|

|

|

May 23, 2021 19:15:00 GMT

|

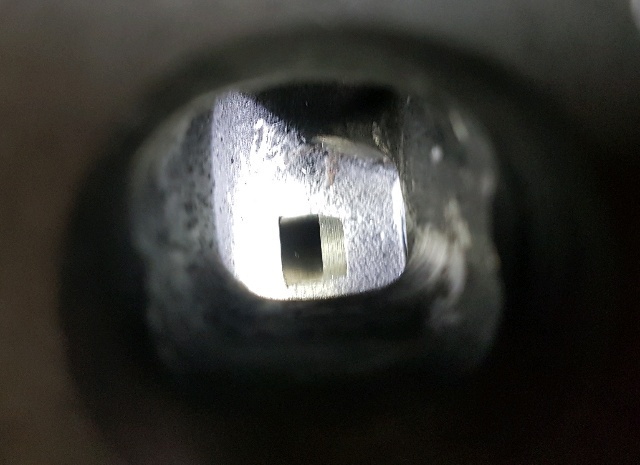

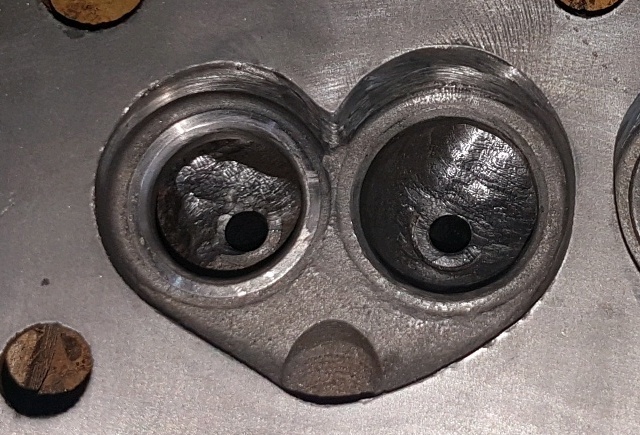

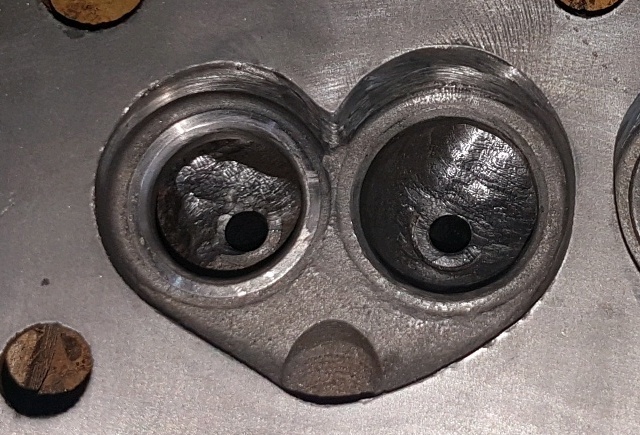

Went to the museum of power autojumble this morning, not much there though, did notice that aftèr the long run the tailpipe on the range rover was a nice grey colour, which indicates that I've got the mixture about right. (Someone has previously been fiddling with the air meter so I've been progressively weakening it until I could feel an effect then backed off a couple of teeth) When we got back I had go at the minor head, needed to change the inlet valve guides, you are supposed to use a stepped punch to get them back in, one old valve stem and an old guide later I had one.  They all went in easily enough but protruded a fair way into the port.  Using the die grinder I cut this off, removed some materal from the port around it and the small radius to give this.  Given we are keeping standard valve sizes there was no point going mad so really it is just about cleaning up the obvious restrictions and following the guidance in vizards book. |

| |

Last Edit: May 23, 2021 19:17:43 GMT by kevins

|

|

|

|

|

|

|

May 27, 2021 21:51:32 GMT

|

Bit more on the minor yesterday, combustion chambers all done at 24cc which gives 9:1 static compression ratio, I think this will work well with the fairly mild cam.  Ports also opened up around the worst restrictions.  By no means a pro job but should be a vast improvement on the original. Just need to lap the valves and the head will be done. Won't get much done this weekend though, I have a conservatory to re-build. |

| |

Last Edit: May 27, 2021 21:54:01 GMT by kevins

|

|

|

|

|

|

|

For the last couple of weeks I have been rebuiding our conservatory, basically everything except one wall and the foundations, it's now got wallls, doors, windows and a roof so I can take a breather. The Range rover has been doing sterling service as a builders truck, 500kg of materials today, after the long run with half a bottle of redex in the tank it's idling much better when cold, so I think my dìagnosis of the injectors needing a clean looks right. I have aldo bought the parts to change the front wheel bearings (one rumbles a bit) and the brakes (discs are rusting around the edges, ferrules on hoses are rusty and a couple of pistons stick). It's far to usefull to take appart at the moment though. Before I start on another car I need to finish the minor, so I have started on the bottom end, crank went in fine, one con rod was tight on the gudgen pin but a light going over the bush with wet and dry sorted that, all the pistons went in easliy. It's pretty much standard so far but I have decided to ditch all the tab washers and use loctite on the mains and big ends.    Next up will be the front plate and checking the cam endfloat, hope to get most of it done by the weekend. |

| |

Last Edit: Jun 9, 2021 19:38:55 GMT by kevins

|

|

|

|

|

Jun 15, 2021 17:32:48 GMT

|

Minor engine is pretty much done now  twin carbs are just a trial, initially it will go back in with the original one, we'll fit these when we have an exhaust manifold and have re-conned them. checked the cam timing which came out pretty much spot on using the standard keyways, certainly seems to have more compression than before!. Still need to paint it when the paint arrives and there's a few bits to put on which the stand prevents but otherwise it's pretty much ready to go in. We have also managed to rent a lock up only 1/3 of a mile away eventually this will be the home for the Minor but for now we have moved the Lotus there, to give us room to work on the minor. So I put the side light back in checked the tyres, connected the battery and it started right up, Throttle cable is sticking even worse than before now, one for it is £40 it looks just like a bike gear change cable with a nipple on one end and screw on clamp on the other so I ordered a top quality teflon lined one of them for £6, Hopefully it will work.... Only other problem was a mouse nest in the boot, they have destroyed the carpet but everything else looks fine. |

| |

Last Edit: Jun 18, 2021 13:58:28 GMT by kevins

|

|

|

|

|

Jun 18, 2021 13:57:58 GMT

|

Minor engine is pretty much ready to go in now, We had hoped to get it in this weekend so I set to prepping the gearbox, the corsa slave cylinder I had fitted had over travelled and although it was working fine when we took it the gearbox off it fell to pieces, so I needed to fit a new 5/8 master cyl to the crossmember (was 3/4) and a new slave, master went easily enough, then when I went to fit the new slave I found this.  wrong one, I should have taken a better note of the exact model of corsa It came off off, hopefully ordered the right one now, it has the same flat back. I'll probably use the wrong one on the 5 speed conversion as I haven't started the adaptor plate yet anyway. Talking of that I Di try the crossmember 10.5 inches further back where it would need to be for the mazda box.  Good news is it on the shallower but flat part of the chassis leg, so a couple of 3/4 alloy spacers and a nut plate to drop inside the chassis leg should do the trick. as we can't do anything else this weekend we will spend some more time beatifying it, to this purpose we have bought a tin of BMC green paint. |

| |

Last Edit: Jun 18, 2021 13:59:42 GMT by kevins

|

|

|

|

|

Jun 19, 2021 19:00:45 GMT

|

Painted the minor engine.  Then needed to tighten the crank pulley, to get it off I used a hammer spanner, but the damped pulley doesen't have access to this. I found 3/4 whitworth socket which fitted but was too shallow to fit over the starter dog.  So chopped it in half and welded a piece of tube in.  Knocked up a flywheel lock and torqued it to 70lbft.  Then looked at hhe street ka, we tried to refil the A/C last week and it leaked out, the hissing was coming from a pipe where it was clipped to the chassis leg. Today I took the wheel off and had a look, difficult to photograph but it's corroded where the clip was and gone porus.   A new pipe is over £300, as the rest of the pipe looks fine I might try going over it with some durafix alloy weld, fortunately I can undo one bolt and pull the pipe into the wheelarch with plenty of access. |

| |

Last Edit: Jun 20, 2021 6:38:56 GMT by kevins

|

|

|

|

|

Jul 10, 2021 22:50:08 GMT

|

For the past 6 weeks I have been building this so no real car work.  But now it's more or less finished a little time on cars, first job is to put the minor back together. Engine and original box built up.  The started fittimg it.  Its all mounted, a couple of hours should see it done by the end of the week. Also tried the mazda box conversion which fits well now, with a minimum of 15mm around the rack just need to sort out the clutch actuation and propshaft.   |

| |

|

|

|

|

|

Jul 11, 2021 18:56:16 GMT

|

|

Fitted the ditributor, wiring alternator oil pressure line etc today, then span it over to set the timing with a strobe, all went well but we do seem to have 100psi of oil pressure, reading around it seems severel people have had the same problem with the aftermarket version of the cooper ball and spring relief valve, might put the original spring and plunger back in for now, fortunatelly I have a spanner I made to get it out without removing the starter.

Other problem I noticed is the alternator belt is about 6mm out of true, looks like turning the pulley round will fix it though

|

| |

|

|

|

|

|

Jul 13, 2021 21:00:08 GMT

|

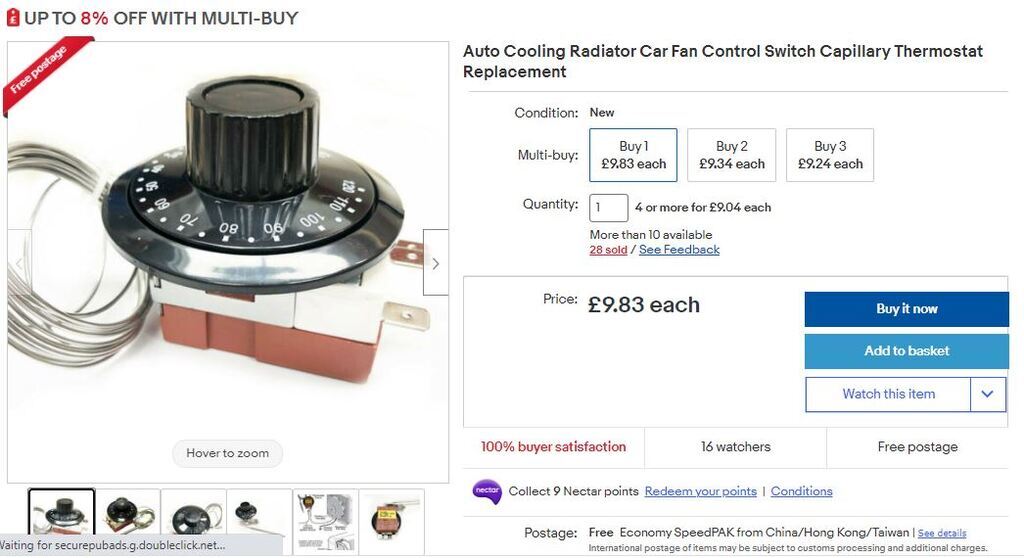

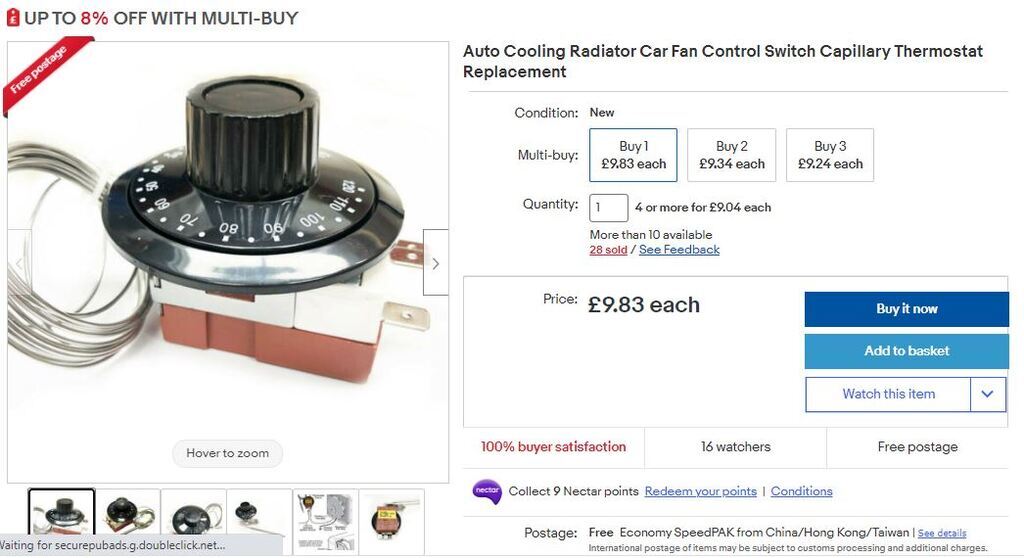

Fitted the old pressure relief valve and spring, now have 60psi when cranking. most of rest of it is done, just need to sort out the alternator pulley, an electric cooling fan, gearbox oil and carpet on the trans tunnel (old one is falling to pieces).  But that means I could try starting it, turned the key and vroom it started instantly.. on 2 cylinders. Put plug leads 2 and 4 in the right place and now it runs perfectly, only ran it for a few seconds as no coolant in there yet but long enough to check the clutch works etc. I'll get the alternator pulley machined tomorrow evening so that just leaves the electric fan to sort out. I had a 9" one but it was just a bit too big so I have ordered a 8" one which will fit behind the radiator on the carb side. Only other issue and the reason there is no coolant s the fan switch, there's no room to put one in the top hose (the free length is only about 3") but there is a m16 x 1.5 boss in the bottom tank of the alloy rad which is not used and you can get a selection of m16 x 1.5 motorcycle fan switches, I've ordered an 85 degree Honda one in the UK but you can get them form Hong Kong in 80, 70 and 65 if need be. I've always thought the best place for a fan switch is as close to the head as possible as this is the temperature which is critical, on the other hand VW make it work in the cold end of the radiator so hopefully it will be OK, anyone any idea what temperature switch they use? |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

|

Some good progress there! The instant start up is a good result and who hasn't had a plug lead out of place at one time or another, lol.

I'm no help on your question however...

|

| |

|

|

|

|

|

|

|

|

|

| |

Last Edit: Jul 14, 2021 7:28:44 GMT by petervdv

|

|

|

|

|

|

|

That's got me thinking, you can get these now  I was going to put an override switch inside the car but I could just fit this under the dash. |

| |

|

|

|

|

|

|

|

|

I fitted mine in the engine bay as there is with my MG no need for frequent adjustments. Once in a while with temperatures around 35 deg F, the fans need to come in a bit earlier

|

| |

|

|

|

|

|

Jul 19, 2021 16:33:52 GMT

|

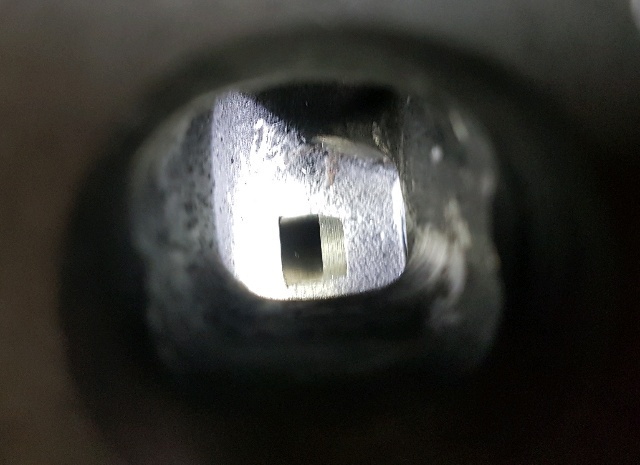

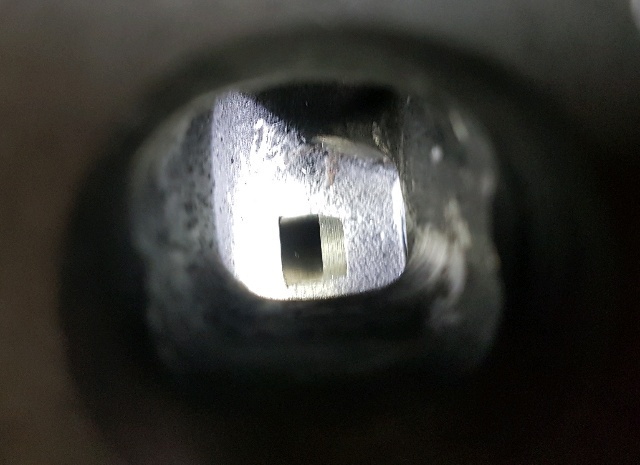

Some progress then a very big step backwards. Used the alloy "welding " kit on the ka ac pipe.  It's basically a solder which sticks to alloy, spread it all over the affected areas and the result is not pretty but after dropping some propane in as a trial it seems gas tight, after 2 days it's still working fine, so I'll order some drop in gas an evacuate it properly. On the minor made a frame for the fan and fitted that, still waitimg for the thermo switch but at least we can use it manually.  We then took it for a test drive and it was going great , until it stopped....  For some reason it spat the distributor and it's drive shaft out, a frgment of something then got caught between no4 big end and the block punching the hole. Aside from the hole with an endescope it doesen't look too bad, some other minor scrape marks but it still turns freely has oil pressure, compression and no water loss. Plan is to take the sump off for a closer look, if it looks recoverable plug the hole and fit a megajolt system, if not get the spare block machined up as a replacement. |

| |

|

|

|

|

|

Jul 19, 2021 18:41:37 GMT

|

|

Dear me. What a shame it was going really well. I wonder what made the dizzy come out. Fingers crossed it's not a hard fix

|

| |

|

|

pptom

Part of things

Posts: 475

|

|

Jul 19, 2021 19:01:01 GMT

|

|

Rubbish. Was looking good too.

Would be interesting to know what failed

|

| |

|

|

|

|

|

Jul 20, 2021 16:45:39 GMT

|

|

As I half suspected it's far worse, while half out of the distributor hole it looks like the drive gear was hit by the crank counterbalance weights, that has taken chunks out of the bottom of the bores and 2 back pistons plus there is an enormous dent in the sump.

Only good news is the cam looks perfect still.

We have a spare 1098 engine which has never been re-conditioned, but the last one took 6 weeks to get the machining done plus we wouldn't really trust the crank, bearings or rods in the broken one after such a trauma.

ESM have in stock a re-conditioned short engine for £515 (block pistons crank and rods) so plan is Andrew will take the good short engine down there and exchange it on Thursday then we will swap all the other parts over and hopefully have it up and running in a week or 2.

|

| |

|

|

|

|

|

Jul 20, 2021 20:10:18 GMT

|

|

I also think I have found the root cause, it seems to be the distributor having jammed up, there is a chink missing out of one of the drive key and it has ejected the vacuum module out of the side. My theory is the vacuum generated by going down a steep hill and having a engine which was actually capable of generating a decent manifold vacuum pulled it further than ever before and something jammed up. it went well for about 3 miles!

|

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

|

Sorry to read of your misfortune such a short time after all that work done. Good to see you don't waste time and are already on the way to recovery.

|

| |

|

|

|

|

|

Jul 21, 2021 12:05:35 GMT

|

|

At the end of the day no one's hurt and it's only money, to put it into context my daughters other half has a 25.000 mile 3 1/2 year old 1 series BMW, engine warning light comes on takes it to a specialist, bill is £1450 for 3 new injectors plus fitting, hardware, diagnostics etc etc. New bottom half of minor engine has just cost me £800 and will probably take 1 day or so to build up and install.

It Could be worse could have been the Lotus (well not this failure because the distributor installation on the Ford engines which it based on is a much simpler failsafe design) at least minor parts are relatively cheap.

|

| |

|

|