v8ian

Posted a lot

Posts: 3,832

|

|

Jan 19, 2014 16:39:27 GMT

|

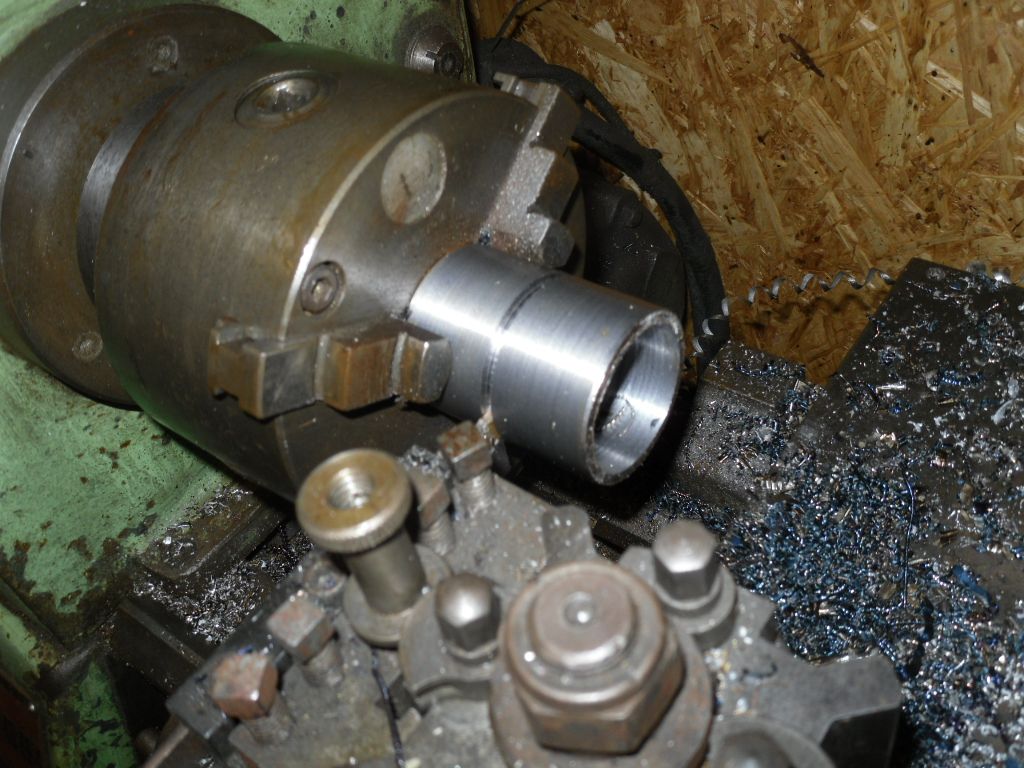

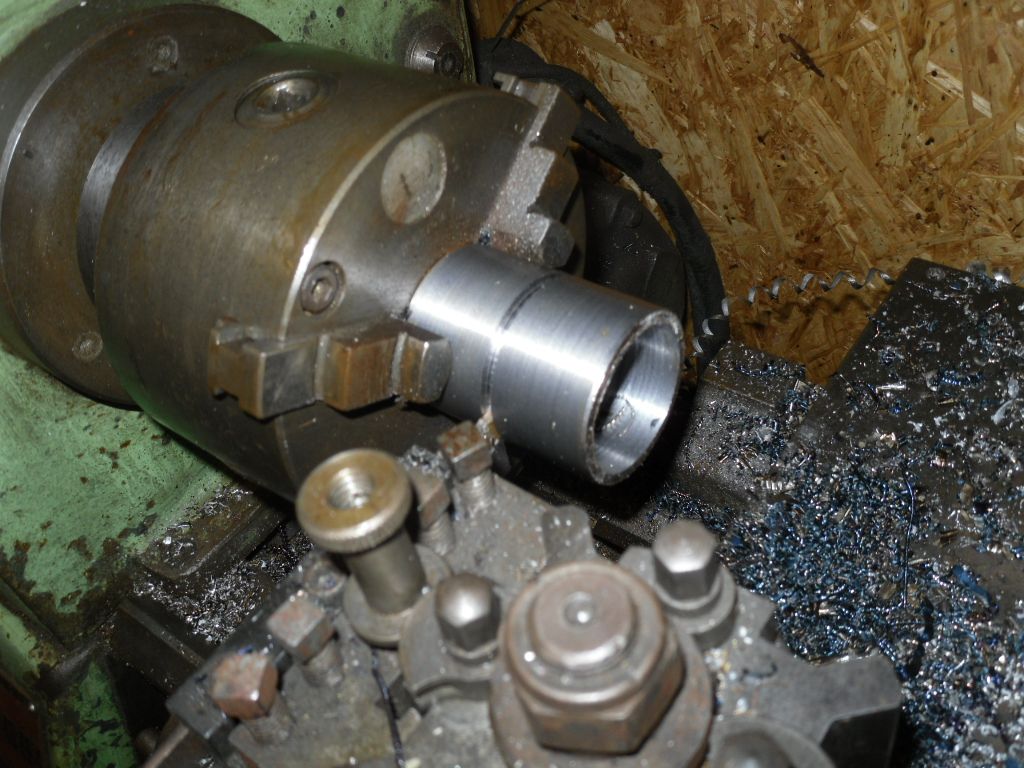

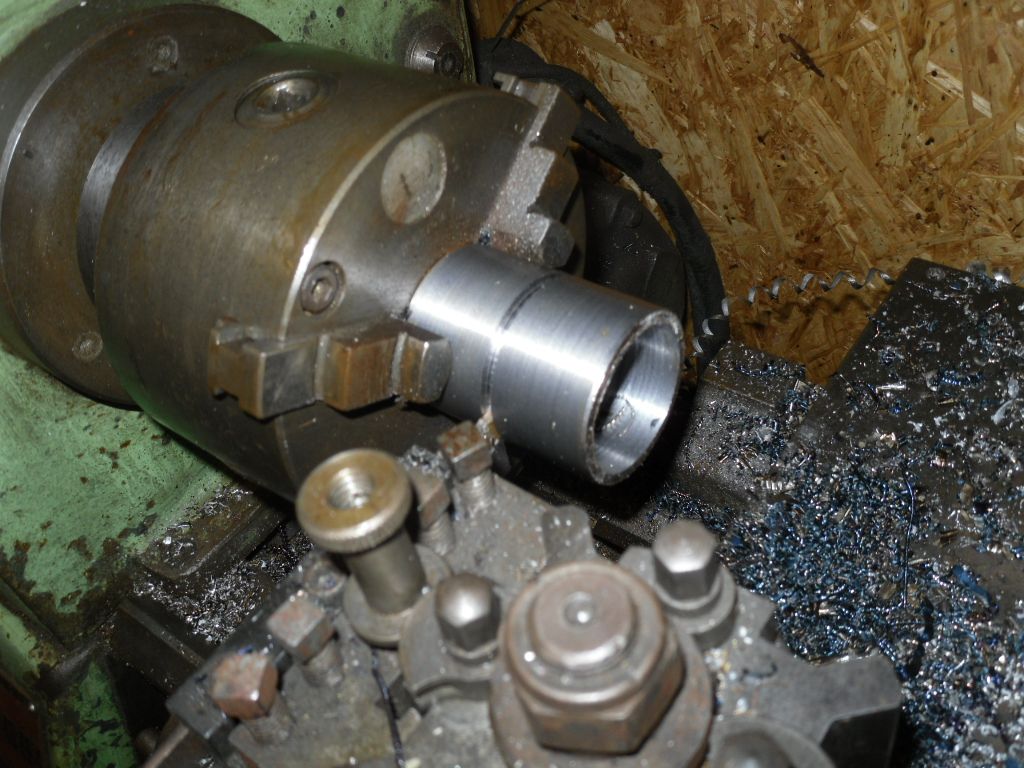

I think the axle casing has come out OK, It was a bit more involved than I first thought as the bearings were friction welded on, so they had to be turned out so the new tube would fit inside, the problem with this has meant I was unhappy with the wall thickness of the housing, so a couple of support sleeves were turned up, and pressed inside the tubes, retained by some big plug welds, downside of going this route is the only place to run a weld to really hold the housings on is weld internally, which means using the lip seal seating, not a problem, I know I can get double sealed bearings, and some super bearing sealer/retainer I have should stop any possibility of leaks. The Alloy centre section tube ends appear to be pushed in and held in place by 3 steel rivets on each side, grind off the rivets and the tubes don't exactly fall out, fortunately I have a big socket that's a perfect fit, which enabled me to drift the tubes stubs out with a FBH, Guess what I found, the new tubes were too big to fit inside the housings, Grrrrrrr a wee bit more machining with a very very slight taper so the tubes entered about 15mm and stopped, Now its time to switch on the cooker, not for the sunday roast, but to warm up the casing halves, 220degs for 20 mins, they came out piping hot, the smell of smoking EP90 is something to be savoured. A slight smear of Loctite sealer/retainer on the tubes, welding gloves on, and take the casing out to the garage, on the floor and drop the tube into the housing, right up to the machined limit  , cool down and I don't think theres much chance of the tubes falling out, they are in there for a while, I will replace the removed rivets by drilling and tapping the housing then fitting 6mm button head allen bolts.        |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

|

|

Jan 19, 2014 17:57:42 GMT

|

|

Great progress, nice looking axle case there. What's next?

|

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

Jan 19, 2014 18:09:24 GMT

|

|

I need to machine the shafts, and assemble the hub sub assemblies, I'm trying not to go overboard on this, but I am upgrading the fastenings, the original wheel studs are 3/8", I'm going to redrill and thread the hubs to take 12mm bolts, that's about double strength rating if I use 12.8s, my problem is I need to be really neat, tidy and compact to make sure I have clearance for the rear wheel cones to seat correctly,

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

Jan 20, 2014 19:53:47 GMT

|

Well its been another day of scratching my head on how to do this back axle, Mainly because I cant buy aftermarket bolt on splined hubs for my specific wheels, which has resulted in the hubs sitting very tightly against the cone shaped of the wheel, I can and have mocked up the assembly trying to sus this out, I think I have sort of reverse engineered it in my mind, I'm waiting for bolts to turn up, the plan is spot thru the flange to the backplate, drill out to about 25mm, there is one place that I can do this safely in the backplate, Using the aftermarket splined hub tap the 4 plain holes that I have drilled to 7/16th UNF, now the Idea is assemble the flange on the axle, do the Big nut up, now for what I will think will be the fiddly bit, push the drum on and thru the 25mm hole push a allen bolt thru the back of the flange, thru the drum and into the tapped hole rotating and repeat for all 4 bolts, loctiting as I go, What it do get is a hub that is that is a pain in the butt to service the brakes as I have to take it all off from behind the drum, but I can take the wheel off at will, The way I see it is most modern cars retain their wheels with fine threaded bolts, I'm using 12.9grade allen bolts, bolted from the rear rather than the normal thru the wheel, Comments please gentlemen.       |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

dw1603

Part of things

Posts: 591

|

|

|

|

|

I'm looking at it without knowing the full complexities, so excuse me if this is a stupid suggestion. Is it feasible to bolt the hub, drum and adaptor together as a single unit on the bench, then fit the whole assembly to the axle, securing it by means of the big hub nut, accessed through the centre of the splined hub adaptor? Pretty much as per a VW Beetle rear hub/drum. You would need to give some thought to locking the hub nut, maybe a keyed locking washer or a lock nut or possibly drilling the adaptor for split pin access. If it worked out, you could adapt a spare wheel spinner to make a hub puller, making brake servicing even easier. Bound to be something you have already considered, but just thinking out loud really.

|

| |

|

|

|

|

|

|

|

|

Lol scatching head moments, yer l've had a lot of them and curse word that doesn't work l'll have to start again.

Good work there with the rear axle, so l see it like this bolt hub to shaft then studs on hub 7/16, the alloy drum then drilled and couter borred so nuts are under flush, l wouldn't bolt wheel spine to alloy hub because the bolts threaded into alloy will be weak point, l'd make steel inserts from the back of the alloy hub and bolt though to them, if you know what l mean.

|

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

|

|

DW, I can bench fit the hubs and drum together, torque everything up, then fit the hub assy to the tapered Halfshaft fit Big nut and washer, then torque that up, goes together easy, No doubt, it will be a pain to remove the drum thru the backplate should I ever need to, BUT in reality, if nothing leaks or breaks, I wont need to touch the rear brakes ever.... 2k a year max, the shoes are hardly going to need changing at anything less than 30k, that's 15 years, of life before service, Built in obsolescence, that's the driver not the car....... I doubt that I could just remove the hub nut and pull the assembly off as the hub is on a taper with a legged puller as there is nothing sturdy to attach the legs to, But, as I am sitting here, I have worked out I can make a puller from the old 42mm wheel hub nuts,  simply drill a 25mm hole in the centre, machine a top hat nut to suit my puller thread, make the new nut an interference fit and push into the wheel hub nut, screw that onto the splined hub with my puller screw, hey-presto, I have a puller, Obviously I will need to make one for each side as the wheel nuts are handed. So now I can blind bolt it together, by tapping the splined hub 7/16 unf, and bolt the hubs up from behind the axle flange, obviously loctiting the bolts, If there is room behind the wheel, I might get some 7/16 K nuts perhaps reduce their thickness if possible, I may be able to fit these and tig them in position on the spline hub, this should give me a bit more thread and an extra locking function. Rob, Believe me there has been some real deep head scratching trying to get this to work, unfortunately the drum/spacer is hollow cast and is not suitable to drill, tap or fit simple top hat bungs   |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

Jan 22, 2014 18:17:24 GMT

|

|

Brilliant work, A7s were always lacking in power, even with the cozette blower. And the TL1000 'widowmaker' was an engine looking for a chassis, bet it didn't expect to be going in an 80 year old chassis! hehehe, Baron Austin will be turning in his grave

|

| |

|

|

|

|

|

Jan 22, 2014 19:44:11 GMT

|

|

will that one keyway on the taper be enough to take the torque? genuinely haven't a clue here.

|

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

Jan 22, 2014 20:01:41 GMT

|

|

The key does virtually nothing, the hub is held in position by bolting it tight onto the taper, the key I think is just to make sure goes back in the right place as they do seat themselves.

Tapers do drive amazing amounts of torque, When I was an apprentice I fitted a taper coupling to a 1 mtr dia prop shaft to a super tanker, that was all that drove a 6mtr propeller that propelled and stopped the HUGE ship,

Mk2 Jags and Jensen interceptors use a similar system of a taper drive.

|

| |

Last Edit: Jan 22, 2014 20:11:37 GMT by v8ian

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

|

|

Jan 22, 2014 22:36:31 GMT

|

well sounds like plan to me, go to it!  |

| |

|

|

dw1603

Part of things

Posts: 591

|

|

Jan 23, 2014 10:44:09 GMT

|

|

Hi Ian,

Well I think I understood your answer, as I suspected. its a bit more involved than first thought. Whatever, I'm sure you will settle on a soundly engineered solution to the problem. My thoughts on the hub puller are a bit more basic (and brutal) than yours. A piece of bar to slip inside the splined hub adapter, bearing against the end of the axle shaft at the inner end and projecting say 15mm beyond the adapter on the outer end. Undo and remove the hub nut from the axle shaft, slide in the above mentioned pusher piece, wind on the spinner and smite it mightily with a hide faced (or copper) mallet. That should pull the hub assy sufficiently to free it from the taper. Of course you would want to protect the axle shaft threads from bruising, and you might need to spread the load a bit at the spinner end so that the rod didn't just try to push through it. Story of my life really, solve one problem and create three more. After many many years, the lesson is starting to sink in, if it ain't broke, DON'T FIX IT!

Regards, Dave.

|

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

Jan 23, 2014 19:56:58 GMT

|

I'm still working on the flange/hub assembly...... More later, On Monday, Mr Taxman gave me a small refund, very nice of him too, So rather than machine my old shafts, which I had intended to do, and would struggle to do lathe as its too short to get the shafts in safely, so I contacted a man in Burton on Trent, to make me some custom length shafts, That was Tuesday lunchtime, Thursday morning, these turned up.  £250 on my doorstep, Pretty good service I think,    |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

|

Jan 23, 2014 22:50:31 GMT

|

|

Looking good.

|

| |

|

|

|

|

|

Jan 23, 2014 23:25:07 GMT

|

|

They look nice, can i have his details as I will need mine shortening or new ones

|

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

|

|

|

Rebels Racing

Belmont Farm

Belmot Road

Needwood

Burton on Trent

DE13 9PH

Tel: 01283 521 557

Fax: 01283 521 558

Mobile: 07973 441 827

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

CaptainSlog

Part of things

Posts: 510

Club RR Member Number: 180

|

Austin 7 Box saloon,CaptainSlog

@captainslog

Club Retro Rides Member 180

|

|

|

|

Why not used cast mini drums rather than the aly ones? Available at MiniSpares.com.

(http://www.minispares.com/product/Classic/Brakes/Drums/Drums/GDB106.aspx?040601&ReturnUrl=/search/classic/rear%20drums.aspx|Back%20to%20search)

|

| |

|

|

|

|

|

|

|

Cheers  |

| |

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

|

|

Why not used cast mini drums rather than the aly ones? Available at MiniSpares.com. (http://www.minispares.com/product/Classic/Brakes/Drums/Drums/GDB106.aspx?040601&ReturnUrl=/search/classic/rear%20drums.aspx|Back%20to%20search) In a few words, Aesthetics, You can see them thru the wheels, they transfer heat better, they look in keeping with the period of the car. |

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

v8ian

Posted a lot

Posts: 3,832

|

|

Jan 25, 2014 17:12:12 GMT

|

|

|

| |

Atmo V8 Power . No slicks , No gas + No bits missing . Doing it in style.

Austin A35van, very different------- but still doing it in style, going to be a funmoble

|

|

|

|

, cool down and I don't think theres much chance of the tubes falling out, they are in there for a while, I will replace the removed rivets by drilling and tapping the housing then fitting 6mm button head allen bolts.

, cool down and I don't think theres much chance of the tubes falling out, they are in there for a while, I will replace the removed rivets by drilling and tapping the housing then fitting 6mm button head allen bolts.

, cool down and I don't think theres much chance of the tubes falling out, they are in there for a while, I will replace the removed rivets by drilling and tapping the housing then fitting 6mm button head allen bolts.

, cool down and I don't think theres much chance of the tubes falling out, they are in there for a while, I will replace the removed rivets by drilling and tapping the housing then fitting 6mm button head allen bolts.

simply drill a 25mm hole in the centre, machine a top hat nut to suit my puller thread, make the new nut an interference fit and push into the wheel hub nut, screw that onto the splined hub with my puller screw, hey-presto, I have a puller, Obviously I will need to make one for each side as the wheel nuts are handed.

simply drill a 25mm hole in the centre, machine a top hat nut to suit my puller thread, make the new nut an interference fit and push into the wheel hub nut, screw that onto the splined hub with my puller screw, hey-presto, I have a puller, Obviously I will need to make one for each side as the wheel nuts are handed.