|

|

|

Feb 14, 2014 21:35:03 GMT

|

I was hoping to get some time in on this today but I've actually ended up having a stupendously long day working on another car. Started it at 8am and literally just given up for the night now. Still more to do tomorrow too so it looks like I might not have any time to work on the Land Rover until next weekend.  As I was tidying everything up before heading home, I just couldn't resist taking these two shots on my phone. I know I am biased in saying this, but I do reckon this is one of the coolest cars ever. That, in turn, makes me one of the luckiest guys on the planet.   Patina? Character? History? It has it all....by the bucket load.  |

| |

|

|

|

|

ZXRob

Europe

Posts: 1,200

|

|

|

|

|

No you are definately not mistaken, this is one of the coolest cars ever.

|

| |

|

|

|

|

|

|

|

|

Cool to the power of Rad = Awesome...!!!

|

| |

***GARAGE CURRENTLY EMPTY***

|

|

|

|

|

Mar 23, 2014 20:40:09 GMT

|

On a scale of great weekends......  |

| |

|

|

|

|

|

Mar 23, 2014 20:51:08 GMT

|

|

It must be said, this is the coolest car ever.

|

| |

Peugeot 307sw - Suzuki SV650S - MX5.

|

|

duncanmartin

Club Retro Rides Member

Out of retro ownership

Posts: 1,320

Club RR Member Number: 70

|

|

Mar 23, 2014 20:53:28 GMT

|

It must be said, this is the coolest car ever. Over and over again.... |

| |

|

|

|

|

|

|

|

|

I have a perverse want to take this to a mud day and get it stuck in a hole in front of a bunch of anoraks..

|

| |

|

|

ChasR

RR Helper

motivation

Posts: 10,309

Club RR Member Number: 170

|

|

Mar 24, 2014 13:14:01 GMT

|

It is great to see it back in action. It looks stunning in the videos. I shall have to catch this in the flesh one of the days. When working, those gearboxes are superb when compared to a BW35 eh?  . |

| |

|

|

|

|

|

Mar 24, 2014 13:36:15 GMT

|

When working, those gearboxes are superb when compared to a BW35 eh?  . You aren't wrong! I haven't had chance to test it out at speed yet (I'll wait until it's got the floorpans made and transmission tunnel fitted before that) but the initial impressions are that it's light years ahead of the BW box. Oh, and did you mention video?  I've got a friend arriving any minute, he's staying for a few days, so I probably won't have time to post up details of the last bit of work that led to the car driving again, but I will do as soon as I can. |

| |

|

|

|

|

|

Mar 24, 2014 16:05:07 GMT

|

|

Sheesh, that is just insanely awesome! It is completely off the scale (and then some)...!!!!!!!!!!!!!!!!!!!!!!!!!!

|

| |

***GARAGE CURRENTLY EMPTY***

|

|

|

|

|

|

|

Mar 24, 2014 21:45:28 GMT

|

|

I saw "that" land rover and clicked it hoping it was the one I wanted to see and yes it was.

Read the thread front to back. Exceptional work, but I'm sure you've been told that a thousand times.

I love this car so much. Bravo!

|

| |

|

|

|

|

|

Mar 24, 2014 21:52:09 GMT

|

|

You hoon Bruce.

|

| |

|

|

|

|

|

Mar 26, 2014 18:52:30 GMT

|

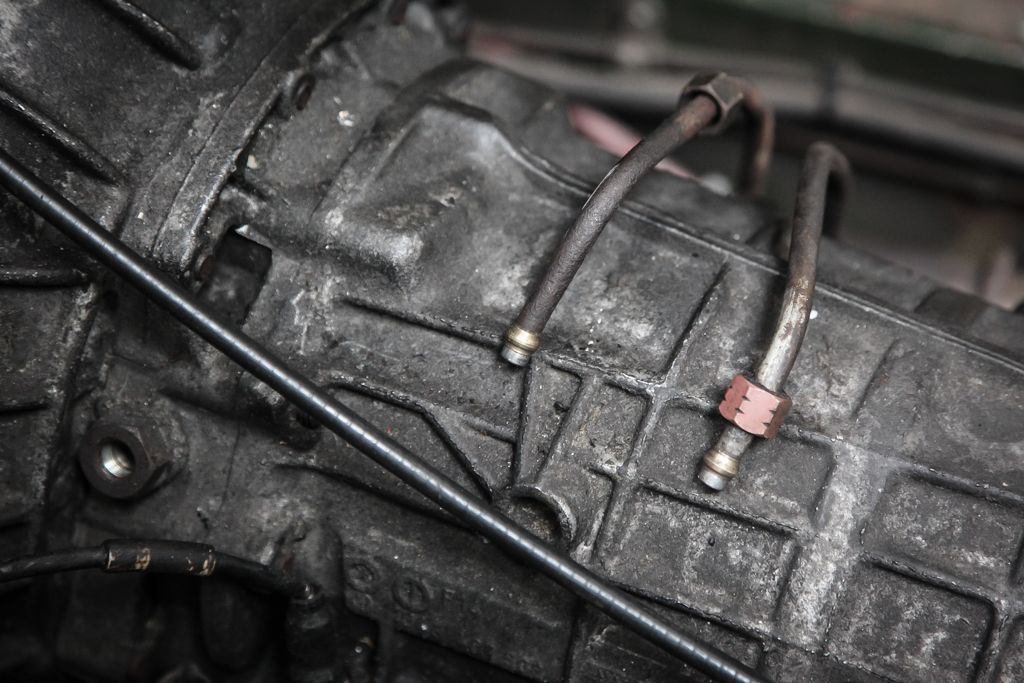

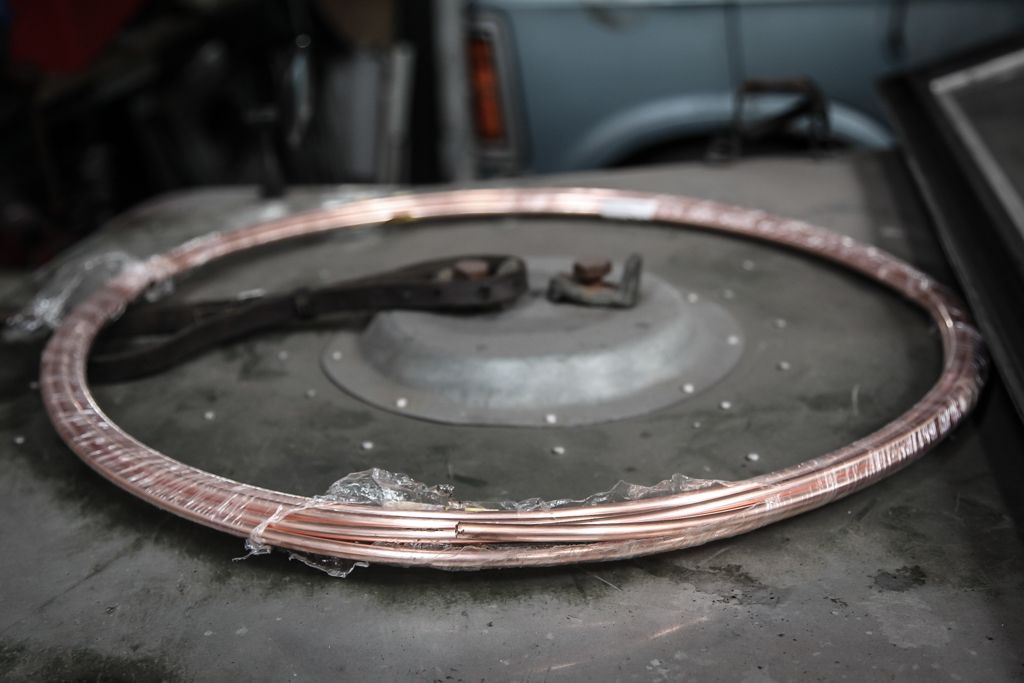

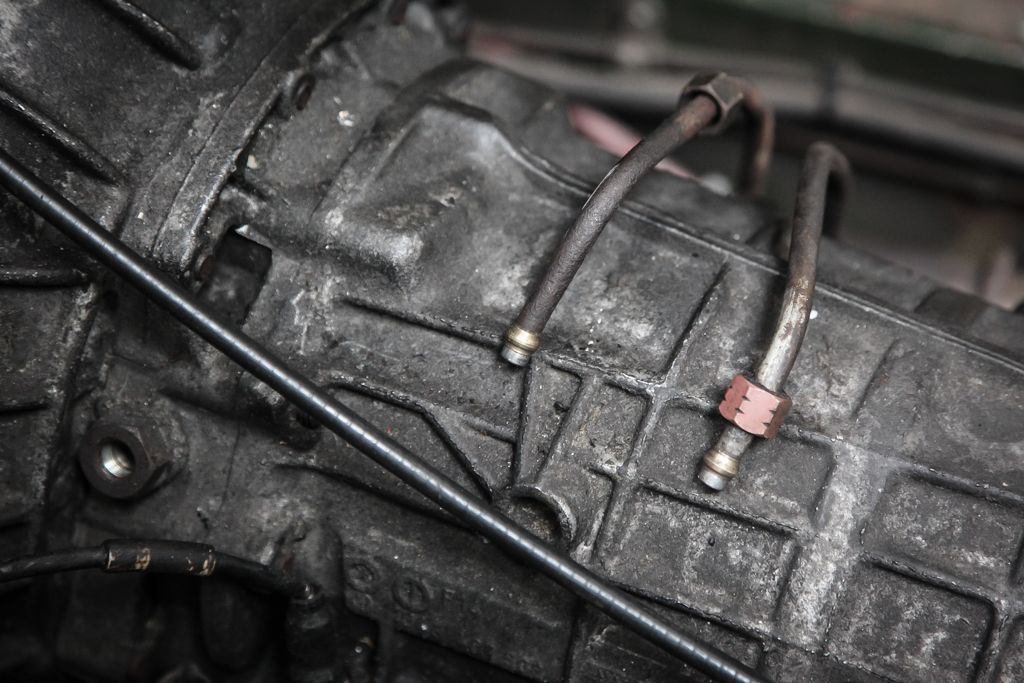

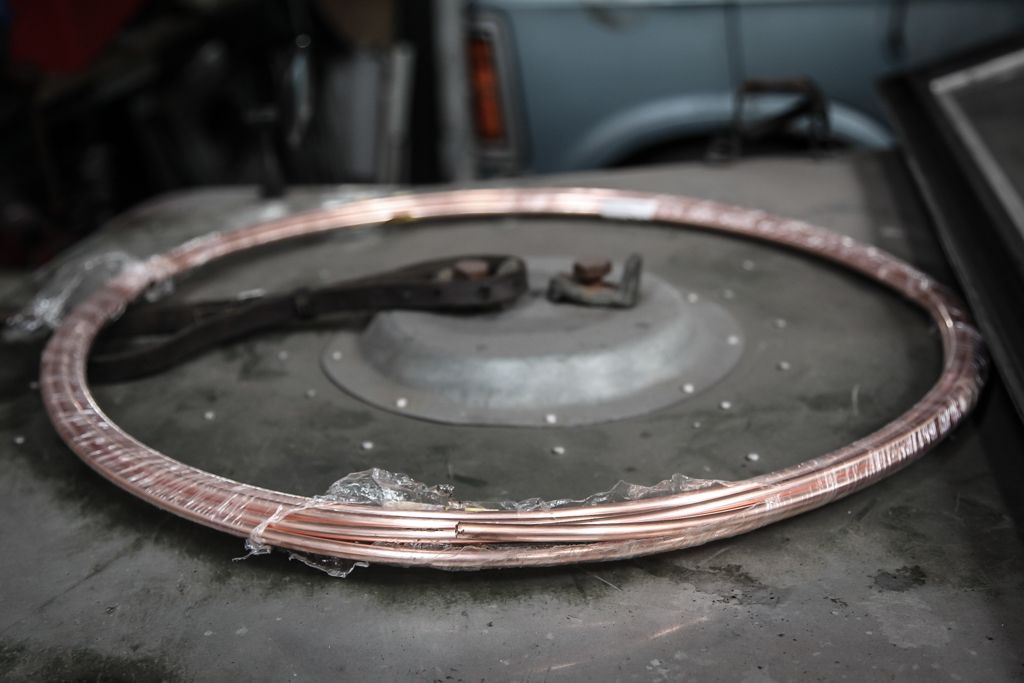

Haha, thanks for the comments guys. I forgot to thank James ( jrevillug) for coming with me on Sunday evening and taking the video. It had been a long weekend (AKA ridiculous!) and everyone was shattered, so I'm grateful he offered to come with me after everyone else had gone so that I could get some photos and the video to celebrate the car driving again. As it turns out, it was exactly two years to the day that it last drove. EXACTLY! How's that for a genuine coincidence? The hard pipes from the Borg Warner for the oil cooler didn't even come close to fitting. With the larger bellhousing of the ZF box, they didn't wrap around anywhere near as well (which puts them further back than needed). Plus one of the ZF connections is under the box, not on the side. Then to top it all, the connections are wrong anyway.  ZF connections are male fittings, the BW connections are female fittings. That ruled reusing the BW pipes then....  OK, so it's obvious to just utilise the original ZF fittings because they, well, fit.  Except that the hoses were cut short upon removal leaving only about 12" of flexible pipe on each one. Not a problem because I can just make a hard pipe to join onto the flexi.  Except that the hoses had seen better days. Something was telling me they were beyond their sell by date. curse word!  So a trip to Plumbase was in order. Ten metres of 8mm 'micro' copper pipe was bought, but thanks to the computer system being down they couldn't find a price, or process the order. "Just give us a tenner, I know it's more than that, so you're getting it cheap". I didn't argue. Nor at the free 8mm olives that he robbed out of some compression fittings because they had no bags of olives in stock.  Cut a few lenghts that I know will be long enough and try to get them a bit straighter. OK, so they'll get bent anyway, but I always like to start with something that kind of resembles a straight edge than a circle.  Now to make some pipes.... |

| |

|

|

|

|

|

Mar 26, 2014 19:30:50 GMT

|

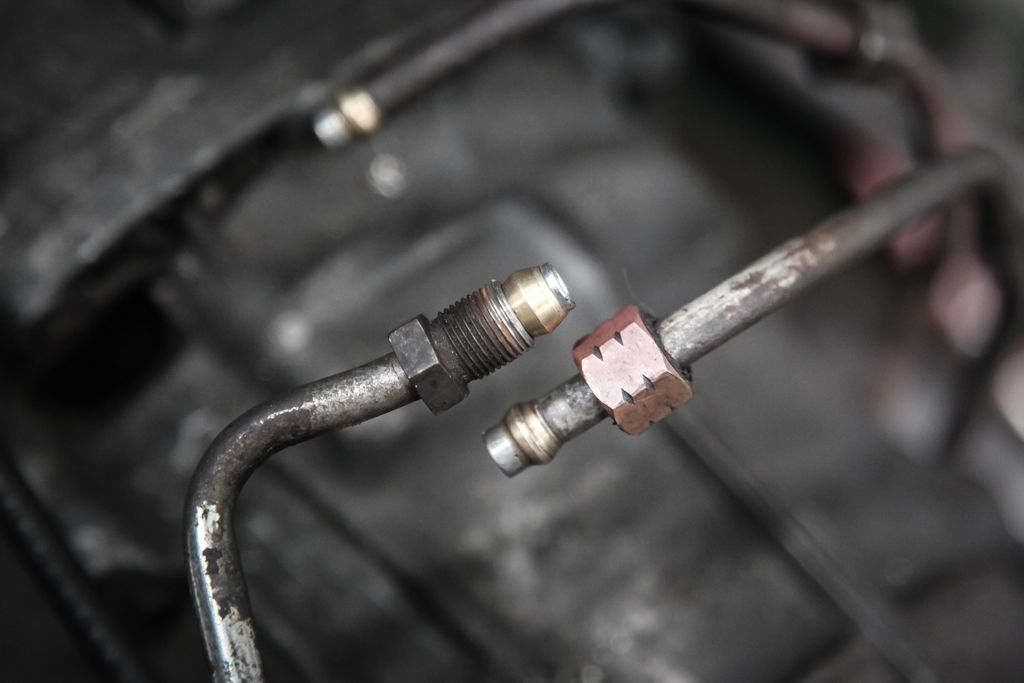

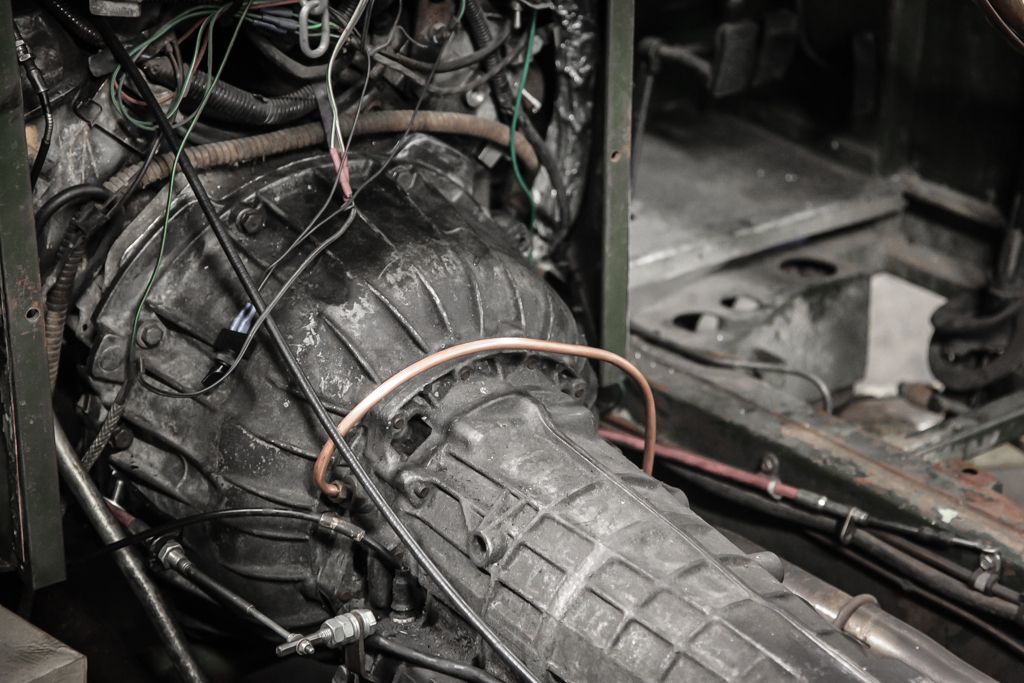

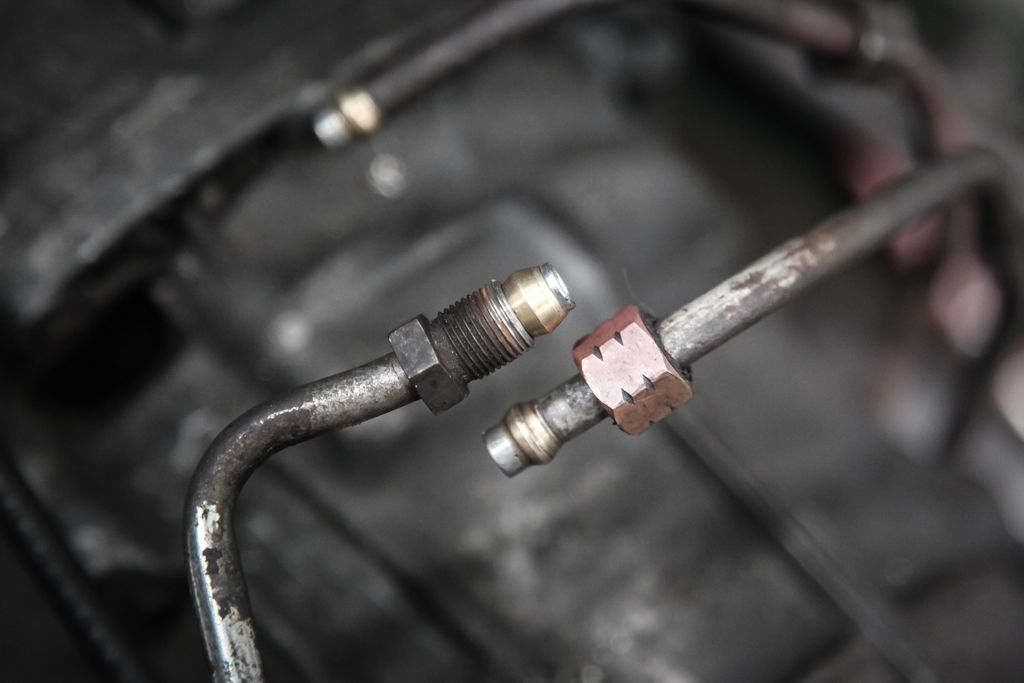

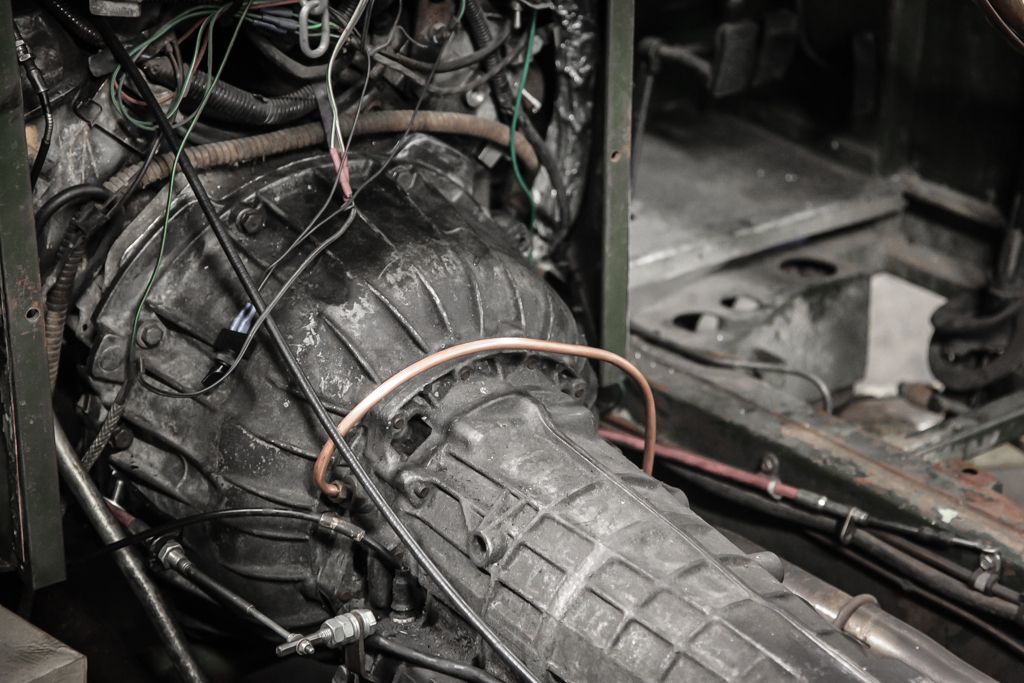

DAVE! ( Butterz) kindly lent me a brake flaring kit. James (Vilerug) has an amazing Sykes Pickavant brake flaring kit, but it doesn't go up to 8mm without buying seperate dies for it, so Dave's one was a bit of a life saver.  Some practice runs on offcuts of copper, I started to get the hang of using it. It was ideal for this job but I have to be honest, I really wouldn't consider using it for actual brake pipes. Compared to the Sykes machine, it just doesn't produce flares/fittings that I'd have any condifence in. Holding low pressure oil in some pipes is one thing, holding life saving brake fluid in a high pressure system is something totally different.  A few hours later (it was a lot more fiddly than I was expecting to get it 'just right') I had some pipes:  ZF connectors and new olives fitted:  It took some work to get the tight 90 degree bends sorted without the pipe folding (it's a LOT more prone to folding/crushing than normal size copper brake pipe...a LOT more) but I got there in the end.  Reusing the original BW clamps, I finally had the new pipes fitted.  This pleased me a lot!   One pipe comes from 'up & over' on the box. The other one comes from under the box.  Not 100% happy with the way this sits, but it works, fits within the tunnel and I don't think I could get it any tighter without getting the pipe creased somewhere...  Time to fill it with ATF. Something I'd been looking forward to doing for a VERY long time. |

| |

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,063  Club RR Member Number: 77

Club RR Member Number: 77

|

|

Mar 26, 2014 20:43:22 GMT

|

That copper pie is a swine for creasing when trying to get tight bends in it. I had fun and games doing my fuel pipes in 8mm kunifer  With the pipe that comes out and over the top, could you not have routed that under the bellhousing area? Although it is a lovely matching curve you have given both the pipes where they meet  |

| |

|

|

|

|

|

Mar 26, 2014 22:33:52 GMT

|

I initially started routing it under the other way, but it pushed the kickdown cable at an awkward angle (or stuck out too far) and came too close to the nearside exhaust (or the crossmember if trying to avoid the exhaust) Then there was the dipstick, the 30mm nut of which takes up most of the area under the bellhousing. I probably spent about an hour and half trying to get it to fo that route before scrapping that idea, straightening another length and running it over the top where it had a free run. I'd have much preferred it to go under, but it just wasn't practical. After filling the gearbox with just over 7 litres of Dexron III (I really should write & photograph a seperate update on the joys and tribulations of that) I decided there was nothing for it but to go for a cheeky drive. Despite the complete absense of floors, transmission tunnel and most other parts that constitute an interior, there seemed to be no shortage of people wanting to come for the initial test drive. James begrudgingly* obliged and we headed out for a little shakedown. I don't think I stopped grinning the whole drive! I don't think he did either?  It was 11pm and I didn't want to wake up too much of Bristol, so headed back to Area 52 and opened beers. The next morning, overflowing with mojo, I decided to crack on with a little job that I've been meaning to do since I bought the car. Fix the tailgate. I parked the LR in the middle of the unit and got the grinder and welder out...  The tailtage edging wasn't joined at the tops which meant that when you lean on it, all the force goes through the ally sheet  This side was even worse - the amount of flex across the top was pretty bad. (I'd already cleaned up the edges in these shots ready for welding)  It hadn't got much worse since I took ownership of the car, but I didn't want to see it spread any further. All the flex in the top of the tailgate was causing the ally to literally tear...   Some hot metal melty action later and it's a bit more solid.  When I say 'a bit', I really mean a LOT more solid. The difference is unreal.  The top of the tailgate now doesn't flex at all and it also opens and closes SO much better.  As you will have seen a few posts above, James and I headed out again to celebrate. Who needs floors anyway?   Have I ever said how much I love this car? |

| |

|

|

|

|

|

|

|

I really like this shot. Reminds me of futuristic highways weaving between buildings. I'm not weird, I swear! Also, before you put the floors on, you totally need to take a Flintstones shot, with some blurry feet action.  |

| |

|

|

|

|

|

|

|

Floors are heavily overrated anyways...  |

| |

|

|

joeytalent

Part of things

ITB Everything.

ITB Everything.

Posts: 440

|

|

|

|

|

The neatness of those pipes put the ones I did on my girlfriends Micra to shame. I have what looks like the same bog standard eBay flaring kit - I was pretty happy with what it produced for brake pipes, but I guess the smaller diameter pipe might've had something to do with it.

|

| |

|

|

s14x

Part of things

Posts: 12

|

|

Mar 27, 2014 20:01:39 GMT

|

|

Now that is eff'ing cool!

|

| |

|

|

|

|

[*]

[*] [*]

[*]

.

.