removing.   i still cant get my head round how coil spring swivel balls are smaller, but the joint inside is bigger. must just be more compact in total (clearance for misalignment is smaller on cv) The series swivel balls are thicker overall, and slightly larger outside diameter. The top bush is quite substantial, carried over onto the 110, though I don't know if they eventually replaced it with the small pin and roller bearings? The bottom roller bearing is also substantial on the series, and smaller on the coiler. Even the size of the axle mounting flange is larger on the series! I'm sure I've heard of people bending the coiler swivel balls in heavy offroading? The only thing that is obviously stronger on the coiler axle are the bolts that hold the ball to the end of the casing. Series swivel on the left, coiler on the right    I don't have a clue on all the different Land Rover variations but its great to see workings of it all, seeing how complex some of this stuff is I'm amazed they haven't all fallen to bits with lack of maintenance, or is it not really that complex? They're extremely simple, dead easy to pull apart and throw back together with basic tools and skills. It's all chunky engineering, based on 1940's technology and the parts bin of their 1940's saloon cars! |

| |

|

|

|

|

|

|

|

wow, thats mental difference thanks for the side by side pics, very useful bookmark info ! i'm also surprised how slender the "defender" half shafts are. much thinner and obviously longer, cant be great for the mechanical advantage and twistyness. i guess land rover thought they could get away with it as engine torque is being divided 4 ways all the time, plus no windup due to middle diff (ignoring when its locked) i like the blending youve done, it doesnt seem that extreme looking at it, and you could argue removing sharp edges actually increases strength (relatively) hope it works out, looks promising  ! |

| |

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

|

|

|

The size difference is not something you'd expect to see that way round. I still don't get why they changed the axle design so significantly for the Range Rover, and with the Heystee disc brake conversion I see no real reason why they couldn't have cast caliper lugs into the swivel housing?

The shaft diameters are deceptive in the photos. Comparing 10 spline and 24 spline shafts is night and day in diameter, can't remember off the top of my head the difference is, but it's a lot. The problem with the series front shafts is that they taper down to the splines, which I believe is where they normally shear or they tear the u/j apart. The uniform thickness of the later shafts allows them to twist along the length spreading the loads rather than concentrating them on one point. Also how the 24 spline ends are formed is generally much nicer than the rough 10 spline cuts.

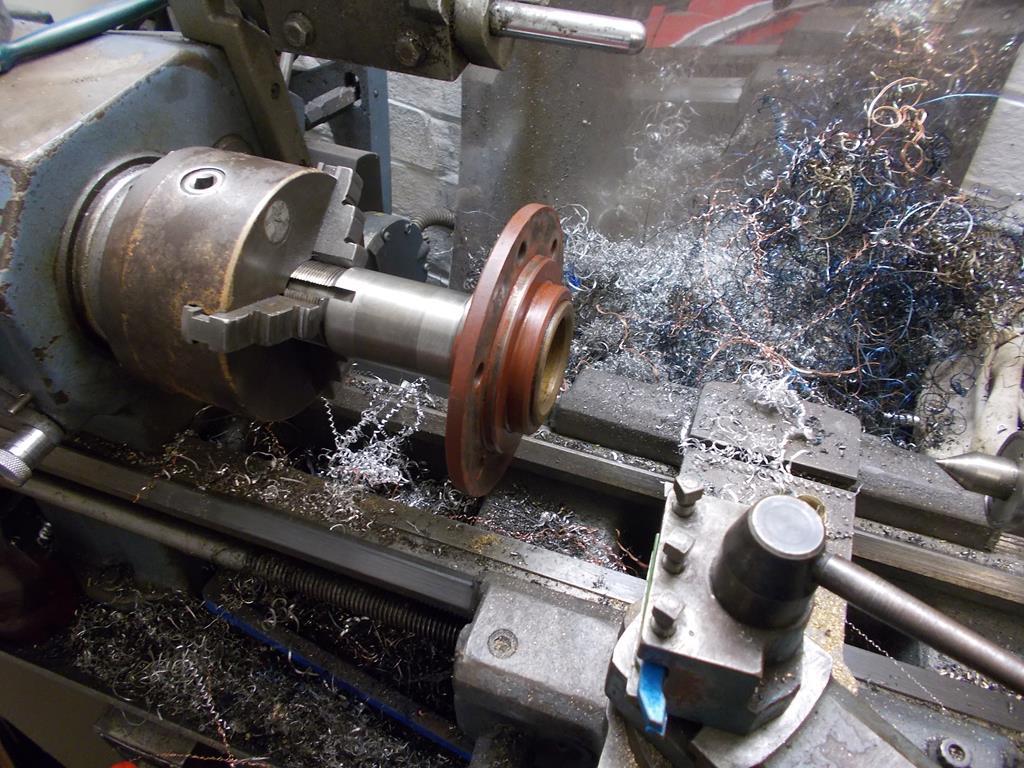

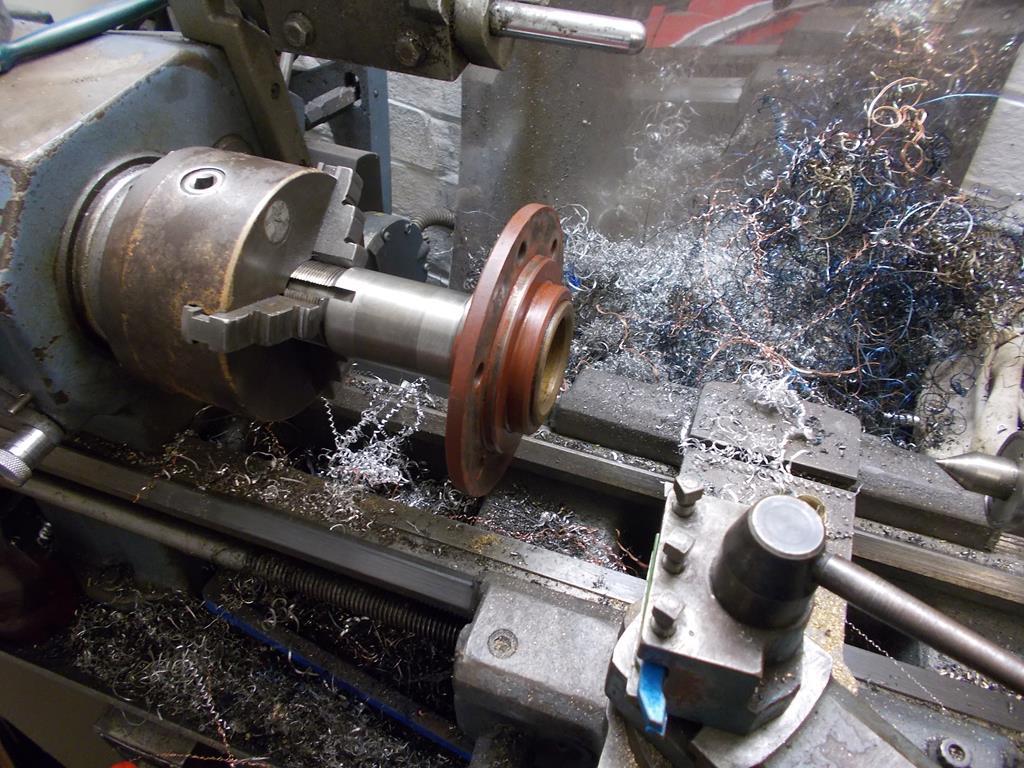

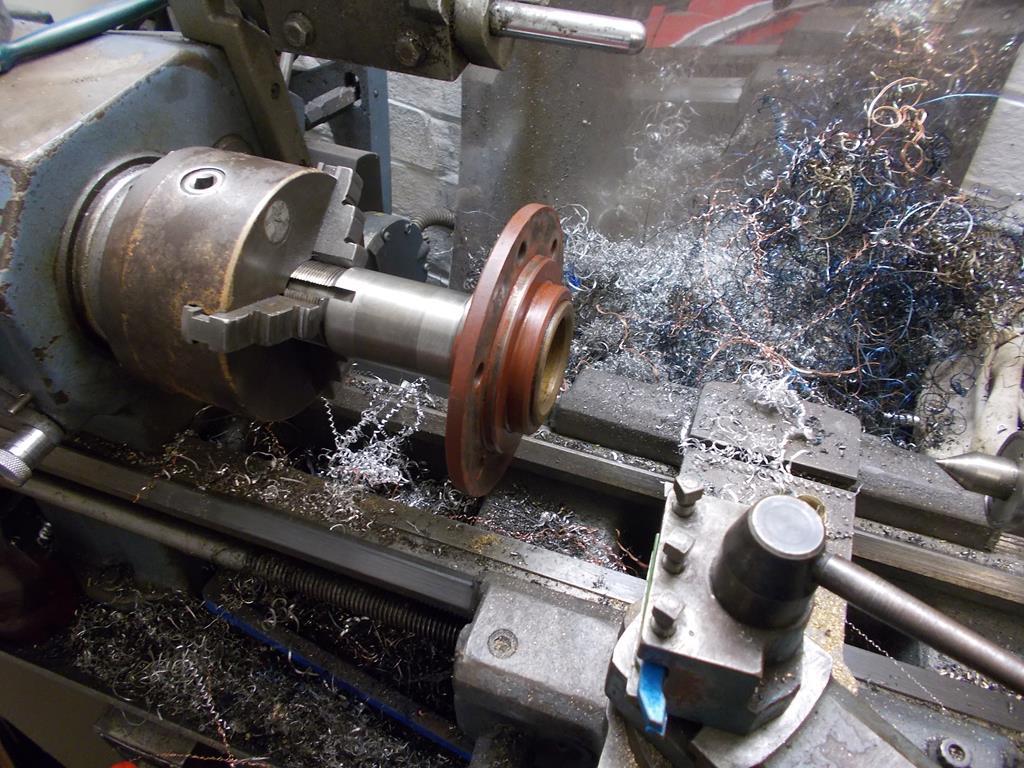

What was a little offputting when I first started properly researching the mods to the swivel balls was people saying they needed to be ground out for clearance. I just had mental images of slash marks all over the inside from a 4.5" grinding disc! I used a powerfile with a 13mm belt, just took the high spots off and blended them down. With the thickness of the metal compared to the coiler swivels I believe there's plenty of reserve strength in them, and they do literally hang off the side of the axle casing with 6 BSF bolts!

|

| |

|

|

|

|

|

|

|

|

"They're extremely simple, dead easy to pull apart and throw back together with basic tools and skills. It's all chunky engineering, based on 1940's technology and the parts bin of their 1940's saloon cars!"

I did wonder if that was the case, I don't think I own spanners big enough to own one just yet!

People used to think I was mad collecting old rusty parts but its great when you need to adapt or compare differences so you can modify and improve things! watching and learning just in case the day comes to scratch the Land Rover itch!

|

| |

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

|

|

Let's just say you can strip, replace and set the wheel bearings up and lock them off with a hammer and chisel in absence of the correct box spanner  Just a basic set of spanners and sockets is technically all that's needed, until the inevitable rust comes into play and stuff doesn't want to come apart  |

| |

|

|

|

|

|

|

|

Jan 16, 2019 10:40:20 GMT

|

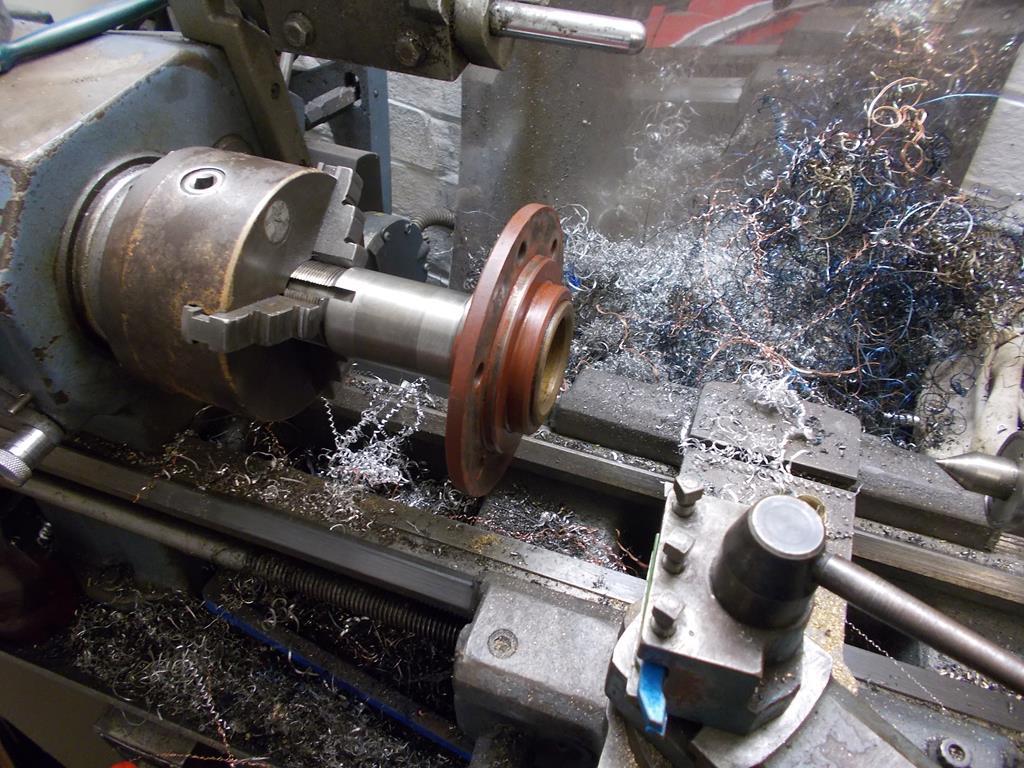

Also since my 109 is a late model, it shares the same wheel bearings and hub dimensions as the later 90/110 models, so I stuck a pair of spare 110 stub axles in the lathe and removed a little material so they dropped into a spare pair of series swivel housings and bolted them down  mr sowern, where exactly did you have to remove the material from, to make coil stub axles fit series swivels ? this has become quite a topical discussion due to the fact early series stub axles are about 40 quid, coil spring stub axles are about 40 quid, and 1980-1985 rationalised series stub axles are 300+ quid. |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,357

Club RR Member Number: 64

|

|

Jan 16, 2019 10:47:51 GMT

|

Also since my 109 is a late model, it shares the same wheel bearings and hub dimensions as the later 90/110 models, so I stuck a pair of spare 110 stub axles in the lathe and removed a little material so they dropped into a spare pair of series swivel housings and bolted them down  mr sowern, where exactly did you have to remove the material from, to make coil stub axles fit series swivels ? this has become quite a topical discussion due to the fact early series stub axles are about 40 quid, coil spring stub axles are about 40 quid, and 1980-1985 rationalised series stub axles are 300+ quid. If you need a set machined Darren, drop them down to me. |

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

|

|

Also since my 109 is a late model, it shares the same wheel bearings and hub dimensions as the later 90/110 models, so I stuck a pair of spare 110 stub axles in the lathe and removed a little material so they dropped into a spare pair of series swivel housings and bolted them down  mr sowern, where exactly did you have to remove the material from, to make coil stub axles fit series swivels ? this has become quite a topical discussion due to the fact early series stub axles are about 40 quid, coil spring stub axles are about 40 quid, and 1980-1985 rationalised series stub axles are 300+ quid. There's a good discussion about it on this forum here: forums.lr4x4.com/topic/94417-slowest-ever-lightweight-rebuild/?page=19 |

| |

Last Edit: Jan 17, 2019 4:08:09 GMT by wiggybum

|

|

|

|

|

Jan 17, 2019 19:13:06 GMT

|

thanks for the link, will have a read |

| |

Last Edit: Jan 17, 2019 19:14:31 GMT by darrenh

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

Jan 17, 2019 21:00:18 GMT

|

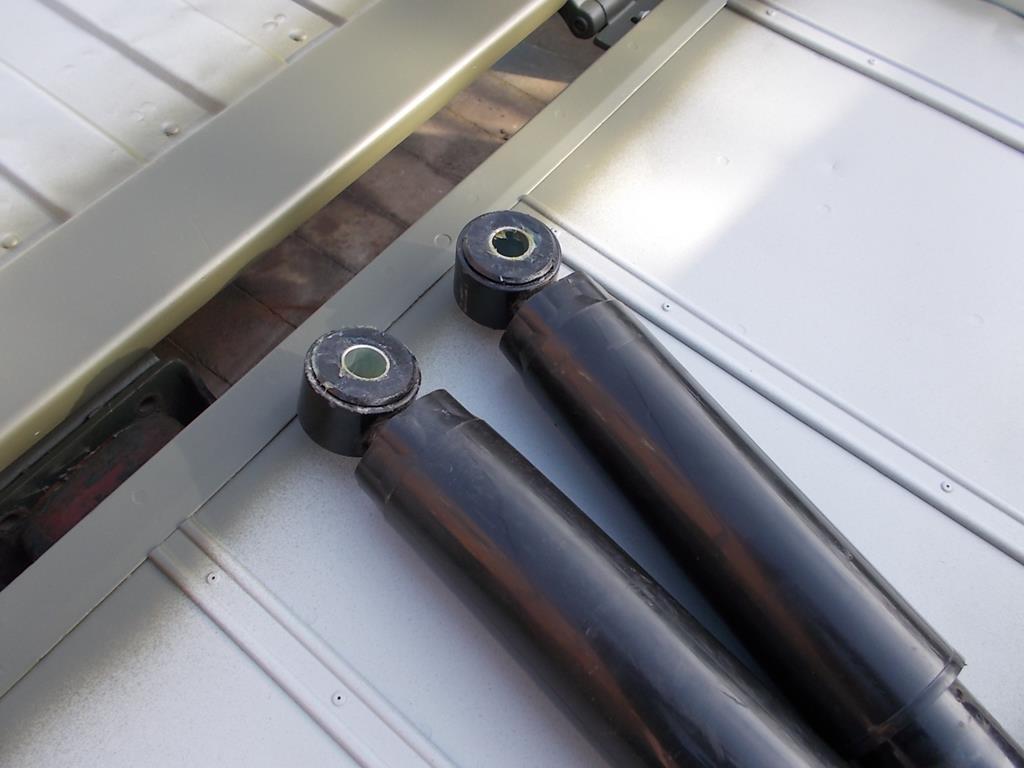

mr sowern, where exactly did you have to remove the material from, to make coil stub axles fit series swivels ? this has become quite a topical discussion due to the fact early series stub axles are about 40 quid, coil spring stub axles are about 40 quid, and 1980-1985 rationalised series stub axles are 300+ quid. I took the material off the first step so the stub axle would drop into the swivel housing. The problem which has been discussed and I can clearly see now is the bush in the back doesn't sit at the correct position for the CV joint to be centred in the swivel housing. The coiler front stubs I've got don't have the locating step for the drum backplate either. It may all line up with standard u/j type shafts and drums? I've been pondering over the last few weeks all possible solutions to keep the costs down, and have got an idea that'll give me a 4 pin 24 spline diff to suit custom inner shafts and help justify the purchase of a set of Stage 1 V8 stub axles.... |

| |

|

|

|

|

|

Jan 18, 2019 18:39:19 GMT

|

mr sowern, where exactly did you have to remove the material from, to make coil stub axles fit series swivels ? this has become quite a topical discussion due to the fact early series stub axles are about 40 quid, coil spring stub axles are about 40 quid, and 1980-1985 rationalised series stub axles are 300+ quid. I took the material off the first step so the stub axle would drop into the swivel housing. The problem which has been discussed and I can clearly see now is the bush in the back doesn't sit at the correct position for the CV joint to be centred in the swivel housing. The coiler front stubs I've got don't have the locating step for the drum backplate either. It may all line up with standard u/j type shafts and drums? I've been pondering over the last few weeks all possible solutions to keep the costs down, and have got an idea that'll give me a 4 pin 24 spline diff to suit custom inner shafts and help justify the purchase of a set of Stage 1 V8 stub axles.... hmm, yeah, the flange being thinner and lacking brake backplate "step" is a bit of a deal breaker |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,357

Club RR Member Number: 64

|

|

Jan 18, 2019 21:02:24 GMT

|

|

I can probably sort you out a set of early stub axles and hubs if you’re stuck Darren.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

|

|

|

Jan 22, 2019 12:10:08 GMT

|

I can probably sort you out a set of early stub axles and hubs if you’re stuck Darren. thanks glen. early stubs don't fit rationalised axles (unless you also fit earlier 109 halfshafts) it doesnt directly effect me (not yet anyway) there was a question on the landrover forum and ended up going down another one of those knowledge rabbit holes. |

| |

|

|

glenanderson

Club Retro Rides Member

Posts: 4,357

Club RR Member Number: 64

|

|

Jan 22, 2019 12:46:39 GMT

|

|

No worries. I’ve halfshafts too if you ever get stuck.

|

| |

My worst worry about dying is my wife selling my stuff for what I told her it cost...

|

|

sowen

Club Retro Rides Member

Posts: 2,245

Club RR Member Number: 24

|

|

Feb 17, 2019 14:38:08 GMT

|

|

|

| |

|

|

|

|

balls to start mocking up the fitment of the CV joint and figure out how much material needed removing and what other mods are required to fit it inside

balls to start mocking up the fitment of the CV joint and figure out how much material needed removing and what other mods are required to fit it inside

!

!