|

|

|

|

|

|

Following the engine and supercharger setup with great interest. It’d be a good fit for the ez30 in the back of my Porsche replica; I’ve got less space constraints so hopefully it will be a little less tricky. Decided on an ECU setup yet? Best thread on this forum by miles!

|

| |

|

|

|

|

whitz

West Midlands

Posts: 216

|

|

|

|

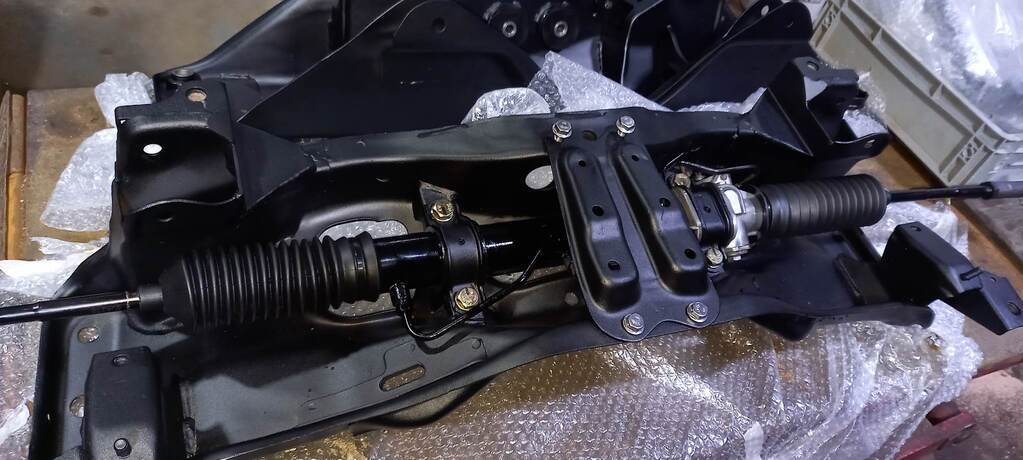

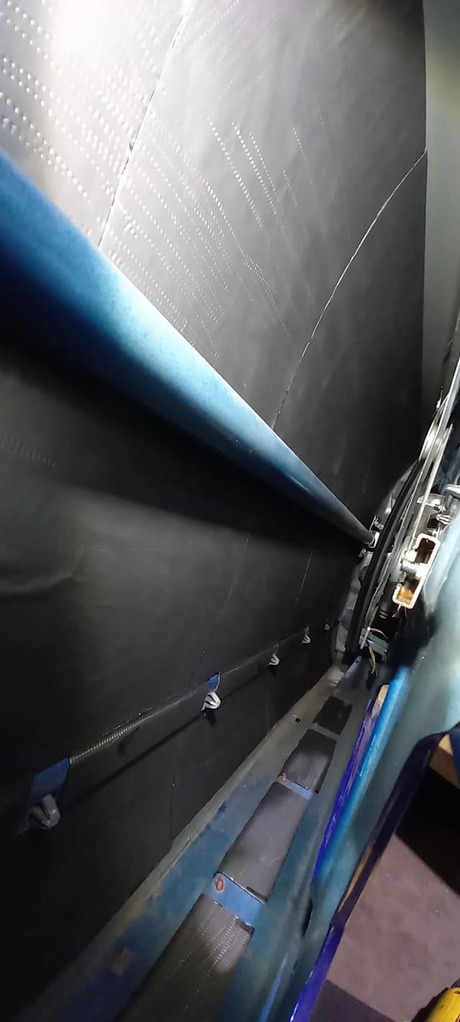

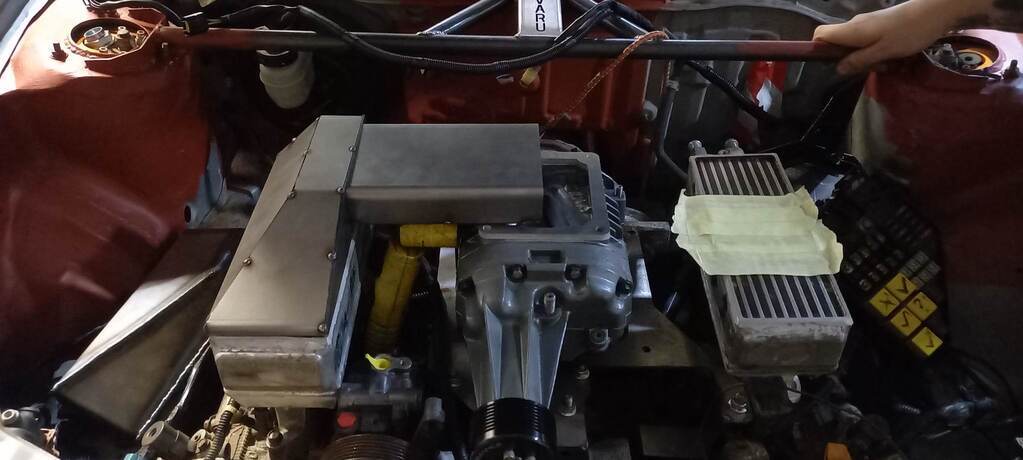

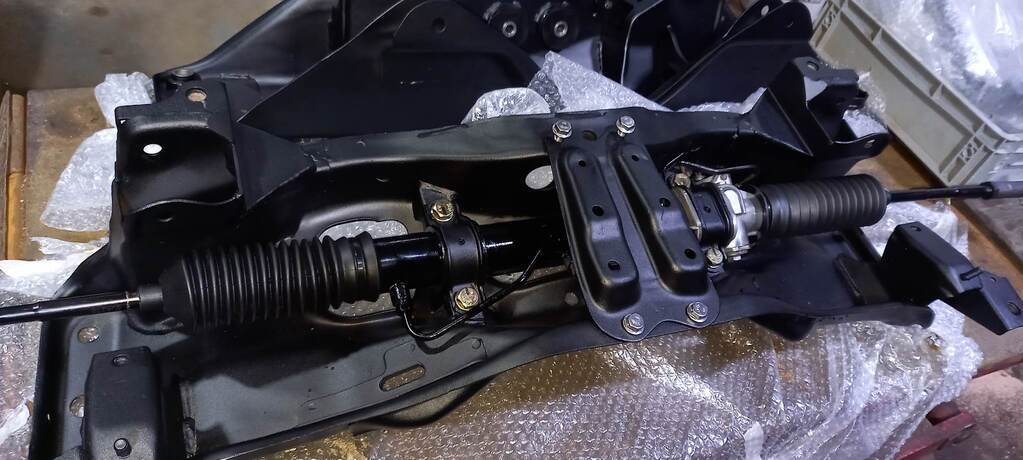

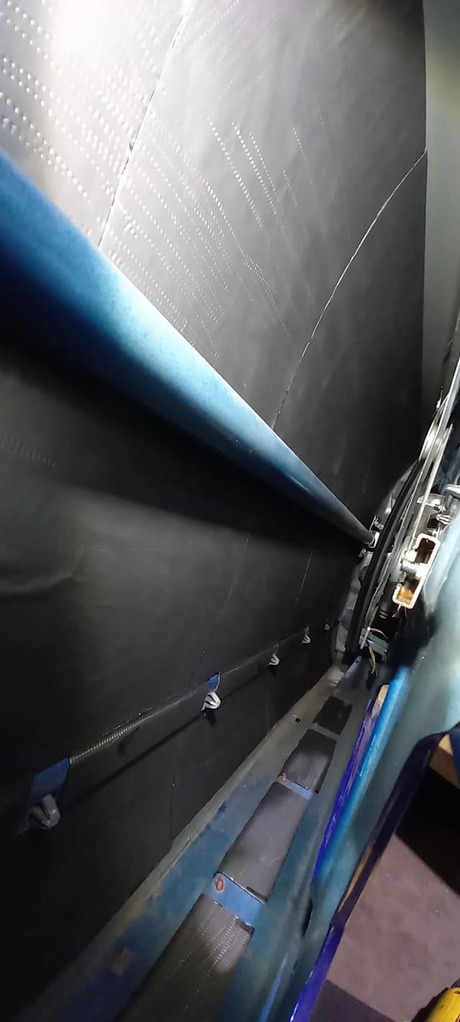

Following the engine and supercharger setup with great interest. It’d be a good fit for the ez30 in the back of my Porsche replica; I’ve got less space constraints so hopefully it will be a little less tricky. Decided on an ECU setup yet? Best thread on this forum by miles! Il be using an MS3 ecu as it has the required outputs to handle the active valve lift and vvc on the intake cams along with the normal requirements Made a few braces for the front subframe to body to make use of the extra braces 4 in total and can see where subframe was notced for manifold clearance, was all caped it and plated for retain all its strength    swapped out subframes and picked closest ratio steering rack i had and put the worst on so i could move the car about and work on the ones i intend to use on the car  whipped the gearbox out so i could finish welding the inside of the tunnel and weld on various captive nuts for the dash brace's, gear stick gaitor and centre console, can see the "wrong" subframe fitted at this point as a placeholder along with the damage to the back of the gearbox i also need to sort  underside was painted in red phosephate then seam sealed and anothe layer of red phosphate to fully seal it all   sprayed lots of this stuff into all the chassis, sills and any other cavity and bolt hole i cold find to help the body last as long as possible  smaller time consuming jobs also done like added in 4 more exhaust hangers, 2 near the front off the gearbox mount and 2 more at the rar off the diff T bar infront of the mid boxes  inside painted in a black vinyl primer after the seams where treated to alot of red phosephate (if you havent guessed i love the stuff)  as i want it to be a nice motorway car its getting fully sound proofed and any voids filled, managed to get about 1.5 sq meter of foam tucked away in the front seat lower mount bar  whole of seating area front to back getitng flash banded and double layered over tunnel and wheel arch areas  subframes came back from blasting and coating, annoying rear poly bushes for the diff the should fit seem to be to wide  closer ration rack being cleaned up  rack rebuilt with new trackrod + rack ends, gaitors and powerflex mount bushes + bolts etc, missplaced my yellow bzp so some stainless place holders in there for now   now to start on getting all this in place, was going to have an audio build too but adds too much time and issues  finally got the supercharger pulley remade to fit the supercharger now so i can make some progress again with that  Ash |

| |

|

|

|

|

|

|

|

|

Flashbanding the floor; are you using that for sound insulation or to seal the floor against corrosion?

Its all coming together now.

|

| |

|

|

|

|

|

|

|

|

I'll do some research on the MS3 and how it fits the EZ30R. I have a Speeduino but I'm a long way from being ready to fire it up. About the supercharger pulley... is it resized to change the drive ratio? Will you be matching all the other pulleys on the engine to the same width as the charger pulley? Great thread!

|

| |

|

|

|

|

|

|

|

|

I see that there are some 'Plug n Play' MS3's for the Subaru that have the AVCS already configured.

I have used MS1 - which i built - and MS2 Microsquirt on various engines. My only comment about using it is the variability of support if you need it, the forums are great but not always helpful. Once you learn Tuner Studio it's great, way better to learn than something like LifeCal.....

Have you thought about Emerald or ECU Master? Both seem good and intuitive.

|

| |

|

|

whitz

West Midlands

Posts: 216

|

|

|

|

Flashbanding the floor; are you using that for sound insulation or to seal the floor against corrosion? Its all coming together now. simply to add thickness and weight to the panel in the same way dynamatt does but at a much lower price I'll do some research on the MS3 and how it fits the EZ30R. I have a Speeduino but I'm a long way from being ready to fire it up. About the supercharger pulley... is it resized to change the drive ratio? Will you be matching all the other pulleys on the engine to the same width as the charger pulley? Great thread! supercharger pulley is the ZZP performance modular system so i can swap out the pulleys to various different sizes, oem belt is a 6 rib but current is a 8 rib but that isnt an issue, i had to have it machined as they only make it for a 3800 GM charger, where as i have a 3800 ford charger, both eaton M90 but not the same....thanks them I see that there are some 'Plug n Play' MS3's for the Subaru that have the AVCS already configured. I have used MS1 - which i built - and MS2 Microsquirt on various engines. My only comment about using it is the variability of support if you need it, the forums are great but not always helpful. Once you learn Tuner Studio it's great, way better to learn than something like LifeCal..... Have you thought about Emerald or ECU Master? Both seem good and intuitive. plug and play is generally to use the donor cars full loom which i wont be doing, havent really looked into those other ecus as ive had MS2 on the fiat for 7 years with no issues and I'm also not very far from dale at Bailey Performance who can do all aftermarket ecu installs and mapping but prefers megasquirt which is why ive chosen that route a few times Ash |

| |

|

|

|

|

|

|

|

|

This is so nuts. Love it.

|

| |

|

|

|

|

|

|

|

whole of seating area front to back getitng flash banded and double layered over tunnel and wheel arch areas  Ash Is the flashband basically a easy soundproofing?? Neverheard of it? |

| |

|

|

|

|

|

Feb 10, 2023 10:03:54 GMT

|

|

Impressive skill to be familiar with Megasquirt as you don't get the same handholding you would with a purchased ECU.

|

| |

|

|

whitz

West Midlands

Posts: 216

|

|

|

|

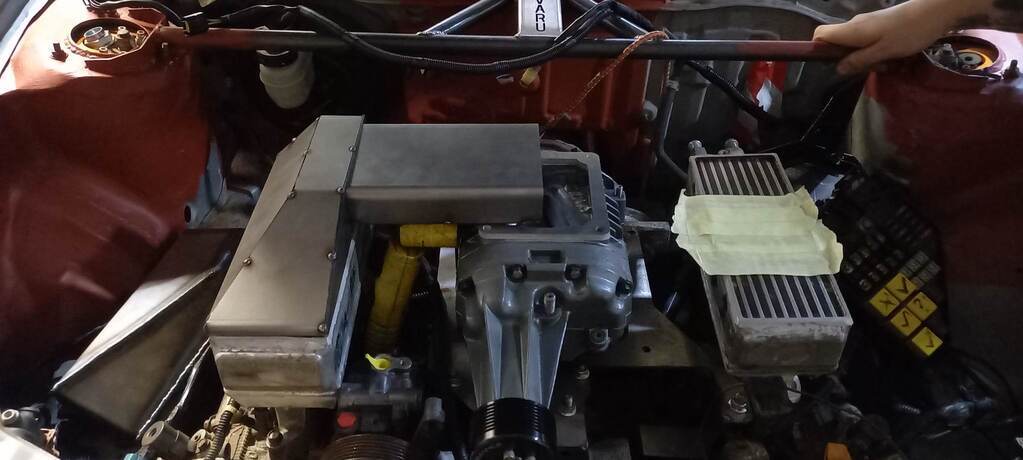

slow update as been held up alot and car isnt going to be ready for POL so also spending more tme on other things then trying to rush it sound proofing continued upto that point, still need to give 1 extra layer on rear turrets and abit more on the floor so its ready for foam  inside doors done fully ready for foam  starting to sort out where items will fit under the dash with heater and fuse box relocation etc  loom pulled through and some unneeded wiring removed, will extend all the engine side at this point removed abs, airbag, ecu plug and ac wiring fully from the loom over few days to slim it down  ended up with 3 variants of top hats made in 3mm steel to figure out clearance, shapes and volumes etc  finally got around to rebuilding the supercharger, new bearings, seals, oil, pulleys and isolators  landrover master cylinder bolts straight onto servo for a larger bore over the standard  one of the many items ive had hold me back while trying to save time, i have a mock up propshaft on the car so easier to get a spare to retube and keep them side by side propshaft 1 was lost via shipper, propshaft 2 same story different seller, propshaft 3 from seller 3 turned up looking nothing like its picture and fit for the bit only  ordered an6 line and they sent me 8mm overbraided stuff, so that thought it was close enough, same for solid fuel lines, ordered 3/8" and was sent 10mm as its "very similiar" but no good for me with compression an fittings so more time and money wasted   6mm ali side plates so it will have some material to be tapped and helicoil.....had to wait for these even longer too as they cut and sent them in 4mm first  have to remount alternator and make sure supercharger lines up again after the issues of the 3600 supercharger pulley kit not fitting a 3600 supercharger and moving its position  Ash |

| |

|

|

|

|

|

|

|

|

|

|

Its all looking great, looking forward to seeing it firing up! Couple of questions: any recommendations for supercharger service parts suppliers, and secondly, what throttle body are you using? Cable drive rather than drive-by-wire? Thanks!

|

| |

|

|

75swb

Beta Tester

Posts: 1,052

Club RR Member Number: 181

|

|

|

|

|

Good to see this back at the top. Can't believe so many parts sent wrong!

|

| |

|

|

|

|

|

|

|

|

Great work. What master cylinder and servo did you use? I’ve got big brakes on mine and pedal feel is pants. And that’s with a rover brm master cylinder which is bigger but only a little bit

|

| |

|

|

whitz

West Midlands

Posts: 216

|

|

Mar 10, 2023 16:41:10 GMT

|

basically yes, its a slightly thinner of what dynamatt is, bitumen base with aluminium backing and a whole lot cheaper, I haven't smelt it in the last 3 cars where as some people say you can Its all looking great, looking forward to seeing it firing up! Couple of questions: any recommendations for supercharger service parts suppliers, and secondly, what throttle body are you using? Cable drive rather than drive-by-wire? Thanks! I bought my snout rebuild kit off "Boosttech Superchargers" on ebay and pulley was a ZZperformance setup it was an utter hassle to have to modify it but now I can just order a different sized pulley and bolt them on easily, I'm using a ford 75mm throttle body off a 4.6 2v modular as I happened to have one lying around for my old v8 mg zt260 and its area was perfect size wise for the charger intake port Great work. What master cylinder and servo did you use? I’ve got big brakes on mine and pedal feel is pants. And that’s with a rover brm master cylinder which is bigger but only a little bit stock zr servo but master cylinder is a "Land Rover Defender ('91 On) Brake Master Cylinder (Non ABS) - LR013018" off ebay for £56 new just have to swap out brake line ends and blank a 3rd Ash |

| |

Last Edit: Mar 11, 2023 20:06:47 GMT by Rich

|

|