Who’s bored of chassis work? 🙋♂️

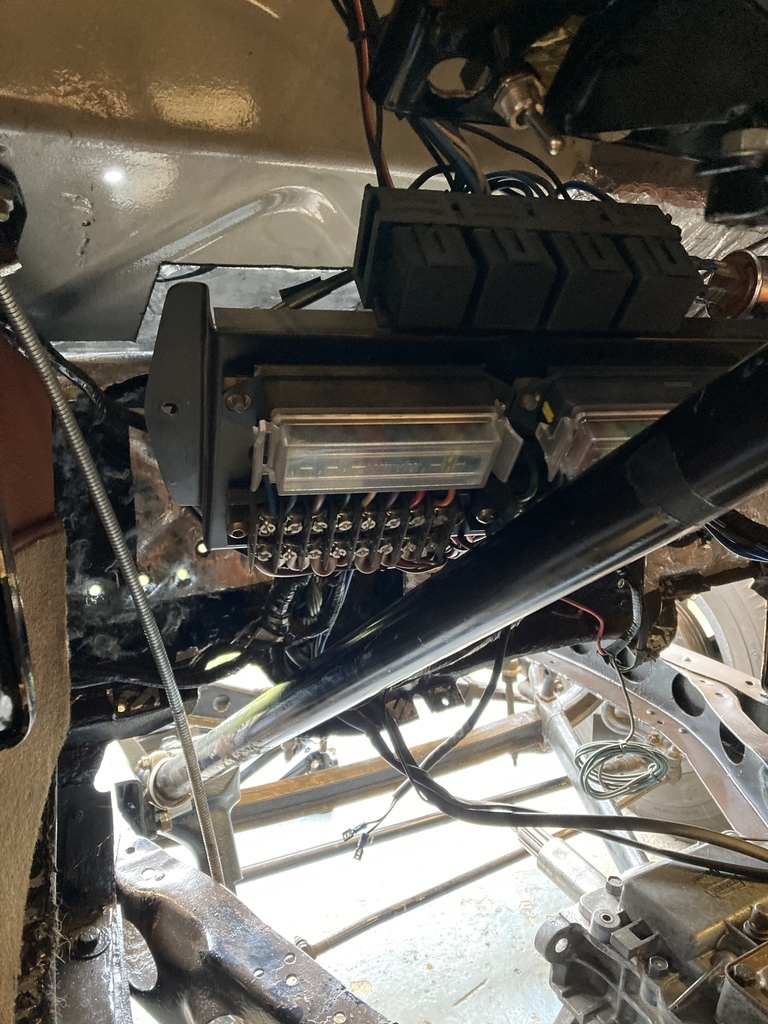

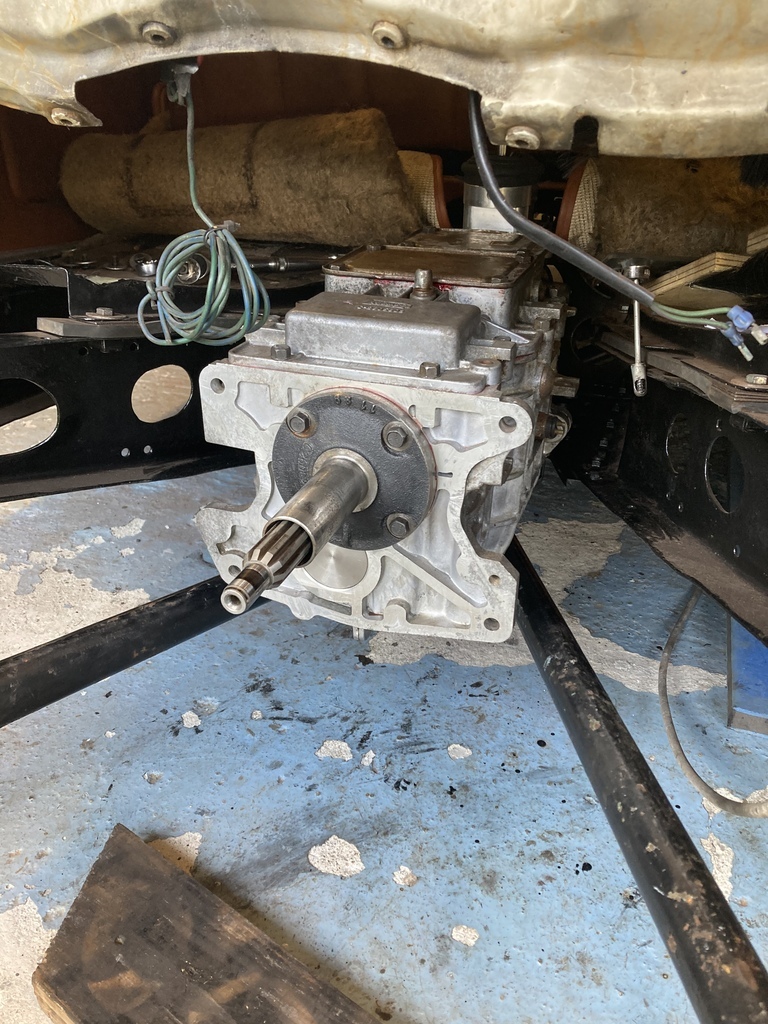

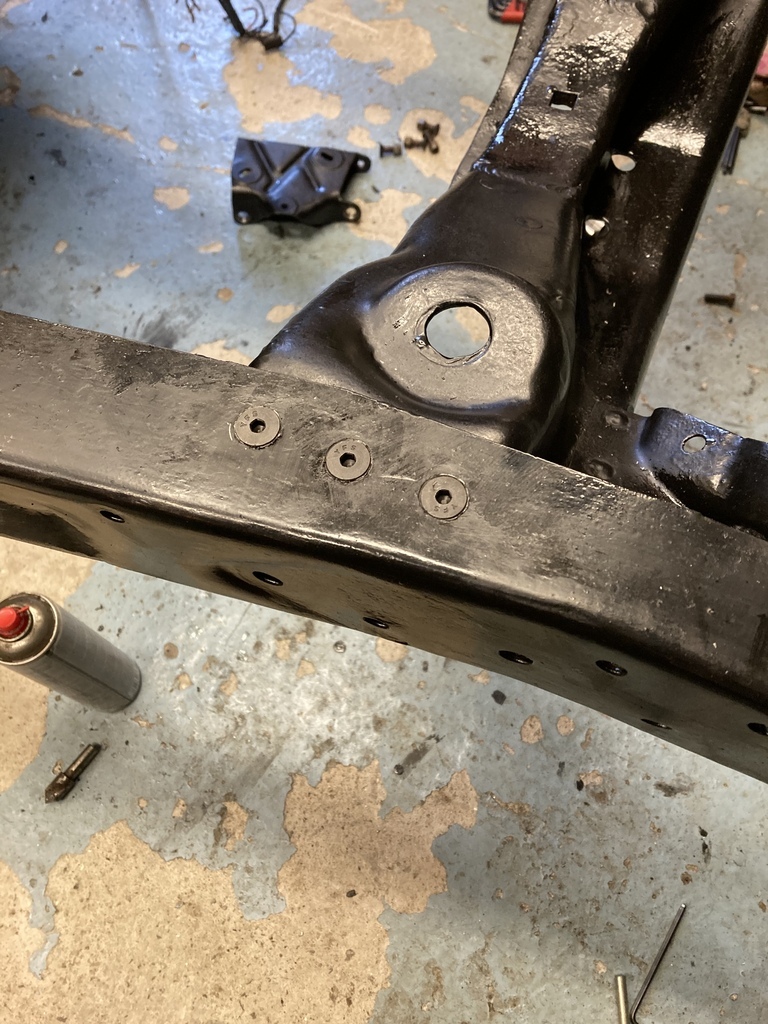

Next major job is going to be fitting the new pedal assembly which would need the steering column/box back in place to know pedal placement.

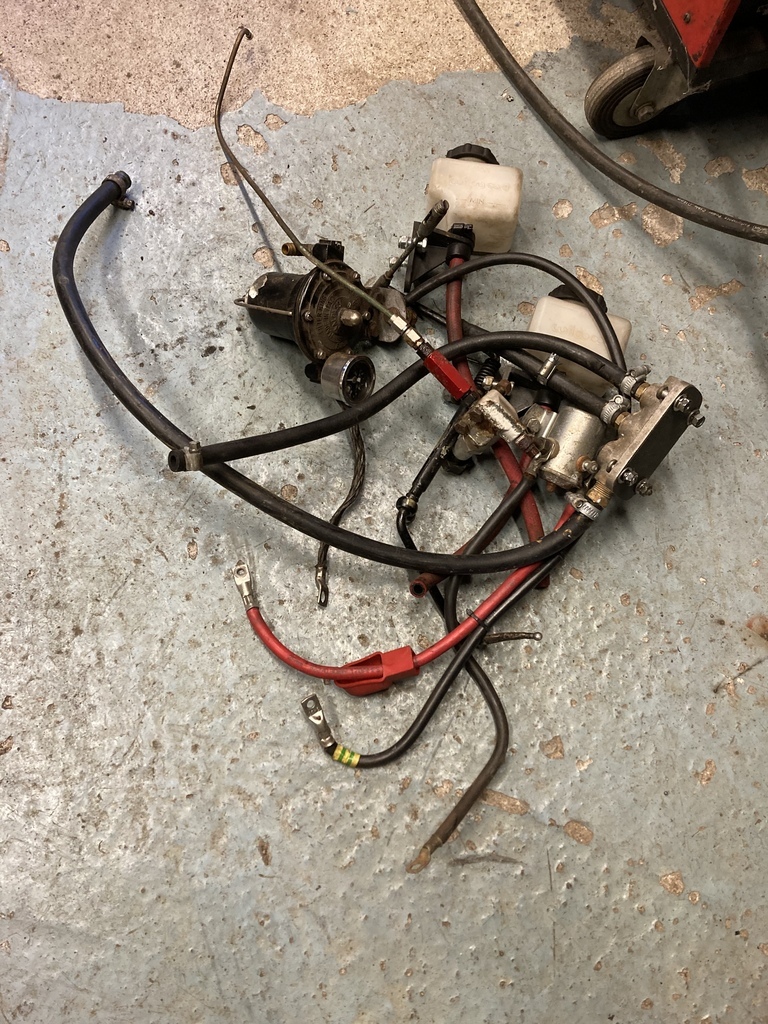

The complete steering had been removed to access the chassis but I’d also noticed that it had started to weep oil from the sector seal.

One of the exhaust header pipes ran very close to the seal so I think the heat had got to it.

Like everything else on the car the steering box had been completely gone through in the past having new bushes, new bearings, new worm and new sector roller.

Being a fairly simple thing and already on the bench I thought I’d go through it again and of course replace the failed seal.

Like an idiot, in my haste to remove the steering I’d not broke free the steering wheel taper from the column.

I had no intention of chasing it around the bench with a rubber mallet trying to break it free.

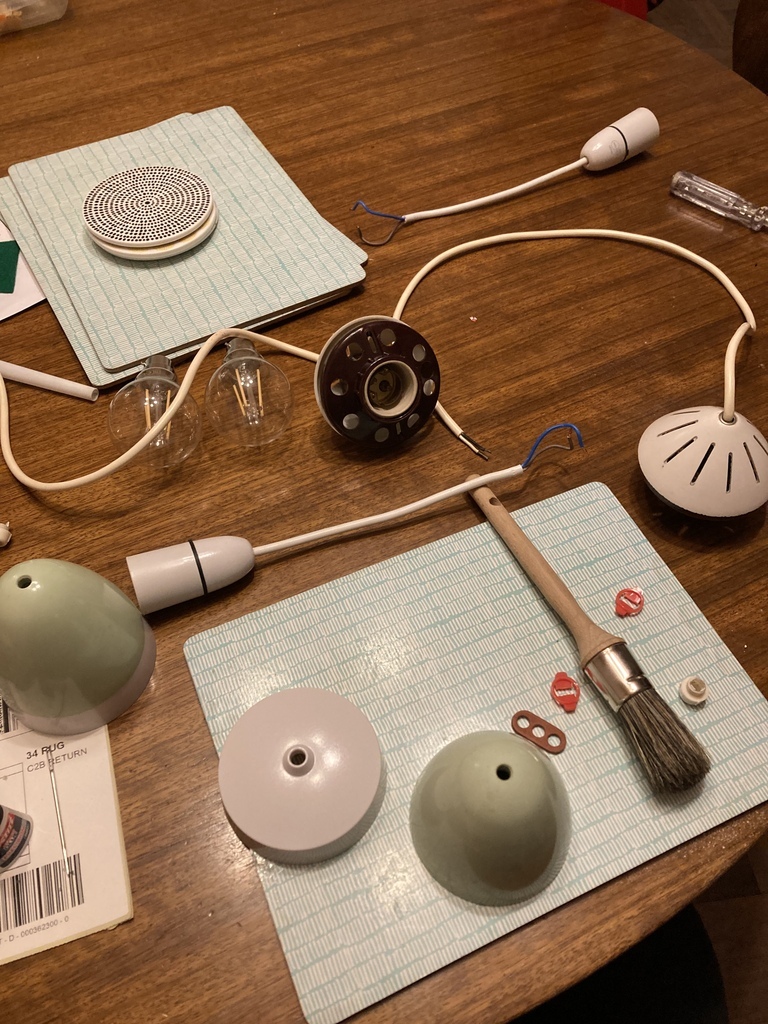

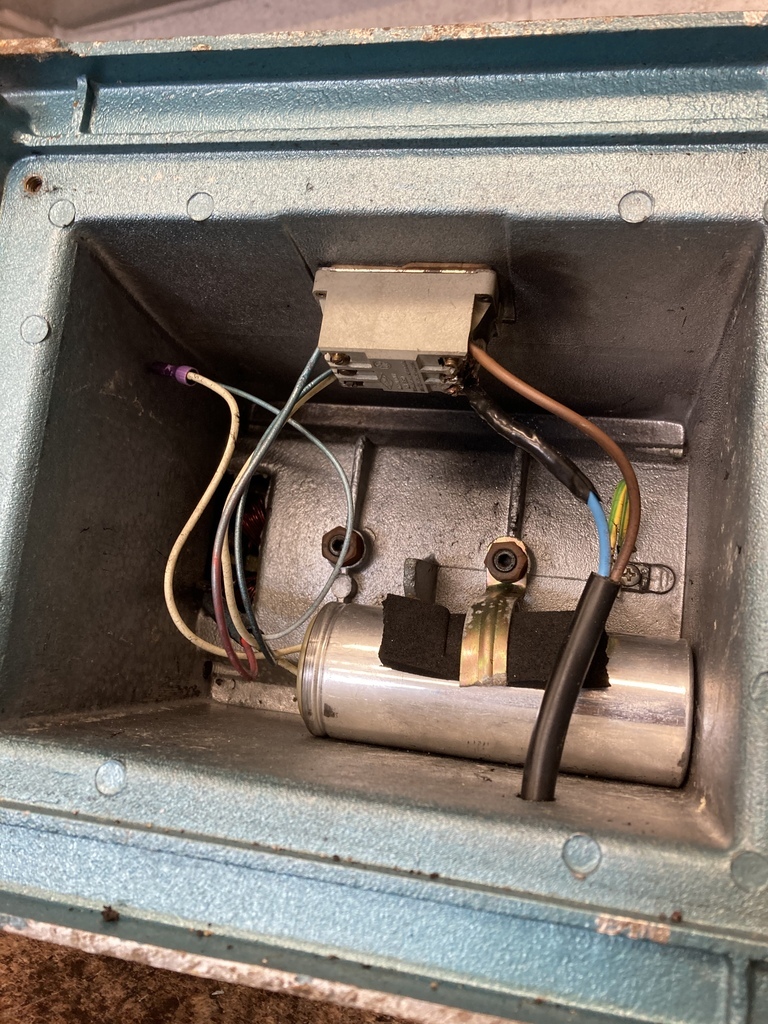

First I removed the horn button and horn wire that runs into and out the bottom of the steering box.

I couldn’t find my Pat. Pend. steering wheel puller so I spent 10 minutes making another.

Like a charm.

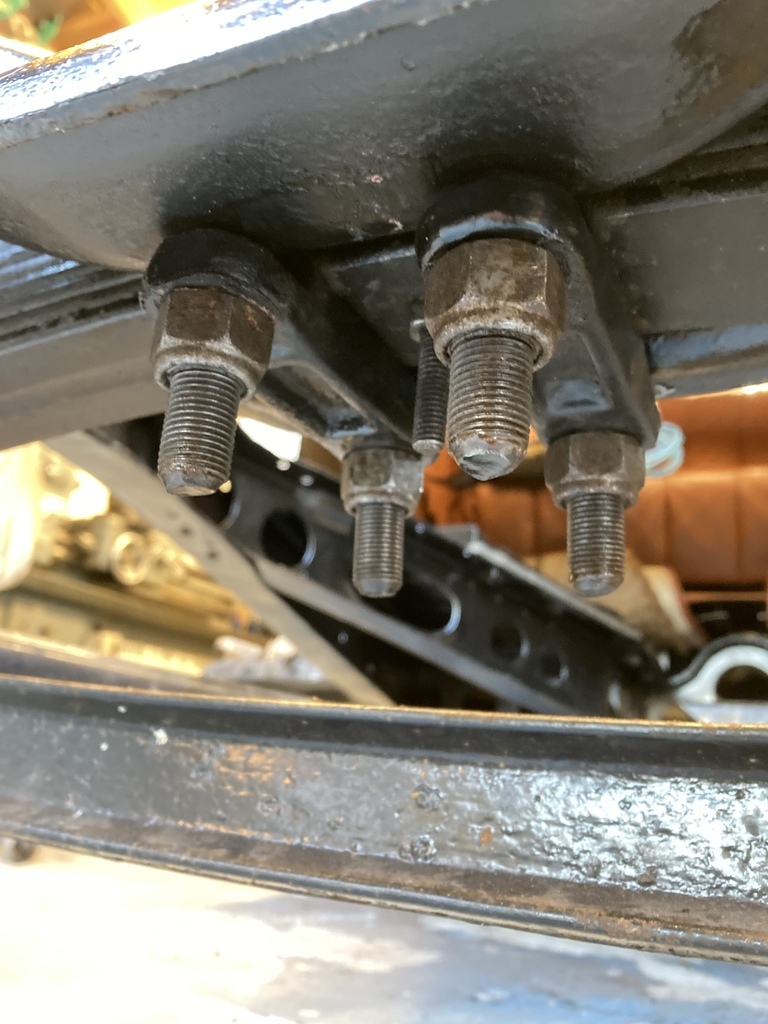

Steering arm off the other end.

The offending seal.

Steering mast can be slid off after the clamp is loosened.

Who put that wall there!

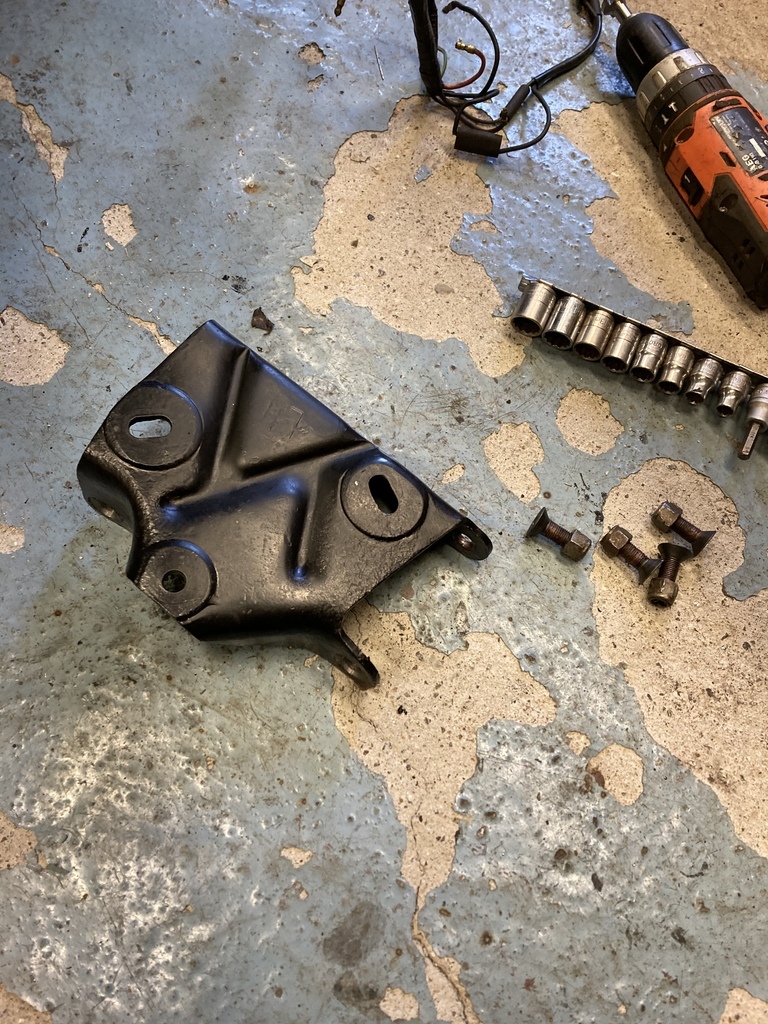

Adjuster plate comes off by removing the 4 bolts and unscrewing off the threaded sector adjuster.

The sector can then be slid out.

The column lock needs to come off as you won’t be able to slide the steering shaft out the box.

The worm end plate comes off exposing the brass horn wire tube.

Bottom bearing and race will drop out followed by the worm attached to the shaft and the top bearing. Top race will stay in place inside the box.

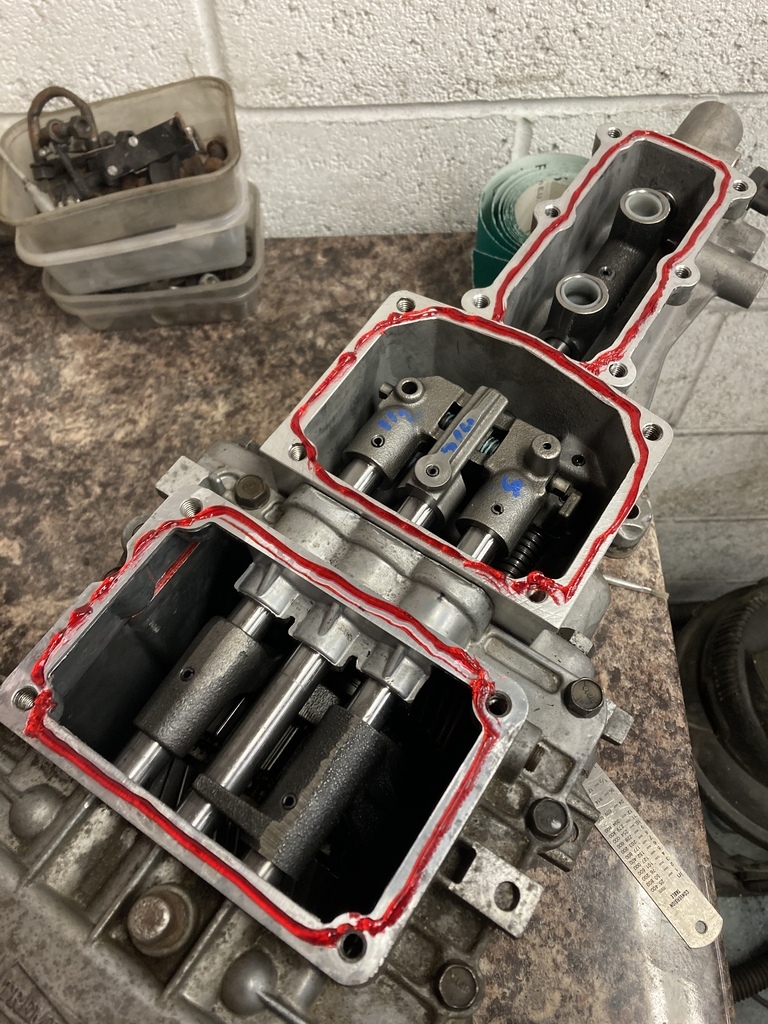

Disassembled ’40 Ford steering box.

Old seal removed. One day I’ll buy some proper seal removers.

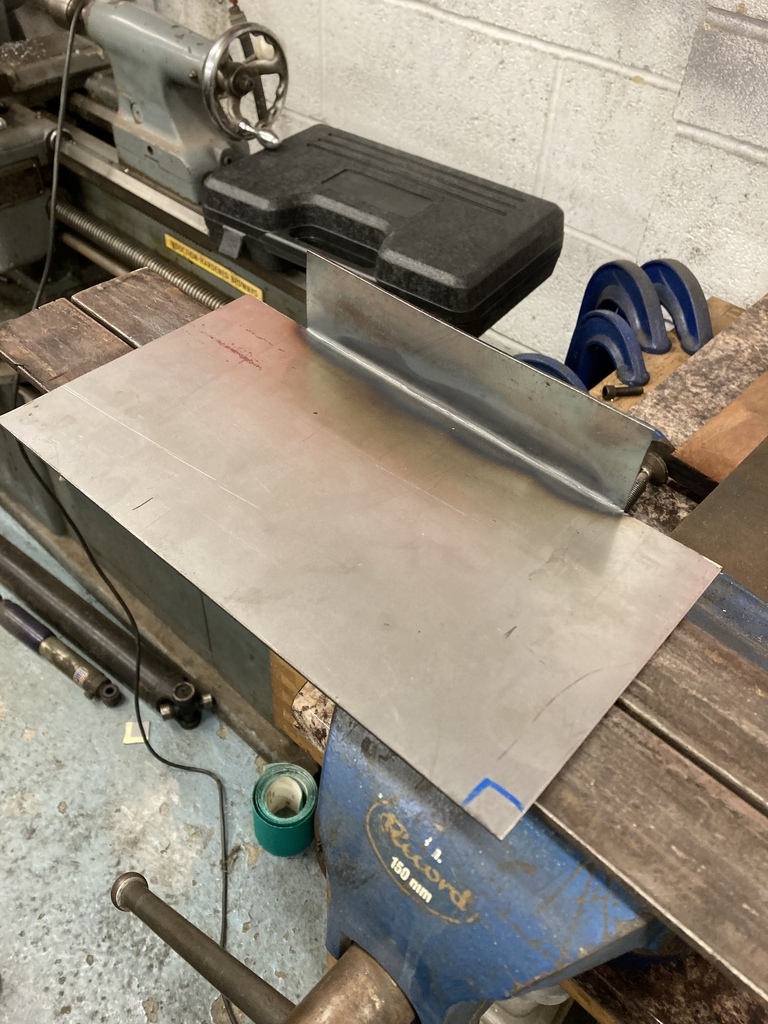

All surfaces draw filed and deburred.

New seal in.

Clean up for paint revealing a past life of being metallic gold!

Hit with the paint stick.

Time for reassembly.

The first part is to set the pre-load on the worm bearings.

This is done with gasket shims under the end plate with the worm in place.

I placed the end plate on with no gasket to get a baseline. The bolts just need a slight nip otherwise the end plate can warp.

I measured 0.022” thou clearance

I didn’t have the proper gasket shims so I used instead a Ford approved 0.024” thou Kellogg’s box.

A beam type torque wrench is used to establish the pre-load.

Most manual steering boxes I’ve come across call for a pre-load setting of around 5 in/lbs, so We’ll go with that.

Be aware this is inch/pounds NOT foot/pounds!

I got a reading of 15 in/lbs. High and you can feel it in the bearing running notchy.

I cut out a new gasket from 0.0016” thou gasket paper and added it to the Ford approved Kellogg’s gasket.

This gave me a reading of 2 in/lbs at most. Low but closer.

Going back down the.. eerrr… recycling bin got me a biscuit box of 0.018” thou.

Gasket paper plus biscuit box got me a spot on 5 in/lb of pre-load. 😆

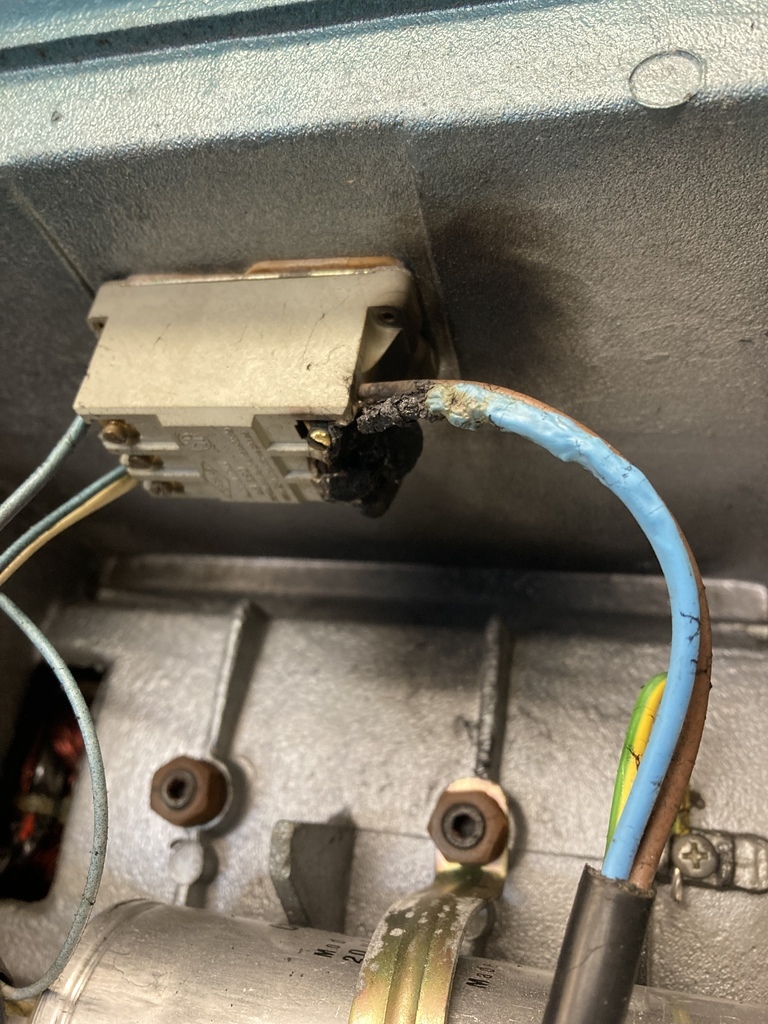

The brass horn wire tube is only crimped to the end plate and can fracture and break causing leaks.

Mine finally gave out and broke away with all the faffing.

The best solution would be to silver solder it back. I don’t have silver solder equipment so I JBWelded it back together.

Making sure it’s straight otherwise you’ll never get it back in the steering shaft!

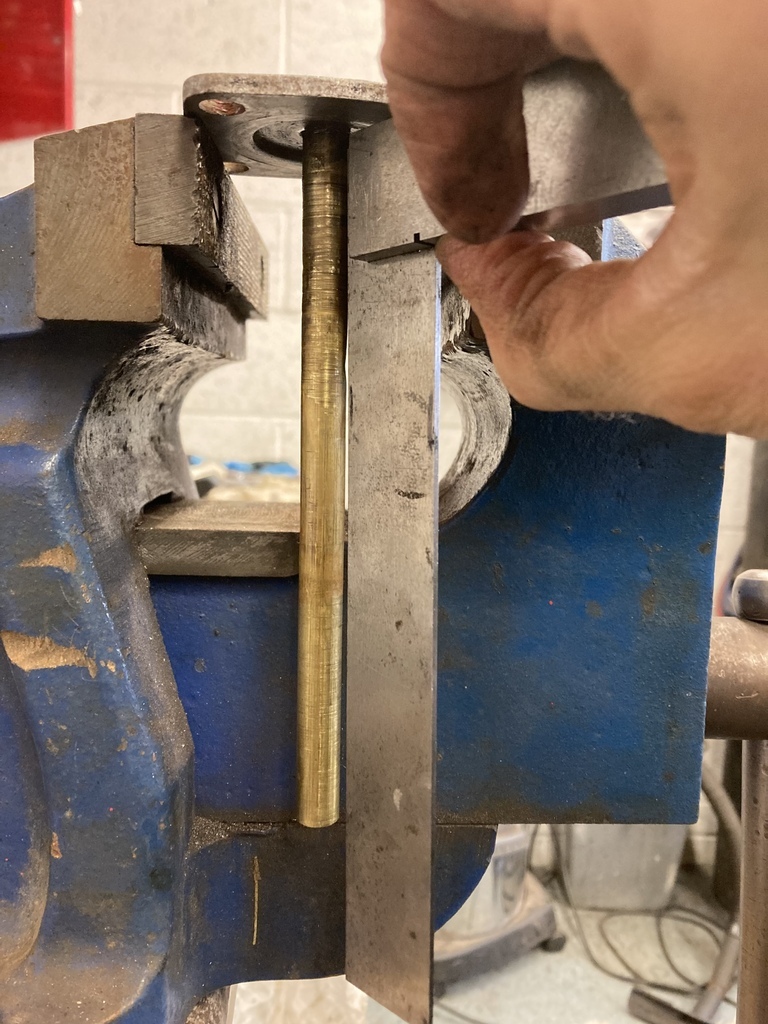

The worm side done the sector can be dropped in.

The adjuster slid in to the sector.

And the adjuster screwed back through the cover.

The steering shaft is marked so I can find the centre of the worm.

The centre of the worm has a high spot by design which slackens off as the worm moves to either lock. This is so when in the straight ahead position the car shouldn’t wander.

The sector roller engagement with the worm needs to be set on this high spot.

This is were things started going off plan.

Peering through the oil fill plug I could see the sector roller moving up and down on its shaft indicating end float that shouldn’t be there.

This small amount of lost motion meant I was already seeing 1/4” of play in the steering shaft. Multiple that again to the 16” steering wheel and you’re looking at 1/2” or more free play in the steering that would be impossible to adjust out.

The sector came out again and I measured 0.010” thou of end float.

As mentioned the sector roller had already been replaced by me in the past so it was right at one time!

I still have nightmares of spending hours grinding down the oversize hardened thrust washers on an oil stone with my bare fingers!

There was no option but for it to come apart again.

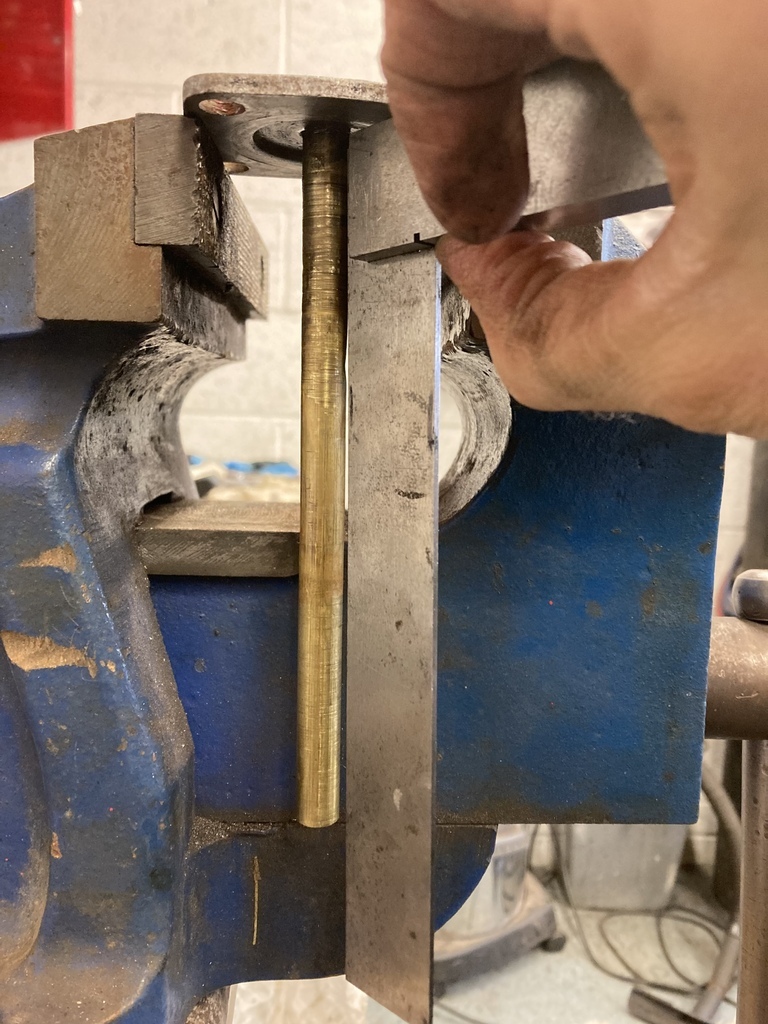

One end of the peened over pin was ground back.

I made two shims from 0.005” thou shim stock.

Try as I might I couldn’t get the second shim in.

With just the one shim in end float was down to 0.004” and trying the sector back in the box play in the steering was greatly reduced.

I took it back out and made another shim from 0.002” shim stock which I just managed to slide in.

The roller pin got two healthy tacks to lock it in.

With the diversion over sector engagement could finally be locked in by just taking up the slack.

Anymore force applied to the engagement by the adjuster will cause premature wear of the worm and roller.

The star washer locks it all into place.

Finished with the end cap and oil fill plug.