|

|

|

Feb 12, 2020 22:24:11 GMT

|

|

Each episode is getting better the video and the content.

Other than the section on using the flaring tool being wired as some how you flipped the image (number Plate reads backwards) a great video.

Looking forward episode 6

|

| |

|

|

|

|

|

|

|

Feb 12, 2020 22:50:33 GMT

|

|

Thanks Pete, I noticed that - its because I used the front facing camera on my phone which witdly inverts the image?!

I'm currently working on the wiper motor which is stripped and being tidied so wont take me long!

|

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

Feb 12, 2020 23:30:58 GMT

|

|

I enjoyed the video as always. But I am disgusted at the time you’re up and working on it! Keep the vids coming.

|

| |

Last Edit: Feb 12, 2020 23:31:30 GMT by jonsey

|

|

|

|

|

Feb 12, 2020 23:46:09 GMT

|

If those are pure copper brake pipes you need to fix them on far more securely than you have. If you can wobble them with your fingers anywhere then they are not fixed securely enough. Copper brake lines will work (vibration) harden in as little as 30 minutes if unsecured or improperly secured which results in the pipe fracturing - normally just inside the nut collar. This can result in some of the most exciting driving you have ever experienced  finding you have no brakes at 80mph in the middle lane of the M25 is quite exciting  Brake pipes should really be Kunifer which is a cupro nickel alloy and does not vibration fracture. It beats me why copper is even sold as it is not really up to std and is never fitted by manufacturers. The most vulnerable lines are across the rear axle, wire ties around the axle & brake line is sufficient - fixings should be a maximum 300mm apart. |

| |

|

|

|

|

|

|

|

|

Thanks Blackpop, I didn't know that about copper, the front to rear has retaining clips that I need to purchase.

I bought the set so long ago I couldn't be sure what material they are but I will check for movement in the pipe but the main offenders are the front to rear and the 4 way to passengers side.

The m25 is awful to drive on at the best of times!

Jonsey, thank you for the feedback - I'm an early riser plus mrs Jim is up at 6am for work which means any light can and will be used and her hairdryer could drown out the sound of a low flying Vulcan bomber!

|

| |

Last Edit: Feb 13, 2020 3:29:21 GMT by jim

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

Feb 13, 2020 10:40:18 GMT

|

|

Its definitely copper, as the Kunifer is a golden sort of colour.

Yeah, we were very lucky - it was very late at night & the motorway was empty, we had only fitted the pipe an hour earlier (to replace the other fractured (copper) pipe) and my mate hit the brakes and squeaked 'we have no brakes' we were able to safely coast to the next exit & use the exit ramp to slow the car.

I've never used copper since unless forced to, so I make sure its impossible for it to move. Short pipes are ok.

|

| |

|

|

|

|

|

Feb 13, 2020 13:05:41 GMT

|

If those are pure copper brake pipes you need to fix them on far more securely than you have. If you can wobble them with your fingers anywhere then they are not fixed securely enough. Copper brake lines will work (vibration) harden in as little as 30 minutes if unsecured or improperly secured which results in the pipe fracturing - normally just inside the nut collar. This can result in some of the most exciting driving you have ever experienced  finding you have no brakes at 80mph in the middle lane of the M25 is quite exciting  Brake pipes should really be Kunifer which is a cupro nickel alloy and does not vibration fracture. It beats me why copper is even sold as it is not really up to std and is never fitted by manufacturers. The most vulnerable lines are across the rear axle, wire ties around the axle & brake line is sufficient - fixings should be a maximum 300mm apart. CU-NI has an endurance limit, i.e. if you keep the stress below a certain level it will never fail if it is higher it will fail though, Copper does not have an endurance limit so eventually in theory it will fail, in reality though if the stress is kept low this could be 10,000 years time, aluminium also has this same characteristic and we are quite happy to make a brake master cyl and even pedals etc out of this. As said above it really comes down to good engineering, if the pipe is not supported properly it will fail whatever it is made out of , if it is supported well both will last beyond your lifetime, there must be many thousands of cars out there where copper has been used and my suspicion is the failure rate is far lower than corrosion in the steel pipe virtually all OEMs use. The other thing about fatigue is it is very sensitive to stress raisers or notches, the crimping marks form the forming tool are a perfect example of this probably why you have seen failures in the nut collar. Personally in many years of vehicle testing I have seen a steel pipe fail in fatigue (after the clips failed) steel pipes fail due to corrosion but never either Copper or Kunifer fail. |

| |

|

|

|

|

|

Feb 13, 2020 13:26:42 GMT

|

|

Agreed - its the 'properly securing' bit thats essential. The copper pipe is particularly sensitive to this if not secured properly.

Agreed it's probably better in terms of corrosion.

I think it's sold mostly as its very soft so easy for diy shaping by hand, whereas the kunifer (or steel) requires hand bending skills beyond the majority of the population or better, it requires proper shaping tools.

|

| |

|

|

|

|

|

Feb 15, 2020 15:56:24 GMT

|

|

I have had the situation where the flared end of a copper pipe fused itself to the union, when I undid the union the pipe twisted around on itself.

|

| |

|

|

|

|

|

|

|

I'll bear all this in mind and I'll ensure it's all supported. Has anyone used silicone brake fluid? I'm wanting to bleed the brakes but I'd like to not worry about my paintwork? I've been avoiding the wiring because I have flashbacks to when I smoked it! So I decided to sort the wiper motor!  The wipers were slow moving and a little hesitant to start up which sounded like the armature needed to attention, one of the bolts that holds the motor together was sheared but easily removed - I couldn't source replacements so I managed to tap it to M5 which has fixed it. As prescribed the armature was scored but the bushes were ok so I used some 600 grit to clean the surface and then re cut the gaps and now it has a lovely movement and starts on the button!   I would recommend doing this if you have a similar aged car and it's relatively easy to do - I filmed it for reference I can't keep avoiding it - it's time to look at the wiring! |

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

|

|

|

|

|

The Cosair looks lovely

Ive always used silicone brake fluid in my oldies and so do most of my friends, my cars can stand for a very long time and the brakes have always been perfect, In 18yrs the Viva is still on the same wheel cylinders/calipers with no corrosion problems or failures, I spoke to a brake manufacturers technical guy who supply to GM and the only reason they don't use it is possible increased wear on seals/bores but you need to be well over 20,000 miles a year to notice

|

| |

|

|

|

|

|

|

|

|

I’ve got silicon fluid in the Cortina. No issues. I’ve had it in the rally car as well since I rebuilt it about 12 years ago. I have had to fit 2 handbrake master cylinders in this time but not had issues with the master cylinder or calipers. Oh, it’s in the van too.

|

| |

|

|

|

|

|

|

|

gtviva thank you,you answered a question I hadn't asked! I was concerned that the cortina will be sat for a while before its road legal but I'd like to bleed the brakes before the engine and box are put in so issues can be solved not that I think there will be any.

|

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

|

|

jonsey - I know if you're using it it's good enough for me! Any advice on how much I'd need for the brake system?

|

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

|

|

|

|

I bought 2 bottles (750ml?) for the Cortina incase I encountered problems and didn’t want to go and get more. I’ve still got one unopened and also bled the Escort with it a few weeks ago and also changed loads of clutch pipes too as they were all dodgy.

|

| |

|

|

|

|

|

|

|

|

Enjoying watching your videos, I am finding them very informative.

Good work!

Warren

|

| |

|

|

|

|

|

Mar 15, 2020 10:29:06 GMT

|

|

I also use silicon brake fluid in my MGB V8 and both my Rover P5Bs. The MGB is on the road for more then 10 years and never had problems with the brake fluid or the seals. On holidays i have a small bottle in the boot but never needed it.

Nice project by the way

Peter

|

| |

|

|

|

|

|

Mar 15, 2020 21:15:06 GMT

|

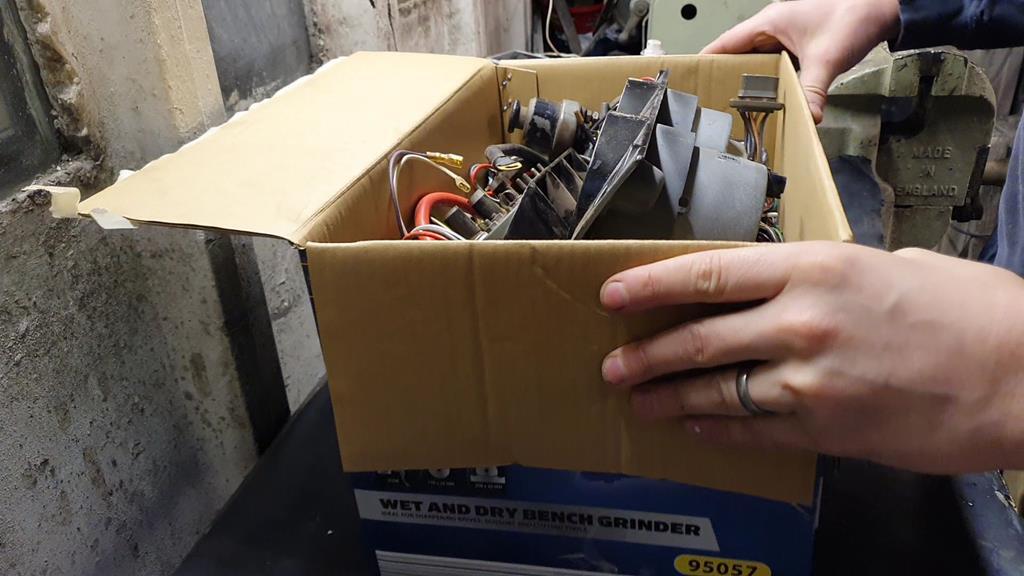

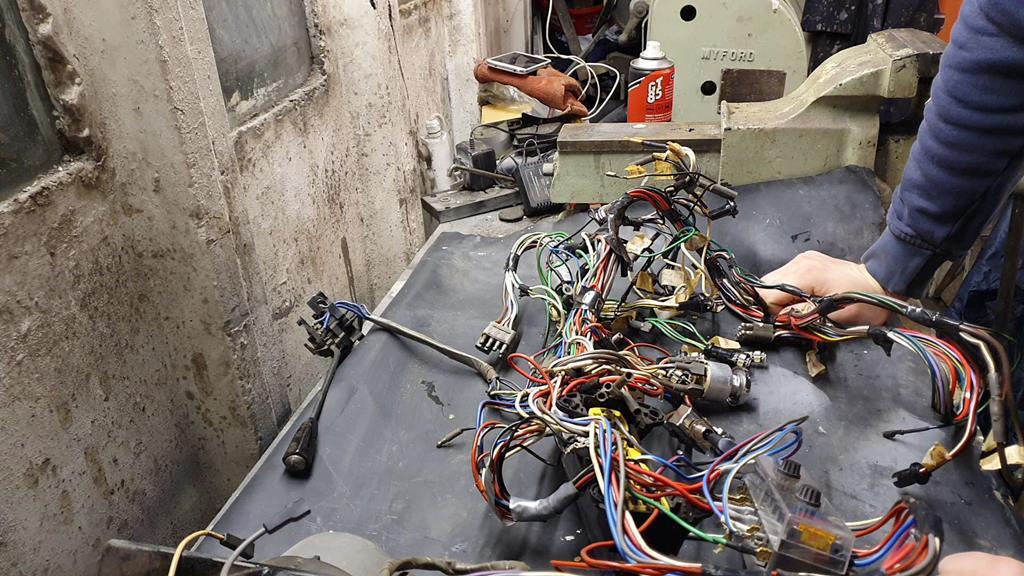

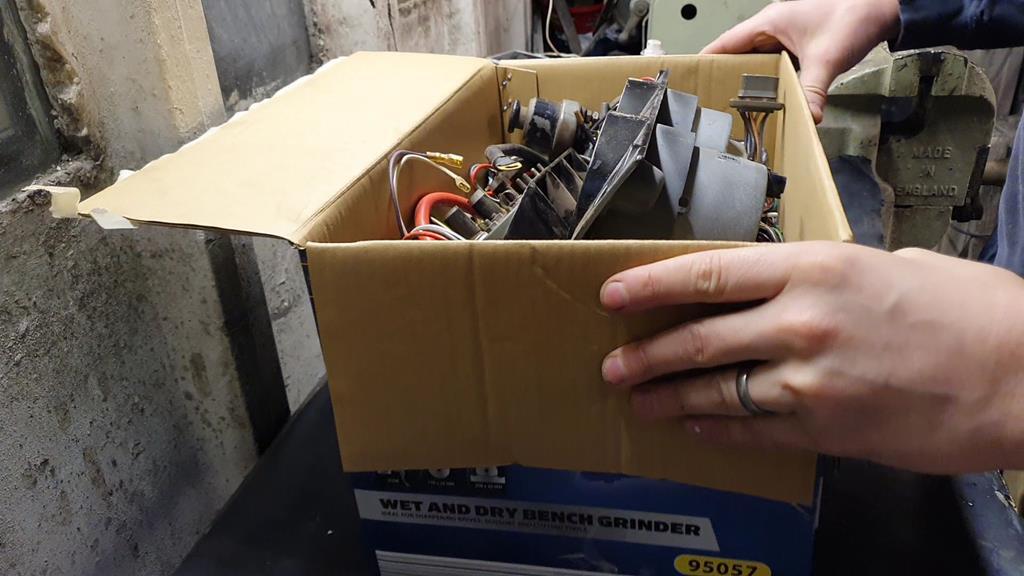

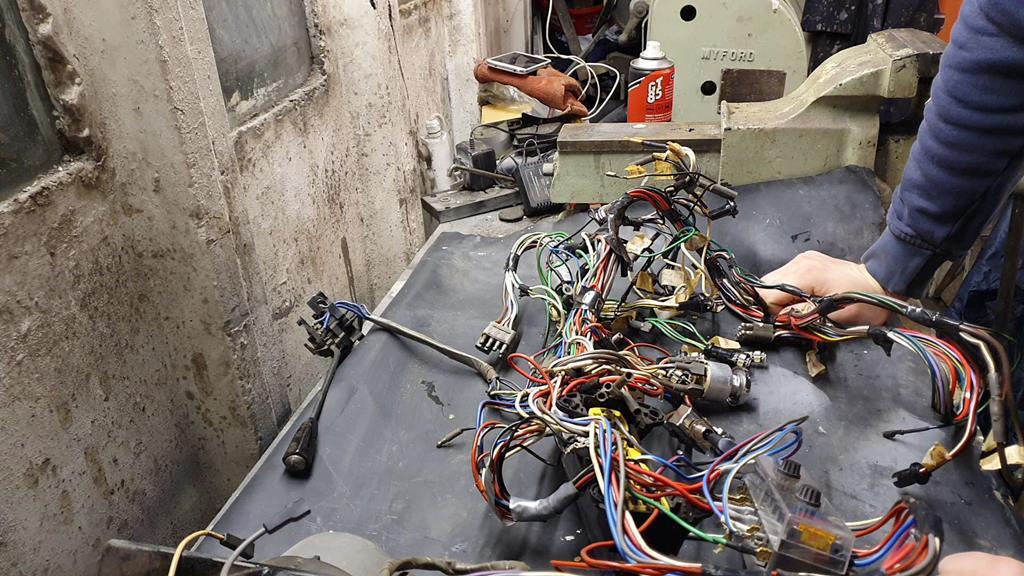

Enjoying watching your videos, I am finding them very informative. Good work! Warren Thanks Warren I didn't realise you was on Retro Rides, do you have a thread about your Mk1? I also use silicon brake fluid in my MGB V8 and both my Rover P5Bs. The MGB is on the road for more then 10 years and never had problems with the brake fluid or the seals. On holidays i have a small bottle in the boot but never needed it. Nice project by the way Peter Thanks for that Pete, it's good to know many of us have used it. I'll get some ordered. The last week has been spent going over the loom, after it was removed I put in a box in the loft it's as it was when I removed it so should be a straight forward job   The engine bay loom needed a new wire running to approximately where the oil pressure sander is as I need to fit an oil pressure switch for the fuel pump. This was easily done as the bulkhead connectors have space for 2 extra wires - you just have to drill it! The only part of the loom I never looked at was the part that goes front to back and it looks as though its had some action. M  It's not from a short as its midway along the loom between the 2 tail lights so something must have caught it. Easily repaired and wrapped  If you're interested in seeing how I added the wires in and repaired the loom - i filmed it. |

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

broady

East Midlands

Posts: 406

|

|

Mar 21, 2020 21:44:59 GMT

|

Just had a good catch up on the last page and a half. All jolly lovely work. The only thing I have of note, though I bet you already know, it to not mix DOT 4 or 5.1 with DOT 5. But as far as I know DOT 5 wont work like paint stripper, so if you do get a splash on a panel it wont hurt! I bet the damaged wire sleeves are from a welded repair at some point in the cars life. The fasty had a bit of that on the whole loom sleeve! Keep it up. Be ready this year  |

| |

|

|

|

|

|

|

|

Just had a good catch up on the last page and a half. All jolly lovely work. The only thing I have of note, though I bet you already know, it to not mix DOT 4 or 5.1 with DOT 5. But as far as I know DOT 5 wont work like paint stripper, so if you do get a splash on a panel it wont hurt! I bet the damaged wire sleeves are from a welded repair at some point in the cars life. The fasty had a bit of that on the whole loom sleeve! Keep it up. Be ready this year  I didnt know 5 was friendlier than 4. The boot loom is an odd one, I need to go over some old photos as I'm not sure I've got in in position correctly - I don't want to wreck this one too! Speaking of the loom I have now mounted it in the Cortina which wasnt as hard as I'd expect it to be although I didnt order enough loom clips!   The under dash is in place but not taped and I want to try it all before I work out the best way to tape it etc so cables arent too short or too long Last weekend I was cleaning the tail lights ready to fit them and found that all 4 bulbs are original Ford ones which I still cant get over the fact they're working after 50 years!  The tail lights just needed the lenses cleaning and new gaskets.     The battery arrived yesterday and I'm hoping to be able to have some functional stuff! |

| |

1966 Ford Cortina GT

2018 Ford Fiesta ST

Full time engineer, part time waffler on Youtube - see Jim_Builds

|

|

|

|

finding you have no brakes at 80mph in the middle lane of the M25 is quite exciting

finding you have no brakes at 80mph in the middle lane of the M25 is quite exciting