|

|

|

Oct 16, 2009 19:06:03 GMT

|

Meanwhile Gordon and I had been looking at the front panel, superficially it looked okay, but there was a lot of rust on the inside of it, in all the difficult to get to areas The Battery tray was also shot  Fortunately Gordon was able to get hold of a NOS front panel  I got finished early at work today, so decided to make the most of the fact that the wife was still out So straight in the garage and off with the front panel ;D  This has exposed a rather suspect looking repair to the front chassis leg, not sure why this side is so poor while the other side is perfect   Also decided to remove the bracket that was here, it will help to sort the rust out  Bracket itself is pretty rusty on the inside, I will get that shot blast and welded back on later  Once the battery tray was removed, it became clear that the inner wing was going to need some attention too  So a repair panel is going to be needed, as this could be seen from both sides, I decided that a butt jointed repair would be the best option So clean up the wing and cut out the rot  offcut of metal  Radiused bend needed so bit of tube in the bender  A bit oversized but will be trimmed  Trimmed and offered up  and Tacked in place  View from the rear, you must ensure good penetration when carrying out butt welds that will be ground off later  Then it was time for tea, so hopefully get more done tomorrow |

| |

Last Edit: Oct 16, 2009 20:17:16 GMT by tonybmw

|

|

|

|

mirafioriman

Posted a lot

My next project.......

My next project.......

Posts: 1,361

|

|

Oct 16, 2009 19:46:16 GMT

|

|

Nice work. Will be watching your butt welded repair to pick up some tips!

|

| |

|

|

mirafioriman

Posted a lot

My next project.......

My next project.......

Posts: 1,361

|

|

Oct 17, 2009 13:34:53 GMT

|

|

Just found the rear arch repair section. Missed that before! That was great and seeing the shrinker/stretcher you have was useful too. Now I must save up and invest in one. Also ordered some of that zintec sheet today from my local supplier. Will be here Monday. I'm going to use that all the time from now on!

|

| |

|

|

|

|

|

Oct 17, 2009 18:51:41 GMT

|

Just found the rear arch repair section. Missed that before! That was great and seeing the shrinker/stretcher you have was useful too. Now I must save up and invest in one. Also ordered some of that zintec sheet today from my local supplier. Will be here Monday. I'm going to use that all the time from now on! Mirafioriman - Glad to hear that the tips are being put to good use, look forward to seeing the results on your thread |

| |

|

|

|

|

|

Oct 18, 2009 19:54:46 GMT

|

|

I too am zintec'ing all the way from now on. Brilliant!

|

| |

1974 Lancia Beta Saloon

1975 Mazda 929 Coupé

1986 Mazda 929 Wagon

1979 Mazda 929 Hardtop

1982 Fiat Argenta 2.0 iniezione elettronica

1977 Toyota Carina TA14

1989 Subaru 1800 Wagon

1982 Hyundai Pony 1200TL 2-dr

1985 Hyundai Pony 1200 GL

1986 Maserati 425 Biturbo

1992 Rover 214 SEi 5-dr

2000 Rover 45 V6 Club

1994 Peugeot 205 'Junior' Diesel

1988 Volvo 760 Turbodiesel Saloon

1992 Talbot Express Autosleeper Rambler

2003 Renault Laguna SPEARS OR REAPERS

|

|

|

|

|

Oct 18, 2009 20:39:18 GMT

|

Xbo11ox - Mirafioriman - Zintec is the future, you wont regret it Not sure if its really a tip or not, but you really have to get good penetration when carrying out butt welds, so you really need to know your welder. to set up my welder, I keep turning the power and wire speed up until I start burning holes, and then I back the power setting down 1 notch, and adjust the wire speed until you have a nice steady weld, without spitting stuttering or burning back into the tip. When butt welding 1mm steel, you really should be expecting to burn through, if not you don't have penetration, but this should be after 3-4 seconds of continous welding, so here is what I do First of all you need plenty of tacks, and the patch must fit well, and be level, extra time spent getting this right will pay off. Then I will try on a scrap piece, perhaps as the weld starts to flow and get hot it will start to burn through after 15mm of travel, so then I only weld for 10mm, and then stop for 0.5 second, then weld another 10mm, then stop for 0.5 again, and so on and so on, just stopping for that 0.5 second, gives the metal just enough time to cool, without going cold, to allow you to continue without burning through. and if your tacks are spaced about 20mm apart then you stop and start on a tack. Then move around the piece, welding between other tacks, this stops the piece or the surrounding metal distorting with the heat. all being well you should finish with this All fully welded  Check the rear for penetration  Now grind off the rear with the flap disc, it does not need to be perfect as primer and paint will cover it later  But more time needed on the front, again grind with 40 grit flap disc, then 120 grit Roloc, then Brown scotchbrite Roloc, then 40 grit DA disc, the DA disc just helps to smooth and even everything out, and nicely rounds all the edges  Then it was time to get rid of the suspension so I could get a better look at the chassis repair needed and also to make a more thorough job of the painting it later.  So I dusted off my AF spanners and soon had these   Hopefully next time we see those they will be all cleaned up and going back on So then stripped the steering coloum and box out and the wiring under the dash, so nothing stopping us now  Victor now looks a bit sorry for itself, but this is definetly a turning point for the front end  More next weekend |

| |

Last Edit: Oct 18, 2009 20:39:54 GMT by tonybmw

|

|

|

|

|

|

|

|

readin the tread and some exelent work goin on , just hope that do such a good job on my own car . and so cant wait to see it done

|

| |

|

|

|

|

|

Oct 19, 2009 10:52:22 GMT

|

|

This threads is truely an inspiration to all, the work you are doing shows us that a bit of welding is not to be run away from and can be taken care of easily if approached calmly and methodically.

|

| |

There is no such thing as a curse word car just overstretched expectations................. Herald 10/10 Gasser 10/10 Total score 20/10 |

|

chip83

Part of things

One day at a time....

One day at a time....

Posts: 357

|

|

Oct 19, 2009 14:28:30 GMT

|

just read this from the start, skills ar inspiring. will keep watching with intrest.  |

| |

Quashqui and Yeti (needs must currently)

SAAB 93 EST (Sold)

Volvo S40(sold)

Volvo V40(sold)

MK2 astra aka "THE SHED"(sold)

Mgb GT (crashed)

Peugeot 405(sold)

Orion 1600i (sold)

Metro (scrapped)

Mk1 Fiesta (Broken for spares)

Mk5 Cortina (crashed)

|

|

|

|

|

Oct 23, 2009 18:53:31 GMT

|

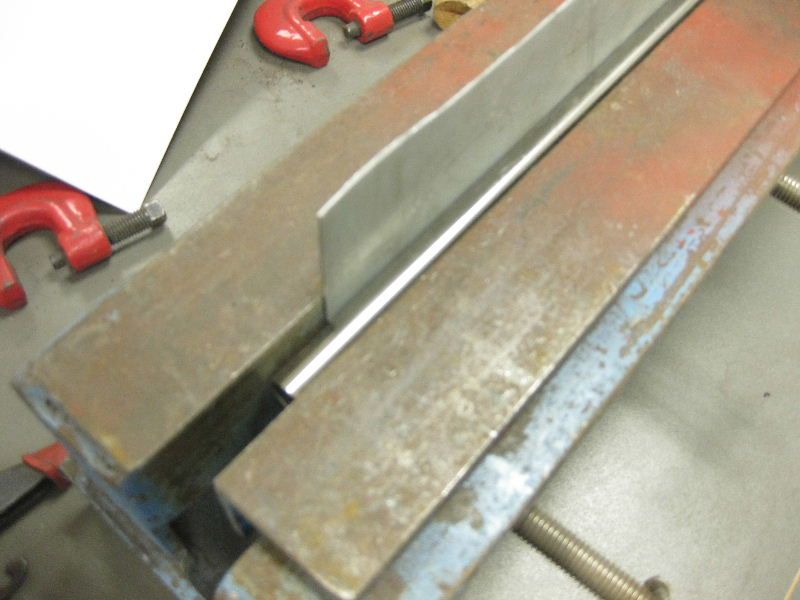

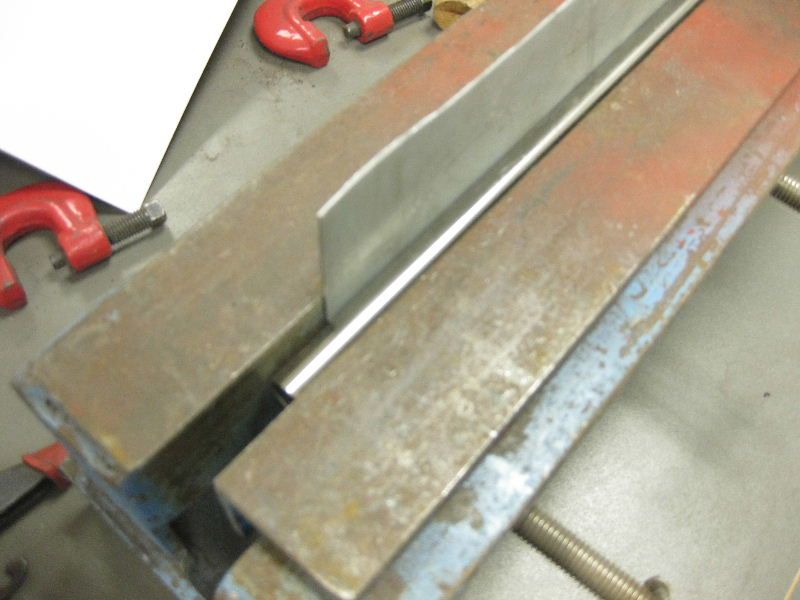

Small Update today Decided to focus on the chassis leg repair   So cut off the old plate and the rot    and made up this repair panel, out of 16swg this time, so a little harder to cut and work with. Transfered the Anti roll bar mountings over too, I hope to get it welded in this weekend  Meanwhile Gordon has almost finished the rust removal to the inside of the bulkhead  |

| |

|

|

|

|

|

|

|

Oct 24, 2009 14:22:26 GMT

|

|

That's some really impressive work there.

It's also great to see a Victor FB being saved - I love the Primrose yellow colour.

|

| |

|

|

|

|

|

Oct 24, 2009 14:43:55 GMT

|

|

Great work Tony. I have just read through eight pages of this saga. Inspirational stuff.

|

| |

1953 Austin A40 Somerset

1959 Austin A35

1958 Austin A55 Cambridge

1975 Vauxhall FE 2300S

1985 Austin Maestro 1.3 Base

|

|

|

|

|

Oct 24, 2009 15:43:51 GMT

|

only just seen this  AMAZING work  if any of us need any motivation & inspirtation [which i will need this winter  ] then i know this is the place to come to  |

| |

|

|

s123

Part of things

Posts: 45

|

|

|

|

|

AMAZING !

I think i have learned more from thread than any other tech article I've read.

Keep up the good work :-)

|

| |

_______________________________________

Life's more painless for the brainless.

|

|

|

|

|

Oct 25, 2009 19:53:32 GMT

|

Thanks Guys, this forum is great for inspiration and encouragement Got back into the garage today the plan was to get the chassis leg finished and then have a go at getting the new front panel fitted So got the chassis repair tacked in   Then fully welded, and zinc primed  Then cleaned off  Then measure up for the closing piece, measuring the angle  Then as before transfer to the sheet  Few more lines and we have it marked out  Cut out  And into the bender, the same as before     Half way there     and finished  Check for fit  Just needs the split welded up, the copper block comes in handy again for these, firstly it is a flat surface to clamp too and keep the 2 halves level.  And secondly it allows you to fill the gap without creating big snots on the inside, this is the inside, it will need just a quick flash over with the grinder to smooth it out  Then spot weld that in, to make it look factory, bumper mounting nut already added to the rear  Coat of etch primer and jobs done  The red primer on the front panel was lifting off in places, so I decided the best thing to do would be to strip it all off and start from scratch, so I do all the difficult to get to bits first and then try it in for size  Again I am going to use the spot welder, the most important advice I could give re the spot welder is to make sure that you dress your tips regularly, it does make a huge difference to the strength and uniformity of the welds, you can buy a small tool that you put in a drill and a few seconds later they are done  Then spot weld away   Finally feels like progress is being made now |

| |

|

|

mirafioriman

Posted a lot

My next project.......

My next project.......

Posts: 1,361

|

|

Oct 25, 2009 20:02:35 GMT

|

|

Looking good. Must get a steel ruler like yours to measure angles acurately instead of guessing!

|

| |

|

|

remmoc

Part of things

Posts: 931

|

|

Oct 26, 2009 20:07:56 GMT

|

|

Top workmanship

|

| |

|

|

Seth

South East

MorrisOxford TriumphMirald HillmanMinx BorgwardIsabellaCombi

Posts: 15,543

|

|

Oct 26, 2009 21:45:56 GMT

|

Continue to be dead impressed by all of this. I will be giving that home brew spot weld drill sharpening a go soon.  |

| |

Follow your dreams or you might as well be a vegetable. |

|

|

|

|

Oct 26, 2009 21:59:23 GMT

|

Continue to be dead impressed by all of this. I will be giving that home brew spot weld drill sharpening a go soon.  Let me know how you get on with it |

| |

|

|

|

|

|

Oct 26, 2009 22:19:59 GMT

|

|

Well i was going to post some pics of the e28 i own but that will take away your well deserved top spot .Great stuff.BTW trisman has a nice e12 project on the way seen it yet?

|

| |

The louder you Scream the faster we go  |

|

|

|

AMAZING work

AMAZING work

] then i know this is the place to come to

] then i know this is the place to come to