moving forward a number of months, research had been done, gearboxes had been searched for. A k10 box was the first port of call however I had my eye on a 5 speed which made the whole issue far harder,

5 speed k10 boxes being as rare as poor quality wobbly children's play pony faeces meant this search was fruitless.

after forum scouring of the relevant info, I decided that a pre facelift 1.0 5 speed k11 box would be suitable, with the output shafts splines supposedly the same as a K10. Furthermore it was reported on the webs that it should bolt right up with minimal hassle. The only job being the 90 degree rotation of the gear selector rod.

I can now say that not all of this is true and a k11 box does not simply drop in and bolt up.

However one was bought and retrieved from the depths of Cornwall.

K11 box waiting patiently to cause much hair to be pulled out

So, with wheels off, ball joints split, hub knuckles apart and drive shafts popped out, The original 2speed Micra box was dropped out with a lot of grunting.

upon removing it, it was very clear that none of the gearbox mounts shared anything in common with the k11 box. Ah...

original mount with datum points bolted on to make it fit the new box, for reference, the 7 bolts that physically attach the gearbox to the engine do in fact line up. which is nice.

so original mount was then cut about and welded with a flat plate that bolted to the new gearbox mount face. metal surgery required to maintain the rubber bushing mount.

new box with new mount

progress is being made very slowly.

A visit to the local breakers was made in hope of finding a more suitable gearbox mount for the front nearside. One was pilfered of a k11. after all the tribulation of finding a k10 box, a whole micra was at the breakers so the inlet manifold was removed for a different purpose involving cbr600 carbs bought a while ago...

Anyway, Back at base it was discovered that a facelift micra nearside gearbox mount is not the same as its pre facellift counterpart..

either way it lined up ever so slightly better than the original mounts, so it was chosen to under go surgery to make it fit.

Gearbox now mated to engine. some slight modifications were required, one non threaded bolt hole on the engine casing needed drilling out from 8 to 10mm to allow bolt to pass through and screw into gearbox. Also dowel holes to locate the two bolt faces needed a light touch with a drill bit to ease the entry.

With the rearward mount now fitted the gearbox was bolted property to the engine, so using a jack and a large pole, the bottom of the gearbox was jacked to take it up to the right height. the driveshafts where then inserted back in with some degree of force, (it helps to split the balljoint on the wishbone to disconnect the hub to it can be eased in with force.

The nearside mount required less work to make fit, On a facelift micra all bolt faces are on the same plane, whereas my gearbox had 2 recessed back 10mm. To make the mount work, a 10mm spacer block was machined up with drilled m10 holes to allow the bolts through, this was then tacked to the mount with the original holes slightly sloted to make fit

The above image shows the mount fixed on with 2 bolts and one through the rubber bushing, attaching it to the vehicle.

In order to make use of the 3rd bolt hole, a flat plate was tacked on to the mount as it was all on one plane now, this allowed a bolt to be put through and test that all 3 lined up. It was then big welded and made stronger.

With the gearbox fully mounted to the car, the control rod was removed and cut and sleeved to allow it to rotate 90 degrees and be re welded. With it partially tacked and refitted, I took this time to make any changes to the gearstick position from within the car. With that sorted it was welded and fitted with a nylock. Splitpins fitted all round on various ball joints. hubs reassembled and wheels back on the car was lowered back onto the floor and pushed outside.

The last job being to fill the new Box with 2.7litres of Rock Oils finest 75w80.

The car fired right up, this time without gearbox whine. After taking the micra up the road and getting with ease into every gear it was deemed a successful swap.

To summarise for anyone wishing to swap a k11 box into a k10, Get a K10 5 speed. But if you do wish to persist, Make sure it is an early pre-facelift 1.0 k11, as the output shafts will fit. however a degree of fabrication skill is required as none of the gearbox mounts to the car will fit, It may help to get the mounts from the donor k11, however i cannot comment as it was never tried. The control rod will re welding 90degrees opposed to its original position. Should this all work it should go in easily... Some m10s are required in place of m8s along with a large washer.

Anyway here is the K10 back on the road with a k11 gearbox inside. next job, suspension.

5 speed k10 boxes being as rare as poor quality wobbly children's play pony faeces meant this search was fruitless.

after forum scouring of the relevant info, I decided that a pre facelift 1.0 5 speed k11 box would be suitable, with the output shafts splines supposedly the same as a K10. Furthermore it was reported on the webs that it should bolt right up with minimal hassle. The only job being the 90 degree rotation of the gear selector rod.

I can now say that not all of this is true and a k11 box does not simply drop in and bolt up.

However one was bought and retrieved from the depths of Cornwall.

K11 box waiting patiently to cause much hair to be pulled out

So, with wheels off, ball joints split, hub knuckles apart and drive shafts popped out, The original 2speed Micra box was dropped out with a lot of grunting.

upon removing it, it was very clear that none of the gearbox mounts shared anything in common with the k11 box. Ah...

original mount with datum points bolted on to make it fit the new box, for reference, the 7 bolts that physically attach the gearbox to the engine do in fact line up. which is nice.

so original mount was then cut about and welded with a flat plate that bolted to the new gearbox mount face. metal surgery required to maintain the rubber bushing mount.

new box with new mount

progress is being made very slowly.

A visit to the local breakers was made in hope of finding a more suitable gearbox mount for the front nearside. One was pilfered of a k11. after all the tribulation of finding a k10 box, a whole micra was at the breakers so the inlet manifold was removed for a different purpose involving cbr600 carbs bought a while ago...

Anyway, Back at base it was discovered that a facelift micra nearside gearbox mount is not the same as its pre facellift counterpart..

either way it lined up ever so slightly better than the original mounts, so it was chosen to under go surgery to make it fit.

Gearbox now mated to engine. some slight modifications were required, one non threaded bolt hole on the engine casing needed drilling out from 8 to 10mm to allow bolt to pass through and screw into gearbox. Also dowel holes to locate the two bolt faces needed a light touch with a drill bit to ease the entry.

With the rearward mount now fitted the gearbox was bolted property to the engine, so using a jack and a large pole, the bottom of the gearbox was jacked to take it up to the right height. the driveshafts where then inserted back in with some degree of force, (it helps to split the balljoint on the wishbone to disconnect the hub to it can be eased in with force.

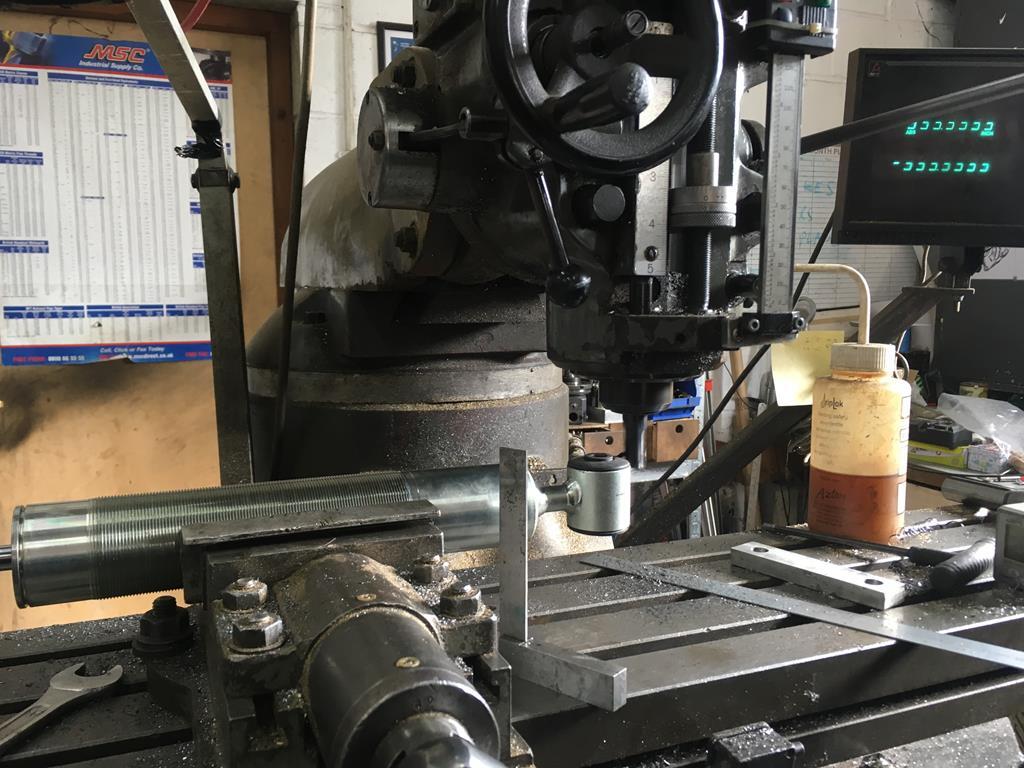

The nearside mount required less work to make fit, On a facelift micra all bolt faces are on the same plane, whereas my gearbox had 2 recessed back 10mm. To make the mount work, a 10mm spacer block was machined up with drilled m10 holes to allow the bolts through, this was then tacked to the mount with the original holes slightly sloted to make fit

The above image shows the mount fixed on with 2 bolts and one through the rubber bushing, attaching it to the vehicle.

In order to make use of the 3rd bolt hole, a flat plate was tacked on to the mount as it was all on one plane now, this allowed a bolt to be put through and test that all 3 lined up. It was then big welded and made stronger.

With the gearbox fully mounted to the car, the control rod was removed and cut and sleeved to allow it to rotate 90 degrees and be re welded. With it partially tacked and refitted, I took this time to make any changes to the gearstick position from within the car. With that sorted it was welded and fitted with a nylock. Splitpins fitted all round on various ball joints. hubs reassembled and wheels back on the car was lowered back onto the floor and pushed outside.

The last job being to fill the new Box with 2.7litres of Rock Oils finest 75w80.

The car fired right up, this time without gearbox whine. After taking the micra up the road and getting with ease into every gear it was deemed a successful swap.

To summarise for anyone wishing to swap a k11 box into a k10, Get a K10 5 speed. But if you do wish to persist, Make sure it is an early pre-facelift 1.0 k11, as the output shafts will fit. however a degree of fabrication skill is required as none of the gearbox mounts to the car will fit, It may help to get the mounts from the donor k11, however i cannot comment as it was never tried. The control rod will re welding 90degrees opposed to its original position. Should this all work it should go in easily... Some m10s are required in place of m8s along with a large washer.

Anyway here is the K10 back on the road with a k11 gearbox inside. next job, suspension.