Fiat 850 Coupe

CLICK HERE

See the XWEBfourm Thread for more Fiat 500-600-850 Build Info

Stance created by Abarth

Fiat Abarth 1300 Front/Rear Springs with 185/60 tires

I kept the open pipe on for a few weeks until I had time to fabricate another muffler setup. It was too loud for the street, but it sure was fun, especially going through tunnels.

Installed a small foam air cleaner to make carb tuning easier. #50 idle jet seems to be working for now.

Complete FlickR Photo Stream available by clicking here

" This car traded owners 4 times and returned to me for restoration; It just kept coming back."

In 1990 I found this car in an East Los Angeles backyard where it looked like kids used it as a trampoline; there were dents and collision damage in every panel. But the car had minimal rust so I couldn't resist. I can't remember for sure, but I think it cost $200 with no engine.CLICK HERE

See the XWEBfourm Thread for more Fiat 500-600-850 Build Info

Stance created by Abarth

Fiat Abarth 1300 Front/Rear Springs with 185/60 tires

Malibu Ca - Gathering of cars before a canyon run through the Santa Monica mountains Jan 2015.

I kept the open pipe on for a few weeks until I had time to fabricate another muffler setup. It was too loud for the street, but it sure was fun, especially going through tunnels.

Installed a small foam air cleaner to make carb tuning easier. #50 idle jet seems to be working for now.

Complete FlickR Photo Stream available by clicking here

" This car traded owners 4 times and returned to me for restoration; It just kept coming back."

The car sat in my yard behind other projects till 1993 when I sold it to Carlos from South Central LA. He kept it for a number of years when he gradually became mentally ill. Then it ended up with a Fiat friend of mine; Robert from West LA. Robert ran out of space for his projects and needed a Bugeye Sprite painted, so he traded the car back to me in 2003 for doing bodywork on his Mazda powered Sprite (see it below).

In 2005 I sold the car again where it was towed to Santa Barbara where it remained until 2010. Once again the owner faced storage problems and sold it back to me.

In all those years, the car was never worked on! It looked the same as when I first saw it except for a few more dents and maybe more rust. Since the car kept coming back to me, my wife said I have to keep it and restore it. We jokingly said there must be some sort of karma involved given it keeps coming back over a 20 year period. So I was able to put it on top of my priority list and started working on it in 2011.

It still needs color-sanding and some parts attached, but since February 2013, I've been driving it every chance I get.

2003 West Los Angeles California where it got kicked out of the garage behind it by an AH Sprite. When this photo was taken I had not seen the car since I sold it in 1993. It seemed amazing to me the car was still being neglected after so many years.

2003 Coupe's arrival at my garage after a 10 Year absence. Both cars just arrived after being towed from West Los Angeles to my garage. I painted the "Speedwell" nosed Sprite in trade for the coupe.

Due to too many projects, I sold the car again in 2005. Here it is in my yard during construction of a garage addition, where it was always getting in the way.

Car stayed in Santa Barbara and Ventura Ca until 2010 when it finally got kicked out of another garage and into somebodies backyard.

After seeing the car outside again, I got it towed back to my garage where restoration started in 2011.

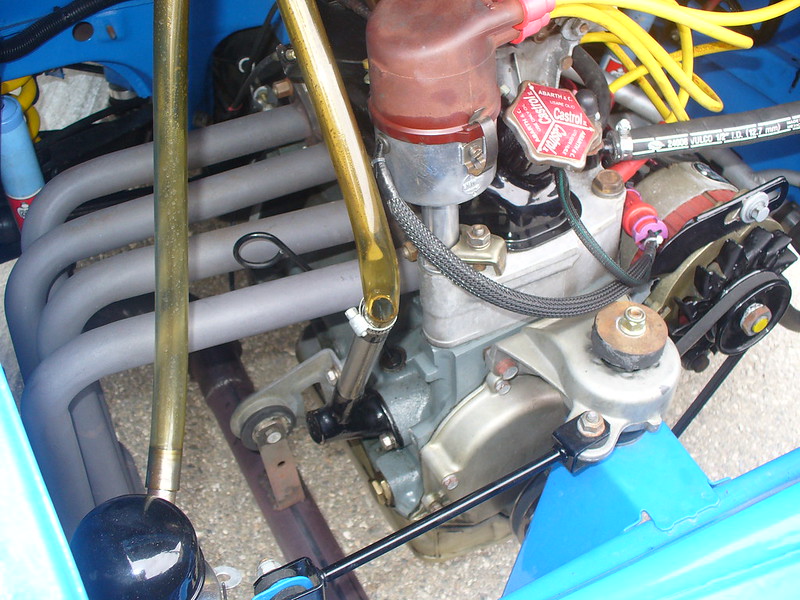

Engine Build Details

1973 Fiat 903 block bored to 66mm, stock 68mm stroke

30DIC Carb, 23mm barrels

Abarth crankcase breather system

Stock oiling path in block with centrifugal oil filter

Stock 903 alloy oil pan

Crane 3000 electronic ignition with late Marrelli distributor

Ported head with improved oiling to restricted cam lobes

Lightened flywheel, 127 pressure plate & disc

PBS 280ST staggered timing Cam

Completely balanced from Pressure plate to Pulley

Oil pump - modified to prevent cavitation and improve flow

Cylinder Head Modification - Improves Camshaft Lubrication

Fiat 850 and 127 heads have factory flaw in the casting where the lubrication path to the #4 intake tappet is starved from oil. I have found most of the time the #4 intake and/or exhaust lobes have more wear than the other lobes. The solution to this problem is to mill or grind a gully for oil to drain into the pushrod hole to match the rest of the head. I've been doing this for every 850 engine I build.

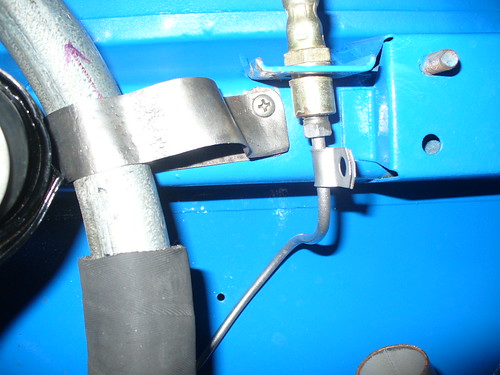

Building the Abarth Breather TRI-AD

The breather triad/fork starts out with a thin wall steel tube filled with oven dried sand and welded plugs at the ends. This is all done to prevent ripples and kinks when making sharp bends. Sand has to be dry to prevent an explosion from pressure caused by moisture/steam.

The piece shown here is packed with sand and is bent as many times as possible. I should be able to get about 5 triads out of this length of tubing. You can see how the ends of the tube is welded shut with a steel plug.

A jig is used to hold the tubing while it's heated to red-hot with a torch and slowly bent to form a tight bend.

In this case I'm making 5 of them for those building Abarth clones. What's done is to cut out a "U" section, drill it in the bottom of the "U" and weld in the straight center creating a fork or triad shape.

Many 600 based cars used this breather setup but the only 850 that used it was the Fiat Abarth 1000 OTS where installation looked skewed since the fuel tank inlet tray was in the way. In this coupe the gas tank was moved up front and the fill tray was removed, so there is more room to work with. I think Abarth's factory did the same thing on the Fiat Abarth OT 2000 in 1966.

In this pic you can also see the cut valve cover oil neck where it needed the breather tube directed toward the triad instead of the bottom of the air cleaner like in a stock 850. A neodymium magnet from an old computer harddrive holds them in place to position it for welding it back together.

Here is my attempt at gas welding; trying to get a "stack of dimes" look. I ended up just grinding it down and smoothing out. The Abarth factory welders laid better looking welds when they did this on 600 based cars.

After smoothing the welds with a abrasive roll & die grinder, it got a coat of epoxy primer and PPG urethane black.

It's tricky to get this kind of gloss out of a spray can. Definitely over restored considering Abarth factory workers just sprayed a fast dry lacquer from what I've seen.

TransAxle

I fabricated a different Syncro Anchor Block (bottom block between the bannana's) and two shorten'd banana springs on 2nd gear. This upgrade applies more pressure faster and applies more positively than the original setup. This modification provides a consistent grind-free shift 100% of the time. Normally, even with new parts, these transmissions grind going into second depending on: wear, temperature, RPM/speed and the oil used.

I'm currently using Amsoil MTF transmission oil and the shifts are reliable with no clashing. Amsoil MTF seems to be working good and has a proper GL4 rating. I really don't think GL5 is the way to go in Fiat transaxles. I've use the new Penzoil Syncro Mesh oil for a while which has no GL4 or GL5 rating at all, plus it's specifically made for late model FWD Chyslers and Fords. I was just experimenting trying a new oil and made a bad choice as it's really a 5/30 oil and won't cling to bearings very well.

GL5 gear oil in these transaxles makes them work too hard; synchro gears need to be slowed or accelerated for a clean shift. Similar to a locomotive trying to stop on oiled tracks; as a syncro dog ring clamps down on the syncro ring during a shift, it can't get a grip fast enough with EP additives so you get gear clash; most often going into 2nd gear. EP (i.e. Extreme Pressure) additives are good for ring/pinion hypoid gears; not synchros. Since transaxles are combined differential and transmission; EP is needed in the differential and non-EP in the transmission. For now I'm going to take care of the synchros with GL4 oil which has less EP additive than GL5. I'm hoping the Ring/pinion will survive lower EP just like Porsche transaxles do regarding this gear oil selection compromise.

Many new oils have been developed in the past few years specifically for synchromesh transmissions. AmsOil, Royal Purple, Valvoline, GM, Redline and Swepco have syncromesh oils with lower EP additives.

Special mention for Sta-lub GL4 gear oil which is non synthetic and is priced under $35 a gallon on Amazon or a bit more at NAPA. I think this would be the best deal and would perform really good.

Below are deber'd and polished bearing and gear tooth surfaces. A sisal wheel and steel buffing compound were used to polish all the bearing surfaces in hopes of putting less strain on the synchros.

The less friction in this area, the easier it should be for synchros to speed up/down a gear before the dog collar teeth mesh with the gear dog teeth.

it took weeks to complete

it took weeks to complete  Since it was all by trial-and-error it took much longer than it should have.

Since it was all by trial-and-error it took much longer than it should have.

finally got rid of 90% of the warp. To go 100% after all this work wasn't worth the effort.

finally got rid of 90% of the warp. To go 100% after all this work wasn't worth the effort.