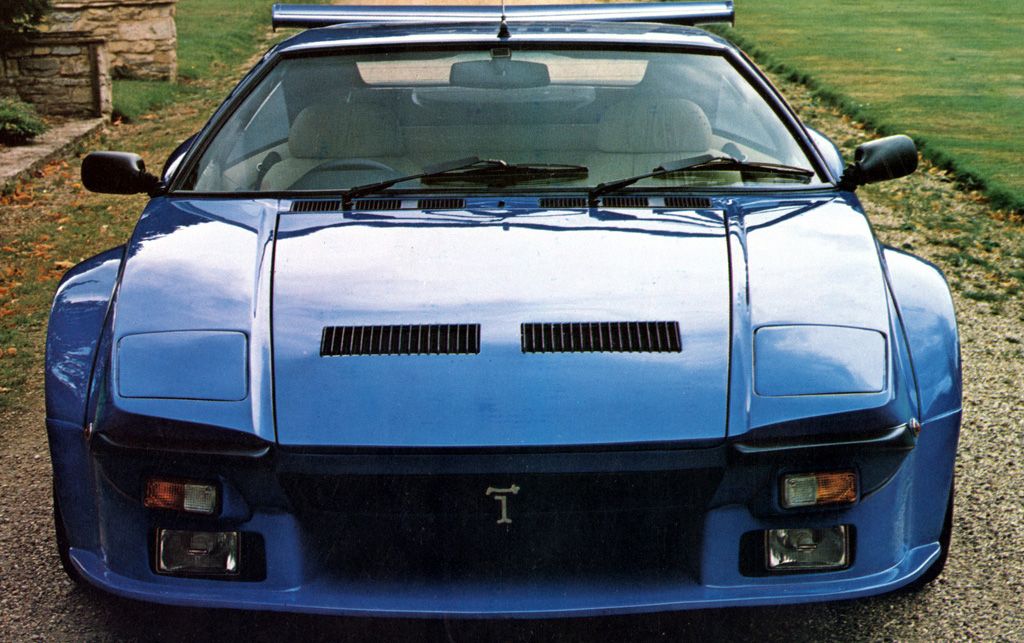

howdy folks! it's been a while, wich had it's reasons but after a quick google this popped up:

sucksqueezebangblow-juice.blogspot.com/2010/01/volvo-340-turbo.html and seeing my thread on here again makes my fingers itch to write an update. i'll try to keep it short and to the main changes

firstoff; what happened last year at the end of august, the manifold was done:

and desided in wanted to give it a clean finish in a stainless-only acid bath, that was a bad move as this was wat came out of the bath:

i won't ever buy a stainless manifold again; the basterd used mild steel for the flanges and even made polluted welds:

building a new manifold was the solution, but that would take me too long before the winter; so dropped a standard B14 in to get me through the cold months. packed a fresh MOT in january 2011 and i was anxious to get started on the new manifold and actually stage 2 of the engine bay. also did a few bits to the exterior at that time

my new manifold would be a 100% own job, so i started with drawing flanges and get them lasercutted out of 12mm stainless steel

manifold flange with first pieces of stainless welded to it

then the merge collector, no fancy tools; just an angle grinder and the TIG machine

after all the welding i ported it

and skimmed it at work, done!

with a few bends and pipe, all the pieces for the manifold

3°C outside, so time to start! put the engine bay of a 340 in the yard as a mockup

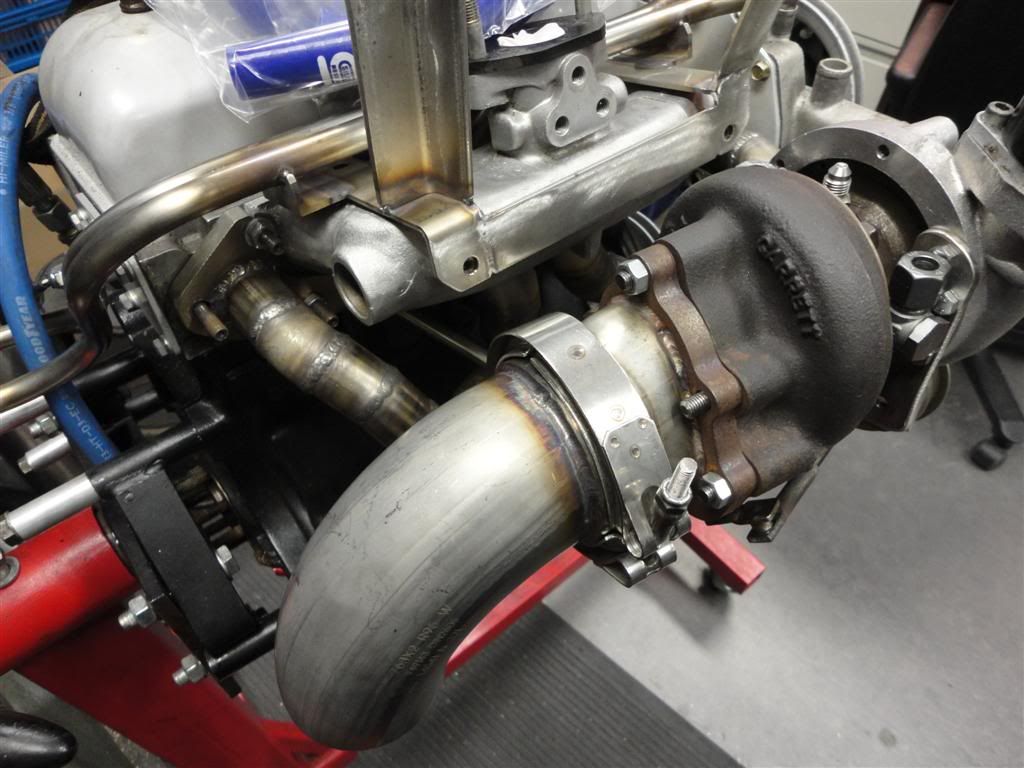

and shortly after the manifold was born

while welding

and the finished product!

i wanted something different with all the coolant hoses on the lump and stuff, so decided to bend stainless pipes to get around.

extra braces on the manifold

first bit of the 3" downpipe and stainless oil return pipe

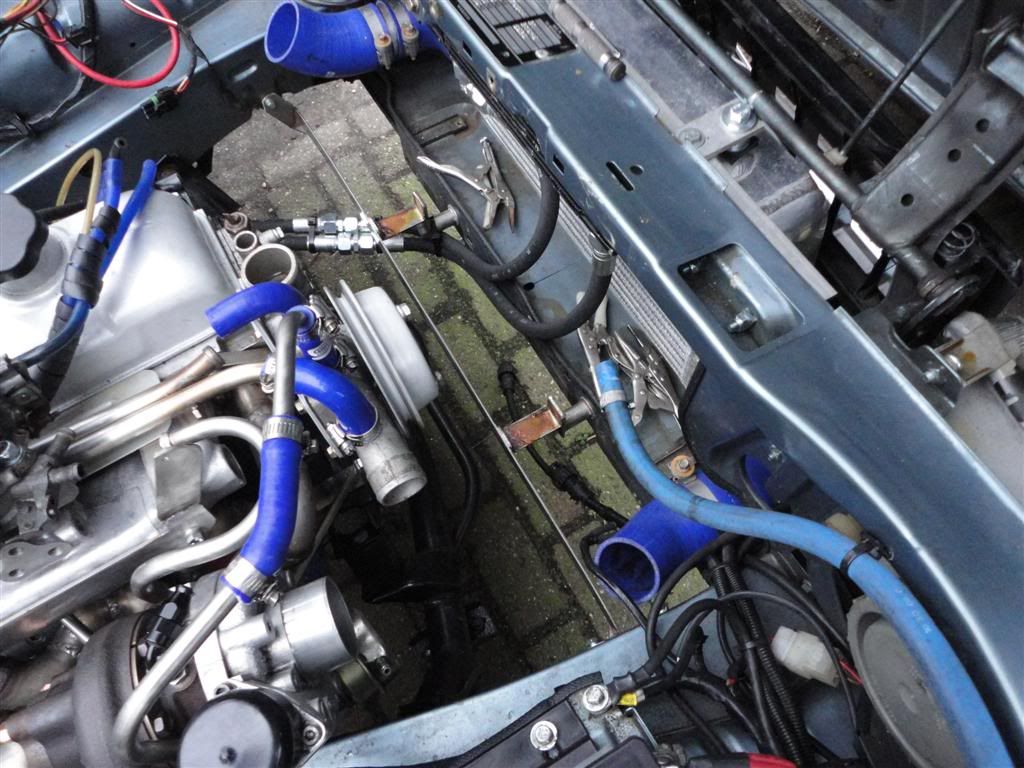

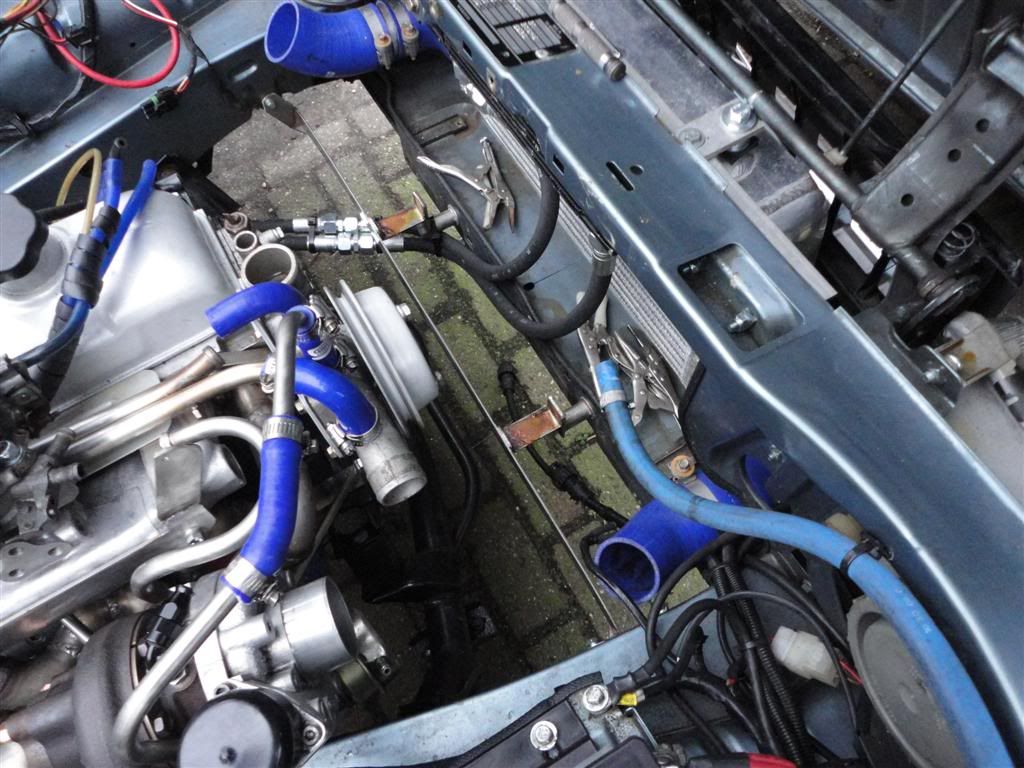

then it was about time to put the thing under the bonnet of the 340:)

first had a joke at work, with a 6 cyl turbodiesel

in with the lump

and it was in

now it was time to get everything connected and up and running, while modifying the bits and bobs i didn't like along the way

so out with the TIG welder, and to work

new lower radiatorbracket

EGT sender in the turbo

downpipe welded up incl AFR bung

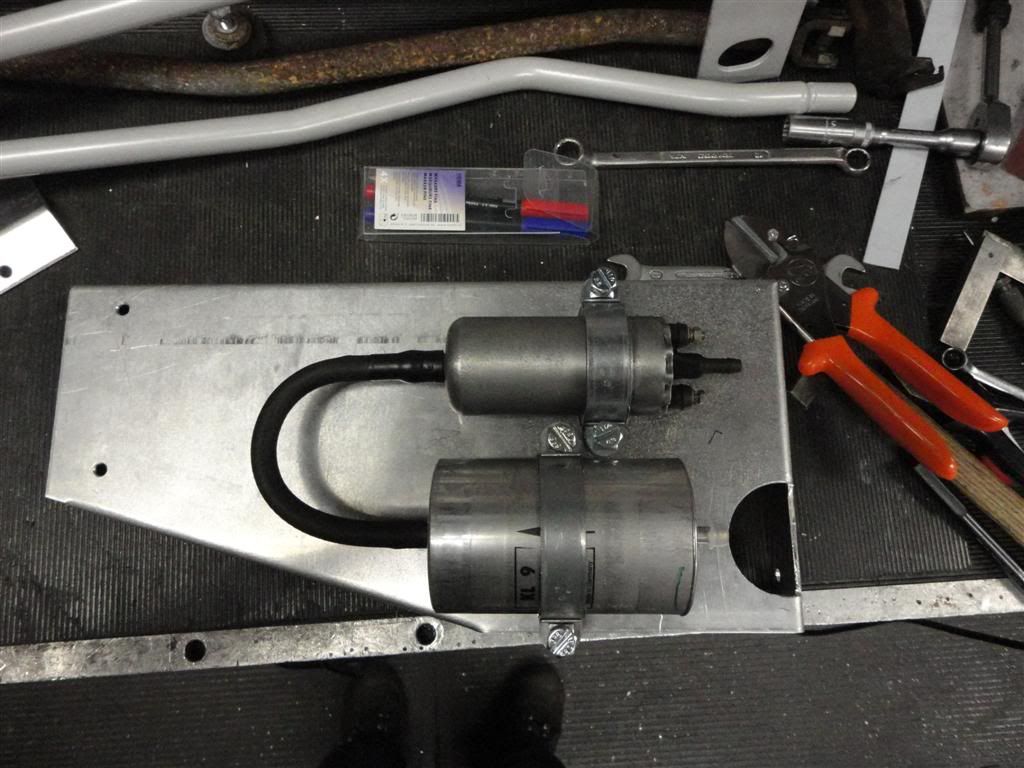

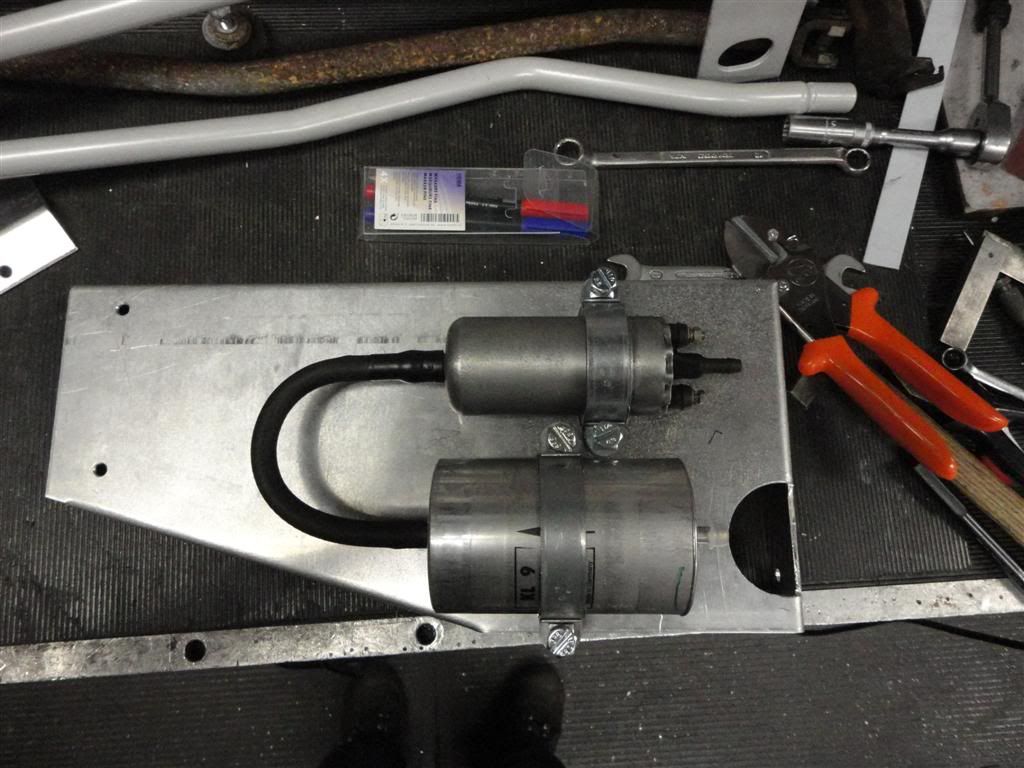

uprated fuelpump and filter

and it started coming back together...

fully stainless oil seperator, twin compartment inside

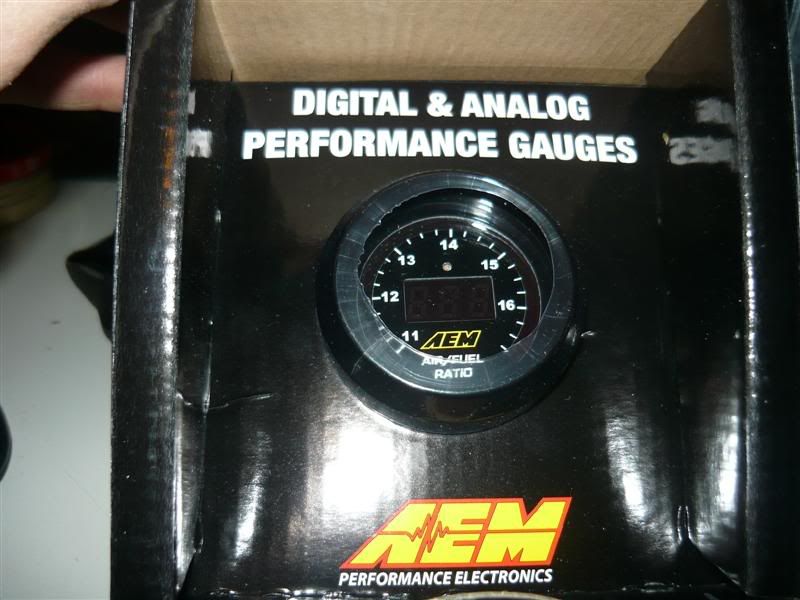

gauged dash in

doing final electrics, filling up and finally... starting!

went well, everything dry and good so i wanted to take it for a drive. after warming the oil up i tried hitting some boost. nothing happened! went home and checkt the obvious things wich concluded that it had to be the GT2560R turbo..

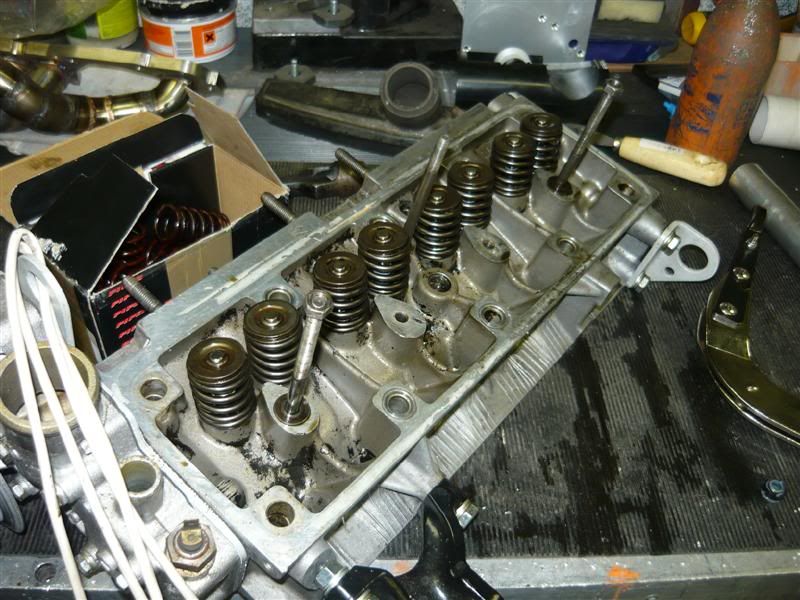

it was after closer inspection..

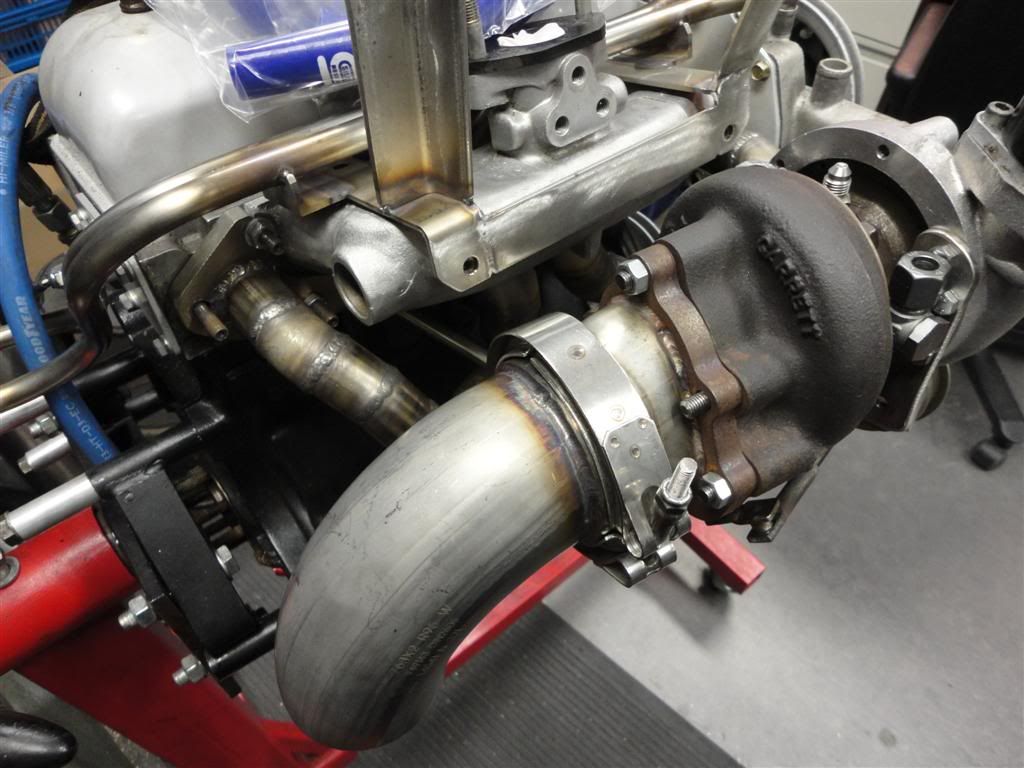

the first trackday was a week away, luckaly the guy who initially supplied this GT2560R knows his way around turboland, no more than a day later i had this sitting on my worktable

brandnew GT2560R wich turned out to be slightly bigger and with nissan flanges

but it fitted,

so made a few new parts to get this beast spooling the B14 up!

didn't want to drill a EGT bung in the new turbo, so the EGT sender moved to the downpipe.

made a new upper radiator mount

and time to spool again! what a difference. was hitting the standard T3 wastegate's 7psi and it allready felt quite quick and powerfull

nice golden glow on the stainless

and it was time for the trackday.

i was very excited an anxious to see what the car could do today at 7psi, first lap went well, before i struck my first time penalty (frontal into a cone) and i decided to scout the track the remaining run. did a small drift in front of the spectator's bend and that broke the throttle cable! it was slack up to halfway the pedal, so could only give 50% throttle:( i "fixed" it at the paddock with a few zipties, but though it worked as it should without the engine running, it resulted in a stuck open throttle on the second run. i decided to drive home and make a replacement part, i calculated that if i had it done and was back, there would be 15 min of tracktime left so one or 2 laps, joy! but unfortunatly, when we got back there and the car was running again they closed it 15min early. bigass bummer!

here are some vids (i forgot to switch the cam of so after the lap there's nothing else interesting),

first run (go to 3:00):

second run with the throttle stuck

spectators view of the second run

on the positive side of thing; no damage after that day and car got home without engine fire (like last year)

so i was very surprised to see the car in the trackday's compilation video:D:D (@ 0:25 and again at 2:15)

so with the last main hurdles out of the way, and the engine, manifold and turbo finally staying in one piece it's time to move on with it.

new coming upgrades are a original volvo 300 bodykit, new rims, fully adjustable suspension, new swaybars (front bigger, and fitting a rear one), coilover conversion, quick rack, hydr. handbrake, 6-pot front and 4-pot rear calipers and vented discs conversion, lots of tiny bits and bobs and a whole lot more things. engine wise i'm currently at 13psi and it will stay that way, for now. up next is a stand-alone injection system conversion and once it's mapped i want to see it at least break the 200bhp mark on the rear wheels (if it may not do so allready hahaha), not bad for the old pushrod 8v 1.4 if i may say so!

also i want to learn a bit of aluminium welding with the TIG machine, obviously welded IC piping and a aluminium radiator from scratch will follow to finish the engine bay off.

after i'm finished with my daily 343

with this massive powdercoating upgrade:

only rebuilding and fitting the rear axle left to do really.

once all that's done i'll get back on the 340turbo. more detailed (and even more picheavy) is the thread at volvo300mania, you can check it out from here if you want to:

www.volvo300mania.com/forum-uk/viewtopic.php?f=13&t=7946&start=270 to see the extended version of what i wrote above

thanks for looking everyone

anjo

;D

;D

?

?