|

|

|

Sept 28, 2019 18:49:57 GMT

|

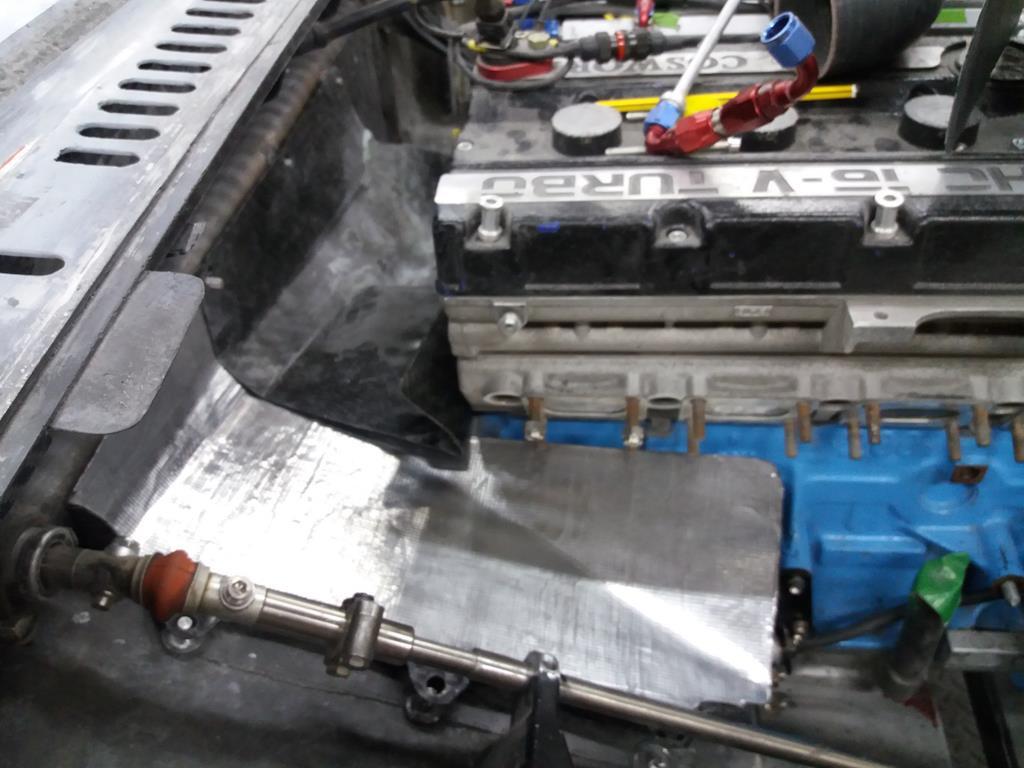

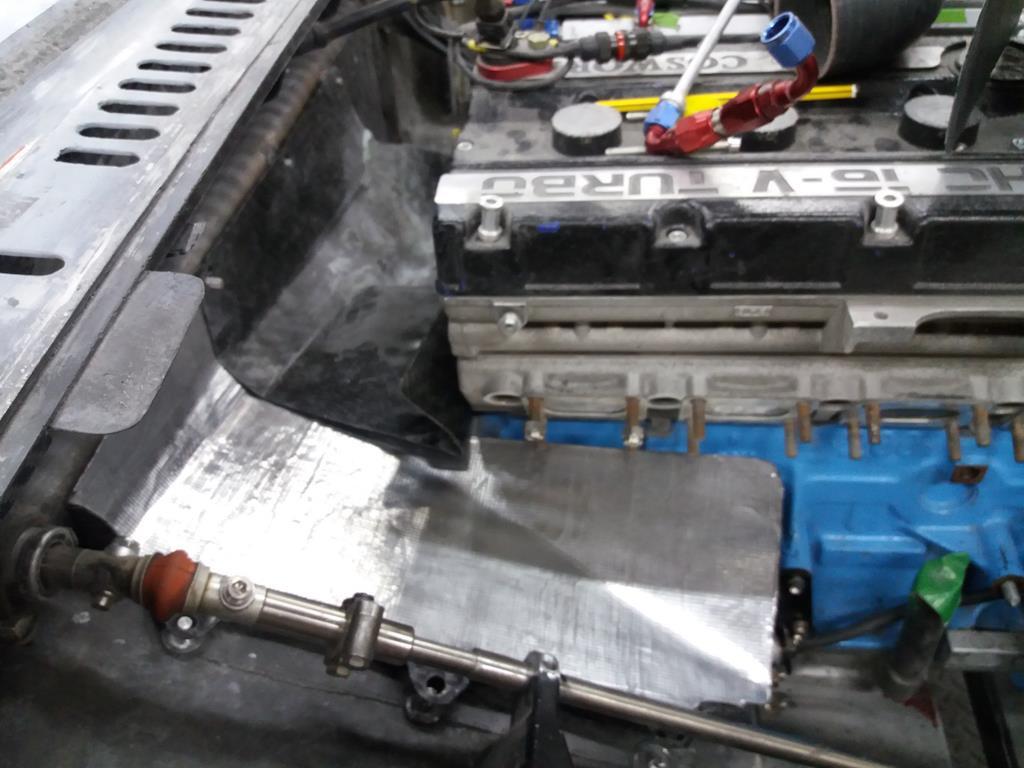

Continuing to work on the exhaust heat shields. First section completed. The second section can be seen in place but not covered on Zircoflex yet.  These three sections are part of the top cover. The section in the background abuts the turbo. The two sections in the foreground used to be one piece. When made out of aluminium I was able to twist and bend it into place behind the engine. You can't do that with carbon plus I hadn't allowed for the main wiring loom cable coming through the bulkhead (just visible in the photo above), restricting wriggle room. The easiest solution was to cut it into two and form an overlapping joint.  |

| |

Last Edit: Sept 28, 2019 18:52:05 GMT by nalesutol

|

|

|

|

|

|

|

Sept 28, 2019 18:43:16 GMT

|

I'd use Mikalor clamps on boost pipes - the weight saving of Jubilees won't be worth curse word compared to the power lost from boost leaks. That is a good call :-) |

| |

|

|

|

|

|

Sept 28, 2019 9:29:53 GMT

|

Looking as good as Swiss cheese👍 Where do you buy your aluminium and titanium bolts? For the larger, structural or visible metric bolts I use Competition Fasteners: www.competitionfasteners.com/They specialise in metric but do a few imperial sizes. Most of my imperial stuff came from the States. However, there are a lot more outlets around these days. Pro Bolt have been around for a while. I haven't used them as they aren't cheap, but they do offer pretty colours :-) For the smaller run of the mill bolts that aren't in your face so I am not to concerned about the surface finish I use AliExpress. They also offer polished bolts similar to those from Competition Fasteners. I am not a metallurgist so can't confirm that they are made from the same grade (although they state that they are). However, I have compared weights and they are identical to the same bolts from Competition Fasteners. You takes your choice and I am not recommending anyone, just stating what I do :-) www.aliexpress.com/premium/titanium-bolts.html?SearchText=titanium+bolts&d=y&initiative_id=SB_20190928012408&origin=y&catId=0&isViewCP=y&switch_new_app=y |

| |

|

|

|

|

|

Sept 28, 2019 9:09:25 GMT

|

Don't you just love working on cars! It is always the most awkward bolt/nut that breaks or rounds or shears off! Well done on getting it sorted.....and inspiring us with your work. Thanks, it could have gone very tits up. Must learn to weld properly :-) The most baffling part of this episode is why I only fitted 3 titanium bolts when I had spares in my collection? |

| |

|

|

|

|

|

Sept 28, 2019 7:45:02 GMT

|

On removal of studs, mole grips (locking wrenches) are ok but small stilson type is much better as long as you can get it in position. Stilsons grip harder as you turn. OR if you have the money an induction heater tool is the dogs danglies. You have to use what is available at the time :-) My Stilson's were too big. Keep looking at induction heaters, they are the sort of tool that will sit in a drawer for years but be a life saver when needed. |

| |

|

|

|

|

|

Sept 27, 2019 22:24:25 GMT

|

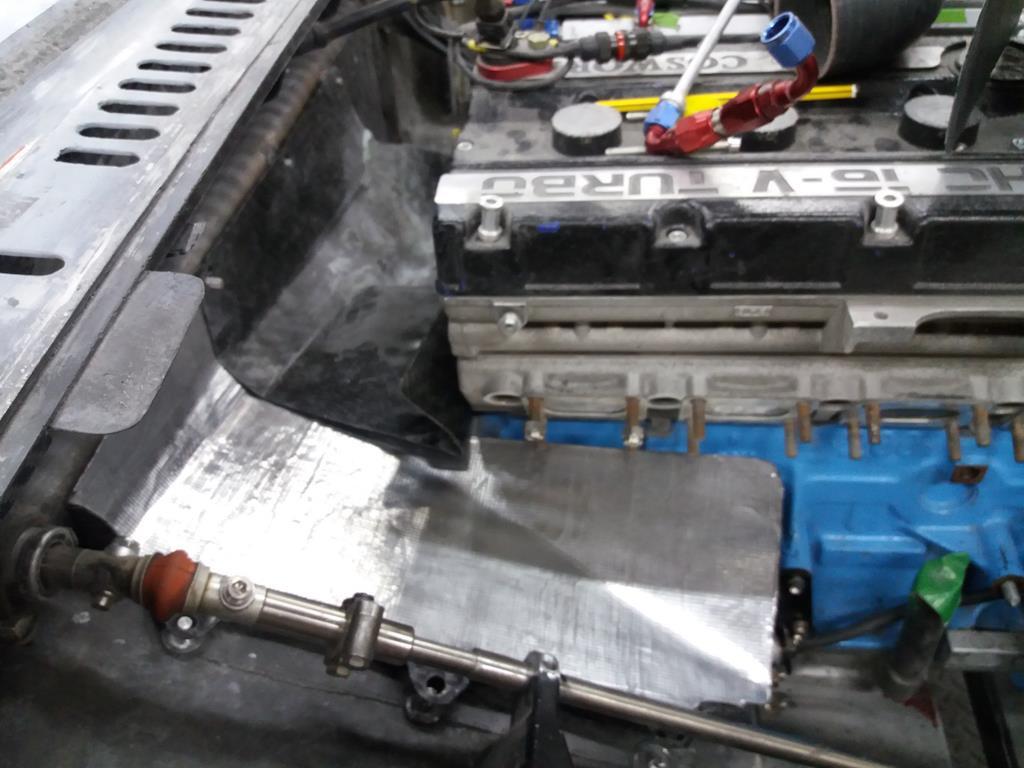

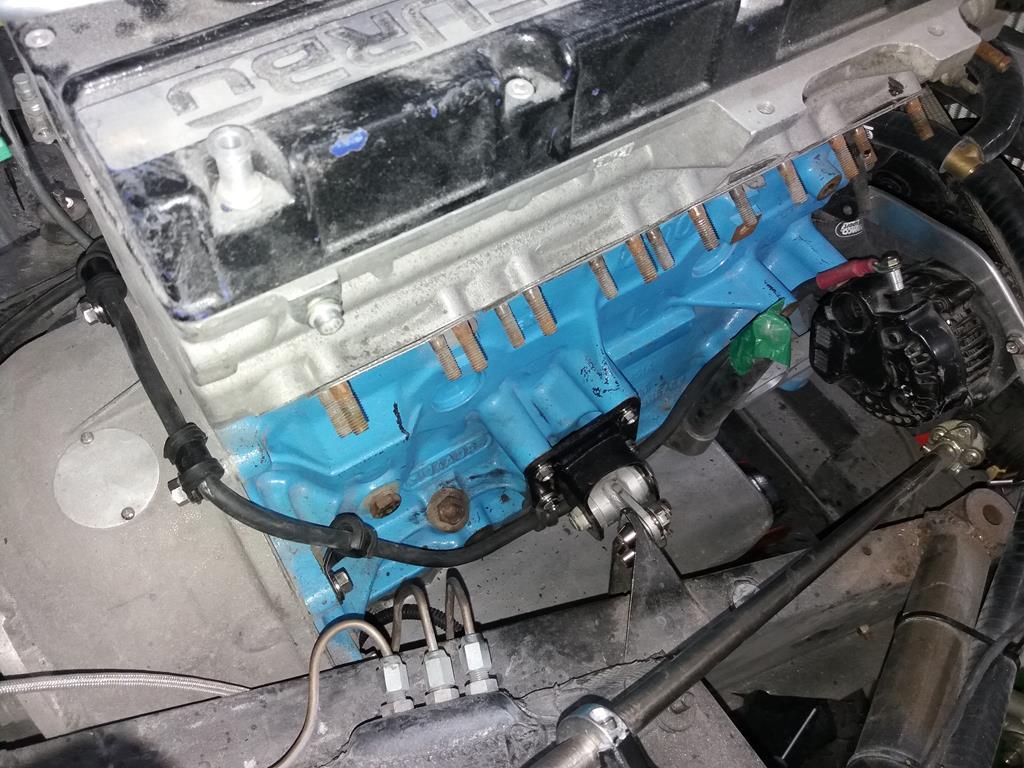

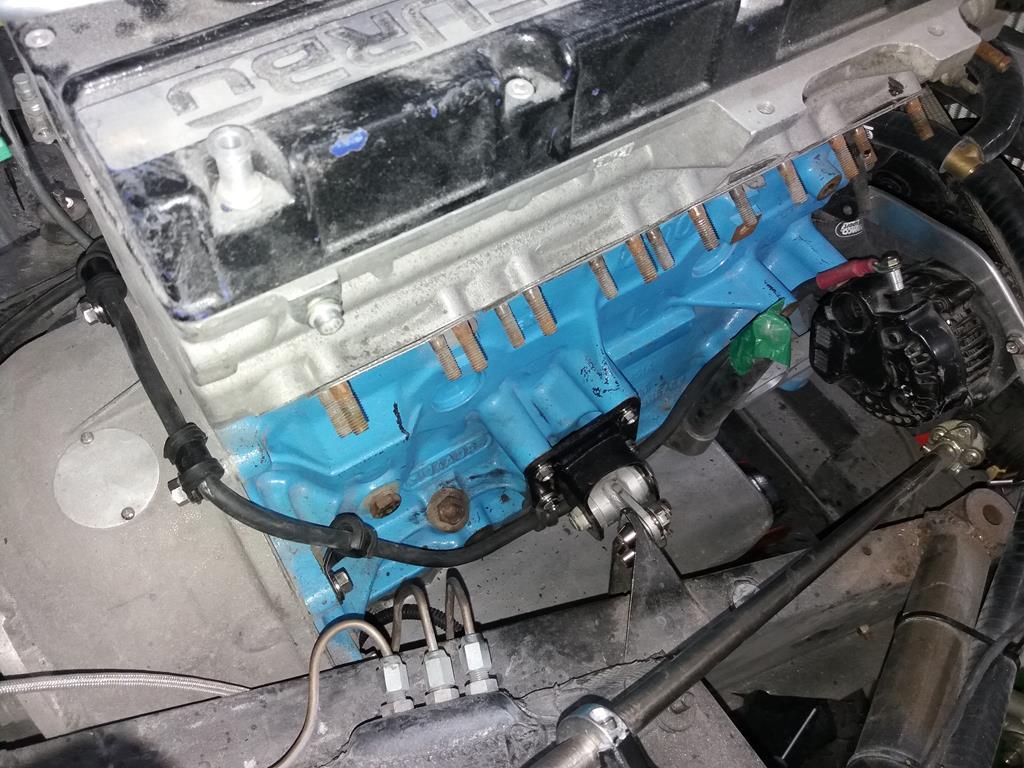

Had one of those days today. What started out as a simple bolt removal almost ended up as an engine out job. When the wiring loom was installed the large cable running from the alternator to the starter motor was looped around the front of the engine. Not only did it look rubbish there was nowhere to secure it to. This was installed when the company owner was in the States as I am sure he wouldn't have signed this off if he had seen it. Anyway, what to do about it? After studying the problem for a while I decided that the cable needed to be re-routed around the rear of the block. As the starter and alternator are on diametrically opposite corners the cable should be long enough. With some messing around the cable fitted so the next task was to sort out support. As I planned to use the bellhousing bolts I had to make the brackets out of steel rather than aluminium. No issues here. However from the bellhousing to the alternator the cable would sag so I decided to use the bottom engine mount bolts to hold additional brackets. One came out easily but, for some reason only known to the idiot who installed the engine (er, me) there were three titanium bolts and one standard 8.8 cap head, which was the one i wanted to remove. This turned into a nightmare. First off, the allen key slot was slightly rounded and the key turned. I decided to try to weld the key in but my welding skills are virtually nonexistent so this coupled with the awkward location meant I only managed to burn through the key! Right, what to do now? Tried hacksaw on the head, no luck. The wheel of death was too big to safely use but I then remembered that I had recently bought a long reach windy grinder. This very quickly removed the head so I was able to remove the mount. This left approx 5mm of stud to work with. Mole grips just turned on the stud. At this point I started to think that I would have to take the engine out!!!!! Brain wave, weld a nut on to the stud! Found a suitable nut and wound it on to what was left of the stud. The thread was damaged so it was tight so some force was required to wind it on and at this point I noticed that the stud moved! unwound the nut and tried again with the mole grips. After a lot of wiggling back and forth the stud came out!!!!!!!!!! :-) Phew! Cable is now in place and I have four titanium bolts fitted :-)   As I had to make sure that the cable didn't foul the heat shield protecting the alternator I decided to finish the carbon version by drilling the fixing holes. I also changed from bolts to studs to aid installation, using rifle drilled aluminium bolts of course :-) I also installed the first piece of Zircotec's Zircoflex self- adhesive heat shield material.  -adhesiv  e  |

| |

Last Edit: Sept 27, 2019 23:03:06 GMT by nalesutol

|

|

|

|

|

Sept 27, 2019 22:07:13 GMT

|

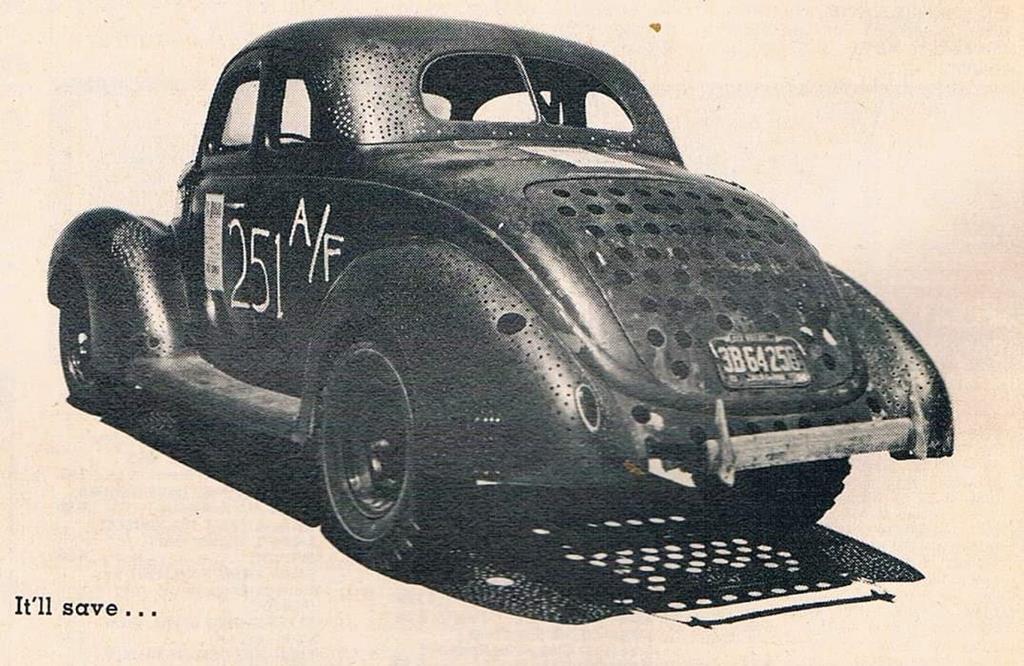

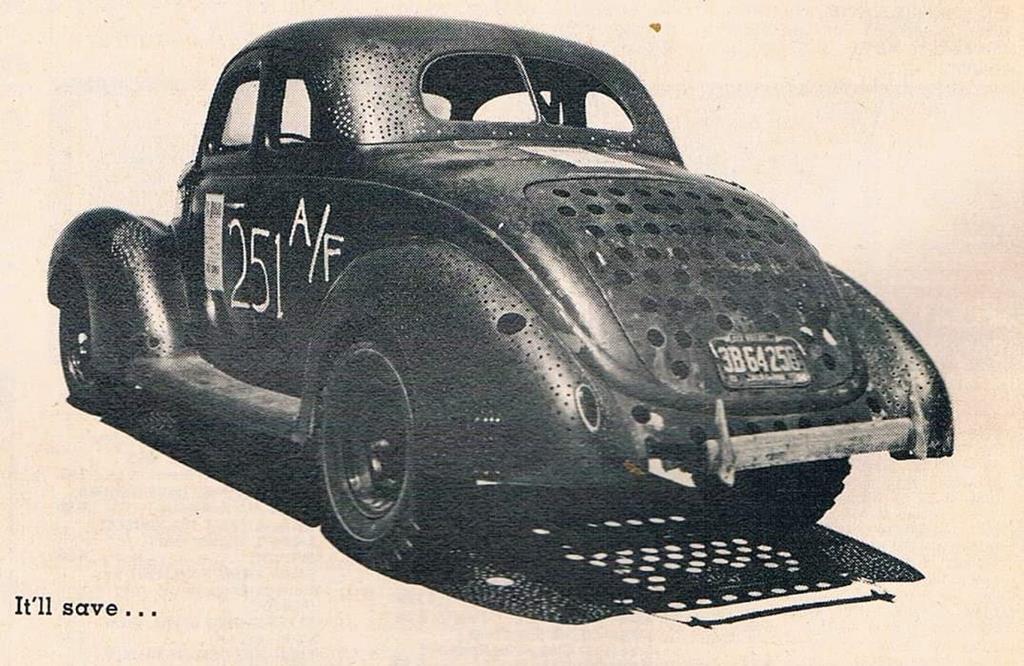

If you are talking about Aerotight all metal nuts, then nylocs are lighter due to less steel in their construction. However, I call your lightened and rifle drilled bolts and raise you titanium nuts and drilled titanium bolts :-)   Obvious really... ! Food for thought?  You want holes? I can give you holes :-)        |

| |

Last Edit: Sept 27, 2019 22:39:18 GMT by nalesutol

|

|

|

|

|

Sept 26, 2019 16:20:39 GMT

|

Ahhhh ok I was imagining ‘adult’ content! Phew! Unfortunately, no :-) Some scenes in a couple of the Essex Boys saga were filmed there. My wife and dog were in one (they found a body in a wood) and wife and daughter were 'travellers' in another. |

| |

|

|

|

|

|

Sept 26, 2019 14:34:27 GMT

|

Next door do filming eh?? The mind wanders  They do indeed. Stormzy was there a few months back filming a music video. |

| |

|

|

|

|

|

Sept 26, 2019 14:32:59 GMT

|

:-) Agreed, but they are a curse word to pull tight without cutting a finger off :-) But, much like the fan blades, how many do you really need? 😂 Stop it, just stop it! :-) I think I will draw the line at removing blades. |

| |

|

|

|

|

|

Sept 26, 2019 9:45:19 GMT

|

Strands of Carbon fiber are lighter than zip ties 😉 :-) Agreed, but they are a curse word to pull tight without cutting a finger off :-) |

| |

|

|

|

|

|

Sept 25, 2019 21:42:38 GMT

|

I have just discovered that I have been using the lightest material known to Man without realising......Drillium :-) Pointless story time. When i worked at rega the bosses used to show me what they were working on. They were playing around building what they considered the best theoretical turntable they could with NO restrictions on cost or anything. Everything was as low mass and stiff as possible. He had a sample of some kind of metal. He had a piece of bar about 2" diameter, 6" long. He said to hold my hand out and he dropped it from about 10" into my hand. I reacted as you would to try and compensate for the weight landing but it weighed nothing! It was like it was made of polystyrene or something. Felt like a really hard alluminium but it wasnt. He quickly took it back so couldnt check it out properly. I wish i could remember what it was. They had all sorts or samples of crazy materials. A little 2cm cube of some kind of daft expensive ceramic that was SUPER hard and felt very odd and other stuff id never heard of. Everything they showed me just didnt feel like anything id touched before. Was cool, wish id paid more attention 😂 I have played this trick on friends who have never experienced titanium bolts. As they are almost half the weight of standard steel bolts I get a similar reaction :-) |

| |

|

|

|

|

|

Sept 25, 2019 20:17:36 GMT

|

I'm pretty sure that bolts are supposed to go in holes, not the other way around... Only if you are not a serious weight reduction nerd :-) |

| |

|

|

|

|

|

Sept 25, 2019 20:15:14 GMT

|

I’m sure you know answer to this question. What’s lighter in weight, a nylock or aero style lock nut?! I find myself doing this everytime I pick up a bolt... If you are talking about Aerotight all metal nuts, then nylocs are lighter due to less steel in their construction. However, I call your lightened and rifle drilled bolts and raise you titanium nuts and drilled titanium bolts :-)   |

| |

Last Edit: Sept 25, 2019 20:16:46 GMT by nalesutol

|

|

|

|

|

Sept 25, 2019 17:51:09 GMT

|

No sooner suggested than done :-) Weight removed, allowing for tidying up and swarf, is 30gms. More impressive, however, is the increase in air flow potential. Assuming that my maths is correct, removing 66 of the 72 circular ribs increased the available flow area by 39% !!! The central fan housing is still held rigidly.   |

| |

|

|

|

|

|

Sept 25, 2019 14:06:25 GMT

|

I reckon you could lose quite a few of those ribs in the fan, should save a few grams. Hmmm, hadn't thought of that, good call. None of them is needed :-) I might just have to have a look at this, cheers. PS, Removing the ribs will also improve air flow, a win win :-) Sometimes you can be so close to a project that you miss the obvious, so if anyone else has any suggestions please let me know (and, yes, I will have a poo before racing :-) ) |

| |

Last Edit: Sept 25, 2019 14:11:18 GMT by nalesutol

|

|

|

|

|

Sept 24, 2019 21:06:17 GMT

|

Hose and wire clamps way too heavy so some surgery was required. Mainly used Millium plus a little bit of Lathium :-) weight reduced from 15gms to 10.5gms, a 30% reduction :-)  From 14gms to 10.5gms, 18% reduction.   And a massive 41% saving here :-)   |

| |

Last Edit: Sept 24, 2019 21:09:07 GMT by nalesutol

|

|

|

|

|

Sept 24, 2019 12:59:25 GMT

|

|

Along with a fair amount of equally light Millium.

|

| |

|

|

|

|

|

Sept 24, 2019 8:53:09 GMT

|

|

I have just discovered that I have been using the lightest material known to Man without realising......Drillium :-)

|

| |

|

|

|

|

|

Sept 24, 2019 8:09:37 GMT

|

The yellow cable ties will be replaced with black ones once I am happy with it. Good call, black is quite a bit lighter than yellow. That's why they make graphite out of it.  Yes, that's why the car will be painted with lightweight black paint....................................:-) |

| |

|

|