markbognor

South East

Posts: 9,970

Club RR Member Number: 56

|

|

Jan 12, 2009 21:23:27 GMT

|

|

Spurred on by a post DarrenW made a while back about his forthcomming evening class in welding I decide to have a look and see if there was anything at my local tech.

Well there were several welding courses, and I've managed to get it paid for as part of my professional development as well.

I'm doing OCN Level one, which is apparently aimed at hobbiests and those wanting a first rung of the ladder to professional welding.

The course was supposed to start last week, but the tutor was sick, so tonight I headed down to the colleged raring to start sticking bits of metal together, only to find that the first weeks lesson was on filling in the enrolement form, and collecting our NUS cards.

So after a few years having to do without I can now get 10% off at Top Shop and more importantly, a free cheeseburger with an Extra Value meal.

There was also a little bit of H&S talk and a brief look at the coursebook/portfolio we have to produce to get the qualification.

I hadn't realised that there was a paperwork aspect to the course, but ho hum it might come in handy writing BTEC assignments.

I felt a bit cheesed off because the tutor decided we could all foxtrot oscar home at 7:45, the couse is supposed to run from 6-9. He mumbled something about getting started with the welding next week. The couse was worded in the prospectus like we were going to get to try a range of welding types. But we've had to choose which disipline we want to follow, mig or tig. So I've chosen mig as its the one i'm most likely to use at school and at home too.

So, I'm off to do my homework,

2, What do the letters MIG stand for?

3, What type of gas is used in the MIG welding process?

etc. a bit of comprehension from the block of text on mig welding at the back of the book.

Hopefully I'll be able to liven this thread up a bit with some pictures next week.

|

| |

|

|

|

|

|

|

|

Jan 12, 2009 21:57:04 GMT

|

|

MIG = Magnesium Inert gas

Gas used = CO2

|

| |

|

|

|

|

|

Jan 12, 2009 22:13:52 GMT

|

|

Metal inert gas / co2 argon mix

|

| |

|

|

|

|

|

|

|

Metal inert gas / co2 argon mix Ooooh, I was waaayy off, thanks Paul. |

| |

|

|

markbognor

South East

Posts: 9,970

Club RR Member Number: 56

|

|

|

|

|

Yeah, the book says Metal Inert Gas,

and just because I'm a bit of a geek I'm going to answer Q3 with

Steel:

CO2

Argon +2 to 5% Oxygen

Argon +5 to 25% CO2

Non-Ferrous:

Argon

Argon/Helium

I didn't mention before but we are also limited to 3mm thick mild steel for the test peices, and presumably most of the practicing, but hopefully I shall get to use some thinner sheet, and have a better idea of how to change the settings acordingly. We are going to have to produce a Butt Weld, T-Fillet, Lap weld and an Outside corner, all hand down, on the bench top.

|

| |

|

|

|

|

|

Jan 13, 2009 18:49:10 GMT

|

Metal inert gas / co2 argon mix Ooooh, I was waaayy off, thanks Paul. Laps in concentration mr grizz ;D thats all, not way off  I only ever use co2 with mine  |

| |

|

|

|

|

|

Jan 14, 2009 20:13:35 GMT

|

|

I did a 12 week evening course in MIG Welding at my local college as work wanted me to have a certificate to show that I could weld. Was a very good course and learnt a lot would definately reccommend doing one.

|

| |

|

|

|

|

|

Jan 14, 2009 20:52:38 GMT

|

|

whereabouts are you doing this?

|

| |

'90 Audi B3 Coupe 2.3 Auto [gone]

'92 Audi S4 Avant 2.2 AAN Turbo Auto [gone]

'93 Audi 80 Avant 1.9TDi [gone]

'96 Audi A4 Avant 2.6 Quattro [gone]

'97 VW T4 1.9td LWB [gone]

'03 Skoda Octavia 1.9TDi [gone]

'05 VW T5 Shuttle LWB 1.9TDi

'15 VW Caddy Maxi Kombi 1.6TDi

|

|

markbognor

South East

Posts: 9,970

Club RR Member Number: 56

|

|

Jan 15, 2009 19:40:58 GMT

|

|

Its now called just chichester college, but i suspect you and i both know it better as chi tech. Quite odd to be back there actually I did my access course there in 97/98, or um possibly 96/97. That seems a long time ago.

|

| |

|

|

markbognor

South East

Posts: 9,970

Club RR Member Number: 56

|

|

Jan 19, 2009 22:38:56 GMT

|

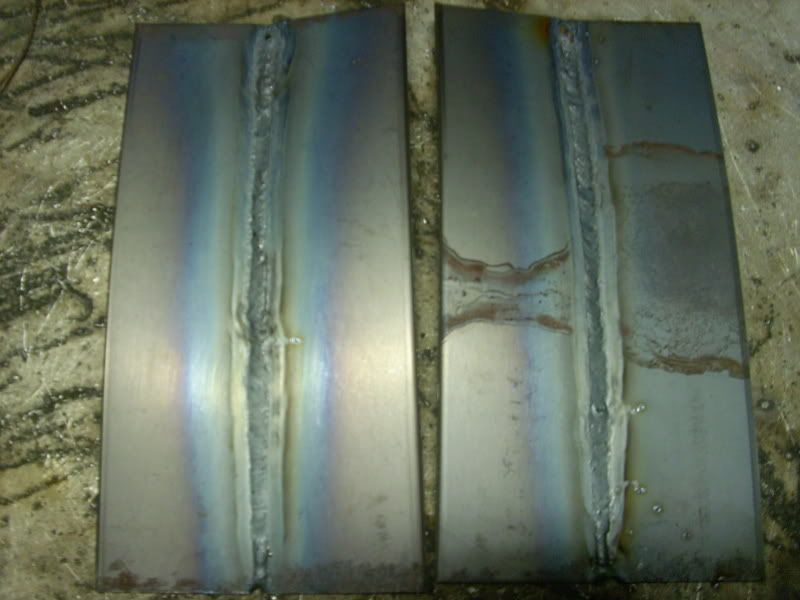

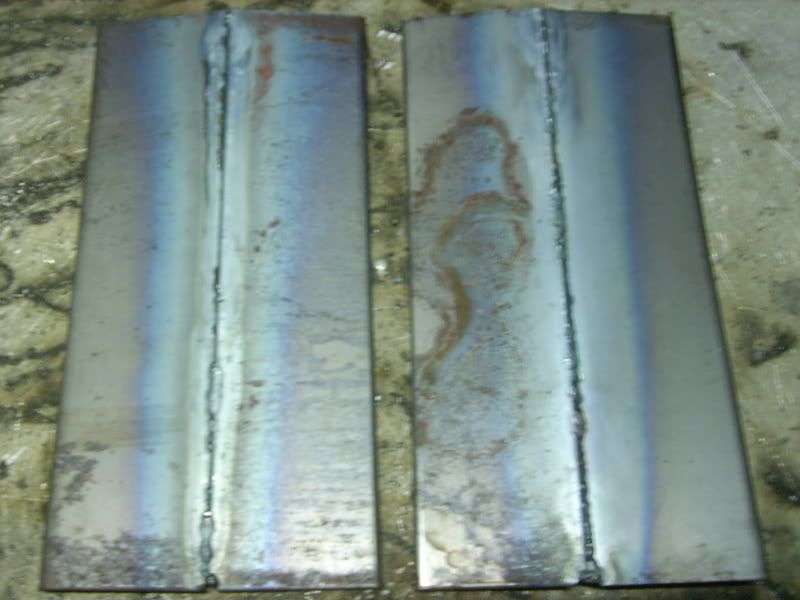

Week 2 Tonights session kicked off with a little bit of Health and Safety. Not so much teaching, more copying the answers down from the projection and into our work books. Then we cracked on with the good stuff. After a quick demo on laying down a bead of weld and a brief introduction to the machines we were given some base settings to start from and told to go and have a play. Here we go, bit too much wire feed i think. The lower plate is my first goes.  I slowed the wire feed down a bit and did some more runs, and tried some butt joints.  Few more runs, going a bit curvey  Another butt joint half completed  I also had a go at some lap and a T joint.     They seem to be starting to look OK, but other than a brief "you've done well tonight" I don't really know if they are any good. Hopefully next week we might learn a bit about how to check our welds. I should have taken some pictures of the backs. I wasn't seeing much weld on the back of the butt joints, but after another go with the current setting turned up they got a bit better. Looking forward to next week. |

| |

|

|

|

|

|

|

|

Jan 19, 2009 22:49:36 GMT

|

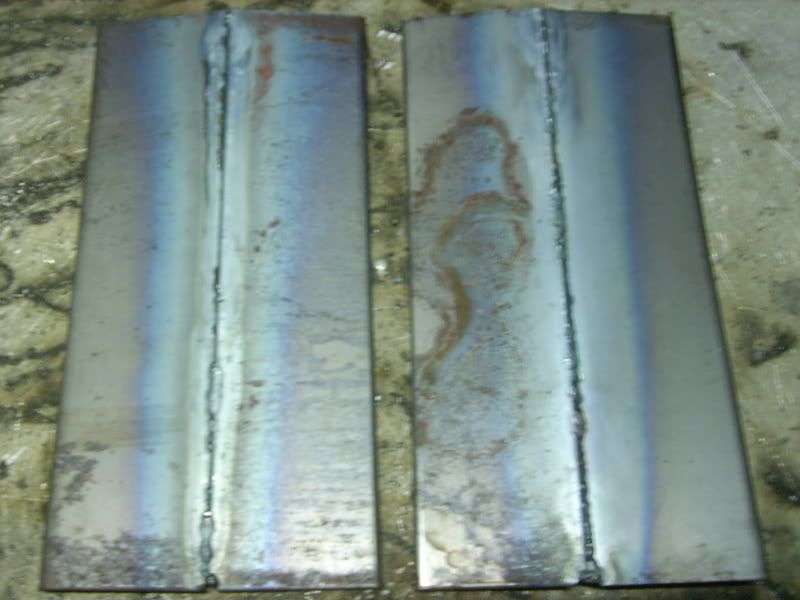

oof nice. When you are welding, are you just basically dragging the puddle across a line? when I was taught to weld, it was described to me as imagine you have 3 bits of metal you want to melt together, imagine you are knitting them together. this means you have to do a "roundy roundy" circles action with the torch. its good, especially where you are welding a thinner bit of metal to something much thicker because you can set the welder for the lighter material (as to not blow holes in it) and as you "knit" them together you slow your knitting while you pass over the thicker material to put more heat (and therefore penetration oo-er) into it. hopefully my practice/learning pictures I took will explain what I mean ;D these are by no means "ideal" welds, they are just some i have pictures of from learning   yours are looking really nicely laid down, maybe some more heat or less wire to make the weld penetrate a bit more and your onto a winner |

| |

|

|

markbognor

South East

Posts: 9,970

Club RR Member Number: 56

|

|

Jan 19, 2009 22:57:45 GMT

|

Cheers, I'll give that more of a go next time, I tried working my way along in a half moon shape accross the join while going from one end to the other, but as we had only been shown to run along in straight lines I didn't want to do too much incase I came accross as trying to be a bit of a smart  . I definately did get better penetration when i did it though. I'll try again with less wire feed and see how i get on. |

| |

|

|

|

|

|

Jan 19, 2009 23:50:02 GMT

|

|

yeah there is that risk at college of looking like that! try it on something inconspicuous first

|

| |

|

|

|

|

|

Jan 24, 2009 16:00:55 GMT

|

|

|

| |

|

|

markbognor

South East

Posts: 9,970

Club RR Member Number: 56

|

|

Mar 16, 2009 21:46:50 GMT

|

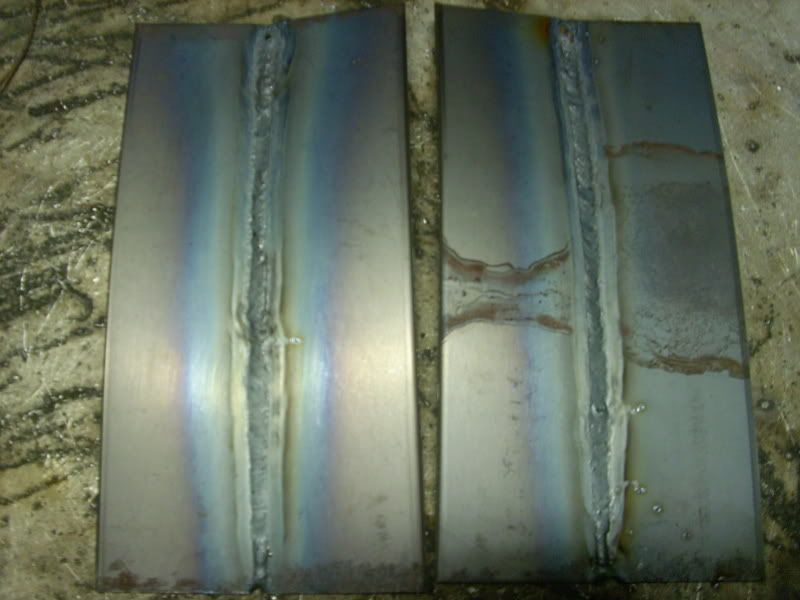

Well after several miseed lessons, through snow, power cuts and events at school I managed to get along to the class the last two weeks. Last week I managed to pass my first test peice. This week I did even better and completed the remaining three. Last weeks Lap weld:  T-Fillet:  Outside corner:   Butt weld:   Just need to get my work book filled in now with aome theory and H&S bits and bobs. Then I'll have the remaining three weeks for playing. I going to try and have a go with some much thinner material because the 3mm sheet we are using for the samples isn't much like what I could expect to be welding on a car.  Edit: Its my welding I'm practicing - Not my photography, looks like I'd best go on a course for that next! |

| |

Last Edit: Mar 16, 2009 21:49:36 GMT by markbognor

|

|

dungbug

Posted a lot

'Ooligan!

'Ooligan!

Posts: 2,852

|

|

Mar 17, 2009 10:16:41 GMT

|

Getting on very well by the look of it, I've been looking for a welding course near me but I can't find one.  |

| |

Past: 13 VW Beetles from 1967 - 1974

Bay Window Campers (1973 & 1974)

Mini's (1992 Cooper lookalike & 1984 '25 Anniversary)

MK2 Polo Coupe S (1984 & 1986)

MK2 Polo Breadvan (1981 & 1984)

MK4 Escort (1989)

MK2 Granada Based Hearse (seriously)

Fiat Uno 60S (1986) Punto 60S (1998) Cinq (1997)

1998 Yamaha YZF600R Thundercat

2003 Ford KA

Current: 2004 Ford Focus (barely alive)

|

|

markbognor

South East

Posts: 9,970

Club RR Member Number: 56

|

|

|

|

So having completed my MIG test peices last week I only had a few pages to complete in my workbook to meet the criteria for the course. Once that was done the course instructor asked me what I'd like to do now. I said I wanted to have a go with some much thinner material. He said I wanted to try TIG. So thats what I ended up doing. I love it. Its just so much nicer than using MIG. The gentle hum of the arc is almost relaxing. Here's the results, welding with 2mm mild steel. First off I was just forming the arc and moving a weld pool along the material, then adding a little filler rod before moving on to trying some lap joints.  First goes were a bit rough and ready, but there are some short sections of weld that show some promise. Here's my best lap joint, the instructor said I need to keep the feed of the filler rod into the top of the weld to keep more of a build up rather than the weld running down. I tried that but still didn't manage anthing as good a this one.  Tried some outside corners too, that was very tricky stopping the material just melting away because the heat was so concentrated on the edge.   Some good penetration on the second one.  Again the weld has gone a bit flat, I should have been adding a bit more filler rod. Last was a couple of tries at making a butt joint,   Didn't have time for much feedback on these, but the lads who were on the level 2 course were pretty amazed that these and the outside corner were from my first evening using TIG. So I'm feeling rather pleased with myself. ;D I'll be bollards at it when itry again next week! |

| |

|

|

|

|

|

Mar 24, 2009 21:30:54 GMT

|

|

Nice work! I need to learn how to weld at some point myself!

|

| |

1972 RA21 Celica - Stalled

1980 Nishiki International - Commuting

"The 2cv's looks at least have certain quirky charm - sort of like an old VW bug with tuberculosis."

|

|

. I definately did get better penetration when i did it though. I'll try again with less wire feed and see how i get on.

. I definately did get better penetration when i did it though. I'll try again with less wire feed and see how i get on.