|

|

|

Jun 29, 2019 17:04:17 GMT

|

Broken brackets?  only one from driving over a rock? It's 42 deg C today, so a perfect day to refit the rad & run car up to temp in the garage! 32 Deg in garage, the extractor fan for paint also serves as a good extractor for hot air, so at least it keeps the garage cool(ish). New rad all back in and no leaks...  good. Thought I'd check the diff oil level as it had been leaking - glad I did as it took nearly 1/2 a litre to top up. Will check the (fixed) leak area and oil level on a regular basis from now on to make sure all is well. Off to Bagshot in it tomorrow, so if its as warm as today it will be a good test to see how the new rad works. |

| |

|

|

|

|

|

|

|

Jun 29, 2019 17:19:39 GMT

|

|

“As if that was not enough fun the exhaust bracket broke off the daily tonight as well, so a fun bit of welding .....”

😂😂😂

Hence me poking fun at you about driving over kerbs....

|

| |

Last Edit: Jun 29, 2019 17:21:07 GMT by Deleted

|

|

|

|

|

Jun 29, 2019 18:20:24 GMT

|

|

Ah! forgot about the daily!, the exhaust on that is 'only' 14 years old (factory from new one) so cant complain really.

|

| |

|

|

|

|

|

|

|

|

Woo, one week later and tyre still a nice 20Lbs pressure, I pronounce that one fixed.

Did a little 50 mile trip out on Sunday, car has now done over 5,000 miles.

|

| |

|

|

|

|

|

|

|

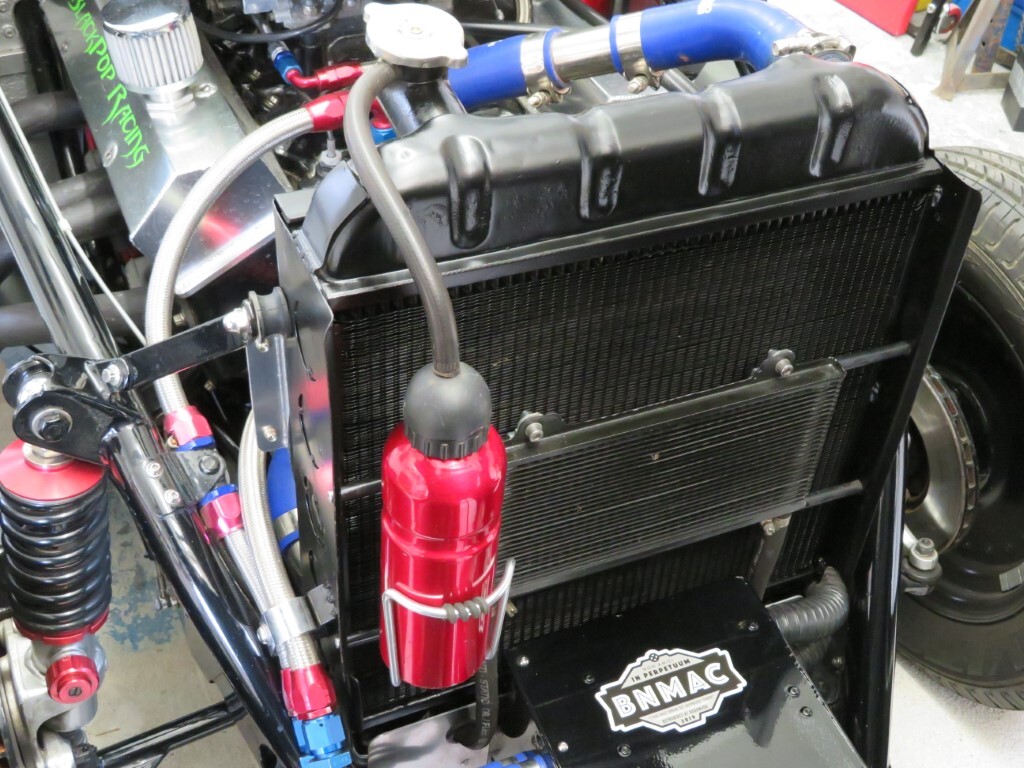

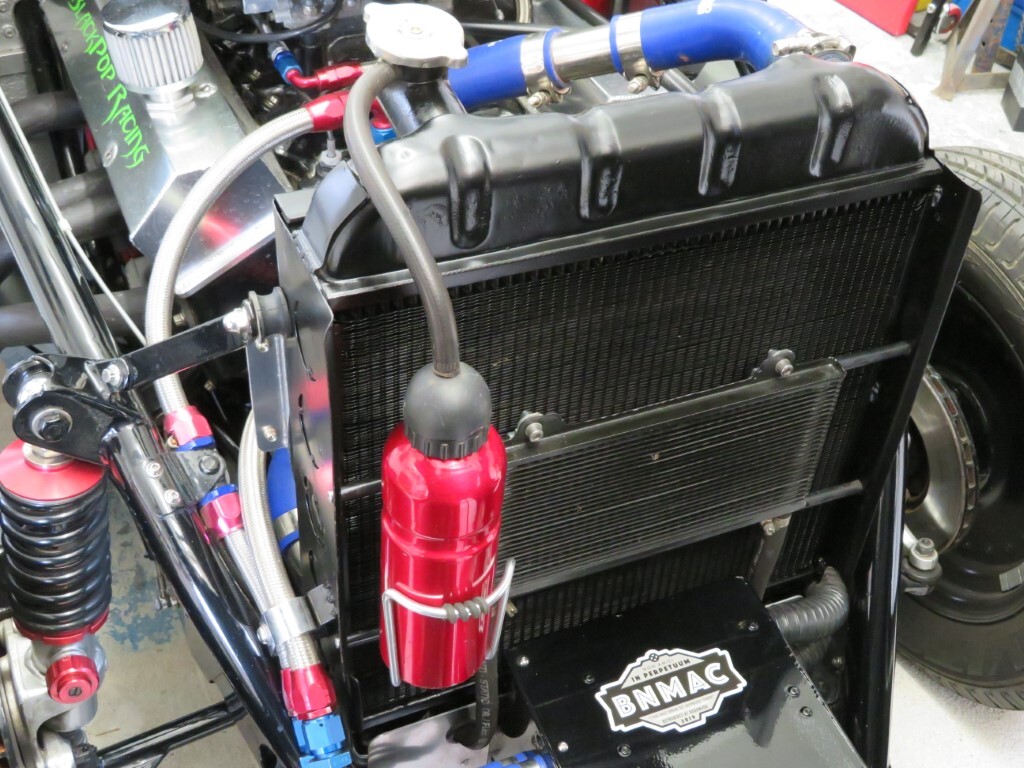

Today I have mainly been eating Lasagne. I have also been making brackets. I knocked up this bracket for the oil breather canister;  And it now lives here;   Next, in the search for more efficiency for the radiator before the oil cooler goes in front of it I had a look at where things currently are.  I thought I could move the radiator overflow canister to behind the rad. So another bracket was made;  Using ny vice folder, which works really well - bracket is 3mm ally.  Bottle now lives here;  Leaving a cleaner area in front of the radiator.  I'll try to take it for a run tomorrow to see if there is any difference. Next job is to get the trans cooler mounted lower and tight to the radiator matrix as it is very inefficient where it is now due to air turbulance. If the matrix's are mounted around 3mm apart the air flows straight through, where it is now caused turbulance and the air does not pass through the rad very well. |

| |

|

|

|

|

|

|

|

Sticker looks good too!  |

| |

|

|

MiataMark

Club Retro Rides Member

Posts: 2,971

Club RR Member Number: 29

|

|

|

|

|

That vice folder thingy looks very useful, off to search ebay.

And yeah I want a sticker...

|

| |

1990 Mazda MX-52012 BMW 118i (170bhp) - white appliance 2011 Land Rover Freelander 2 TD4 2003 Land Rover Discovery II TD52007 Alfa Romeo 159 Sportwagon JTDm

|

|

|

|

|

|

|

|

The fin pitch on both the rad and the oil cooler looks very tightfrom that photo. A less dense pitch would probably give you better airflow through the pack. In engine cooling, airflow is king. For that fin pitch and thickness of radiator would ideally need an engine driven fan. Please ignore me if I'm teaching Granny to suck eggs.

(Just to add) To work with what you have, with the fin pitch tight and also with vertical radiator and horizontal cooler you have probably doubled the air side pressure drop of the cooler area so air doesn't want to go through the cooler at all. A greater chunk of airflow area has been taken up by tube which doesn't pass air. As you say moving it away from the rad should improve this or indeed turning it through 90 degrees so the airways line up. This bit may not look as nice though.

|

| |

Last Edit: Jul 6, 2019 7:10:03 GMT by jonsey

|

|

|

|

|

|

|

|

It's a shame that it has to be mounted in front of the rad, compromising the rad's efficiency (you moved the overflow canister for that very reason). The narrowness of the front end restricts location options, but is there nowhere where it could be mounted at 90 degrees to it's existing orientation with a small vane to direct air to it?

With regard to cooling the oil, is it actually necessary? I assume that it is otherwise why go to the trouble of fitting one? I take it that it is thermostatically controlled?

No criticism implied, just curious :-) I planned to fit an oil cooler but decided against it as the sump has been enlarged and I have no plans to do roundy roundy racing or long trips on congested roads :-)

PS. Love the bracket work.

|

| |

Last Edit: Jul 6, 2019 8:08:38 GMT by nalesutol

|

|

|

|

|

|

|

|

jonsey,

Fin pitch was opened up on this core - it was tighter on the 3 core but I am at the mercy of the rad guy so have to assume he knows the correct pitch.

I don't have any issues with engine temps, it always runs at about 190f /87c to 200f/93c but I think it uses the fan a little more than it should.

The new core will hopefully run with less fan use, especially with the relocated overflow and correctly fitted trans & oil coolers.

nalesutol,

it's a trans cooler fitted at present, oil cooler will fit above it which will block more of the rad. Oil cooler is definitely required! Anything over 50mph and the oil temps rise significantly. Oil temps at motorway speeds are 250f/120c or higher which is a bit too hot, I want to get the oil down to 210-220f really.

Rad is shrouded to the front of the car fairly tightly, but there is a gap above the rad to the bonnet top of about 2" so I think another bracket can be made to close that off which may help.

The fan is totally shrouded on the other side, which makes the fan incredibly efficient, but does possibly restrict the air exiting the rad - bit of a catch 22 there unfortunately.

|

| |

|

|

|

|

|

|

|

|

Of course, should have read the post more carefully :-)

This is interesting, IMO.

|

| |

|

|

|

|

|

|

|

jonsey, Fin pitch was opened up on this core - it was tighter on the 3 core but I am at the mercy of the rad guy so have to assume he knows the correct pitch. I don't have any issues with engine temps, it always runs at about 190f /87c to 200f/93c but I think it uses the fan a little more than it should. The new core will hopefully run with less fan use, especially with the relocated overflow and correctly fitted trans & oil coolers. nalesutol, it's a trans cooler fitted at present, oil cooler will fit above it which will block more of the rad. Oil cooler is definitely required! Anything over 50mph and the oil temps rise significantly. Oil temps at motorway speeds are 250f/120c or higher which is a bit too hot, I want to get the oil down to 210-220f really. Rad is shrouded to the front of the car fairly tightly, but there is a gap above the rad to the bonnet top of about 2" so I think another bracket can be made to close that off which may help. The fan is totally shrouded on the other side, which makes the fan incredibly efficient, but does possibly restrict the air exiting the rad - bit of a catch 22 there unfortunately. The electric van will do very little for airflow over 30mph it adds a tiny bit but it is minuscule. If you have no issues with cooling in traffic you may have enough capacity to reduce the fan size and add some blown flaps to the fan shroud. When he fan is is in in traffic they close so it sucks through the rad, at higher speed when the fan is off the ram air will blow open, reducing the air side pressure drop across the pack so more air will flow through the rad and coolers. But with such a dense fin pitch in the coolers the air flow will still take the easiest route which is around the coolers and straight through the rad. Open up the fin pitch and it will go through that too. An oil cooler with a larger tube with internal turbulators will also make a huge difference too. It's all a balance when it comes to cooling when the space you have is minimal. I used to work for an oem cooling supplier developing and testing cooling systems. The designers would use a program to get a ball park design but you always had to test lots of packages in wind tunnels before the best was found. |

| |

|

|

|

|

|

|

|

Looking at the radiator I think it does not have enough capacity (no header tank) at the top the hottest part of the rad?

For the size of engine you are running.

|

| |

Last Edit: Jul 6, 2019 15:29:04 GMT by peteh1969

|

|

|

|

|

|

|

|

Pete, It's a Jag MkII rad, renowned for being big enough for small block Chevy's. I don't have any issues at all with engine cooling, its never got hot in road use - even in an hour of traffic in the west end of London.

Ragging it really hard round Goodwood got it pretty hot (235f/112c) but it did not overheat or lose a single drop of water.

I'm probably over cautious with it really. jonsey, the trans cooler is fairly open being the stacked plate design - it looks tight but there is plenty of gaps in it when held up to the light. For the oil cooler I will visit Think Automotive as they have a LOT of experience and will recommend something for me.

Talking to a few cooling specialists they have advised that with any trans or oil coolers in front of the rad - as long as they are tight to the rad core make very little difference to the airflow through both cores. The air will be a little warmer but with good flow its makes very little difference aparrently.

There is some room in the 4 corners to add some small blown flaps, I'll see how it all works out in the real world. The rad guy did say the fin pitch is a lot more open than the last one (which also cooled fine)and it's the same core as used by the Aston Martin V8's so in theory it's enough.

What fin pitch do you think it should have & how do I count it?

|

| |

|

|

|

|

|

|

|

|

As the radiator you have is a really old design (looks like a copper brass) what you need to think about is fins per inch rather than fin pitch. I started working in engine cooling in 1996 and this technology was long gone by then so I can't recommend anything but the principles of air flow ar the same. Fin pitch is the distance in mm it takes for 1 cycle of a fin in a modern aluminium style core, usually 1.2 to 1.7mm ish. I left the industry 10 years ago so things may have changed with changes in louvre technology . A louvre is the little slits in a fin that allow air to flow through and transfer the heat to the air. These are crucial to the performance of the heat exchanger. If you had 2 rads the same core size, one with a good louvre and one with a bad louvre design, the effect on the top hose temperature could be huge. This is where small rad manufacturers fall over. I know how hard it is for oem to keep this quality where parts are cut and examined under a lab conditions regularly. Your small outfit will struggle here.

Your top hose temperature of 112deg is not bad at all. If it was say 20 deg at Goodwood and let's say this engine thrashing is a worst case scenario, then with 50:50 coolant boiling at 127 deg you know you could get drive like this in an ambient temperature up to 35 deg. So engine cooling is ok (although I would cut off at 120 set for safety so your ok up to 27 deg ambient). A thinner aluminium core would vastly improve this but not look as fitting in this car.

I would like to see a better pic of the cooler, but I would say it's really not suitable. Like I did earlier air flow is king. This is closely followed by coolant flow. It looks quite restrictive in both respects. It looks more like an a/c condenser where you have up to 30 bar pressure to force refrigerant through rather than an oil pump.

|

| |

Last Edit: Jul 6, 2019 19:53:20 GMT by jonsey

|

|

|

|

|

|

|

|

Hi Jonsey, I'm a little confused on your last paragraph? The cooler in front of the rad is the auto trans cooler - which is low pressure (max 50 psi cold fluid), this works really well and keeps the trans under 160f even when towing uphill at low revs.

Engine oil cooler is not bought yet.

Car rad is as you say an old design being a Jag MkII. It has now got a modern 4 row tube with 10 fins per inch with approx 2-3mm gaps between the fins (they are a bit varied).

Original jag core was 2 row with the old style wiggly 'z' fins - which also kept the engine cool enough !! but was a bit old & clogged.

I upgraded to a 3 row tube & fin 4 years ago which was fine but upgraded to this one as I will be adding the oil cooler so wanted a bit more cooling capacity to offset the rads in front of it - if that makes sense?

Goodwood was a really hot day - approx 25 deg C.

|

| |

|

|

|

|

|

|

|

|

Apologies I thought it was trans oil getting hot, not engine oil. Why not get the trans oil cooler placed in the bottom rad tank and have an engine oil cooler in front of the radiator.

|

| |

|

|

|

|

|

|

|

Trans 'cooler' in bottom rad tank is just a tube, and water in a trans will kill it in minutes (clutches are glued with non waterproof glue) so a complete no-no in most peoples book  Trans was getting a bit too warm (190f up hill towing) with the same style cooler on it but only 3.5" tall, this one is 5.5" and it only now gets to 160f towing uphill, so perfect. I'm running a 3500rpm stall converter so a lot of heat is generated at low revs so the OEM tube in bottom tank in rad would be woefully inadequate! What do you think of the rad tube/fin pitch? It's pretty easy to see through so should have good flow? |

| |

|

|

|

|

|

|

|

|

I did write a big long bit about engine cooling but then I rechecked your numbers and decided to scratch it. If the top hose was only getting to 112 in a 25 ambient then that is pretty good for the fpi you have. If your only getting to 120deg oil, that is good too. We would abandon test by 150 deg as per standards.

If it were my car I wouldn't fit an oil cooler. In fact I've taken them off previous race cars. I'd rather have warm oil in the engine then cool oil on the floor due to a leak.

|

| |

|

|

|

|

|

|

|

|

Those water temps were with the old rad core so hopefully the new one will be better.

Oil cooler is needed as if I take it to 80mph plus the the temp just keep climbing. Goodwood ragging saw it climb to around 300f in under 5 mins! I hear you on the possibility of leaks though.

|

| |

|

|

only one from driving over a rock?

only one from driving over a rock? good.

good. only one from driving over a rock?

only one from driving over a rock? good.

good.