Things have been a little quiet for a while, and here's why...

When the weather's wet and bitter cold, trapped indoors and unable to do bodywork a man's mind inevitably turns to things like wheels, metalflake paint, naked girls and turbochargers.

I'm quite happy with my wheels at the moment, and if it's too cold to be chopping out inner wings its certainly too cold for laying on some killa 'flake. Which leaves us with naked girls and turbochargers.

I went digging in the garage, through all the parts that I've amassed throughout the years. I didn't find any naked girls, but I did find this...

^ A collection of turboey goodness!

Here we have:

SU HIF44 from a MG Montego Turbo

CT-26 Turbo from a Toyota Supra

Lucas 4FP fuel pump

Saab 9-3 BOV on aftermarket t-piece

Various hoses and pipes for playing with

Lancia / Fiat Intercooler

This stuff has all been accumulated, magpie-like, by my good self with the view of nailing it all to the side of an engine... at some point...

Originally this was going to be a 4.5 V8 that I'd scored, but the sheer amount of work needed by the broken engine, coupled with me upping sticks and going to live in Cornwall on the spur of the moment meant that that particular idea was canned.

The broken V8 was parted out on my return and I was left with a nice fat CT26 turbo and some other bits.

It's unlikely that I'll have the time and space to transplant an engine on my driveway, so I'm left with my existing engine. And a turbo. Can you see what's coming?

First, a bit of general offering up...

^ That's very roughly where it will go. It needs to sit quite a bit higher than that though. At least I know that there is enough room (just!)

Next I removed the old downpipe. The thing had gotten a good battering from hitting the ground so much!

^ Totally FUBAR'd.

^ The flange will be used as part of the new downpipe though.

The turbo came without the V-clamp, and try as I might I couldn't find one. So I sourced a V-clamp from a smaller Mitsubishi turbo and adapted it to fit...

^ I spread out the two halves and used a longer bolt.

^ The other side posed a bit of a problem. Originally it had a steel loop holding the two halves together, but this was too small for the new application so I made a new one out of some M6 stock as it was lying around. If I ever come across a genuine clamp I'll swap it, but this will do for now.

Fuelling will be provided by an SU HIF44 from a Montego Turbo. This is ideal as it is very similar to the original Stromberg 175 CD it will be replacing, and the two cars are both 2.0 engines. So I'm hoping the jetting will be near enough.

One thing that is different on the SU is the throttle linkage - the Merc has a series of rods whilst the Montego has a cable.

So, I raided my "parts bin"...

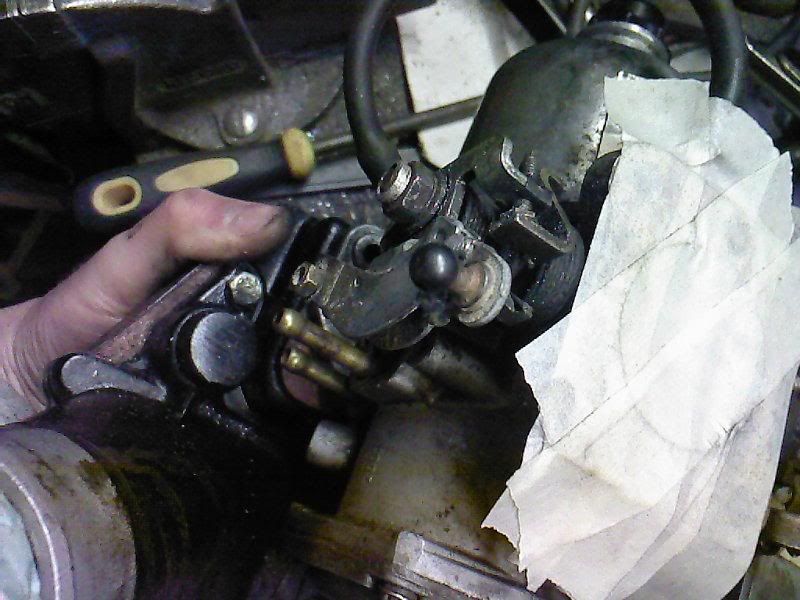

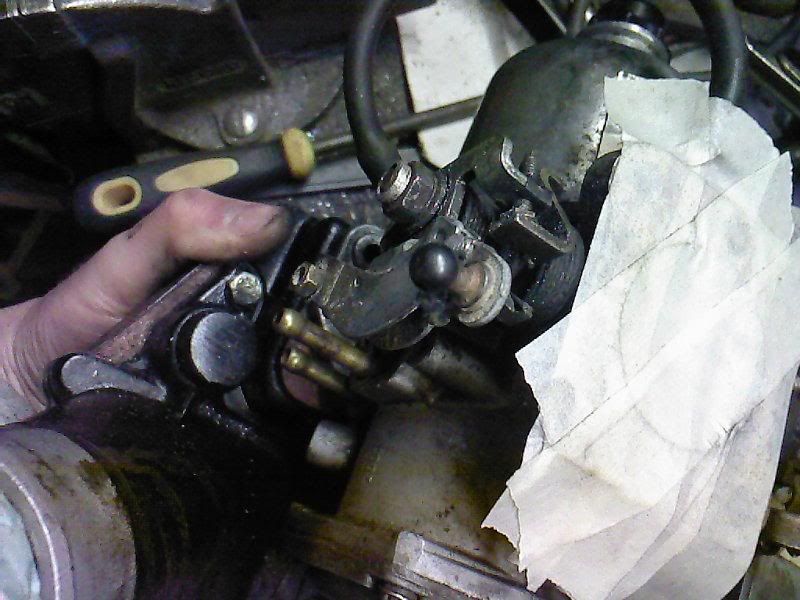

^ Original 175CD with balljoint fitment.

^ This V8 linkage has the ball-joint fitting needed to mirror the Stromberg linkage.

^ SU carb with cable linkage

I cut off the ball-joint fixing from the spare V8 linkage (I want to leave the original carb alone incase I need to put it back to stock), and welded it to the SU carb linkage...

^ One SU HIF44 with Mercedes-friendly throttle linkage!

Another thing which is vital in a turbocharger set-up is maintaining the correct fuel pressure. To do this a rising rate fuel pressure regulator is needed.

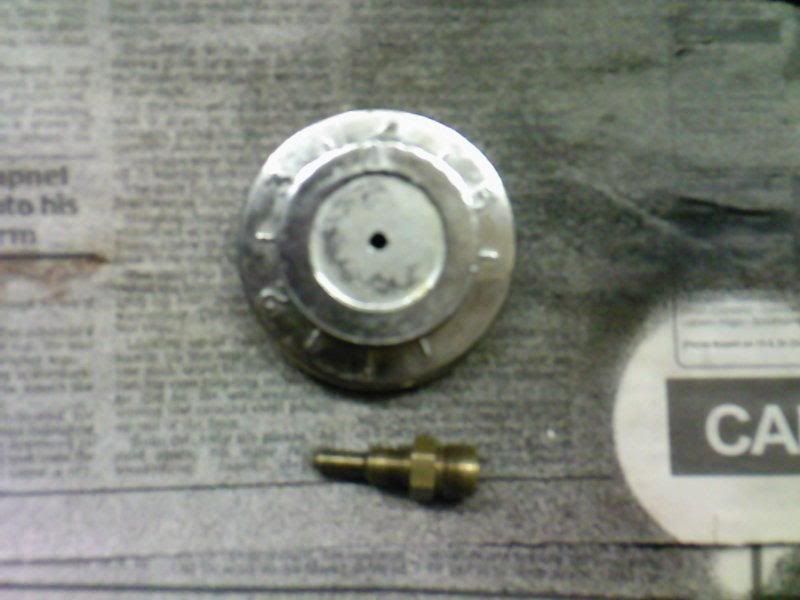

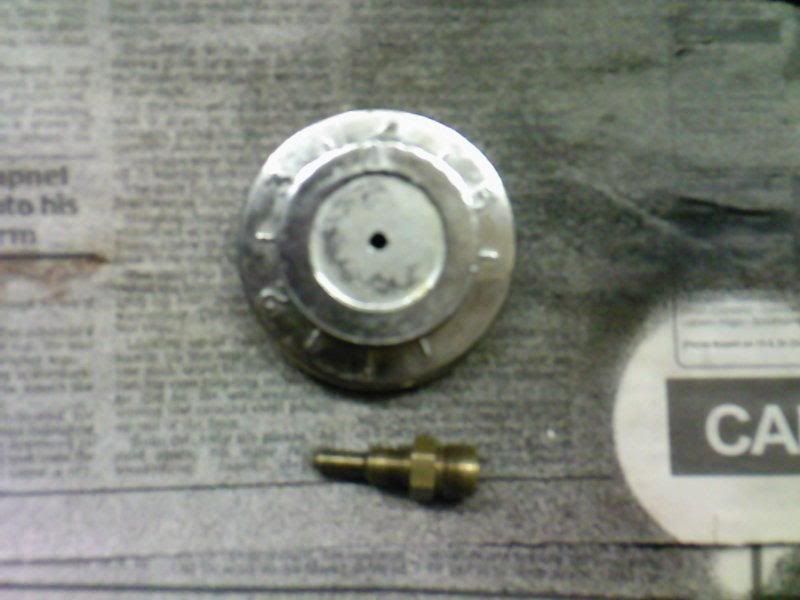

I had an ordinary fuel pressure regulator and proceeded to make it turbo-friendly...

^ The top of the FPR had a little hole in it already. The hose barb seen below it will need to be put through the hole.

^ So I drilled it out to the right size.

^ Poked it through the hole, made it gas-tight and re-assembled.

So, the barb will be attached by a small pipe to the plenum. Now when the engine is on-boost, the pressure will act on the diaphragm in the FPR and increade fuel pressure, so maintaining a constant fuel pressure above boost.

This *might* not work... it's untested! But if the worst comes to the worst I'll have to get a rising rate one from a Montego / Maestro or R5.

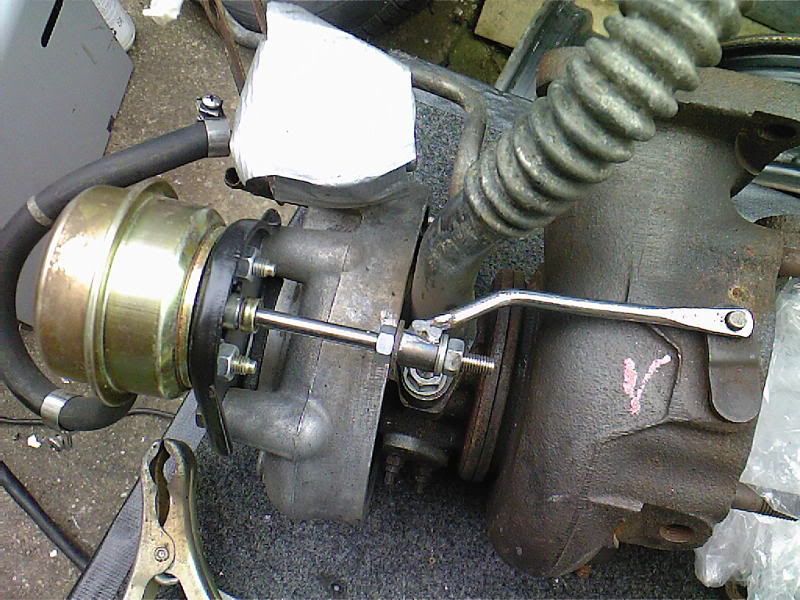

I've been pondering oil supply and return too. Quite handy when you're installing a component that spins at 130,000 rpm! ;D

Oil supply will be from a T-piece from the oil filter housing, where the oil pressure gauge fits. This will ensure a good clean source of oil.

The oil return is unpressurised, so needs to be at a downward angle, as close to vertical as possible.

Ideally I'd put the return into the sump, but the Benz lump has a smallish steel pan joined to an ally upper part. I can't be sure if the top of the steel pan is above the oil level as it needs to be, so I needed to look for alternatives.

^ This plate is about halfway up the block and seems to be an access plate to a tensioner (I didn't look that closely). But it does go directly into the sump, and is lower down than the turbocharger. So I should be able to get the return pipe at about a 30-40 degree angle, which I hope will be sufficient.

That's about as far as I've got at the moment. I've offered up the SU, and need a little bit of an angle on the mounting flange for the plenum to clear, but it will go on.

Bit of a break from bodywork isn't it?! But I figured I'd have to make a new downpipe anyway, so why not incorporate a turbocharger?!

More updates soon... I will finish the welding too, I promise! ;D

. I couldn't remove the driver's side because it'd mean taking off the master cylinder and servo... didn't fancy that. I had to watch that it didn't catch fire when I was welding the bulkhead though. I'm sure it's got some surprises in store for me

. I couldn't remove the driver's side because it'd mean taking off the master cylinder and servo... didn't fancy that. I had to watch that it didn't catch fire when I was welding the bulkhead though. I'm sure it's got some surprises in store for me  . Today is definitely not the day to take that lot off! ;D

. Today is definitely not the day to take that lot off! ;D

I'd have ballsed that up, probably! ;D

I'd have ballsed that up, probably! ;D

;D

;D [*]

[*]