|

|

|

Jun 15, 2015 16:05:42 GMT

|

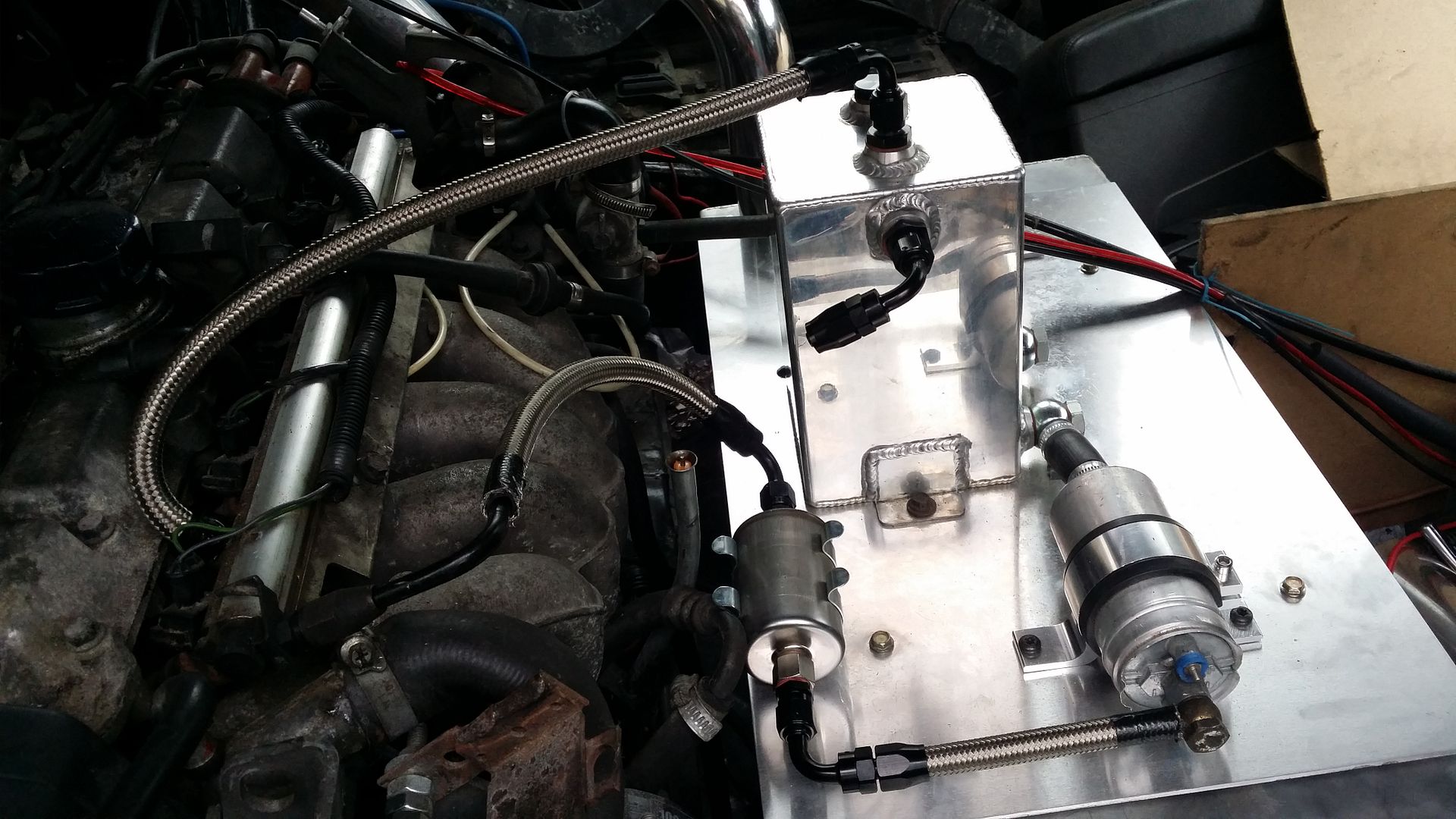

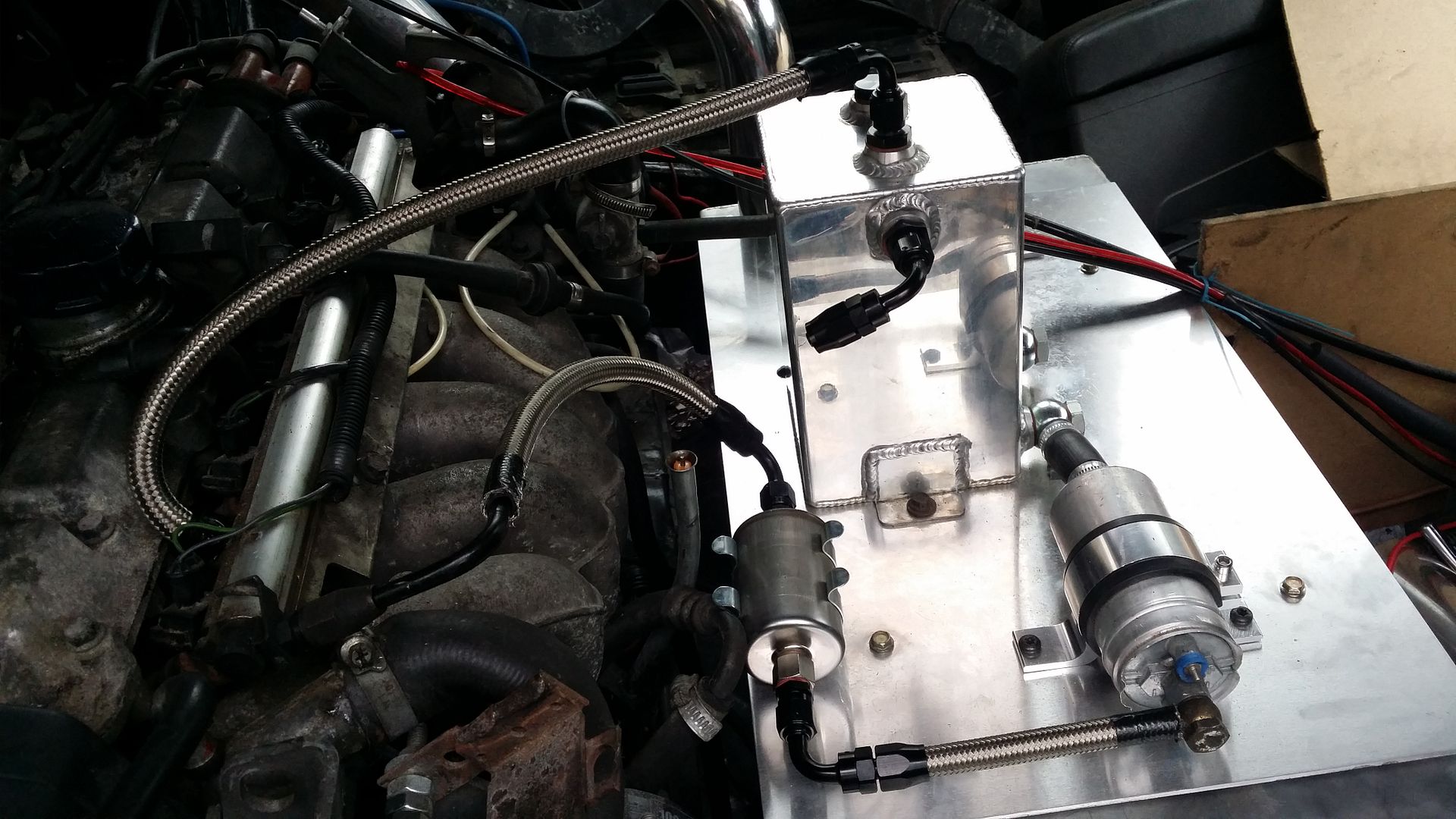

It's been years since I last looked at this likely this is a bit mad. Love those arches and that roof scoop is kinda subtle. Well subtle in the context of florescent yellow paint, 2 engines and wide arches. It's also been at least a year since I last looked at this too. Madness. Just madness. But I'd love to see this in action Thank you very much  Started on the pipework yesterday, my thumb is like a pin cushion today:   |

| |

|

|

|

|

ulver

Part of things

Posts: 67

|

|

Jun 15, 2015 19:40:55 GMT

|

|

Love it.

|

| |

'99 Alfa Romeo 156 2.5 V6  |

|

|

|

|

Jun 16, 2015 11:15:01 GMT

|

|

Have just spent all morning between calls reading this, crazy project, loving it! Some seriously good work gone into this so far, definitely bookmarked now!

|

| |

|

|

|

|

|

Jun 16, 2015 13:17:21 GMT

|

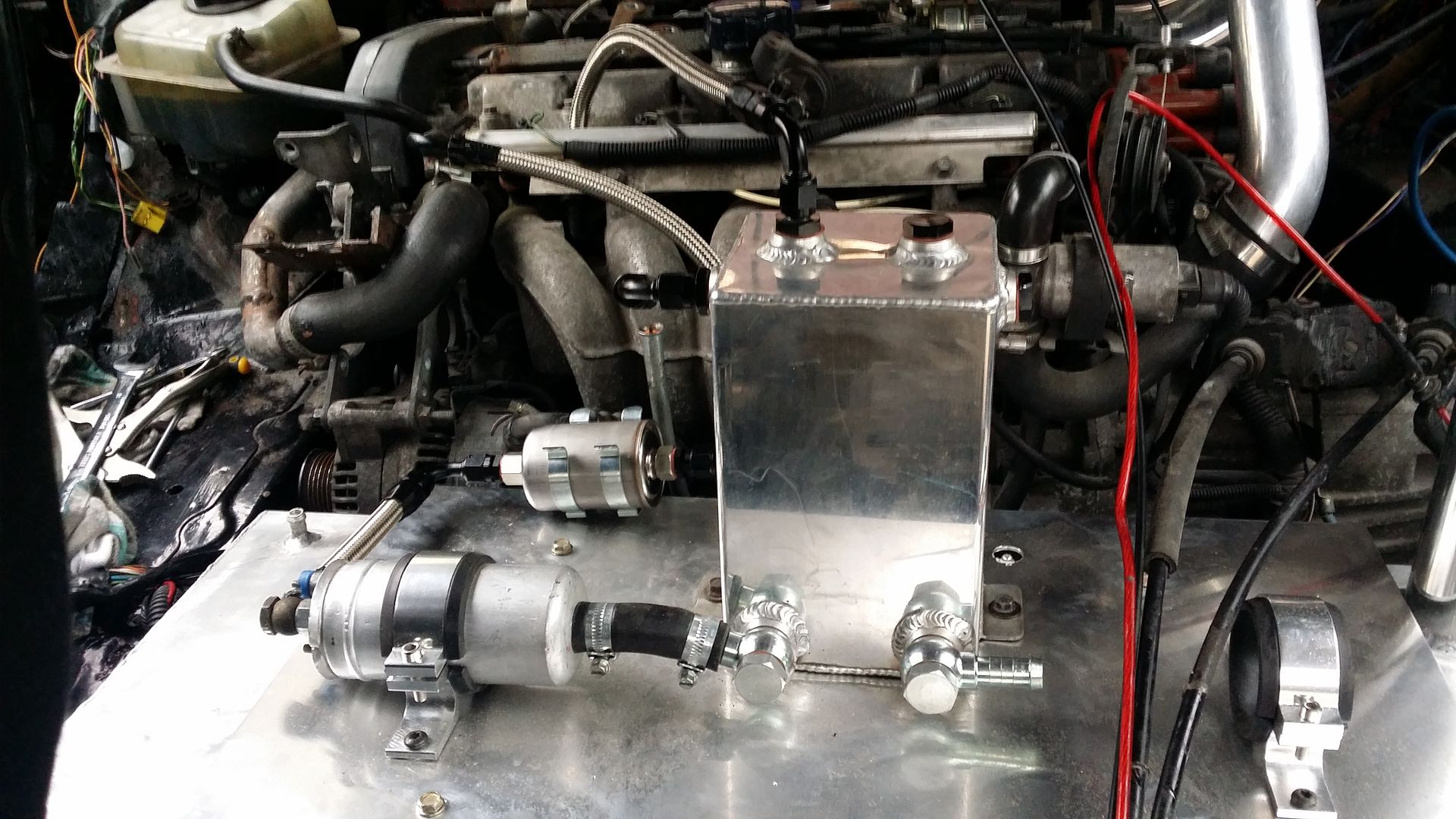

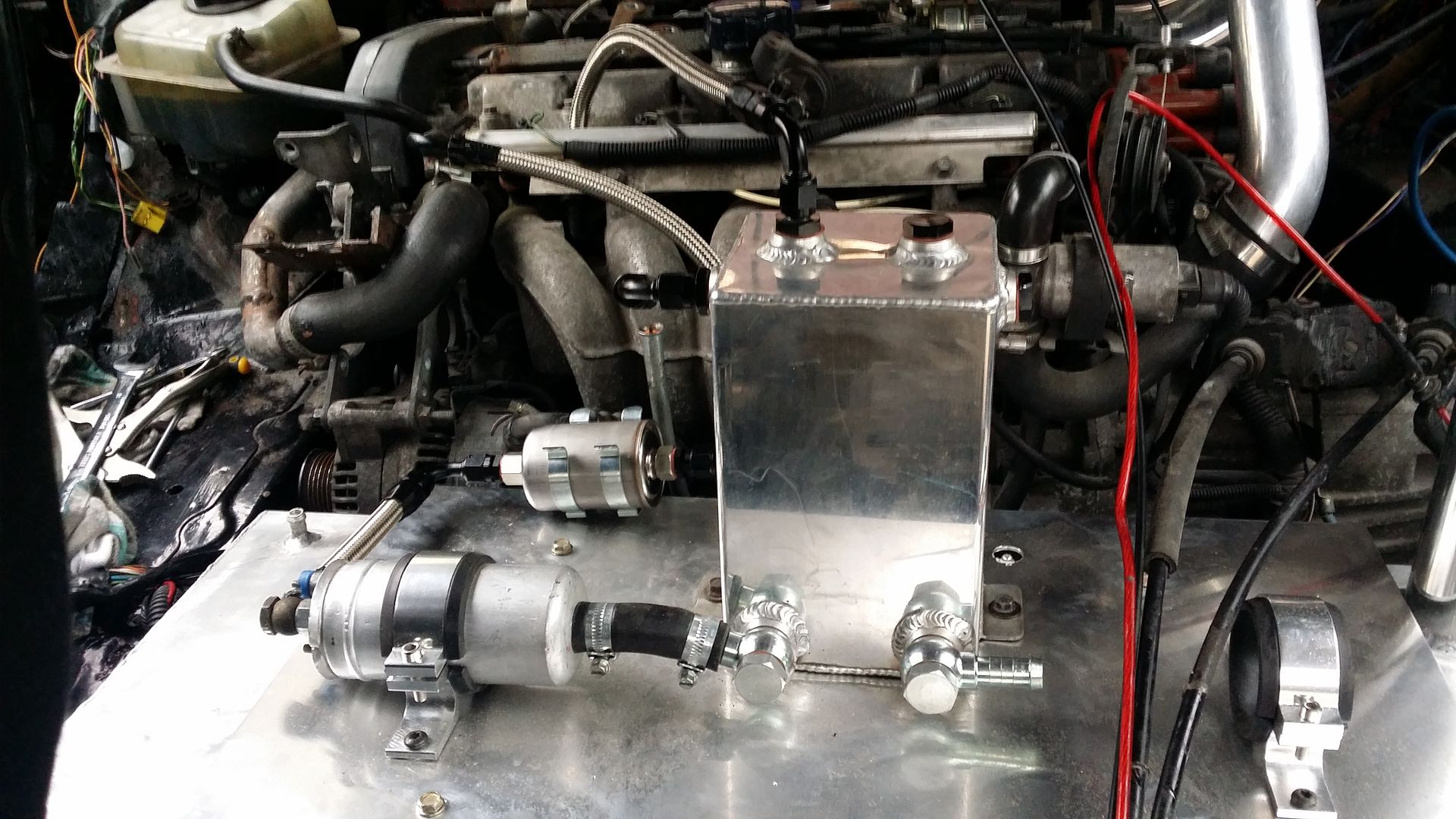

Not much to see, I need a couple more silicone bits, then she should be running Heres a couple of picks of the Mounts, I'll take them off and tidy them up and give them a coat of paint once I'm sure they work ok    Just a bit of information, I still haven't taken the brackets off to 'tidy them up and give them a coat of paint'  |

| |

|

|

|

|

|

Jun 27, 2015 16:12:41 GMT

|

|

|

| |

|

|

|

|

|

|

|

First start up of the rear engine with the new fuel tank and pumps, plus a bit of re-wiring, so I was a bit apprehensive, but I needn't have worried  |

| |

|

|

adam73bgt

Club Retro Rides Member

Posts: 4,998

Club RR Member Number: 58

|

|

|

|

Such a beast of a car! I love it  |

| |

|

|

|

|

|

|

|

|

The most jaw dropping build on here, mental stuff and is no doubt inspiring many others to build something unusual and insane just for the hell of it.... Well done that man!!!!

|

| |

'96 Volvo 850T5 x2, '97 Alfa 145 Cloverleaf '96 Alfa 155, '91 XR2i 2.0 Zetec (sold), '88 BMW 520i slug (sold), '81 Escort Mk3 Project, '68 Mk1 Escort Estate, Berlingo Parts Chaser.

|

|

|

|

|

|

|

Saw this briefly at last years gathering, it's good to see the latest progress. The twin gearlever linkage is a tidy solution but thinking about things I'm confused or I've missed something...  "fun" mode = both engines running in synch, 1 gearlever works both g/boxes in synch. sounds simple   "sensible (road)" mode = only front engine & box used, rear engine & box "disconnected". What's the plan here - put the RWD box into neutral & disconnect the rear gearlever linkage so it stays "off" ? have fun, keep the updates coming!  |

| |

|

|

|

|

|

Jul 10, 2015 17:04:48 GMT

|

The most jaw dropping build on here, mental stuff and is no doubt inspiring many others to build something unusual and insane just for the hell of it.... Well done that man!!!! Cheers mate  Saw this briefly at last years gathering, it's good to see the latest progress. The twin gearlever linkage is a tidy solution but thinking about things I'm confused or I've missed something...  "fun" mode = both engines running in synch, 1 gearlever works both g/boxes in synch. sounds simple   "sensible (road)" mode = only front engine & box used, rear engine & box "disconnected". What's the plan here - put the RWD box into neutral & disconnect the rear gearlever linkage so it stays "off" ? have fun, keep the updates coming!  yep, disconect the rear gear lever and just lock it in neutral. The rear looks a bit better now that the mini fuel tanks have gone          |

| |

|

|

|

|

|

|

|

Jul 14, 2015 16:00:50 GMT

|

I've now come to the problem I've been avoiding for twelve months, how to operate two clutch slave cylinders from one master cylinder, I did try and 'T' the pipe off to the two cylinders in the vain hope that there would be enough capacity to work the two, but alas no  , so any helpful ideas? |

| |

Last Edit: Jul 14, 2015 16:01:12 GMT by claymore

|

|

adam73bgt

Club Retro Rides Member

Posts: 4,998

Club RR Member Number: 58

|

|

Jul 14, 2015 16:13:37 GMT

|

I'm no expert by any means and just throwing an idea out there but could you fashion a dual piston master cylinder? If you had them side by side you could get the one pedal to actuate both? I've no idea if this is feasible or not  |

| |

|

|

|

|

|

Jul 14, 2015 16:14:55 GMT

|

|

Twin engined golf I was involved with used an early Golf 1 brake master cylinder for the clutch. It had two completely separate systems inside it. Only mod was with the length of the piston and spring to get both to operate right from the start. Easy enough to do, if you pull the two feed pipes off and check when the delivery port on both closes.

Original vw beetle could also work. I also know there was an early BMW that had a master cylinder with the same flange as the Beetle, but had a 23mm bore up from the beetles 19mm. Unfortunately most modern cars have gone away from a dual circuit twin piston inline mater cylinder.

|

| |

Last Edit: Jul 14, 2015 16:21:19 GMT by Deleted

|

|

|

|

|

Jul 14, 2015 16:16:02 GMT

|

I've now come to the problem I've been avoiding for twelve months, how to operate two clutch slave cylinders from one master cylinder, I did try and 'T' the pipe off to the two cylinders in the vain hope that there would be enough capacity to work the two, but alas no  , so any helpful ideas? Why don't you talk to Ian Birch at Dubsport Colin? He built a twin VR6 engined Golf some years ago, I'm sure he would be able to suggest a solution... |

| |

'96 Volvo 850T5 x2, '97 Alfa 145 Cloverleaf '96 Alfa 155, '91 XR2i 2.0 Zetec (sold), '88 BMW 520i slug (sold), '81 Escort Mk3 Project, '68 Mk1 Escort Estate, Berlingo Parts Chaser.

|

|

|

|

|

Jul 14, 2015 16:37:29 GMT

|

|

The volvo has a dual circuit, but one pipe appears to be about 5mm and the other 6mm, I think if I could get a brake one with enough volume, that would probably be the best option, I like the idea of having the pipe T'd off to the two slaves as that would mean they will both work at the same point.

|

| |

|

|

|

|

|

Jul 14, 2015 17:44:00 GMT

|

|

Actually Claymore, I don't think they would actuate at the same time when split from a single master cylinder. When depressing or releasing the pedal the clutch with the stronger diaphragm spring would be last to release and first to engage. The issues is that the system works on fluid displacement not pressure, and pressure won't be balanced.

The best option would be a large dual circuit master cylinder, at least you can guarantee the same amount of fluid for each as the pedal moves. Pressure might be unequal, but the volume would be constant.

|

| |

|

|

|

|

|

Jul 14, 2015 17:45:09 GMT

|

|

Having thought about it a bit, there is a way you could get more fluid displacement without changing the master cylinder. If you took a small diameter double acting hydraulic cylinder and plumbed the output of your master cylinder into the port closest to the rod that comes out the cylinder. Then connect both slaves to the other port on the cylinder. This would increase volume of brake fluid displaced by something around 1,75 to 1,at the expense of a harder clutch pedal.

|

| |

Last Edit: Jul 14, 2015 17:52:49 GMT by Deleted

|

|

|

|

|

Jul 14, 2015 17:51:18 GMT

|

Actually Claymore, I don't think they would actuate at the same time when split from a single master cylinder. When depressing or releasing the pedal the clutch with the stronger diaphragm spring would be last to release and first to engage. The issues is that the system works on fluid displacement not pressure, and pressure won't be balanced. The best option would be a large dual circuit master cylinder, at least you can guarantee the same amount of fluid for each as the pedal moves. Pressure might be unequal, but the volume would be constant. Tend to agree. Adjustment on both clutch slave Cylinders, ie changing the amount of free play could be used to tweak the point where both clutches engage, disengage. That's how we did it on the Golf.. |

| |

|

|

fer4l

Posted a lot

Testing

Testing

Posts: 1,497

Club RR Member Number: 73

|

|

Jul 14, 2015 18:45:38 GMT

|

|

Maybe single output m/c into a splitter block at a high point (with a bleed nipple) feeding roughly equal length hoses to standard slaves then experiment with cylinder size for feel?

|

| |

|

|

jonomisfit

Club Retro Rides Member

Posts: 1,788

Club RR Member Number: 49

|

|

Jul 14, 2015 18:51:07 GMT

|

|

You could use your single master cylinder to power a remote slave that then pushes 2 masters cylinders that operate the two slaves on the gearboxes. Bit circuitous but hydraulics don't usually end up with too much in the way of losses.

If you don't upgrade the original master clutch cylinder you will end up having to push with twice the force though, so might make the clutch a bit heavy. bite point could be a bit strange though as no way to sinc them like that.

If you did decide to re-jig the pedals you could do a similar but fixed arrangement to a two cylinder bias brake pedal.

Any way to use a linear actuator on one of them that instantly de-clutches when the pedal is touched, and only releases after the first hydraulic clutch releases? You'd get a normal bite etc on the first engine, and the second would drop in pretty quickly after the first has released.

I like this build :-) Mental = good

|

| |

|

|

|

|

"sensible (road)" mode = only front engine & box used, rear engine & box "disconnected". What's the plan here - put the RWD box into neutral & disconnect the rear gearlever linkage so it stays "off" ?

"sensible (road)" mode = only front engine & box used, rear engine & box "disconnected". What's the plan here - put the RWD box into neutral & disconnect the rear gearlever linkage so it stays "off" ?

, so any helpful ideas?

, so any helpful ideas?

[*]

[*] [*]

[*]