|

|

|

Jan 30, 2023 18:29:55 GMT

|

did they end up close to 39 1/4 across the car? No Danknight. From memory they are about 37”. I would have to trim the bottom of the slope back to get them to 39.25 centres. It will obviously move the damper further out towards the wheel with its obvious issue. Gary Martin said on one post “if your going to use Gartrac measurements, then use Gartrac parts”. These aren’t Gartrac turrets. I think originally Gartrac used turrets out of a Capri, so you got the spacing that you got. On an arched car you can get away with the 39.25” because the axle is so much wider. Some people lean the turrets even further in to get more space for shocks. I’m happy with the 37” it gives me more space to play with and don’t think it’ll make any difference to handling. In fact I don’t think the turret being to far forward will make a difference but I’ll sort it anyway. Did yours end up at 39.25”? If so did you have to trim the slope and have you got enough space for coil overs? It’s nice to get another view point |

| |

|

|

|

|

|

|

|

Jan 30, 2023 19:27:50 GMT

|

My shock/wheel clearance  My neighbours’ shock/wheel clearance (bubble arches car)  I need every bit of clearance I can get |

| |

|

|

|

|

|

Jan 30, 2023 21:37:13 GMT

|

cant remember tbh i will get my mate who owns it now to have a measure up its running on single leafs / tramp bars / panhard rod and normal group 1 bilstein shocks  |

| |

|

|

|

|

|

|

|

cant remember tbh i will get my mate who owns it now to have a measure up its running on single leafs / tramp bars / panhard rod and normal group 1 bilstein shocks  👍 cheers Danknight |

| |

|

|

|

|

|

|

|

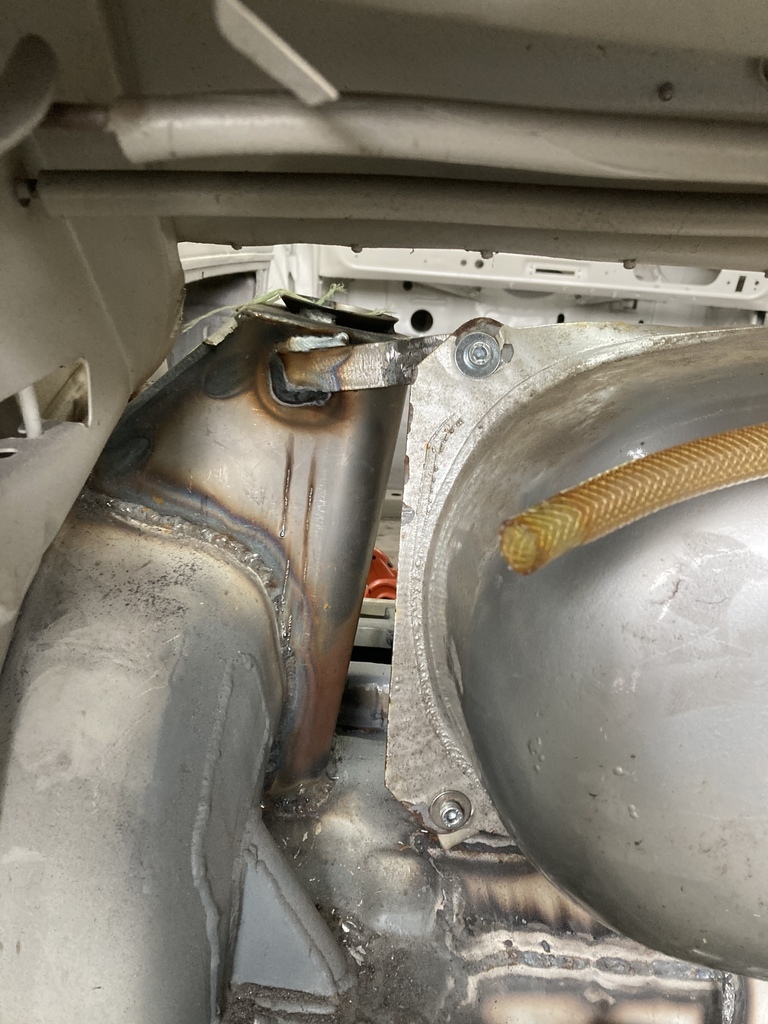

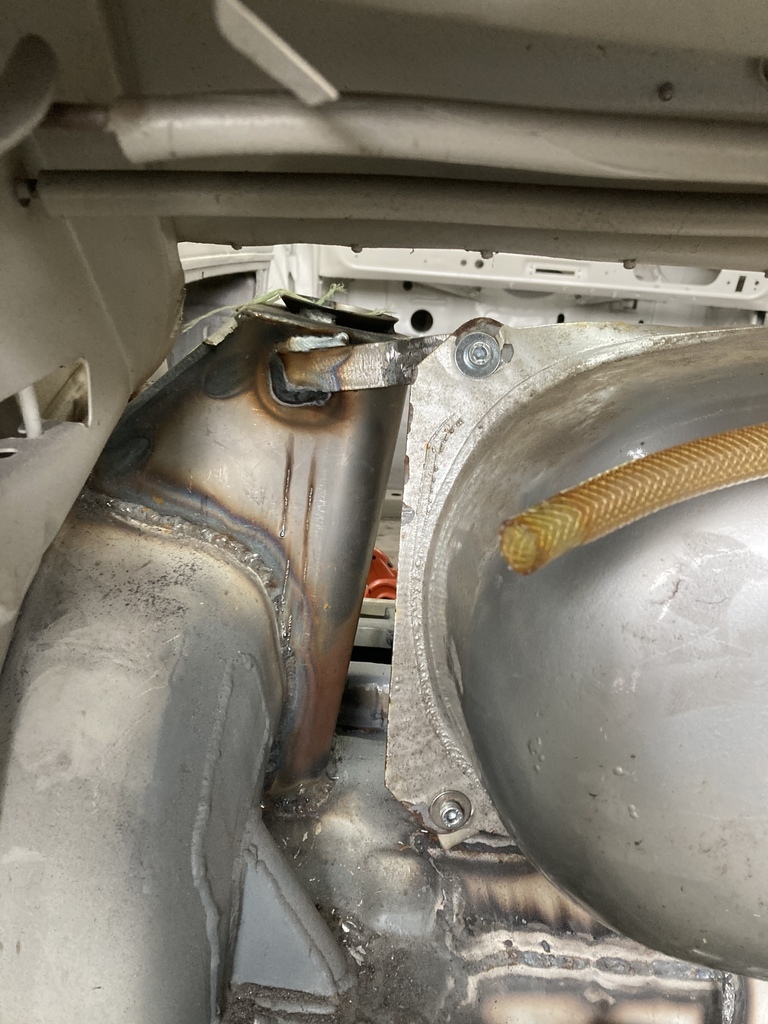

I had a day off today as I’m working the weekend. After being dragged around the shops by Mrs Jonsey, and then blagging some cutting discs off my brother, I cut the tacks off the turret and removed it.  Next I made good the chassis rail and floor  This has always been the plan but all the pondering and swearing last time had meant this didn’t happen Then I dressed it back  A little bit more cutting and swearing and I had this  The shock is now central in the turret and in line with the axle So before I pondered some more, I welded the turret in   I trimmed the turret back as there was a good bit protruding into the wheel tub and welded the bottom of the turret to the chassis rail so it now looks like this  I’ll finish dressing the welds when it’s back on the rotisserie. I now need to make good the gaping hole in the tub and get the other turret in position. |

| |

|

|

|

|

|

|

|

I’m on call today so managed to get a couple of hours in before work. So passenger side turret. I trimmed the tub back to where I wanted it.  Next I made good the floor to chassis rail joint  And then ground it all back  I could now tack the turret in position. I had to do this a few time as the turrets are not the right shape to fit the car. The inside of the car where the top is welded is not parallel to the chassis rail. So when you clamp the bottom in place it moves the position of the shock hole on the top. So I tacked the top on position the clamped the bottom in with a sash clamp. I suppose it puts a twist in the turret but who cares. So after checking the height was the same as the driver side and the distance from the door opening was the same, I then welded it in before I lost my mind   And from inside the car  Next I need to make good the wheel tub where the old turret was fitted. As a disclaimer I’ll just add, if you came to this thread looking for info on how to fit turrets and short link boxes to a mk1 Escort, DO NOT USE THIS THREAD AS A REFERENCE OR HOW-TO GUIDE. |

| |

|

|

|

|

|

|

|

|

I’ve put a question in the technical section if any anyone can help me please 🙏

|

| |

|

|

|

|

|

|

|

So, where were we? Holes in tubs. I was on call yesterday and got a few hours in before. Came in for food and sat down with the Mrs to watch a documentary about Pamela Anderson (as you do), and just as they showed Pammy run down the beach in Baywatch cossy, I got called out😩. So no time to update yesterday as I didn’t get home until midnight. So here it is today. Driver side first. Lip of chassis rail needs repairing where the old turret sat.  So that got done first  Next a section of floor needed to go in on top of that   Ground some old welds of the strengthening brace  Next it was the wheel tub. The easiest way to repair would be to cut a section from an old tub and graft in. I asked on lots of FB groups but nobody replied. I’d asked a question in the tech section here. I got some good replies (thanks for those everyone) but decided to just give it a go and see what happened. So I cut a strip of metal a bit longer than needed. The side is flat except for a shallow curved ridge that a just bent with a hammer over a steel bin. The top is curved slightly which I just bent over the handle of the MIG trolley with my bare hands 💪. The compound curve between the two was the problem. If I just bent it, it would only have the curve in one direction. Which would look odd. So for 2” or so where the curve should be, I put the metal in the shrinker. This put a slight curve in the panel one way before I bent it by hand the other way, giving a compound curve. I shrunk it more than I think I needed because after a couple of tries the curve wasn’t enough.  At this point I had been working on the car on the lift. The axle was on putting more weight to the back. To counteract this I had put a ratchet strap over the bonnet to hold it down. I’d noticed the front was “floating” a bit off the pads. But what could go wrong?  When I stepped in the car the strap obviously loosened and moved from where it was hooked and as I moved in the car it slowly did a wheelie. All sorted now though. So I next tacked one side of the strip in. It still looked a little flat so I tapped the rear up with a curved wood dolly a made up and then tacked in   not sure how got it is yet. Perhaps I’ll get some more done on the weekend but Jones Junior (The elder) has his driving test on Wednesday so I’ll probably be in the car with him for most of it. |

| |

|

|

|

|

|

Feb 11, 2023 17:43:08 GMT

|

So after driving lessons, I got a few hours in. Wheel tub repair welded in  And ground off   It’s not ideal but it will have to do. And from underneath   I didn’t clean up anymore of this as I can do it when it’s back on the rotisserie and not get covered in grinding dust. Next I had to fill this gap  I bent and cut a bit of 3mm to shape  Welded it in  And grounded it back off  So then using this template with a bit taped on to fill the gap  I made a strengthener, welded it in  And primed it  So next it was onto the other side  I got the lip welded on the chassis rail  And ran out of time as I had to pick up Jones Junior (the younger) from the park. Hopefully I’ll get a bit more done tomorrow |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,126

|

|

Feb 11, 2023 23:57:51 GMT

|

|

That is excellent stuff, dude.

|

| |

|

|

|

|

|

|

|

That is excellent stuff, dude. Cheers Teaboy. Much appreciate. |

| |

|

|

|

|

|

Feb 12, 2023 16:59:05 GMT

|

Only got an hour or so done today. First reinstate the missing piece of floor   Then ground back  When I fitted the old turrets I had bashed the wheel tub up to meet them so the metal had stretched. I cut a couple of slots in it so I could bash the high sections back down  I then cut a bit of steel and started making the tub repair by using the shrinker to put a curve in the steel  And started tacking it in  It was then starting to get cold so abandoned it. |

| |

|

|

|

|

|

Feb 14, 2023 19:33:58 GMT

|

Another day on call so another few hours in the garage before work. First I fully welded in the repair for the tub.  Next up I made a section to repair the strengthener  It goes here  Welded it in  And ground it and the tub off (no photos but you can see them in a bit in the next photo) Made another tub to link box strengthener using the template from the other side. It fitted good so I must of done something right. And welded it in   Gave it a bit of primer  And here’s both sides done.  Next I need to make some skids to protect these bits that hang down underneath. Then I can cut out the redundant bit of tube where the bottom links sit.  |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,126

|

|

Feb 14, 2023 19:43:33 GMT

|

|

Good progress and nice work, dude.

|

| |

|

|

|

|

|

Feb 14, 2023 20:21:05 GMT

|

did they end up close to 39 1/4 across the car? No Danknight. From memory they are about 37”. I would have to trim the bottom of the slope back to get them to 39.25 centres. It will obviously move the damper further out towards the wheel with its obvious issue. Gary Martin said on one post “if your going to use Gartrac measurements, then use Gartrac parts”. These aren’t Gartrac turrets. I think originally Gartrac used turrets out of a Capri, so you got the spacing that you got. On an arched car you can get away with the 39.25” because the axle is so much wider. Some people lean the turrets even further in to get more space for shocks. I’m happy with the 37” it gives me more space to play with and don’t think it’ll make any difference to handling. In fact I don’t think the turret being to far forward will make a difference but I’ll sort it anyway. Did yours end up at 39.25”? If so did you have to trim the slope and have you got enough space for coil overs? It’s nice to get another view point my mate has measured up on the escort i built and its 38 3/4 across the turrets i bet all of the escorts out there are slightly different due to variations on the turret manufacturer etc , i think the turrets i used were rix engineering |

| |

|

|

|

|

|

Feb 14, 2023 20:37:47 GMT

|

Good progress and nice work, dude. Thanks Teaboy. I enjoyed today. |

| |

|

|

|

|

|

Feb 14, 2023 20:40:29 GMT

|

No Danknight. From memory they are about 37”. I would have to trim the bottom of the slope back to get them to 39.25 centres. It will obviously move the damper further out towards the wheel with its obvious issue. Gary Martin said on one post “if your going to use Gartrac measurements, then use Gartrac parts”. These aren’t Gartrac turrets. I think originally Gartrac used turrets out of a Capri, so you got the spacing that you got. On an arched car you can get away with the 39.25” because the axle is so much wider. Some people lean the turrets even further in to get more space for shocks. I’m happy with the 37” it gives me more space to play with and don’t think it’ll make any difference to handling. In fact I don’t think the turret being to far forward will make a difference but I’ll sort it anyway. Did yours end up at 39.25”? If so did you have to trim the slope and have you got enough space for coil overs? It’s nice to get another view point my mate has measured up on the escort i built and its 38 3/4 across the turrets i bet all of the escorts out there are slightly different due to variations on the turret manufacturer etc , i think the turrets i used were rix engineering Thanks for the info Danknight. I think it all depends how much of the slope the manufacturer puts on there and how much people decide to trim off. I want the extra space so I’ve left them untrimmed. |

| |

|

|

|

|

|

Feb 15, 2023 18:08:45 GMT

|

I’ve had a nightmare today. I’d booked the day off work as Jones Junior (the elder) had his driving test. I realised yesterday that I would have to leave the house at 7am this morning, but I was on call until 8am. A quick grovel to the boss and that was sorted. We jumped in the car to go, he puts the wipers on and they stop half way up the screen. WTF! Quick squirt with wd40 and a wiggle and they’re going again. Bl00dy Clios. So we go for a drive around before the test and the boot has now decided to unlatch itself with being asked, twice it did this. Anyway he has the test, 3 minors, but fails as he did 55 on the dual carrige way but it was a 50 zone. I was gutted for him. And the girl who had her test the same time passed even though her mother had to park the car for her before the test!! So quick macies breakfast and home. So out the garage I go to hit things and console myself. First fitted the petrol tank.  I now need to make new top mounts as they exited the car on the old turrets    The tank needed refitting as I need to remake the firewall leaving cutouts so I can access the top of the shocks So I started making bits  I welded this on top of the turret- fully welded, then cut it to short. I also realised it wasn’t the shape I wanted. Getting stressed I got the grinder out and cut it back off  I’d wanted a nice round piece around the turret and for some reason i’d followed the shape and put a right angle in. So I made a new bit, and taller  And then welded a top on after cutting the new bit to the correct height   That’s better, and what I was after. I’m off work again tomorrow as I’m working Saturday so might get this side finished and start on the other ( which is going to be a bit harder. |

| |

|

|

|

|

|

Feb 15, 2023 19:42:03 GMT

|

|

nice work mate

|

| |

|

|

|

|

|

Feb 15, 2023 19:51:53 GMT

|

|

|

| |

|

|