DutyFreeSaviour

Europe

Back For More heartbreak and disappointment.....

Posts: 2,944

|

|

Feb 25, 2008 13:35:59 GMT

|

Once more put to shame OB...... great work as ever. Every time I see 'had a few hours in the garage' I cringe at what you manage to achieve!  Thanks to a mate I'm borrowing a welder, so mine will hopefully get a move on too. Pity about the Osnabruck dates - got me going for a second there too. We'll have to make it another one...... that's a promise. Keep up the astounding work. John |

| |

Back from the dead..... kind of

|

|

|

|

|

|

|

Feb 25, 2008 13:38:58 GMT

|

|

ur dash is brilliant OB, nice and smooth, just what i like.

if u can carry that scheme over to the engine cover then your laughing, id be careful not to let it get too light blue if u know what i mean?

|

| |

|

|

|

|

|

Feb 25, 2008 14:29:31 GMT

|

Well, you have been a busy boy Dave. I just had a date with a tall Blonde..... but I guess you made more progress than me. Well done again, I look at your bending, blending and welding , and just imagine people sticking their noses against your front windo saying.... ooohhh, thats nice ! They will never know just how much work has gone into all of that. Thanks Rian, that´s the same with every car on here that´s been restored or modified. If you´ve not been there yourself and earnt the T-shirt you just don´t know what it takes. If someone asks and is nice about it and really interested i´ll tell them the story but if it´s just some pratt who "had one of those a few years ago" i just tell em its all standard and i bought it like that!  Excellent work, really interesting watching it come together Thanks mate, it just comes up good on the photos! Luvin' da fabbin'!! Excellent patience and skillz OB! Keep it up! Cheers, will do, there´s still a long way to go! I really need to learn how to weld.. just so that I can make pretty curved bits of metal like you have.. In all seriousmess though, what you're doing is more than just very impressive. Every time I check the thread you've come up with some new piece of fabricating juiciness to solve the latest problem... And all this to a van that was drop dead gorgeous in the first place.. where most people would have settled with what was already an awesome ride.. you just keep adding, and ammending and improving.. I'd love to know what your final vision is for the van.. or whether it's always going to be a case of tweak this, fiddle with that...  How do you know when you've reached perfection ?? I´m not after perfection Posam, it´s just not quite finished yet, and it looks a lot better in the pics than it does for real! I should have done this first, then painted it to be honest. Further plans will be to upgrade the front and rear axles to match the engine, including discs all round, and i fancy some hidden electric windows, central locking and power steering and and and... ;D That´s the beauty of a van, you´ve got so much room to play with! Once more put to shame OB...... great work as ever. Every time I see 'had a few hours in the garage' I cringe at what you manage to achieve!  Thanks to a mate I'm borrowing a welder, so mine will hopefully get a move on too. Pity about the Osnabruck dates - got me going for a second there too. We'll have to make it another one...... that's a promise. Keep up the astounding work. John Thanks John, don´t believe everything you read. I tend to underestimate a bit when i´m waffling on about garage time (or so the misses recons! ;D).. Shame about the Bergrennen, it´s one of the highlights of the year but as we´re doing RR08 it´s not going to happen this year. Are you still up for a convoy? ur dash is brilliant OB, nice and smooth, just what I like. if u can carry that scheme over to the engine cover then your laughing, id be careful not to let it get too light blue if u know what I mean? I think i´ll do the floor in black carpet and as i´ve got a bit of paint left over from painting the van i´ll try the engine cover in blue, maybe with some white squares around the bottom like on the dash. I´d like to take this opportunity in thanking everyone who looks in here, can´t believe how many people have read and posted on here. It´s a great motivater to get me out into the garage when my get up and go has got up and gone. Much appreciated, Cheers, Dave |

| |

|

|

|

|

|

Feb 25, 2008 19:35:51 GMT

|

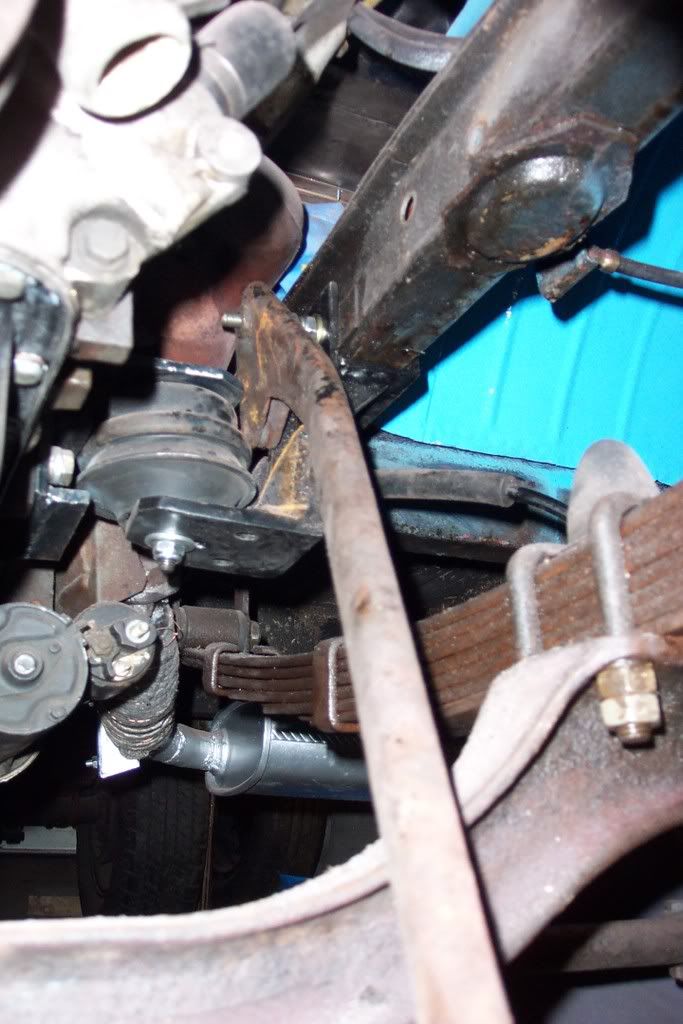

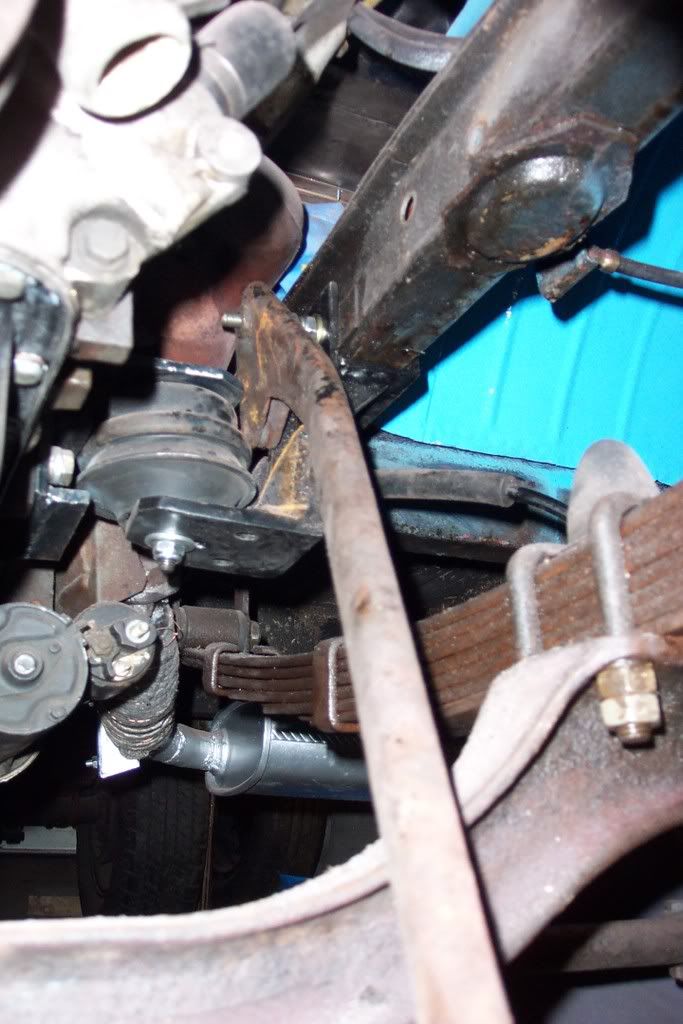

When i got in from work this afternoon, this was waiting for me....  My all singing, all dancing new, purpose built propshaft from Shelley Transmissions in Wolverhampton..don´t ask me where they got the rear Taunus Transit joint from but it looks great. Front end 24V - rear end Taunus Transit. Only took two weeks (and most of that time was postage) and i think more than fair at 120 quid...! Started sorting out the handbrake lever. This is what it looks like when it´s not fitted...  It would normally go in here but it won´t go as there is a crossmember running directly underneath it.....  So modified the holes a bit to get it further back...    ...in cross section....  I´ve now got a couple of mm clearance.....  so all i have to work out know is how to join this bit up, around the engine and gearbox, to the other half....  I´ll worry about that tomorrow ;D |

| |

|

|

Anglia68

Posted a lot

Powered By Boredom.

Powered By Boredom.

Posts: 2,050

|

|

Feb 25, 2008 21:11:00 GMT

|

Looking good.  Back about 15 years ago I had a prop made by Des Shelley,aka Shelleys,for a Rover V8 Capri I had and all I had to do was fit and forget it,well,apart from keeping the UJs greased up that is.It totally transformed the car,no more noise or vibration,it was a joy to drive.Nice to know they're still going and still making quality parts. |

| |

|

|

|

|

|

Feb 25, 2008 22:30:52 GMT

|

|

Hi Dave, thought I would pop on here and have a look at your baby. Looking good good good. Strikes me there are a hell of a lot of similarities betwixt the Taunus and Thames. I can really appreciate the amount of work in this, as in a lot of cases we are doing the same things, albeit you are modding a bit, and I am restoring.

To save me reading back through so many pages, tell me what gearbox is it, engine fitted etc.? And what sort of linkage do you need for the box?

Incidentally, I live about 6 miles from Des Shelley Shafts.

Best wishes.

Andy

|

| |

1960 Ford Thames 402e resto

1965 Ford Thames 400e van 5.7 ltr

1965 Ford 100e 2.1 Pinto power

It all takes time and money, why do I never have them both at the same time?

|

|

|

|

|

Feb 25, 2008 22:32:30 GMT

|

Looking great Dave  don't forget to duct the rest of the grill opening to the rad though or all your hard work will not be seeing the full benefits ! Just close it in around the bottom or all teh air will exit there rather than passing through teh core Fabrication looks great ;o) really impressive Thanks for the invite BTW ;o) will take you up on that for sure - be nice to bring the Kadett out for it |

| |

|

|

|

|

|

|

|

Looking good.  Back about 15 years ago I had a prop made by Des Shelley,aka Shelleys,for a Rover V8 Capri I had and all I had to do was fit and forget it,well,apart from keeping the UJs greased up that is.It totally transformed the car,no more noise or vibration,it was a joy to drive.Nice to know they're still going and still making quality parts. Top quaulity work and great service. They came recommended from V8Ade and he was right. When you think about it, they get a call from a complete stranger in Germany, and based on my old prop and a couple of photos with measurements come up with the goods. Not bad eh, call Warick he´s the man!  Hi Dave, thought I would pop on here and have a look at your baby. Looking good good good. Strikes me there are a hell of a lot of similarities betwixt the Taunus and Thames. I can really appreciate the amount of work in this, as in a lot of cases we are doing the same things, albeit you are modding a bit, and I am restoring. To save me reading back through so many pages, tell me what gearbox is it, engine fitted etc.? And what sort of linkage do you need for the box? Incidentally, I live about 6 miles from Des Shelley Shafts. Best wishes. Andy Thanks Andy, i´ve been following your restoration and you´re right, there´s a lot of similarities between the two, shame there are no parts that are interchangeable. That´s one of the reasons i´m replacing all the running gear with something more modern.....parts availablity for these things is not too good, to put it politely. It´s hard to believe nowadays the back in the Fifties Ford UK and Germany didn´t work together on the van project, in fact both countries were developing seperate models to replace them until Dearborn stepped in and told them to work together on what became the MKI Transit. The engine is the 2.9l 24V V6 out of the Scorpio with it´s autobox. Linkagewise i´ll be adapting the column change mechanism to operate the box...hopefully!! It´s one of those tricky ones as everything is in the way. Your van is looking good, are you going to Classic Ford or RR08 this year...we´ll be there...if i can get the van finished by then! ;D Looking great Dave  don't forget to duct the rest of the grill opening to the rad though or all your hard work will not be seeing the full benefits ! Just close it in around the bottom or all teh air will exit there rather than passing through teh core Fabrication looks great ;o) really impressive Thanks for the invite BTW ;o) will take you up on that for sure - be nice to bring the Kadett out for it Cheers Dom, once i´ve got the handbrake and the gearbox linkage´sorted i´ll be closing the radiator off...airtight as you suggested. Where it is now though that shouldn´t be too difficult, i might even get away with using some of the original ducting. What i will need are some brackets to hold/strengthen the bottom of the radiator just incase i do drive over a brick.... My all singing and dancing lightweight motorsprt radiator has become very heavy though as the frame is steel. This was the first time since leaving technical college nearly 25 years ago that i wish i could weld aluminium...(like you! ;D) |

| |

|

|

|

|

|

Feb 26, 2008 13:53:14 GMT

|

|

blue with whites squares would look cool OB, glad u take notes of everyones suggestions too, its very easy to over look comments when u have such a popular thread.

|

| |

|

|

|

|

|

Feb 26, 2008 18:26:32 GMT

|

blue with whites squares would look cool OB, glad u take notes of everyones suggestions too, its very easy to over look comments when u have such a popular thread. Cheers, i need all the help i can get and i´m more than happy to accept critisism and discuss ideas and correct if i´ve forgotten anything. That´s what this place is all about and i always try to answer everyone individually, i think that´s the least i can do if someone makes the effort to read all my waffle and write a comment on it. ;D This is definately not a "how to" thread more of a "this is what i did have i forgotten anything important ?" type of thing ;D |

| |

|

|

|

|

|

Feb 26, 2008 18:51:08 GMT

|

Continued the battle with the handbrake linkage today.... The main problem is that i don´t have any room for the pivot. It was welded to the frame exactly where the new engine mounts had to go in..... well to cut a long story short, after loads of measuring up and a few cups of tea i thought i´d try to fit use the enginemount bolt as a pivot. I´ve replaced the M10 bolt with a longer one ....  and hung the pivotarm in to see what needs adapting.... Well the angle is all wrong so cut the arm off turned it round and welded it back on!  Strengthend it a bit...   It´s still going to need some more time invested tomorrow to get it to work properly and it´ll need shortening as well....  but i´m confident it´ll work. The main reason i want this to go through the gap is i need to get the gearselection linkage through here somehow too...and i haven´t got the foggiest how i´m going to get that sorted! ;D |

| |

|

|

|

|

|

Feb 26, 2008 19:29:40 GMT

|

This is definately not a "how to" thread more of a "this is what I did have I forgotten anything important ?" type of thing ;D brilliant quote, just had to make it my new sig hahaha I'm afriad i wont be able to tell u where ur going wrong as ive got curse word all skills but I'm quite good at making things pretty so if i can help there i will |

| |

|

|

|

|

|

Feb 26, 2008 19:42:28 GMT

|

|

Hello again Dave, that makes sense I suppose, using a V6. I'm not sure what your original engine was, but the Thames is 1700cc, and enough torque to pull the skin off a rice pudding on a good day.

Now regards your linkage, I have had the same thoughts, and yes a mechanical linkage will work with rods, bits of allthread for adjustment etc, here's a suggestion. I have the same scenario on my Thames van, with 5.7 Buick and TH400. The gearbox linkage will be about 4 feeet behind driver, and about 7 feet from bottom of shifter. What I have thought about doing is using a Morse cable, which are readily available if you know the right place, and to get the correct throw make only one bracket at the column nd. By knowing the full travel at the gearbox end from P to 2, it should be a simple matter to make a lever on the column drop the same amount of travel.

Therefore 1:1 ratio for the shifting mechanism. Does that make sense? I know what I mean!!!

By using a cable you can make the cable run whichever route to clear other bits of the chassis.

You have a PM, please PM me if the above does not compute...

Andy

|

| |

1960 Ford Thames 402e resto

1965 Ford Thames 400e van 5.7 ltr

1965 Ford 100e 2.1 Pinto power

It all takes time and money, why do I never have them both at the same time?

|

|

|

|

|

Feb 26, 2008 20:04:12 GMT

|

This is definately not a "how to" thread more of a "this is what I did have I forgotten anything important ?" type of thing ;D brilliant quote, just had to make it my new sig hahaha I'm afriad I wont be able to tell u where ur going wrong as ive got jolly pain in the backside all skills but I'm quite good at making things pretty so if I can help there I will ;D ;D ;D ;D Thanks for you offer of help. There are times when i regret living so far away... Hello again Dave, that makes sense I suppose, using a V6. I'm not sure what your original engine was, but the Thames is 1700cc, and enough torque to pull the skin off a rice pudding on a good day. Now regards your linkage, I have had the same thoughts, and yes a mechanical linkage will work with rods, bits of allthread for adjustment etc, here's a suggestion. I have the same scenario on my Thames van, with 5.7 Buick and TH400. The gearbox linkage will be about 4 feeet behind driver, and about 7 feet from bottom of shifter. What I have thought about doing is using a Morse cable, which are readily available if you know the right place, and to get the correct throw make only one bracket at the column nd. By knowing the full travel at the gearbox end from P to 2, it should be a simple matter to make a lever on the column drop the same amount of travel. Therefore 1:1 ratio for the shifting mechanism. Does that make sense? I know what I mean!!! By using a cable you can make the cable run whichever route to clear other bits of the chassis. You have a PM, please PM me if the above does not compute... Andy Hi Andy, i get exactly where you are coming from. I was thinking along similar lines myself, more as a back up if my cunning plan doesn´t work. The main reason i stayed with the automatic box is that it would have been a nightmare to adapt the 4 speed column change to five speed manual. The gearbox linkage arm requires 6cm of movement from P to 2nd. When i block off the third and fourth gear movement on my column change, the bottom of my gearchange moves 12 cm, and more importantly in the correct direction (from front to back) Originally there were a set of rods connecting it all and i want to try and reuse these if possible. Your cable idea has the advantage, like you say, that you can place that line anywhere you want. In fact you´d need two, one for each direction as they are only good for pulling and not pushing. With a bit of luck i´ll be starting playing around with the gearchange at the weekend. I´ll see how it goes mate and we can have a natter on the phone depending on how i get on... ;D |

| |

|

|

|

|

|

Feb 26, 2008 21:00:18 GMT

|

|

|

| |

Volvo back as my main squeeze, more boost and some interior goodies on the way.

|

|

|

|

|

Feb 26, 2008 23:04:49 GMT

|

;D ;D ;D ;D Thanks for you offer of help. There are times when I regret living so far away... Hello again Dave, that makes sense I suppose, using a V6. I'm not sure what your original engine was, but the Thames is 1700cc, and enough torque to pull the skin off a rice pudding on a good day. Now regards your linkage, I have had the same thoughts, and yes a mechanical linkage will work with rods, bits of allthread for adjustment etc, here's a suggestion. I have the same scenario on my Thames van, with 5.7 Buick and TH400. The gearbox linkage will be about 4 feeet behind driver, and about 7 feet from bottom of shifter. What I have thought about doing is using a Morse cable, which are readily available if you know the right place, and to get the correct throw make only one bracket at the column nd. By knowing the full travel at the gearbox end from P to 2, it should be a simple matter to make a lever on the column drop the same amount of travel. Therefore 1:1 ratio for the shifting mechanism. Does that make sense? I know what I mean!!! By using a cable you can make the cable run whichever route to clear other bits of the chassis. You have a PM, please PM me if the above does not compute... Andy Your cable idea has the advantage, like you say, that you can place that line anywhere you want. In fact you´d need two, one for each direction as they are only good for pulling and not pushing. AY? The ones I am thinking of are used on narrowboats, and the steerer has control of the engine mounted maybe 12 feet away. Not a cable, but a flexible rod, with eyes on each end. |

| |

Last Edit: Feb 26, 2008 23:07:34 GMT by sidspop

1960 Ford Thames 402e resto

1965 Ford Thames 400e van 5.7 ltr

1965 Ford 100e 2.1 Pinto power

It all takes time and money, why do I never have them both at the same time?

|

|

|

|

|

|

|

That is a good idea. I´ve just been looking through that link you posted, some interesting stuff there.....thanks. The Actuator and electrics would be really easy if i can´t get my rods to work, i think the switching to get each gear in could be a bit more difficult or have you done something like this before? Sounds good too, have you got any pics? Oh and thanks for that eBay link Andy, i´ll have a look at that tonight when i get back home... |

| |

|

|

bazzateer

Posted a lot

Imping along sans Vogue

Imping along sans Vogue

Posts: 3,653

|

|

Feb 27, 2008 10:24:02 GMT

|

If this is what you're capable of with limited arm mobility God only knows what you could have done with full mobility! If I was wearing one I'd take my hat off to you, but I'm not. So as I'm alone in my office I'll quickly take something else off!  |

| |

1968 Singer Chamois Sport

1972 Sunbeam Imp Sport

1976 Datsun 260Z 2+2

1998 Peugeot Boxer Pilote motorhome

2003 Rover 75 1.8 Club SE (daily)

2006 MG ZT 190+ (another daily)

2007 BMW 530d Touring M Sport (tow car)

|

|

|

|

|

Feb 27, 2008 12:40:29 GMT

|

I have'nt built one yet, but its how i was planning on shifting gear before my mid engined P100 got shelved when i had to move, i figured if i couldnt find a way of manually switching the actuator on and off in the right places I'd see if i get an elctronics whizz to knock me up a small box of tricks that switches power on for a set time in whichever direction i needed. They don't require power to hold position, once they get where they are going they stay there so its just a matter of getting your selector to tell the actuator to move in or out for so many seconds so it travels a known distance. I was going to go with a shift lever that you just knocked back or fowards for up and down, with a gear indicator light on the dash, but there is no reason why it couldnt be set up so that the lever sat in a specific place marked "Drive" or whatever in the same way a standard selector does. You'd only need a small light actuator and elctrical stuff is a lot more reliable these days than it used to be so i cant see any reliablity issues, I'm sure i saw a 50's yank with elctric buttons on the dash for gear shifting so its not new, Aston Martin Use hydrualic rams on top of a normal manual box in their flappy paddle box!! just a thought anyway, nothin wrong with an extra gadget to impress the lads with.  |

| |

Volvo back as my main squeeze, more boost and some interior goodies on the way.

|

|

|

|

|

Feb 27, 2008 13:14:28 GMT

|

If this is what you're capable of with limited arm mobility God only knows what you could have done with full mobility! If I was wearing one I'd take my hat off to you, but I'm not. So as I'm alone in my office I'll quickly take something else off!  No, no, leave it all on mate, before you get into trouble with the boss. ;D Being partially disabled actually can help....i get into the - fook the doctors you´re going to do it anyway- mode....! and just get stuck in! I have'nt built one yet, but its how I was planning on shifting gear before my mid engined P100 got shelved when I had to move, I figured if I couldnt find a way of manually switching the actuator on and off in the right places I'd see if I get an elctronics whizz to knock me up a small box of tricks that switches power on for a set time in whichever direction I needed. They don't require power to hold position, once they get where they are going they stay there so its just a matter of getting your selector to tell the actuator to move in or out for so many seconds so it travels a known distance. I was going to go with a shift lever that you just knocked back or fowards for up and down, with a gear indicator light on the dash, but there is no reason why it couldnt be set up so that the lever sat in a specific place marked "Drive" or whatever in the same way a standard selector does. You'd only need a small light actuator and elctrical stuff is a lot more reliable these days than it used to be so I cant see any reliablity issues, I'm sure I saw a 50's yank with elctric buttons on the dash for gear shifting so its not new, Aston Martin Use hydrualic rams on top of a normal manual box in their flappy paddle box!! just a thought anyway, nothin wrong with an extra gadget to impress the lads with.  Thanks for the ideas mate, my problem is and always will be electrics. I have to rely on a mate of mine to sort out all the electrics on the van(cheers Mike) and as he lives two hours down the road i don´t want to impose to often. I´ll play around for hours bending metalwork but as soon as the wiring needs sorting i´m buggered. So think i´ll try and sort it out myself which means old fashioned bodging mechanics. The old selector rods are more or less the right stuff for the job, all i need to work out is how to get them from underneath the front bumper to the middle of the van via the engine ;D |

| |

|

|