|

|

|

Sept 14, 2021 22:29:46 GMT

|

Hello everyone, I have returned from a very nice time in the Greek Islands  Sooooo........where were we........? Ah, yes ....Sills. Passenger side one is now fully welded up and smoothed off;  415 hours. |

| |

|

|

|

|

|

|

|

Sept 15, 2021 22:43:41 GMT

|

The last of the sill repairs was completed tonight, and they are now tacked on to the body. I need to get both doors back on and check/set the alignment wedges before welding properly to make sure the door to sill clearance is correct. Did a little more filler application before finishing for the night on the last few marked areas thet needed a tiny bit more. Not much to look at but sills tacked on.....   417 hours. |

| |

|

|

|

|

|

Sept 16, 2021 8:32:24 GMT

|

|

Still looking in admiration! Glad that you had a good break away, was the air travel/covid testing etc a PITA?

|

| |

|

|

|

|

|

Sept 16, 2021 12:30:15 GMT

|

|

Thanks Phil.

Testing was a simple affair, paperwork for the tests was a PITA but only took about 30 mins.

|

| |

|

|

|

|

|

Sept 17, 2021 8:31:16 GMT

|

|

Looking great! Are you tigging those sections in or MIG? I thought MIG until you mentioned fusion welding...

|

| |

|

|

|

|

|

Sept 17, 2021 20:44:00 GMT

|

|

My first thought was, "Good Grief! He's welded it to a fibreglass wheel arch. That's impressive."

Anyway, I've worked it out now.

Lovely work, keep it up. Glad to hear you hade a good break.

James

|

| |

|

|

|

|

|

Sept 19, 2021 20:04:58 GMT

|

Biturbo,

They are migged - I fused the outside by welding fast with a low wire feed to just fuse the edges.

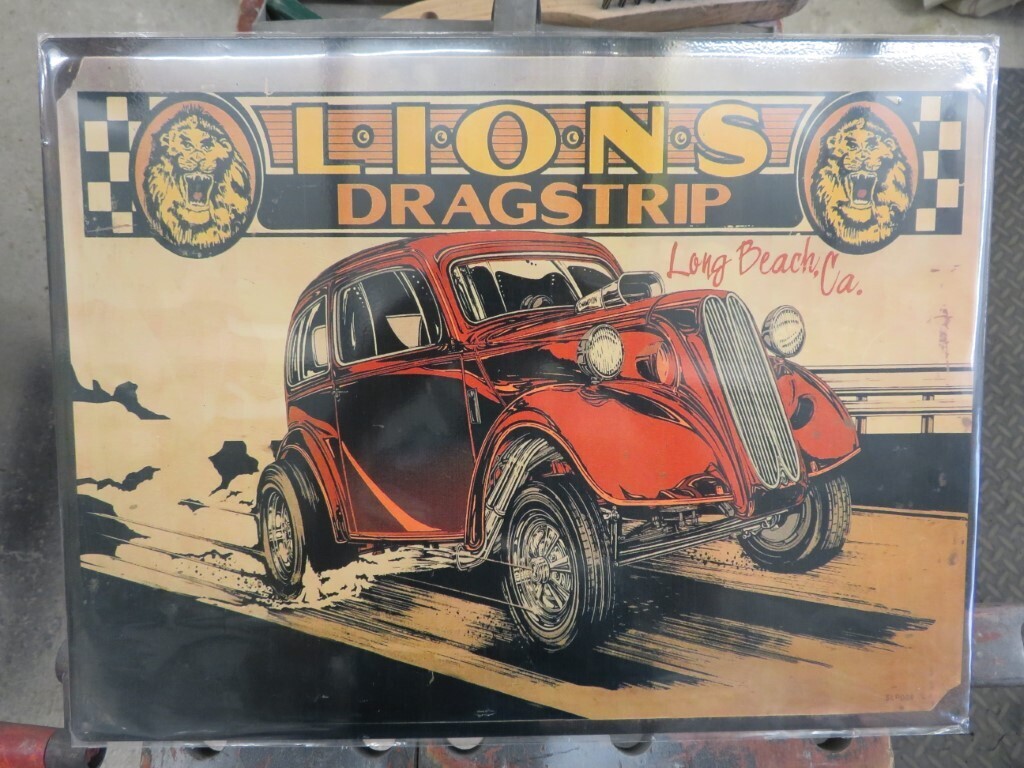

Been off grid for a few days at Santa Pod for the Hot Rod Drags. These are a few photos the people sent to me of my car.

I picked up a nice tin sign for the workshop while I was there as well. Phil was there in our group and he gave me some of the bits I need to move forward, notably the offset door wedge. Std door wedge held up to it as a comparison.  Next job was choppity chop chop and cut the lower door mount face off.

I could then add a 2mm packing plate behind the lower hnge which got the door lined up rather nicely.

The lower door hinge will have the front face welded back in later on.

The other part was back from our friend Rob who made a new threaded mount and extended the towing eye for us. I can now make the mounting to fix it the the front of the chassis.

417.5 hours.

|

| |

|

|

|

|

|

Sept 20, 2021 13:55:29 GMT

|

Interesting, didn't know you could do that with MIG. Will give it a try next time! Looking good! What's the purpose of the offset door wedges? Is it that the originals never lined up properly from the factory? The foggy sunrise picture is stellar  |

| |

Last Edit: Sept 20, 2021 13:56:14 GMT by biturbo228

|

|

|

|

|

Sept 20, 2021 22:51:43 GMT

|

Offset wedges are exactly as you guessed - doors did not line up from factory. Passenger side sill is mostly welded on and smoothed off - just a bit on the B pillar and the underneath welding to finish on it. Hinge cover plate is now welded back on;  419.5 hours. |

| |

|

|

|

|

|

Sept 21, 2021 23:01:24 GMT

|

I mounted the drivers door again and set about getting it lined up. It needed a thin packing plate in the top hinge to move it back a little, but this has been achieved without cutting the outer skin off like I had to do on the passenger side. I could then sort out the door wedge positioning. This did not need an offset wedge, but the position was still way off, so the mounting points were drilled out to 15mm holes to allow for repositioning the fixing points. I cut some 6mm plate and drilled and tapped the holes to 1/4" UNC to match the original screws. The original wedge has had a quick clean up as well.

With the position sorted the plate was welded into the door. Not the prettiest of welds, but it only needs to hold it in place for the wedge to be screwed on.

I'll call that another win I think.

With the door posiion sorted I could check the sill positioning - it needed a little repositioning with a BFH special bodywork tool  but once that was done I could stitch weld the sill in place. The B pillar is a pig to weld as its an open gap and requires very careful dressing back of the welds. I remember doing this on mine as well and it was just as bad on that.

Passenger sill starts to get some filler work done on it.

422 hours. |

| |

|

|

|

|

|

Sept 22, 2021 22:40:54 GMT

|

Another 2 hours tonight saw the passenger sill completely welded up including the underneath. All the welds were dressed back and a covering of filler went over most of it. I'll sand off 90% of that tomorrow, lol.  Then it was time to make the towhook fixings. I templated a shape & cut two side plates out of 6mm steel. Forgot to take photos of this though. Then they were welded to the screw bung. Plenty of amps went into those welds.   It will be welded in here soon, I'll need Phil's help to hold it while I tack it in though.  424 hours. |

| |

|

|

jamesd1972

Club Retro Rides Member

Posts: 2,920  Club RR Member Number: 40

Club RR Member Number: 40

|

|

Sept 23, 2021 7:20:23 GMT

|

|

Nice elegant solution to the tow hook giving the starter handle hole a role in life.

Enjoying the updates but realising that I will never ever have the patience or skills to build a show quality car !

James

|

| |

|

|

|

|

|

Sept 23, 2021 8:45:56 GMT

|

|

I hope the tow hook never needs to be used! They bend very easily even at stock lengths and damage the bumper they screw through. That will do some serious damage to the grille....

|

| |

|

|

|

|

|

Sept 23, 2021 12:31:06 GMT

|

|

Nick,

I've used mine and it did not bend, Pops are probably a lot lighter than a std car though!

|

| |

|

|

|

|

|

Sept 23, 2021 13:07:20 GMT

|

Nick, I've used mine and it did not bend, Pops are probably a lot lighter than a std car though! 15 years as a recovery driver means I don't trust them at all. I've bent them, and on one car pulled the front panel off the car. A strop, or soft winching brothers around the lower arms are what I would insist on. |

| |

|

|

|

|

|

Sept 23, 2021 16:54:26 GMT

|

|

You can't on pop, a strop on a wishbone will rip the front wings upwards as soon as it tightens. The difference here is the mount is central and is almost directly linear to a winch on a trailer or recovery truck so all forces are in the thread only, with virtually no lateral forces on the hook.

|

| |

|

|

|

|

|

Sept 23, 2021 16:56:35 GMT

|

|

They are tested to recover the fully loaded car up something like a 30% gradient at sideways an angle , so should be fine for any towing or recovery on tarmac, of course that is a new car with no corrosion or dodgy previous repairs.

That said the nut has come un welded inside the crossmember on my nieces after a local recovery when the engine blew up eye is still fine though just can't get it out (To be honest I'm not surprised nothing about it seems that well engineered)

|

| |

|

|

|

|

|

Sept 24, 2021 8:56:12 GMT

|

|

I expect they're tested that they don't rip out or shear under those conditions, not that they don't bend and wreck the bodywork. I know the ones on 406 coupes bend and are a PITA to unscrew/screw back in if you're not very gentle with them.

But yes, pops are well under a ton and it's in a central location. Make sure the bracket behind it is beefy enough and I'm sure it'll be fine.

|

| |

|

|

|

|

|

Sept 26, 2021 19:43:31 GMT

|

|

|

| |

|

|

|

|

|

Sept 27, 2021 12:16:17 GMT

|

|

Well done Mark, you have earned that.

|

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|