|

|

|

Feb 19, 2019 23:57:45 GMT

|

:-) So do I. I am getting there, but there is just me working on it. And how much weight have you managed to shave off of yourself for the lightness cause?  (Not meant in a "you are all the pies" fashion either, just as a matter of interest) Pies......Mmmmmmmmmm As it happens, I have just started my weight shaving program. Base weight is 85.7kg and I am aiming for around 77kg (I am 6' 1") which would be my racing snake fighting weight. |

| |

|

|

|

|

|

|

|

Feb 19, 2019 14:58:02 GMT

|

This is 'Dragging' on too long now - speed up man, I want to know what she'll run! :-) So do I. I am getting there, but there is just me working on it. |

| |

|

|

|

|

|

Feb 19, 2019 13:49:03 GMT

|

Original pedal pads weighed 360gms. They now weigh 167gms so almost 200gms removed. And that is just from the pads. As it arrived from OBP.    |

| |

Last Edit: Feb 19, 2019 13:50:07 GMT by nalesutol

|

|

|

|

|

Feb 19, 2019 10:16:03 GMT

|

Nah, halfwits put white bulbs in yellow bulb holders, I'm a wholewit as I put orange bulbs in a white bulb holder  Surely that would make you a nowit? :-) |

| |

|

|

|

|

|

Feb 18, 2019 19:28:56 GMT

|

In order for throttle pedal to clear the top of the footwell I needed to trim around 7mm from the top of the pad. I did this on the band saw and did the same on the bottom to even it up. I then spied my mini mill and thought as I was there it would be rude not to, so I spent half an hour removing all the unnecessary aluminium from the back of the pad. It started off at 80gms :-)  I think that I will revisit the brake and clutch pads :-) |

| |

|

|

|

|

|

Feb 17, 2019 20:30:44 GMT

|

The cast log manifold will be fine power-wise. The thing about cast manifolds is that you can make any shape you want. It is unequal but that's not really an issue when you're mashing it through a turbine. The equal length business and the 4-2-1 or 2-1 or 4-1 design details are all about making pulses accelerate other pulses as they run down the header to the rear. The idea is to create a draw-thru effect so pulses pull other pulses and accelerate the exhaust gases. Then you combine that with valve overlap where the intake and exhaust are open at the same time so the air rushing down the exhaust accelerates the air coming through the intake. But soon as you plonk a big snail in the system none of that matters any more. Turbo camshafts don't benefit from draw-through effect either, if anything... having the exhaust valve closed while the intake is open is the preference so you can stuff the cylinder with pressurised intake. I only mentioned it for weight-saving reasons. A tubular manifold will be about half the weight. Yup, agree with all of that :-) If I ever manage to use all of the available power one upgrade would be a twin scroll turbo, 4 branch manifold and external wastegate. However, that is way into the future. |

| |

|

|

|

|

|

Feb 17, 2019 19:35:16 GMT

|

Great picture and I love the van ! is it a Commer? I think that is was a BMC J2 |

| |

|

|

|

|

|

Feb 17, 2019 16:44:13 GMT

|

Just found this from way back in the late 70s/early 80s  |

| |

|

|

|

|

|

Feb 17, 2019 10:10:14 GMT

|

We used Zircotec too. Nice company to deal with. Agree. I am also using their Zircoflex heat shield material. More expensive than the boy racer stuff but worth it. |

| |

|

|

|

|

|

|

|

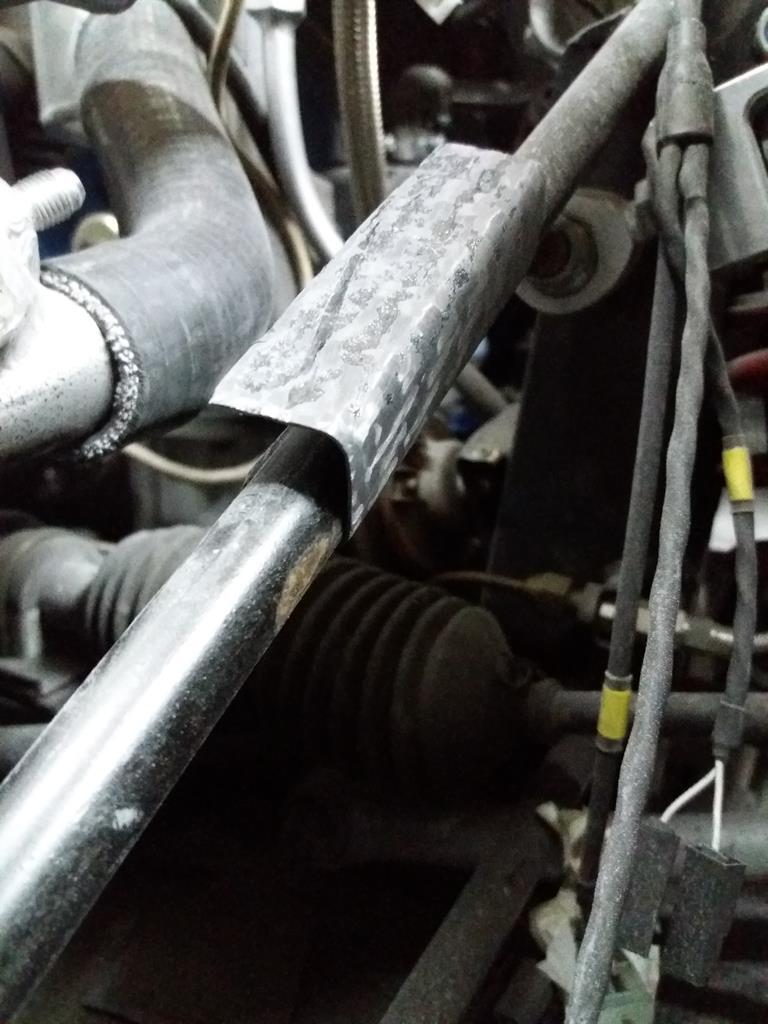

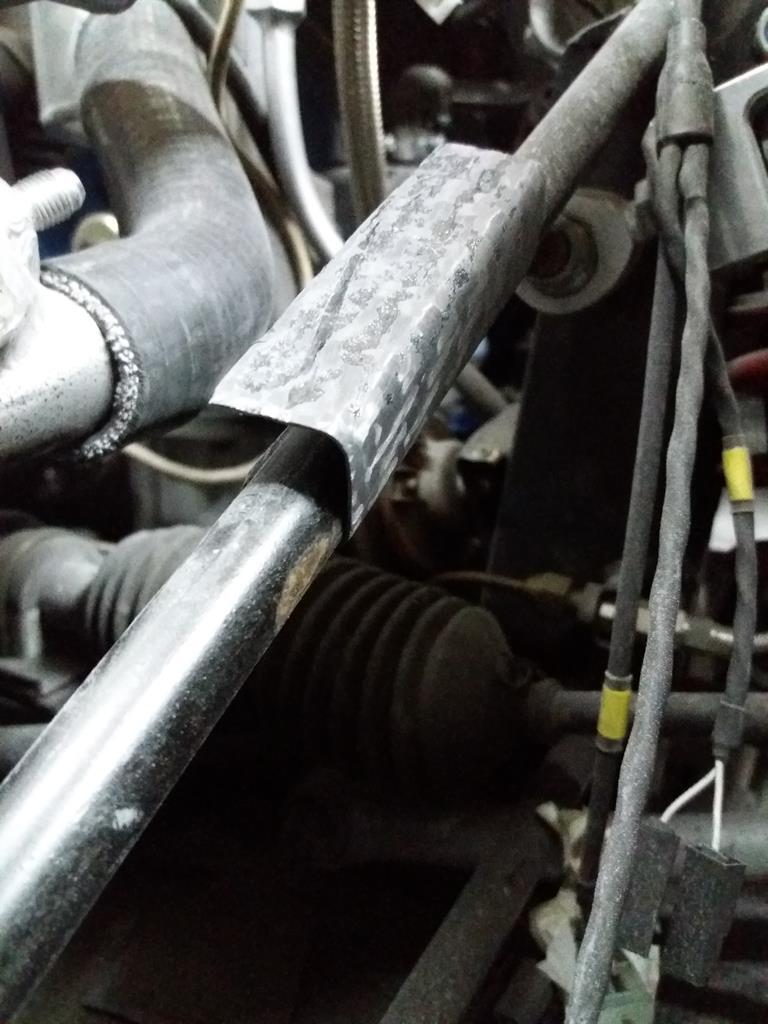

That was discussed with my engine guru. He has built many YB engines, in fact he built the first RS500 engine so he knows a thing or two about them. He recommended 3" for the 520bhp I have so that is what I went for. Complete system (apart from 4WD manifold) prior to ceramic coating.  Manifold and main pipe coated.  For that power level that would be spot on I'd say.... 2.5 is ok up to about 500hp... although the closer you get to that level the closer to the limit you'll be. Maybe at about 400-450 you'd think about 3-inch. BTW... an equal length stainless tubular manifold weighs way less than a cast log manifold. Has that been added somewhere in the 97 pages? 3" will do me for quite a while. When we built this engine space was at a premium as well as cost and I wasn't anal about weight back then :-) Space is now not so critical (flip front and no inner wings) and a tubular manifold has been designed but won't be made until I have managed to make use of all of the existing power :-) |

| |

|

|

|

|

|

|

|

Feb 16, 2019 23:54:41 GMT

|

What exhaust diameter did you go for? The boy racers think anything less than 3-inch diameter is too small. I'm of a different view and just wanted to see if a highly detailed build like this confirms my suspicions. That was discussed with my engine guru. He has built many YB engines, in fact he built the first RS500 engine so he knows a thing or two about them. He recommended 3" for the 520bhp I have so that is what I went for. Complete system (apart from 4WD manifold) prior to ceramic coating.  Manifold and main pipe coated.  |

| |

Last Edit: Feb 17, 2019 0:02:05 GMT by nalesutol

|

|

|

|

|

Feb 16, 2019 15:03:16 GMT

|

More toys arrived today :-)  |

| |

|

|

|

|

|

Feb 15, 2019 18:02:50 GMT

|

Taking James' advice, I have trimmed the side skirt to match the strake. Roughly shaped, it will be sanded to shape tomorrow. Apologies to the form over function aficionados, but it isn't all swoopy and shapely, just functional :-)  |

| |

|

|

|

|

|

Feb 15, 2019 14:55:42 GMT

|

Might stop you catching ankles / hands on it ! Some nice progress. James Good point. |

| |

|

|

|

|

|

Feb 14, 2019 22:45:48 GMT

|

Working out the fine details on the front clip and the adjacent aero. Looking at how to get the air out of the rear of the front wheel well as it is a bit of a mess. I will fill and smooth the hole and tidy up the end of the removable floor panel, but I also want to direct the air along the side of the body. To that end I have designed a strake that will also act as a support for the end of the side splitter (one item doing two jobs - Colin will be impressed :-) )   I have yet to decide whether to remove the section of splitter in front of the strake or not.  |

| |

|

|

|

|

|

Feb 12, 2019 18:19:22 GMT

|

An ill wind etc. Well, sort of. Having to redesign the filter box fixings due to the bonnet opening limiters, I ended up with a weight saving :-) New fixings (when both have been trimmed) including clips and glue, came out at 20gms the pair. The original bobbins and nuts plus the steel tags to be welded to the tubes, weighed in at over 110gms. 90gms saving may not seem a lot to most, but I am doing this over the whole car and to every new and existing part. Everything I do is subjected to the same question, can I make it lighter but still functional and safe? Original car with the Lotus twincam engine weighed exactly 700kg wet. I now have a much heavier engine, gearbox and diff, a full roll cage, underfloor panels, intercooler, pneumatic system, twin fuel pumps, swirl pot, induction system (ran open trumpets on the twincam), nitrous etc etc but hope to keep the car below 650kg.  |

| |

Last Edit: Feb 12, 2019 18:20:07 GMT by nalesutol

|

|

|

|

|

Feb 11, 2019 23:36:47 GMT

|

How often do you do something only to discover that is affects something else? A case in point. Finally sorted out how I plan to allow the bonnet to be pulled forward prior to being opened. Works fine but I have just realised that where the sliding restraint goes is where I had planned to mount rubber AV bobbins to locate the air filter box on to! A redesign was called for. After a little thought I came up with this. Bent up some aluminium to form patterns and threw some carbon onto them and cooked at gas mark 5 for 90 minutes. Once rubbed down they will be presentable. They will be glued to the frame and the sliding bonnet restraints will slide under the filter box.   The filter box is covered in plastic as the filter is oiled.   |

| |

Last Edit: Feb 11, 2019 23:38:05 GMT by nalesutol

|

|

|

|

|

Feb 11, 2019 22:37:54 GMT

|

|

|

| |

Last Edit: Feb 11, 2019 23:14:35 GMT by nalesutol

|

|

|

|

|

Feb 11, 2019 22:34:50 GMT

|

I've discovered in painting my imp that a workshop can be too hot. It was 34 degrees when I did my top coat and at the time I thought great.. The paint will set nicely. But I think it just went to help in creating my new awesome orange peel finish :-( Not that you'll have a problem there in the UK with 34 degree temps... In winter. 34 deg F maybe :-) |

| |

|

|