While the main build thread for the project is at grassrootsmotorsports.com/forum/build-projects-and-project-cars/volvo-p1800eskinda/72311/page1/ I thought that some on this board might be interested.

The car was purchased as a bare rust free shell along with a complete but rusty donor car. The original plan was to simply graft the front and rear Miata suspension subframes on to the Volvo frame and drop in a for 302 V8 with an AOD gearbox.

Well, things took a turn along the way.

The original plan was simply to graft MX5 suspension on to the Volvo with an adapter that slipped over the Volvo frame-rails and picked up the MX5 a-arms. Course that left the top of the shocks with no place to park, and required more design work.

Foam engine blocks are a great tool to have when building hot rods. Looks llike everything is going to fit and the front suspension is in place.

![]()

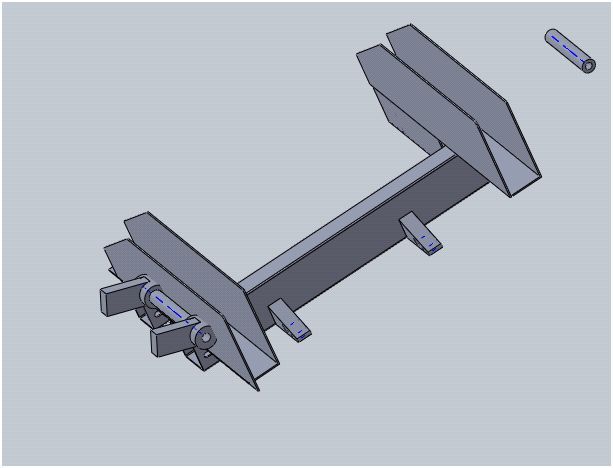

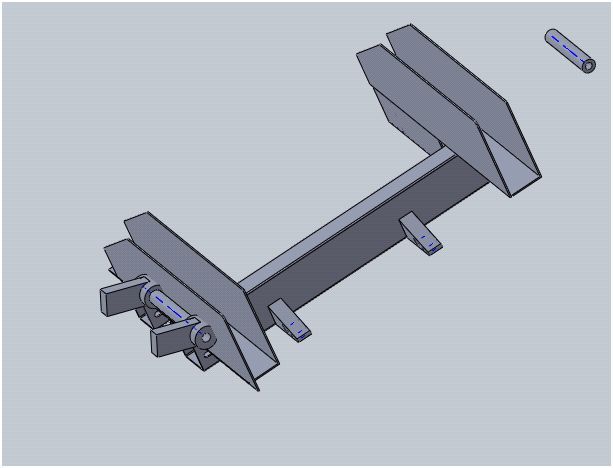

This is what the MX5 suspension adapter looked like. Note that the upper a-arm wants to occupy the same space as the Volvo frame and the long bolt needs about a foot ahead to slide out. I am starting to wonder about how wise I really am?

So, I did a quick requirements list:

1-need suspension attachment points

2-Need a transmission tunnel that will accommodate the AOD

3-Need easy button for V8 conversion

4-Need steering, pedals,HVAC and electrical controls

5-Needed a place to mount seats

When I stoped to think about it, Mazda has already done all that work for me, and the MX5 V8 converters have done a lot of the rest of it. So, not being one to re-invent a wheel, enter the Miata donor. This was actually donor #2, #1 was rusty but proved the concept.

Made a huge hole in the Volvo. You can see remains of MX5 #1 in the back half.

Built a gantry and gently lowered the Volvo over the MX5

Pretty much where she is going to end up.

View to the back. Yes, the rear seats are gone. But not like you would put a human back there anyways.

View from the front. Going to take some stitching to mate the two firewalls. MX5 seats will come up a couple of inches and so will the steering wheel. Going to have a modified Volvo dash over the MX5 hardware.

Of course, since the two cars have different wheelbases, something needed to be done. Picked the spotwelds apart that held the front clip to the firewall and extended the legs. Welded it back together.

Check to make sure the engine still fits where it needs to. Note the tubular front subframe designed for converting a MX5 to 302 power. It was designed such that the oil pan straddles the steering rack. We kind of went off the reservation when we extended the wheelbase 7.3". But its all good.

Had to make up some panels to join up the wheelwells to the firewall since the wheelbase stretch left a big gap. Nothing fancy.

Brings us pretty much up to date. I have the task of doing a good job of building this a-post structure to integrate the MX5 and Volvo a-pillar structure. The Volvo has plenty of strength in the a-pillar. The MX5 has significant structure in the lower part that is inside the A-pillar and this can simply be welded together. The work to be done is in transferring the upper strength of the Volvo a-pillar to the MX5 upper structure.

While this is just thinking out loud and trying stuff, the tape shows the load paths that I want to capture in any design I implement.

That brings us up to date. As I said, I will be doing most of the updates on the GRM board, but if there is any interest I can do the occasional post here.

The car was purchased as a bare rust free shell along with a complete but rusty donor car. The original plan was to simply graft the front and rear Miata suspension subframes on to the Volvo frame and drop in a for 302 V8 with an AOD gearbox.

Well, things took a turn along the way.

The original plan was simply to graft MX5 suspension on to the Volvo with an adapter that slipped over the Volvo frame-rails and picked up the MX5 a-arms. Course that left the top of the shocks with no place to park, and required more design work.

Foam engine blocks are a great tool to have when building hot rods. Looks llike everything is going to fit and the front suspension is in place.

This is what the MX5 suspension adapter looked like. Note that the upper a-arm wants to occupy the same space as the Volvo frame and the long bolt needs about a foot ahead to slide out. I am starting to wonder about how wise I really am?

So, I did a quick requirements list:

1-need suspension attachment points

2-Need a transmission tunnel that will accommodate the AOD

3-Need easy button for V8 conversion

4-Need steering, pedals,HVAC and electrical controls

5-Needed a place to mount seats

When I stoped to think about it, Mazda has already done all that work for me, and the MX5 V8 converters have done a lot of the rest of it. So, not being one to re-invent a wheel, enter the Miata donor. This was actually donor #2, #1 was rusty but proved the concept.

Made a huge hole in the Volvo. You can see remains of MX5 #1 in the back half.

Built a gantry and gently lowered the Volvo over the MX5

Pretty much where she is going to end up.

View to the back. Yes, the rear seats are gone. But not like you would put a human back there anyways.

View from the front. Going to take some stitching to mate the two firewalls. MX5 seats will come up a couple of inches and so will the steering wheel. Going to have a modified Volvo dash over the MX5 hardware.

Of course, since the two cars have different wheelbases, something needed to be done. Picked the spotwelds apart that held the front clip to the firewall and extended the legs. Welded it back together.

Check to make sure the engine still fits where it needs to. Note the tubular front subframe designed for converting a MX5 to 302 power. It was designed such that the oil pan straddles the steering rack. We kind of went off the reservation when we extended the wheelbase 7.3". But its all good.

Had to make up some panels to join up the wheelwells to the firewall since the wheelbase stretch left a big gap. Nothing fancy.

Brings us pretty much up to date. I have the task of doing a good job of building this a-post structure to integrate the MX5 and Volvo a-pillar structure. The Volvo has plenty of strength in the a-pillar. The MX5 has significant structure in the lower part that is inside the A-pillar and this can simply be welded together. The work to be done is in transferring the upper strength of the Volvo a-pillar to the MX5 upper structure.

While this is just thinking out loud and trying stuff, the tape shows the load paths that I want to capture in any design I implement.

That brings us up to date. As I said, I will be doing most of the updates on the GRM board, but if there is any interest I can do the occasional post here.

So today was the day to see if all the measurements were going to work as far as fitting the front sheet-metal. I have to say I am happy with the way it fits.

So today was the day to see if all the measurements were going to work as far as fitting the front sheet-metal. I have to say I am happy with the way it fits.