|

|

|

|

|

I'm planning on an engine swap into my little Volvo, but I'm hoping to keep the standard transmission. The hardest part is getting the engine matched up with the bell housing so i can attach it to the prop shaft and then the gear box. ( the cars a Volvo 340 with the gear box at the back) I'm still in the planning stage, so nothings been bought or chopped up yet (except the car  ) so I'm wondering what the best way to get the 1.4 volvo bell housing onto the 4age engine would be? Would it be best to make an adaptor plate or to frankenstein the two together like in the picture below:  The red dotted lines are where i'd cut it Heres the volvo bell housing and the 4age bell housing for comparison, both looking at the side that bolts to the engine block:  ^^ 4AGE bell housing  ^^ Volvo 340 1.4 bell housing Thanks alot for any advice guys. Heres a fruity 4age to spur you on:   |

| |

Too many projects, not enough time.

|

|

|

|

RobinJI

Posted a lot

"Driven by the irony that only being shackled to the road could ever I be free"

"Driven by the irony that only being shackled to the road could ever I be free"

Posts: 2,995

|

|

|

|

|

Looking at those 2 the first thing that comes to mind would be to use the 4age bell housing, and making an adapter to go on the prop-shaft side of it, as it looks like the bolt pattern for the Volvo on that end's quite a bit smaller, so should cause less issues with bolts getting in the way of each other, and the Volvo bell housing looks deeper, so the adapters thickness could take up the difference in depth.

|

| |

|

|

|

|

|

|

|

|

That's a whole lot of work to do every time the box decides to call it a day, which i'm pretty sure it'll do quite often.

I'd leave the stock box on the engine, and fit a proper rear axle to it. I'm sure it'll be much better in the end.

|

| |

Last Edit: Nov 2, 2011 6:49:22 GMT by dude

|

|

bmw156

Part of things

Posts: 796

|

|

|

|

what about the location of the starter motor bulge? is on the opposite sides  |

| |

|

|

|

|

|

|

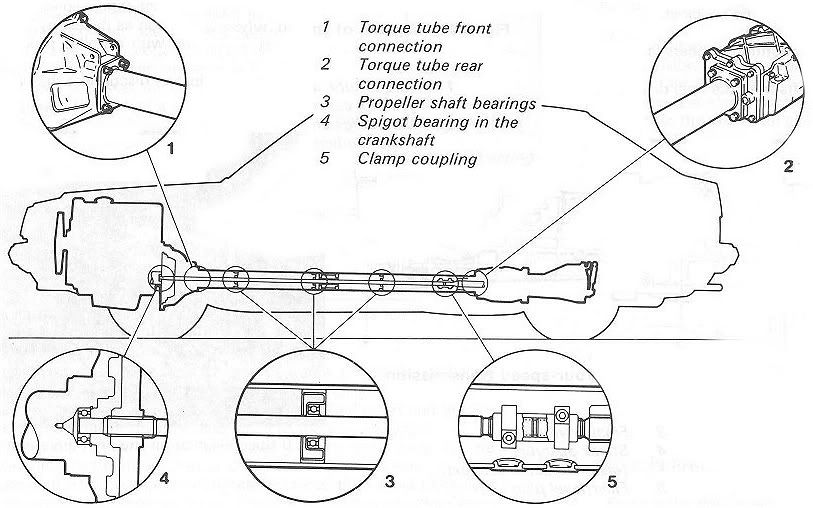

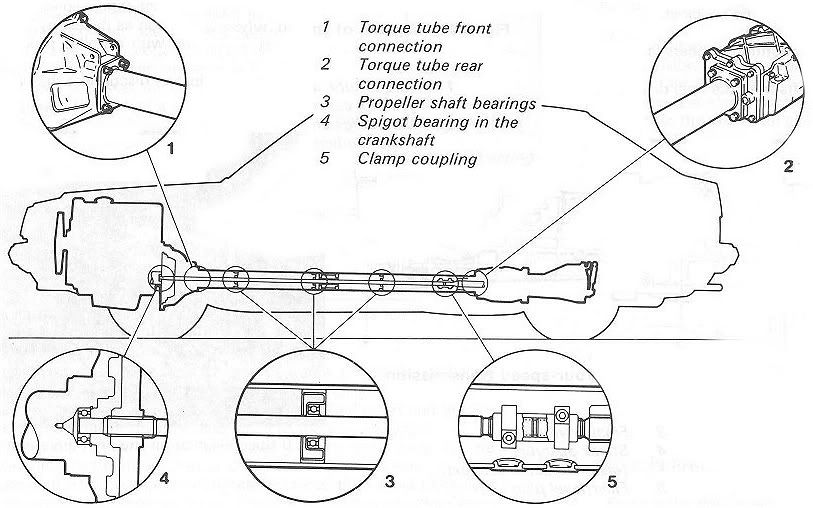

|

Thanks guys, I'll look into making a plate that will let me use the 4age bell housing and connect the cluch to the volvo prop. Would be alot easier if the gearbox was at the front so there was enough room to just swap them over but its a bit of a faf to put a regular setup in  Heres a diagram for anyone thats interested in the crazy sewdish layout   |

| |

Too many projects, not enough time.

|

|

|

|

|

|

|

|

It is actually a crazy Dutch idea, the 340 was actually developed as a Daf 77.

I would bolt an adaptor plate between the 340 bellhousing and 4Age, but getting the length right for the clutch might be a bit tricky.

|

| |

Click picture for more |

|

|

|

|

|

|

Crazy! An adaptor plate could work. Could just extend/ bend the thrust bearing arm aswell to compensate for it being further back. Would it be best to use the 4age flywheel and the volvo cluch plates so its easyer to atach the prop shaft??? Nowts ever simple but hell its going to be worth it  |

| |

Too many projects, not enough time.

|

|

|

|

|

|

|

|

Looking at what you need - Bolt the 100% complete volvo bellhousing upto your engine, making you life a zillion times easier for the clutch and starter.

Then a flat plate to bolt to the back of the bellhousing, a plate to bolt to the torque tube thingy, with a hole in the middle of both for the prop - weld a decent sized steel tube between the two plates.

Done

|

| |

You're like a crazy backyard genius! |

|

|

|

|

|

|

It is possible to cut and shut two bell-housings - provided they are both aluminium, but quite alot of effort. I did this to get a Supra W58 into my Triumph Vitesse using the front 30mm or so of the Vitesse bell welded onto a cut down Supra bell. First you have to offer up the gearbox to the engine and determine the face to face dimension you need. You'll then need to have a careful measure of both bell housings with the above in mind and work out where they match best for diameter. Cut both off with a few mm to spare and get the cut faces milled flat. Some bell combinations aren't going t Before cutting any bells I made a jig to set the position of the input shaft relative to the flange. This is a bit tricky as there's usually some sideways movement on the input shaft tip. The correct way to do this would be to use a gearbox casing and input shaft with the input shaft bearing replaced with a solid ring to hold the shaft solid. I took the centre point of the available movement. Got away with it. New gearbox and both bits of bell then go on the jig and are tacked up. Try it on for size straightness and concentricity before welding fully. Some more information and picture here under "special interest projects". www.triumphowners.com/registry.cgi?section=triumph&vehicleID=574&i=2In this case I wonder if it would be easier to make something to go at the back of the bell to match up with the torque tube. I also think that the 1.7 and 2.0 versions had a different arrangement to your pic with CV joints on the prop front and rear. It also occurs to me that there is quite a selection of interesting Volvo and Renault engines that would go in without this aggro.... Cheers Nick |

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

RobinJI

Posted a lot

"Driven by the irony that only being shackled to the road could ever I be free"

"Driven by the irony that only being shackled to the road could ever I be free"

Posts: 2,995

|

|

|

|

|

With the clutch and stuff, I'd be looking to do what I suggested and make a plate to go between the toyota bell housing, and the volvo torque tube, then use the toyota starter, flywheel, pressure plate and clutch release assembly, then try to find a clutch that will fit your propshaft, but be the right diameter for the toyota flywheel. If such a thing exists (which is more likely than you might think) then the only custom bits would be the adapter plate, and maybe some simple bits of the clutch release.

|

| |

|

|

|

|

mk2cossie

Club Retro Rides Member

Posts: 3,061  Club RR Member Number: 77

Club RR Member Number: 77

|

Adapting bell housingsmk2cossie

@mk2cossie

Club Retro Rides Member 77

|

|

|

|

I'm sure theres a good reason for the toyota lump but....

why not bolt up a renault 16v lump from a clio/19?

as the 1.4 is already the same engine used in the renault 5 anyway ;D

|

| |

|

|

|

|

|

|

|

|

Use the Quinton Hazell catalogue (download it off their site) and you can easily find other clutches that work

It gives the measurements of A (diameter of clutch) B (diameter of spline shaft) and C (spline count) for every car

eg: a volvo 340 has two different spline counts, either 20, or 24 (only the 2L engine had 24 splines), and THREE different shaft diameters (20.5, 21.4, and 23)

Without knowing what your engine has come out of, I'm just going to spuriously say, for the sake of example, a Toyota Celica, 1.6

A:200

B:24

C:21

So, what you'd need is a clutch with the same outer dimension as the toyota engine (200mm) but with the volvo centre section - so lets just say yours has the 1.4 engine, with the following specs: 190x21.4x20

even though the plate is 10mm out, there is every chance, the standard clutch plate could actually work! And looking through the catalogue, there are NO other standard clutches with the spline count... so it would have to be a "custom" clutch plate if the standard clutch couldn't cope

actually... looking through the volvo section... for the 340, if the standard clutch doesn't fit, there are NO other standard volvo clutches, of differing diamters, with the same spline count on any other model?

It's almost as if they were determined to make sure no clutches were interchangeable??

|

| |

You're like a crazy backyard genius! |

|

|

|

|

|

|

Use the Quinton Hazell catalogue (download it off their site) and you can easily find other clutches that work It's almost as if they were determined to make sure no clutches were interchangeable?? Probably need to be looking in the Renault section....... Most combinations exist already. There's even one for a Triumph Vitesse with a Supra gearbox - which was a welcome bonus!! Nick |

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

Thanks for all the help guys! Ive got a volvo bell housing in the post and I'm going to get a 4age one and compare them.  I think ill go with the idea of using the 4age bell with an adaptor plate to fit thetorque tube straight into it, then see how it goes using the volvo clutch on the toyota flywheel. If this doesnt work ill get a prop made up with the correct spline to just use the toyota clutch. There are 2 toyota clutches though, a 200 and 220mm version, so that'll hopefully mean theres an interchangeable clutch from a vehicle that dissapeared 70 years ago ;D Everyone at work thinks I'm crazy, but i love these engines  Heres lots of chrome and pikes, with a chunk of power thrown in as a thank you   |

| |

Too many projects, not enough time.

|

|

|

|

|

|

|

as soon as you get them, slap some pictures up my man!  |

| |

You're like a crazy backyard genius! |

|

) so I'm wondering what the best way to get the 1.4 volvo bell housing onto the 4age engine would be? Would it be best to make an adaptor plate or to frankenstein the two together like in the picture below:

) so I'm wondering what the best way to get the 1.4 volvo bell housing onto the 4age engine would be? Would it be best to make an adaptor plate or to frankenstein the two together like in the picture below:

) so I'm wondering what the best way to get the 1.4 volvo bell housing onto the 4age engine would be? Would it be best to make an adaptor plate or to frankenstein the two together like in the picture below:

) so I'm wondering what the best way to get the 1.4 volvo bell housing onto the 4age engine would be? Would it be best to make an adaptor plate or to frankenstein the two together like in the picture below: