|

|

|

Dec 25, 2012 18:34:27 GMT

|

Well thought yesterday Id figure out a job Ive been putting of for awhile and thats the throttle linkage mount for the single TB. Armed with the inlet set up, a piece of mild steel, hacksaw, files and welder I had ago!! from  To this  Which when the post that is being used to secure the injector rail to manifold is flattened and a mounting hole drilled through where the throttle cable mount meets it should all be fine!! Then ill tidy it up smooth the edges and paint it silver!   Red line is around where the cable hole needs to be.  So on to the next thing I need to work out is the inlet feed to the TB, Idea was to use a silicone 90 degree reducer 70mm to 51mm, alloy tubing then 90 degree 51mm to 40mm which then goes onto the set up as was on to the charge cooler......... Start off with placing the charge cooler where it goes, ah ok I over looked a few fitting problems  ;D I knew the chassis leg was close but...  Luckily I never cut the mounting legs down so balancing the cooler on a scissor jack I lowered the cooler still higher than the chassis and regained the space I had without it there.    As you can see Ive got about 50mm (45mm max really) of clearance space, Brainstorming time please! Any items you can think of that would work? I need to take the feed pointing towards the front of the car, Ive looked at the measurements of the silicone reducer pipes and I'm thinking I'm not going to get one in there and still manage a hose clip or clear the chassis leg!  Cheers Chris |

| |

Last Edit: Dec 25, 2012 18:44:36 GMT by deadlikeme

|

|

|

|

|

|

|

Dec 30, 2012 18:51:48 GMT

|

|

yep moving the Tb now so its away from the manifold clearing the chassis rail easily.

Looking at my to be chargecooler system and looking at radiators, has anyone ever used a little oil cooler as a radiator before? You know the type 9, 13 row etc?

thanks

Chris

|

| |

|

|

|

|

|

|

|

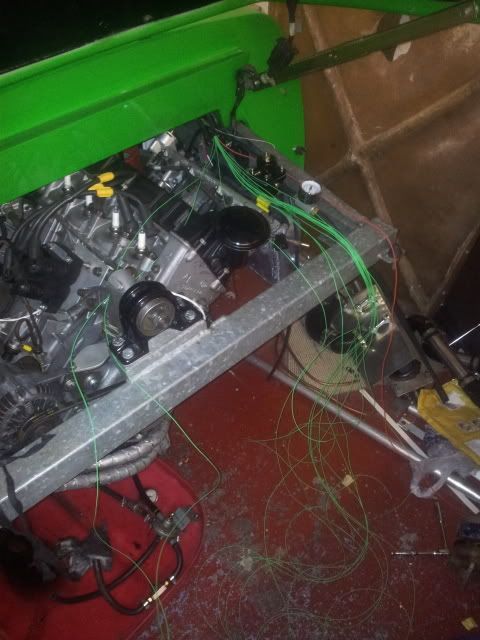

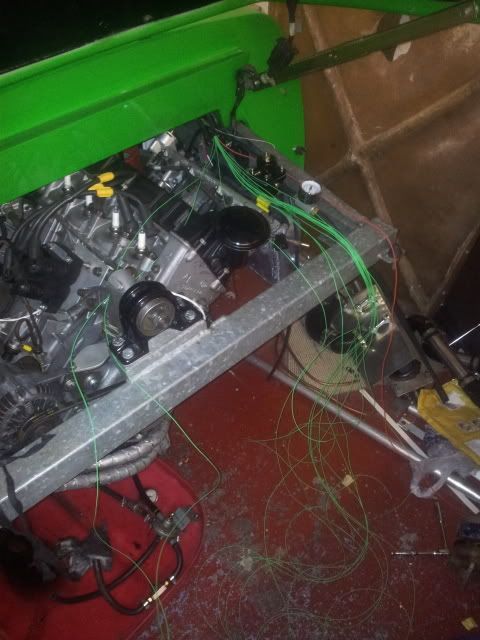

been buying things to get me going on the new install again which has means...  and Ive purchased an alloy bend and alloy 8mm plate, after hacksawing, hole making and crappy spot welding Ive now sorted the inlet issue with plenty of chassis clearance!    Will get it tigged up properly then can carry on with the build! Also made the initial wiring loom for the ecu. |

| |

|

|

pork

Posted a lot

Posts: 1,666

|

|

|

|

|

Did you get your long wire?

|

| |

|

|

|

|

|

|

|

|

Nope, havent ordered it yet I'm reluctant too although theres no way around it lol..... £55 bloody quid extra!!

|

| |

|

|

pork

Posted a lot

Posts: 1,666

|

|

|

|

|

Ouch!

|

| |

|

|

|

|

|

|

|

Evening mate, looks like you are making good progress  Just a word of warning, with the spray pattern of those injectors, you are going to struggle with fuel running down the inside of the injector mounts. The tips really need to be in the airflow rather than tucked right up inside the tube. Keep up the good work  J |

| |

|

|

|

|

|

|

|

|

Oh yeah thatll be something for me to look out for then! I don't think they're to far away from the end with the angle they're at, something that can be adjusted later on if need be!

Cheers J

Chris

|

| |

|

|

|

|

|

|

|

been making progress, started wiring up the dta harness, but waiting on some loom tape arriving before feeding in the drivers side and down the length of the car and the basic set up all confirmed fitting, just need to mount plumb and wire up the chargecooler water system and find a more suitable battery as the demand is getting bigger!! old and new turbo being set up to match orientation  New bonnet, annoyingly you can tell the colours not quite right.....  Recored rad with fan refitted  lifted up to work under it wiring up ect  Fuel system all finished  window vent, which I'm copying and re making out of carbon faced fibreglass     Boot thats going to have vents mesh and all sorts of air expelling variations in it, perfect colour match  cooler one, 2nd one might fit below chassis and the duct Ill fit on the side so water wont run in and itll be a smaller version, wouldnt actually be a problem if I did mount on top as rain, beer, etc would run through and hit the tarmac below anyhow!!  DTA fun!  New water and mtxL gauges fitted in place the wideband still needs wiring up  Cheers Chris |

| |

|

|

pork

Posted a lot

Posts: 1,666

|

|

|

|

Nice work going on there  |

| |

|

|

|

|

Mark

Posted a lot

Posts: 3,825

|

|

|

|

|

I love this.

Great work.

|

| |

E36 BMW 318is saloon (rare as a hens false tooth)

VW Caddy Maxi 2010 (usually full of Labradors)

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,126

|

|

|

|

What he said.  |

| |

|

|

Sven

Part of things

Posts: 341

|

|

|

|

|

What they said, nice motor!

|

| |

1969 Chevrolet 4x4 C10 Pickup

1969 VW extended cab pickup (doka)

1980 Volvo 240DL

1995 Mazda Miata MX-5

2007 Toyota FJ Cruiser

2007 Dodge Ram 2500 Cummins Diesel

2011 MK Indy R (building)

|

|

bazzateer

Posted a lot

Imping along sans Vogue

Imping along sans Vogue

Posts: 3,653

|

|

|

|

|

Look forward to seeing this at Perth Chris!

|

| |

1968 Singer Chamois Sport

1972 Sunbeam Imp Sport

1976 Datsun 260Z 2+2

1998 Peugeot Boxer Pilote motorhome

2003 Rover 75 1.8 Club SE (daily)

2006 MG ZT 190+ (another daily)

2007 BMW 530d Touring M Sport (tow car)

|

|

|

|

|

|

|

|

have you considered a motorbike radiator for your chargecooler? Pipe diameter is already small anough so you won't have to use reducers and what not and they're alloy so light and have a high heat transfer. Dirtbikes usually have 2 radiators having from the side of the tank, making them rectangular which is probably what you need.

|

| |

|

|

|

|

|

Feb 10, 2013 22:38:04 GMT

|

Hi all back on it a little this weekend..... Yes did think about a bike rad but thought Id give a little cooler a go first and monitor the inlet temps in the manifold to see if it was effective........ if its not Ill stop being gay and put the rad up front in the bonnet area, just trying to make it look fancier in my mind at least! Inlet all ready with temp sendor in it.  Boot wiring well under way  Proposed cooler positions, the top one is offset to miss the light fittings which will be mounted in mesh so air can escape too.  wiring all sorted, bar the spares which are just coiled up for now whilst I read up if I need/want them yet, if not Ill shorten them, wrap em and hide them. Front wires where also feed down the tunnel to the front ready for connecting up once back on the deck!  Things starting to get crammed back in!  Turbo air feed going up....  and out to the side window vent which will be via my in line filter jobby  Also made a blanking plate for the bottom of the fuel rail as I will be feeding the fuel in from the top now.  Thats all for now, just about to order some more bits that I need so will be able to carry on when they arrive!! Chris |

| |

|

|

|

|

|

|

|

|

this is ace! gis a go misterr.....

|

| |

in africa every 60 seconds.....a minute passes.

|

|

|

|

|

Feb 12, 2013 22:43:16 GMT

|

It be ok, itll be ok, itll be ok........................ Its got to look worse to get better.......  Erm yeah, basically I don't want to cut the finished lid up to suit the turbo set up, if I ever go back to N/A I can use the original clamshell. With the lower cooler strapped in position I marked cut and drilled until happy....  Now it will close fully and air can escape! just need to get air in now which is next up! then massive repairs then paint again somehow along with the front bonnet!! Oh and itll be finished of with matching grill to the front  Got more on order for when I open up the area around the rear lights. Chris |

| |

|

|

pork

Posted a lot

Posts: 1,666

|

|

Feb 12, 2013 23:20:25 GMT

|

I love thus car!!  Great stuff |

| |

|

|

|

|

|

Feb 13, 2013 21:29:05 GMT

|

cut hole, scratched body paint, touched up body paint ready for 2500 grit and buff, hole will need more fettling but basic idea   thats all from tonight! Chris |

| |

|

|

|

|

;D I knew the chassis leg was close but...

;D I knew the chassis leg was close but...

;D I knew the chassis leg was close but...

;D I knew the chassis leg was close but...

[*]

[*] [*]

[*]