sonus

Europe

Posts: 1,392

|

|

|

|

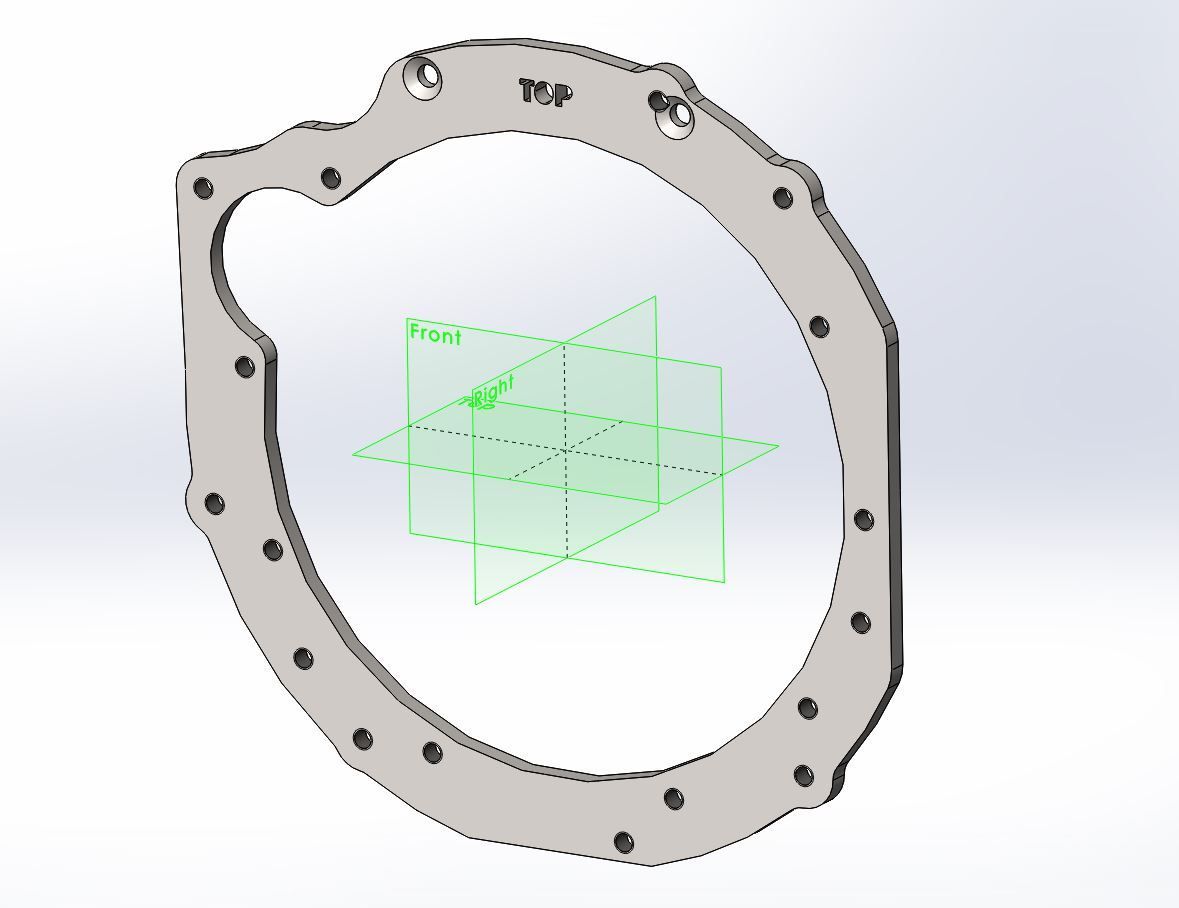

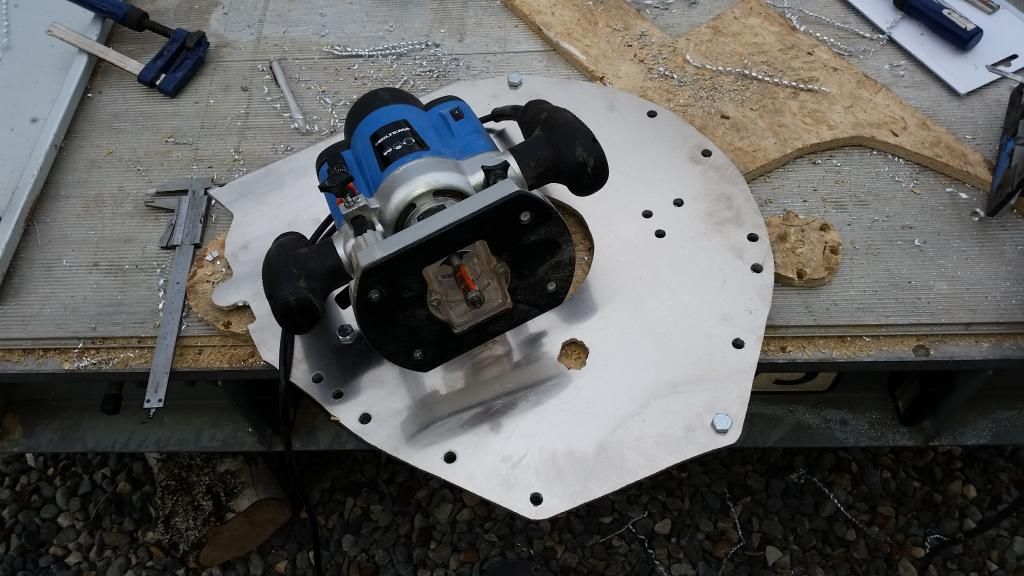

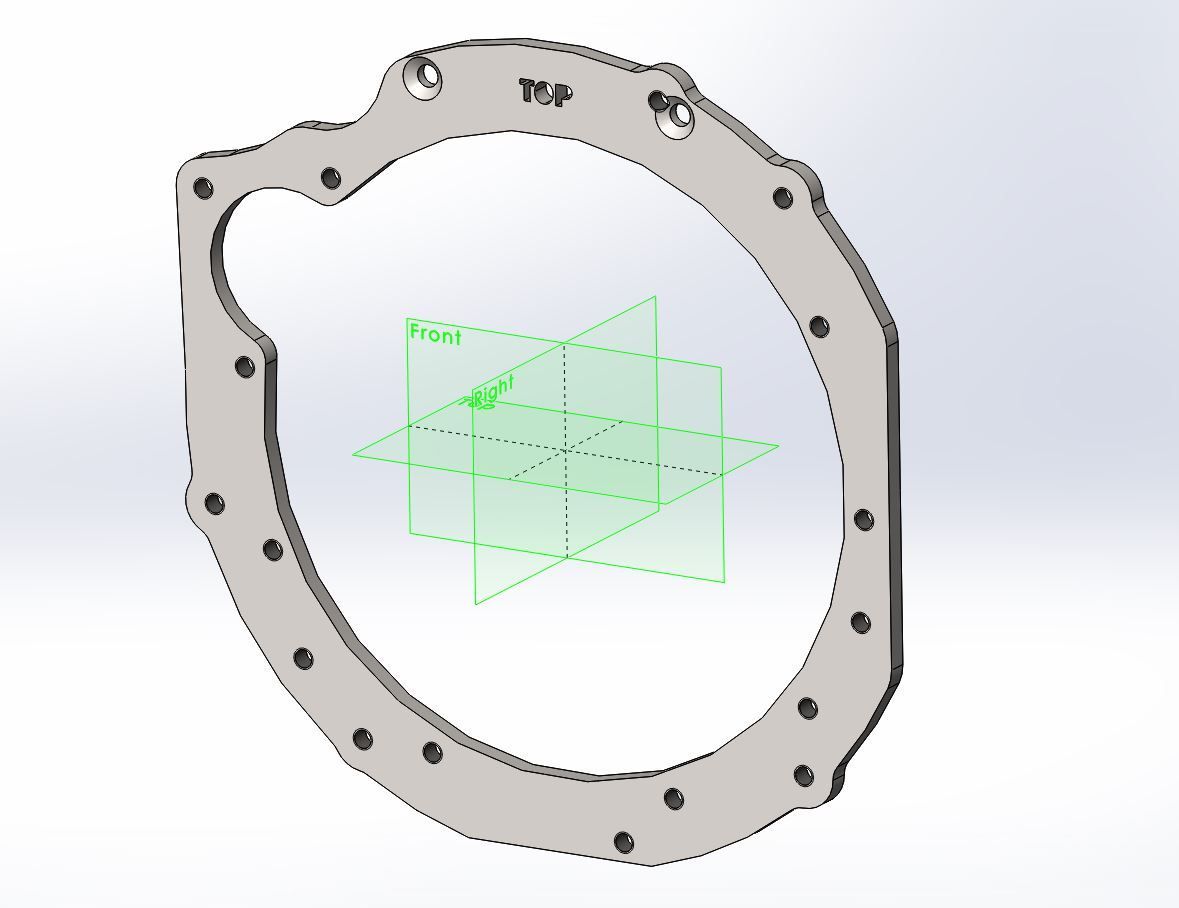

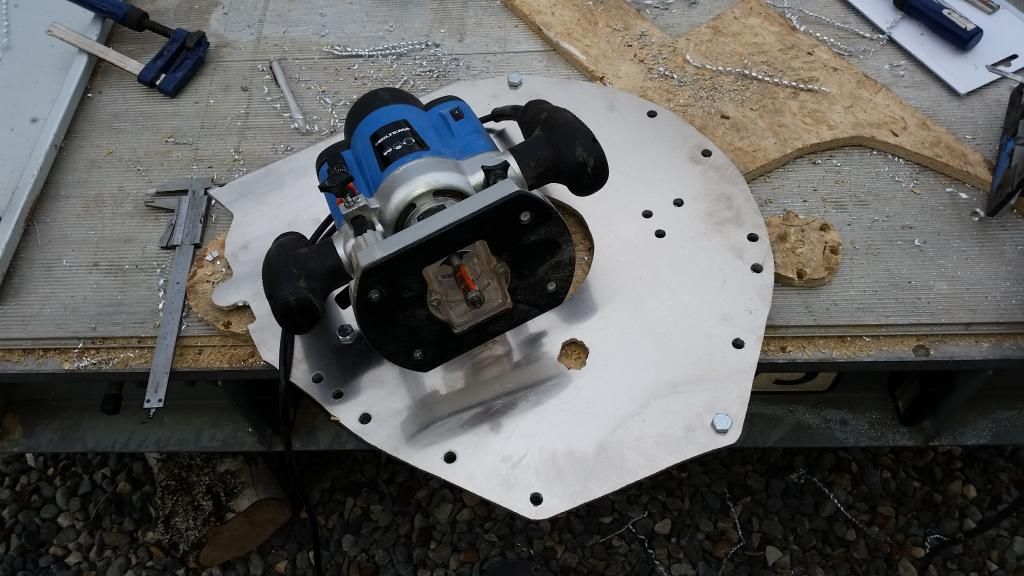

Really liking this! That adapter plate would have been very easy to mill out of aluminum with a router and carbide bit. I did that when making my adapter plate between my Daimler v8 and BorgWarner T5 Thank you, and that looks like a nice job  I was only doing the plywood version to verify this:  I have designed it in solidworks with a view to being able to Lasercut it, Waterjet cut it or just CNC Machine it out of Tooling plate, all of which I can get done at work. That will be much more accurate than my plywood template. Hopefully I should have the finished steel product sometime this week Cheers for looking as always Dom Ahh.. Access to those tools renders my approach rather cumbersome and unaccurate:) |

| |

Current

1968 TVR VIXEN S1 V8 Prototype

2004 TVR T350C

2017 BMW 340i

Previous

BMW 325d E91LCI - sold

Alfa Romeo GTV - sold

Citroen AX GT - at the breakers

Ford Puma 1.7 - sold

Volvo V50 2.0d - sold

MGB GT - wrecked by fire

MG ZT 1.8T - sold

VW E-golf Electric - sold

Mini Countryman 1.6D -sold

Land Rover Discovery TD5 - sold

|

|

|

|

sonus

Europe

Posts: 1,392

|

|

|

|

Really liking this! That adapter plate would have been very easy to mill out of aluminum with a router and carbide bit. I did that when making my adapter plate between my Daimler v8 and BorgWarner T5  I don't want to hijack this thread but, do you have more information or perhaps your own thread on how you did this? Thanks I'll post a thread in technical when I've got the time. Will PM link when done. |

| |

Current

1968 TVR VIXEN S1 V8 Prototype

2004 TVR T350C

2017 BMW 340i

Previous

BMW 325d E91LCI - sold

Alfa Romeo GTV - sold

Citroen AX GT - at the breakers

Ford Puma 1.7 - sold

Volvo V50 2.0d - sold

MGB GT - wrecked by fire

MG ZT 1.8T - sold

VW E-golf Electric - sold

Mini Countryman 1.6D -sold

Land Rover Discovery TD5 - sold

|

|

jpsmit

Posted a lot

Posts: 1,274

|

|

|

|

I don't want to hijack this thread but, do you have more information or perhaps your own thread on how you did this? Thanks I'll post a thread in technical when I've got the time. Will PM link when done. I appreciat it, thanks! |

| |

|

|

|

|

|

Jun 14, 2015 19:00:42 GMT

|

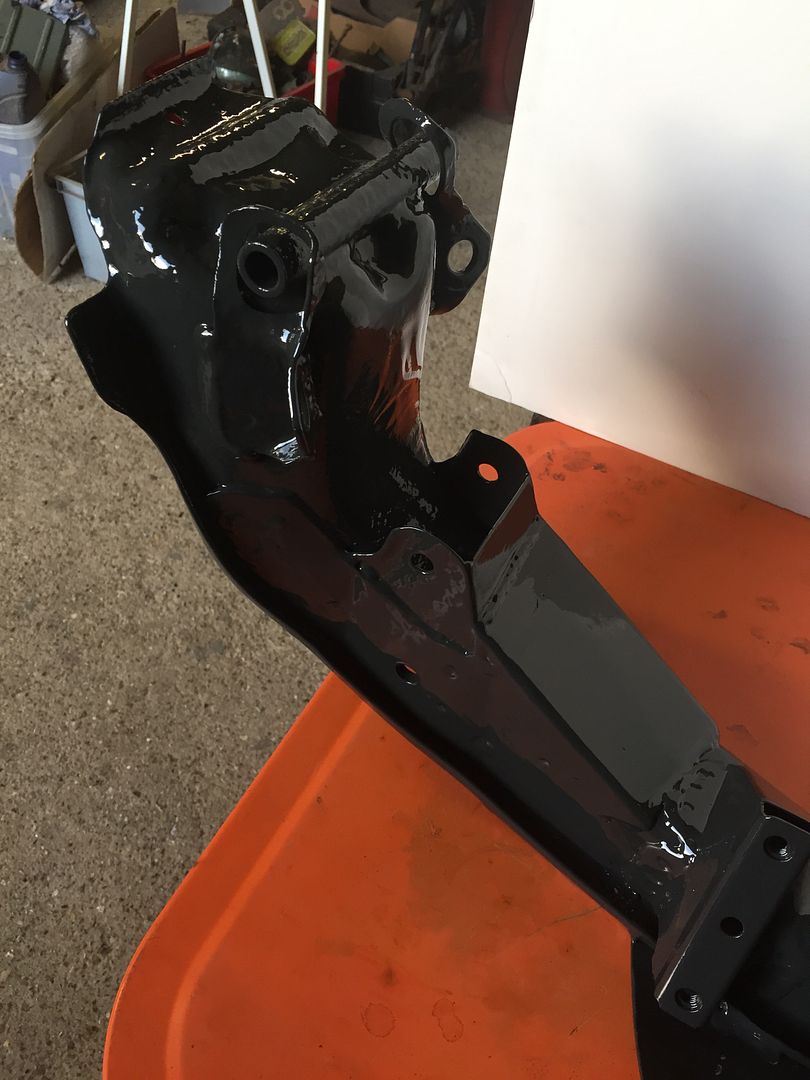

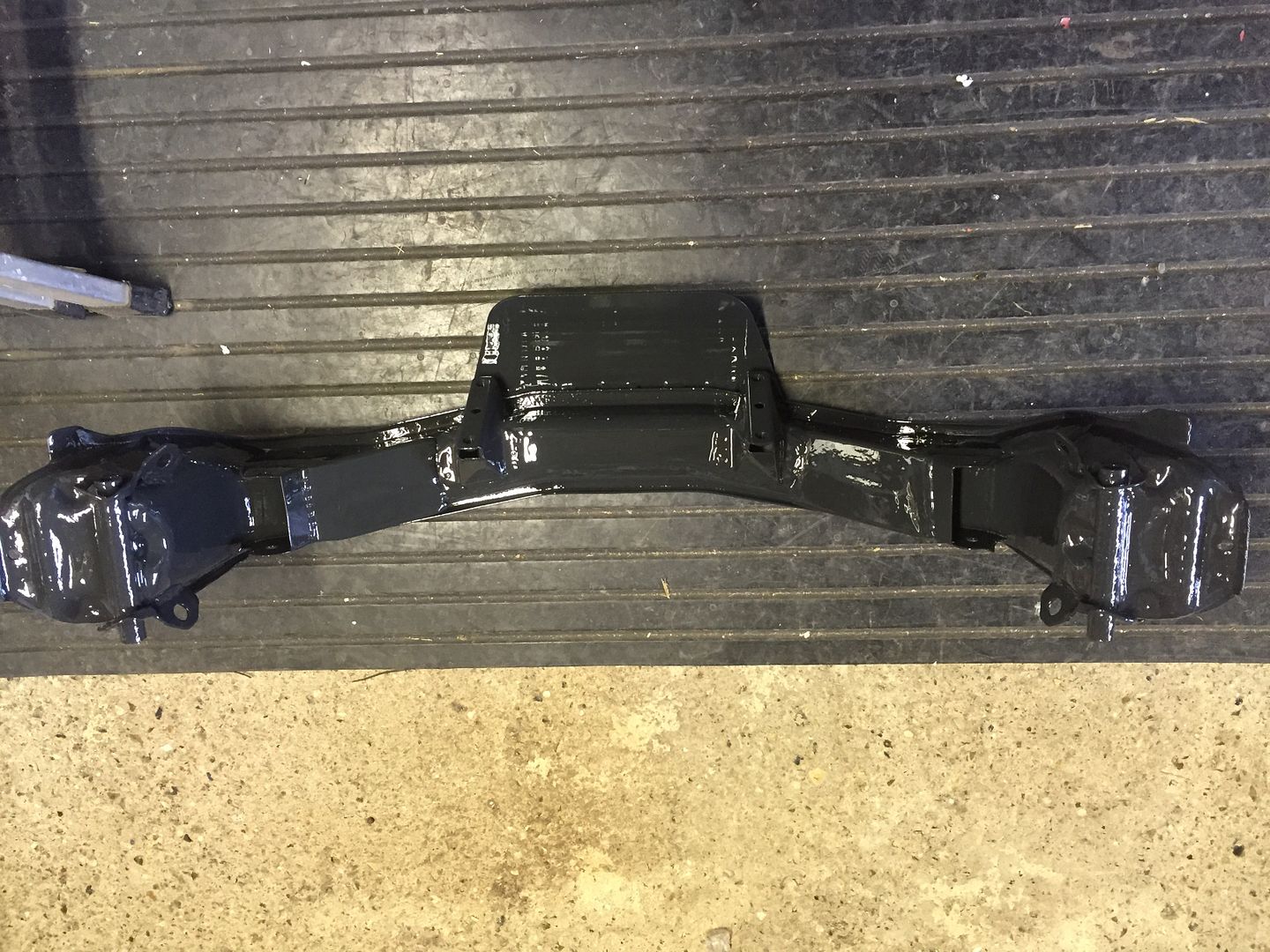

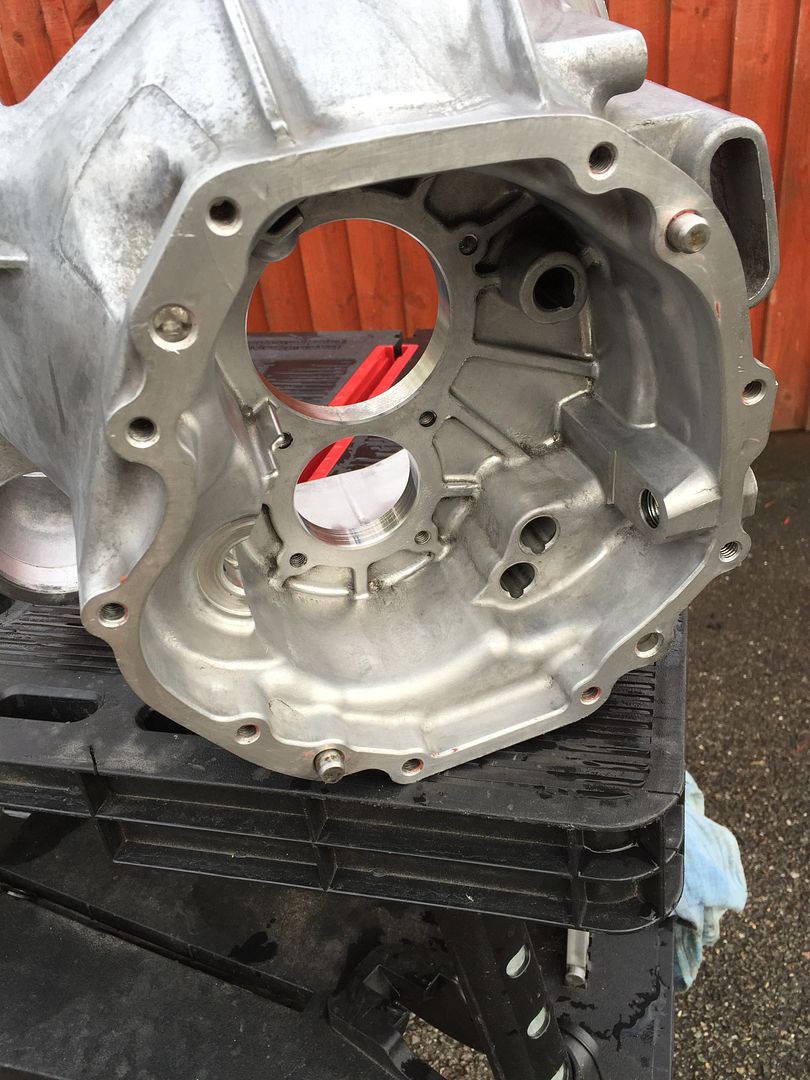

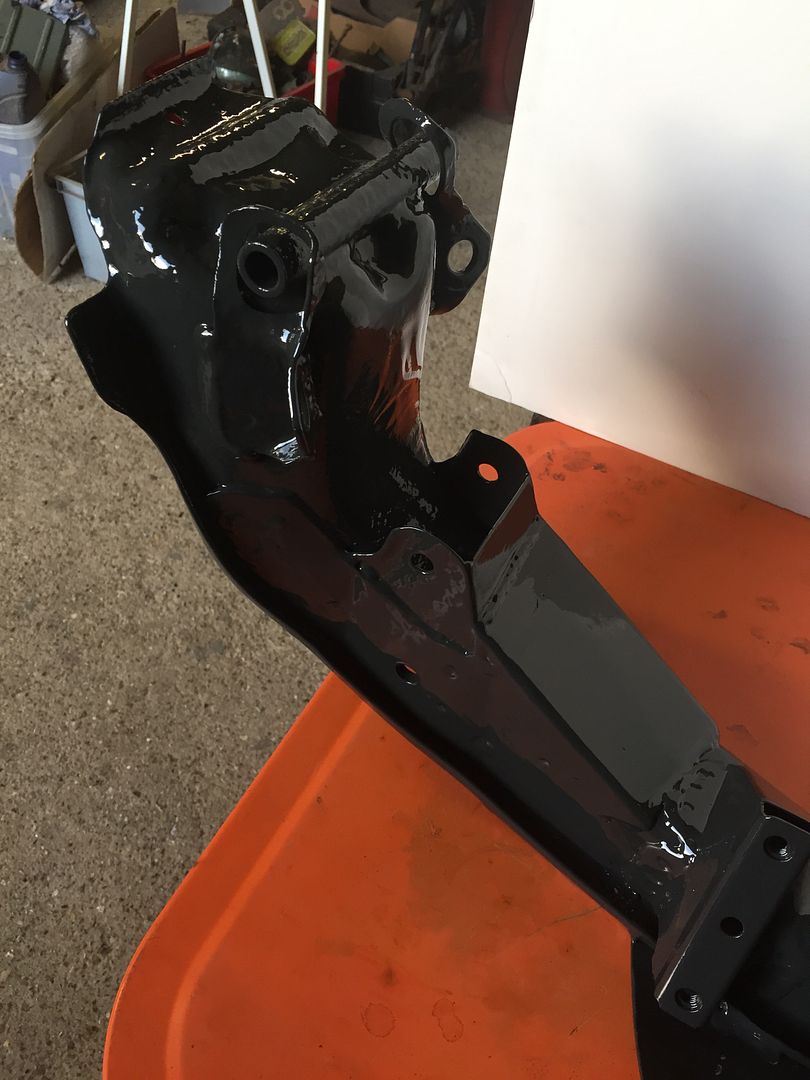

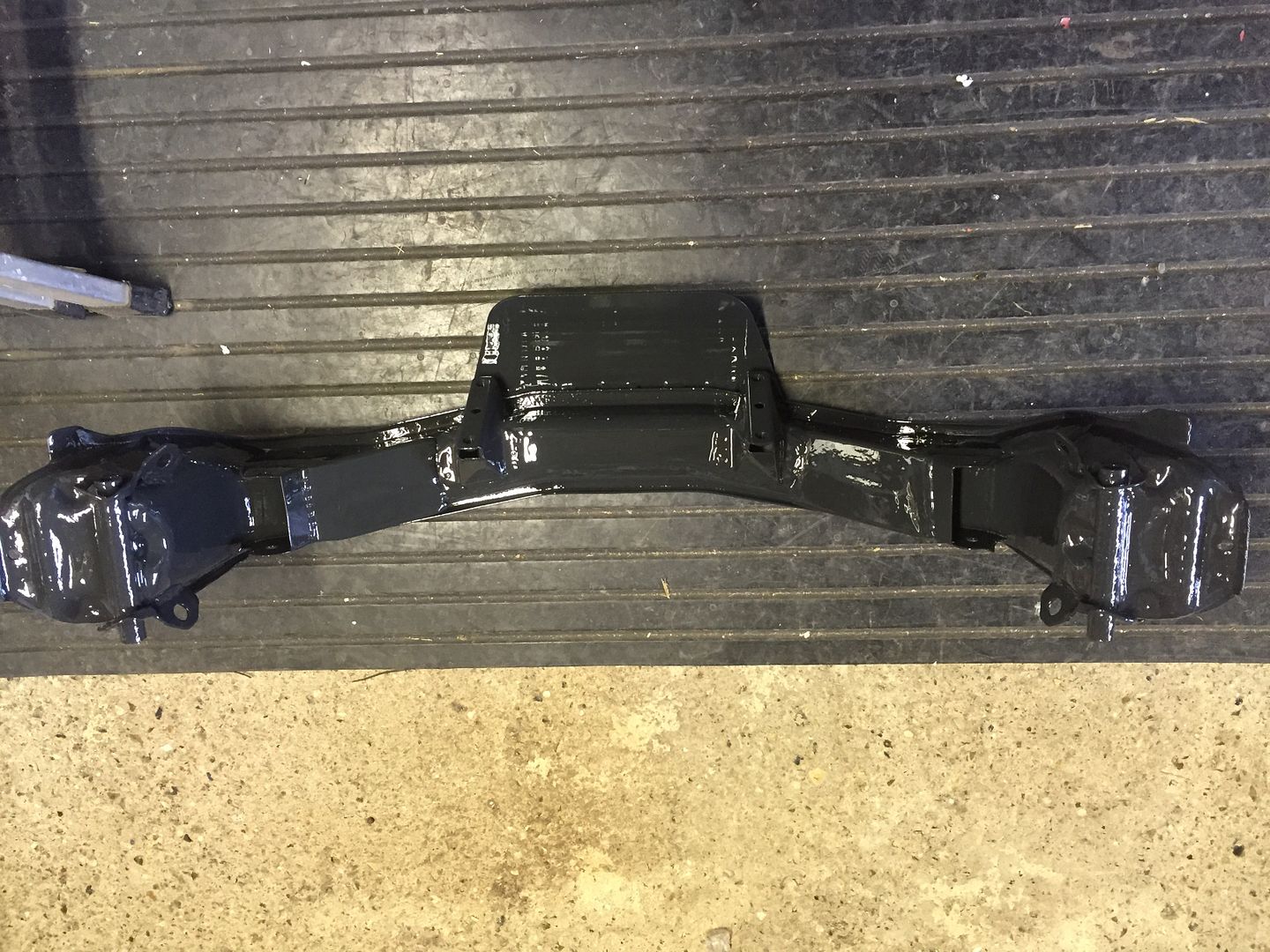

Just a quick update, I got my Crossmember blasted again after all the strengthening was finished, and then in to paint too         Not much of an update but psychologically very important for me, apart from the rack strip down and detail, this is an almost completely overhauled front end, re plated / painted and ready to go back together. Nice to be able to put finished stuff on the shelf now. In other news I was assured my Adaptor plate was going to be Waterjet cut on Friday night, so hopefully I`ll see it for the first time on Monday !! Fingers crossed it works as Hoped. That's important too, as it means I can get the dummy block and box back in the car, then see what mods I need to make to the shell and tunnel to get it all to work nicely together. I`ll probably put an exhaust tunnel in while I am there too, save messing about later and make it much easier to flat floor too. Thanks for looking as always Cheers Dom |

| |

|

|

|

|

|

Jun 16, 2015 14:49:06 GMT

|

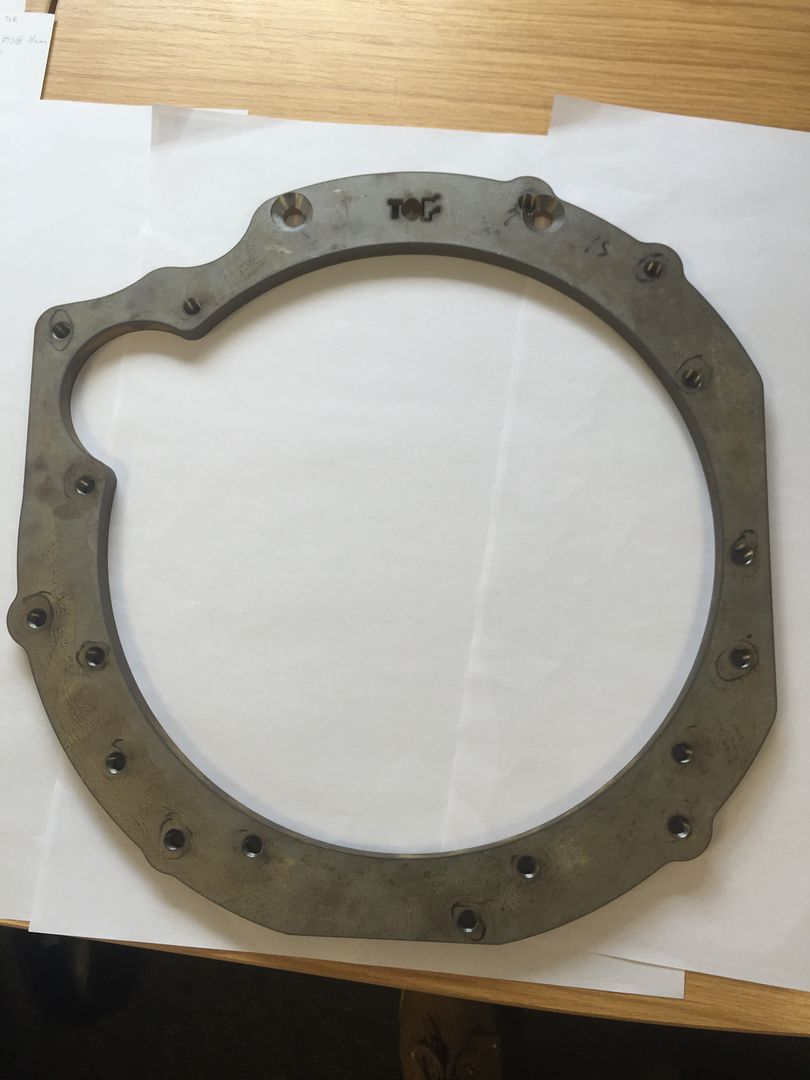

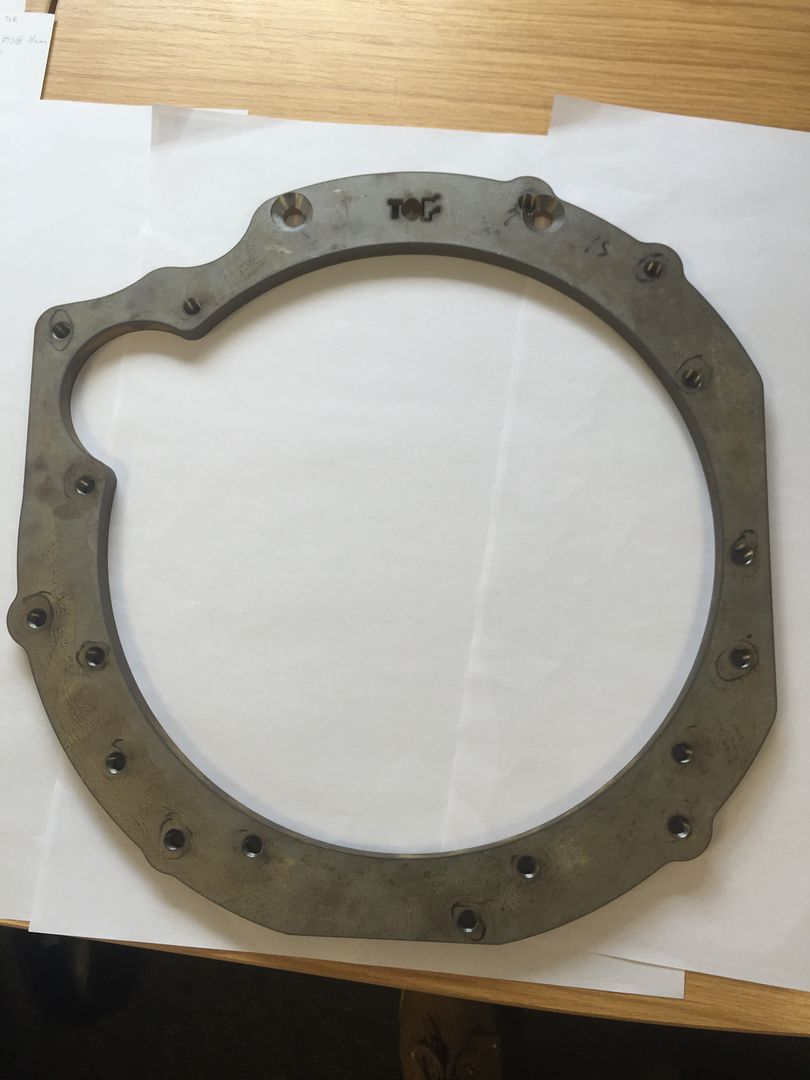

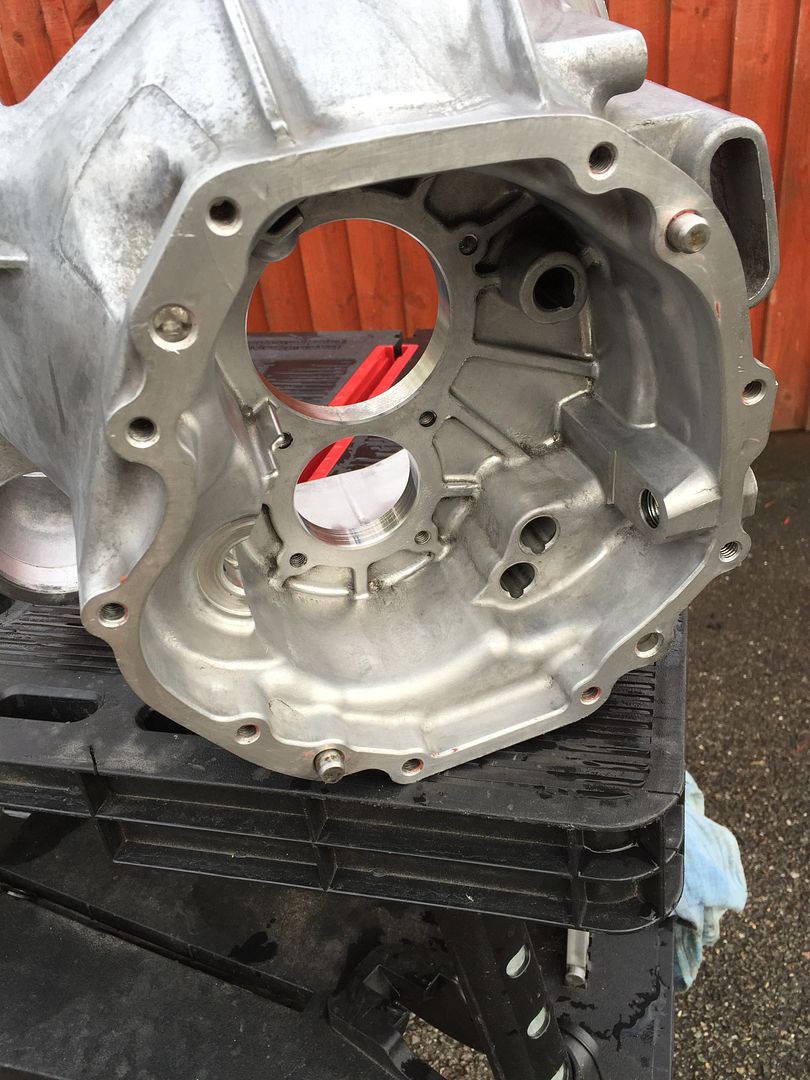

Well I now have an adaptor plate to try when I get home   Waterjet had a bit of a wobbly on the lettering  And I've got the 2 top block fixings countersunk as well  so fingers crossed I`ll try it on tonight Thanks for looking as always (If you do? its a bit quiet in here) Hopefully more pics with it all together later Cheers Dom |

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,971

Club RR Member Number: 71

|

|

Jun 16, 2015 15:27:15 GMT

|

|

Always look at every update - don't always have something constructive to say

Liking that - I can put up with wobbly lettering

|

| |

|

|

|

|

|

Jun 16, 2015 16:51:18 GMT

|

Always look at every update - don't always have something constructive to say Liking that - I can put up with wobbly lettering Thanks Fella  You wont see the lettering anyway once its fitted |

| |

|

|

|

|

|

Jun 22, 2015 11:36:51 GMT

|

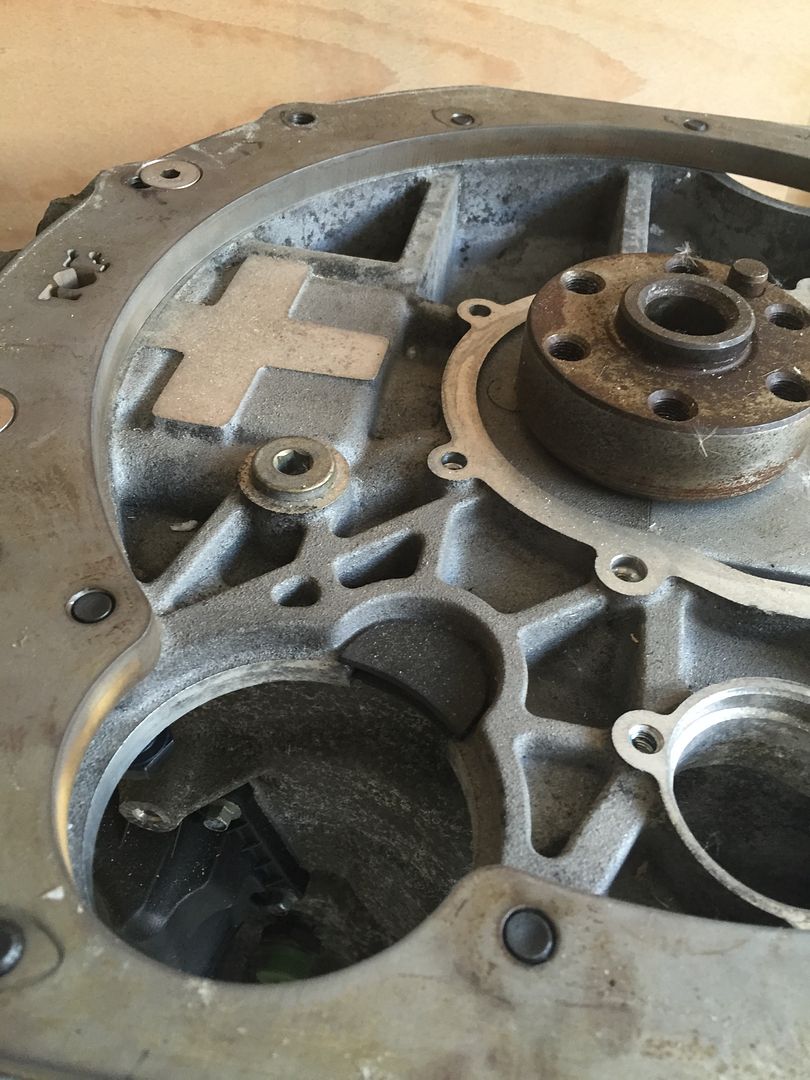

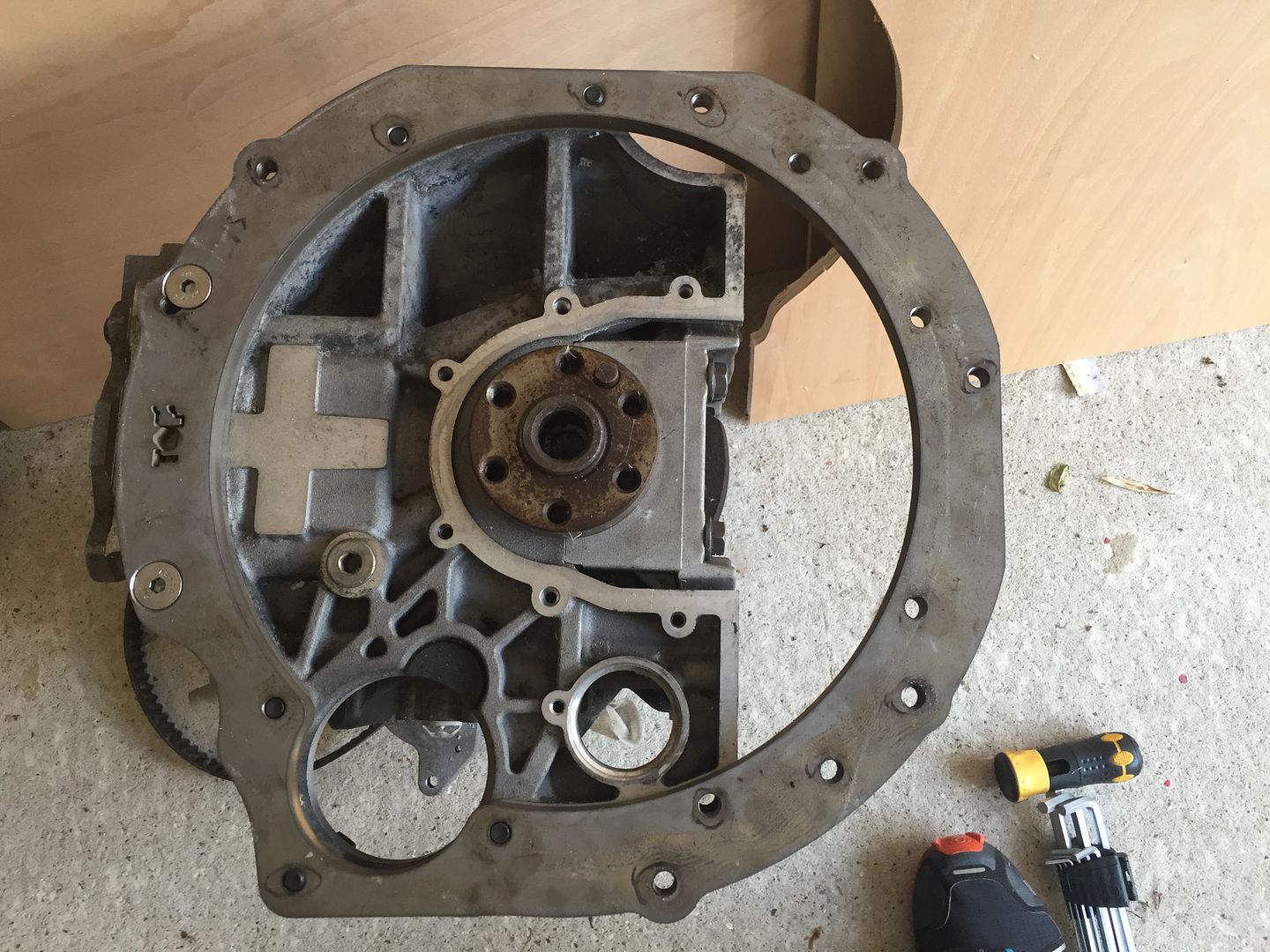

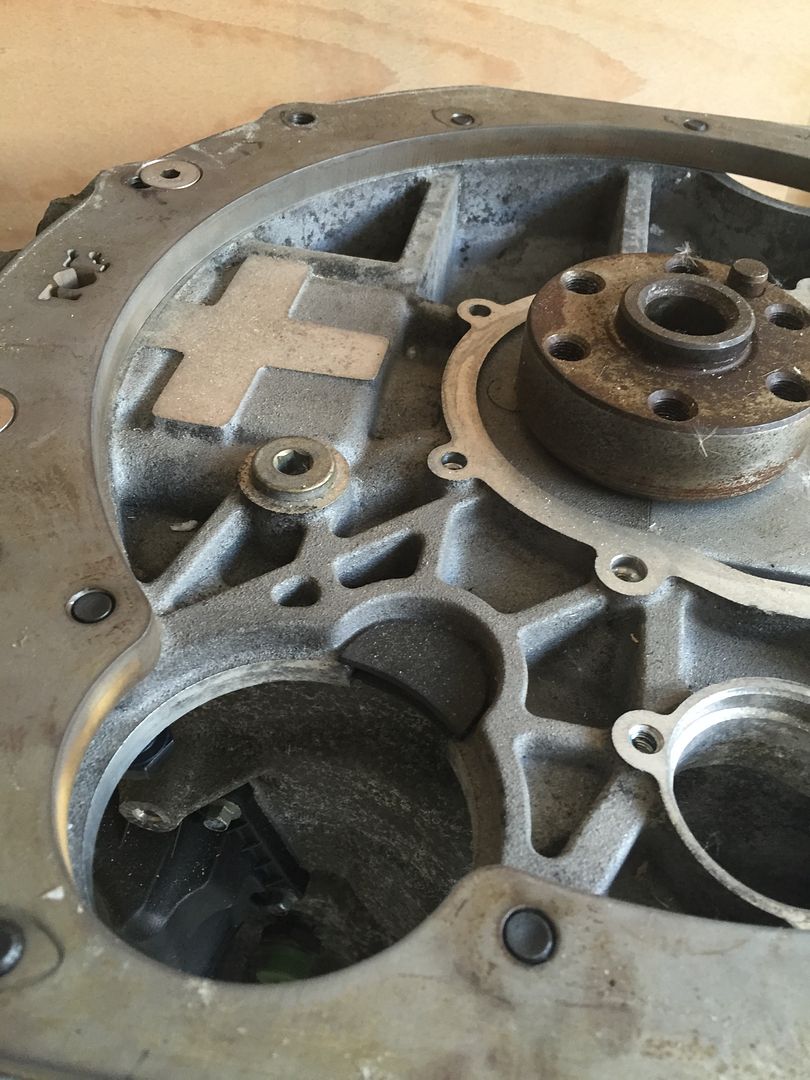

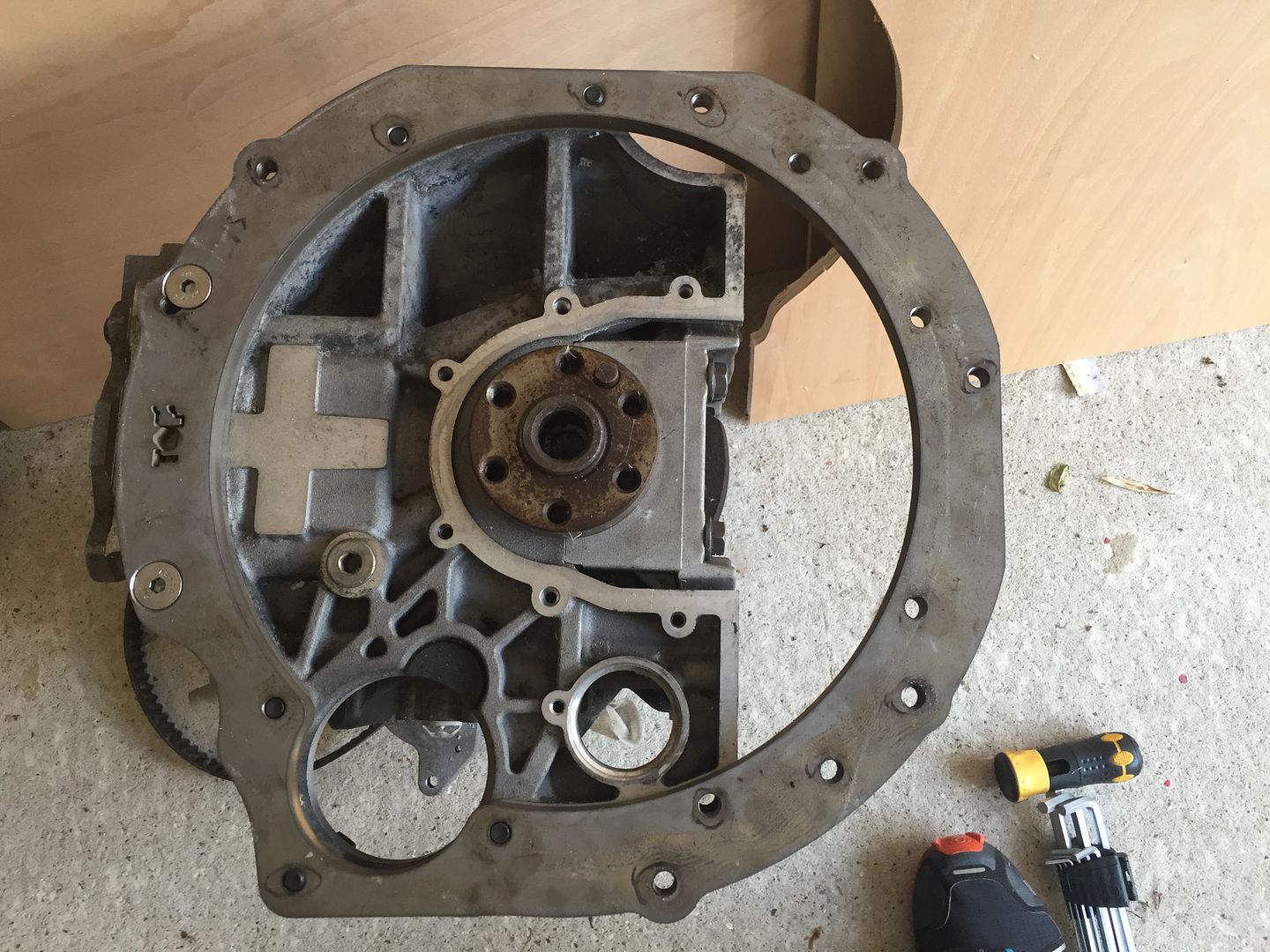

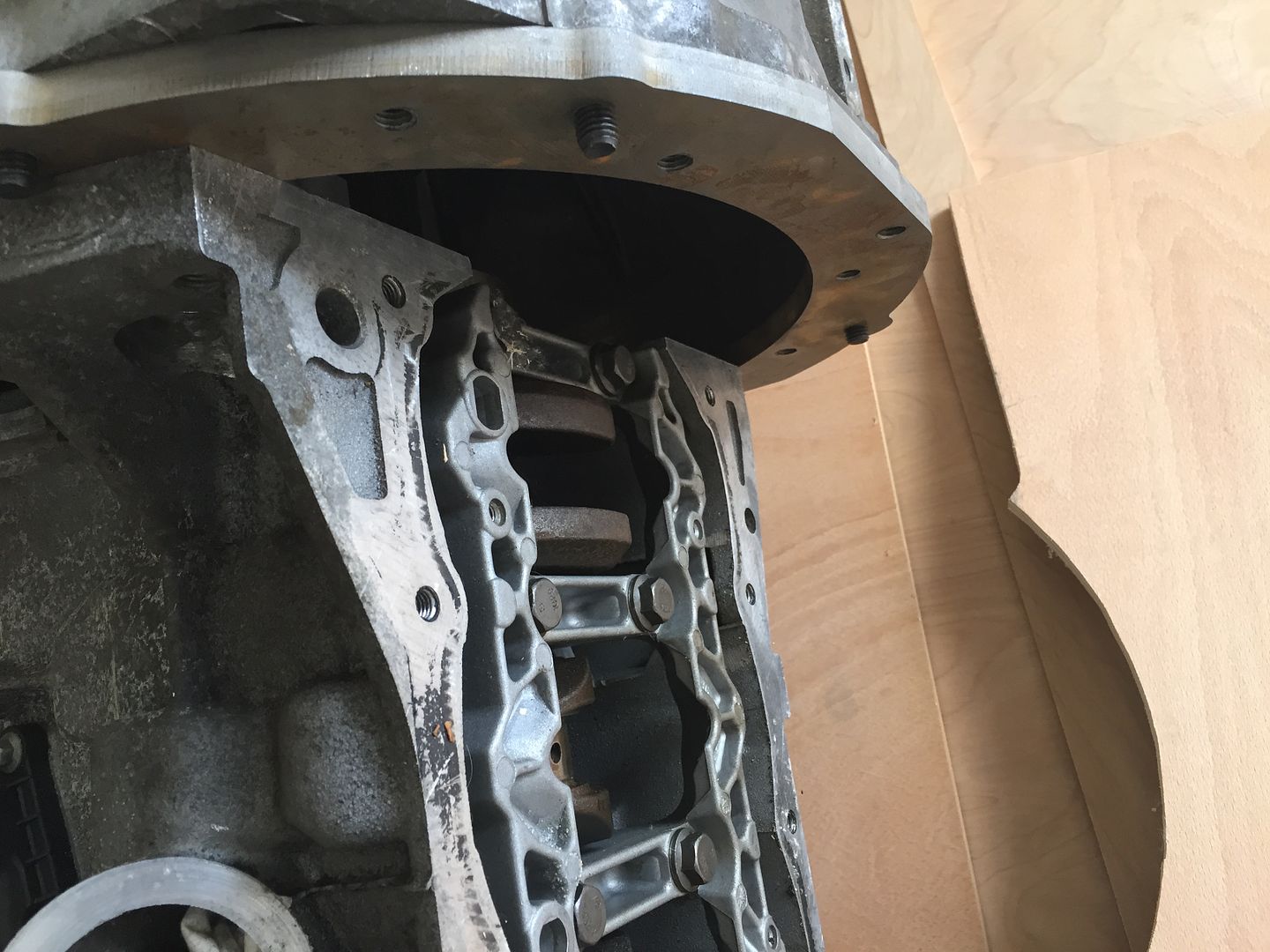

Well it looks like it just might work        I need to get the front of the box off to make some clearance for the sigma starter motor, while it is off I am going to measure the hole positions on the CMM (Co-Ordinate measuring machine)as That's the only bit I didn't do. Its slightly out so I want to get it right. I may tilt the box slightly too which will allow me to share a hole rather than a partial offset that we have at the moment. That would also enable it to be waterjet cut from Aluminium and I would helicoil the fixings to get the nessasary pull out strength on the thread. I`ll drop to 10mm thick from 12 to give me more spigot bearing engagement too. Thanks for looking as always Cheers Dom |

| |

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Jun 22, 2015 12:15:45 GMT

|

|

Looks good mate, and very professional too.

|

| |

|

|

|

|

|

Jun 22, 2015 12:58:17 GMT

|

Looks good mate, and very professional too. Thank you, I`m lucky to have access to some fantastic kit at the moment, I don't have the hours available to spend in the shed right now so I have to use the tools I have available to keep progress going. I want it to look like a Factory prototype, kind of a modern interpretation of a period Works car...... I suppose the closest analogy I can think of is a Singer GT3RS 911 |

| |

|

|

|

|

teaboy

Posted a lot

Make tea, not war.

Make tea, not war.

Posts: 2,125

|

|

Jun 22, 2015 17:56:06 GMT

|

I want it to look like a Factory prototype, kind of a modern interpretation of a period Works car...... That sounds like perfection to me. |

| |

|

|

|

|

|

Jun 24, 2015 16:42:15 GMT

|

|

Dayyyym!

Amazing work dude - that adapter fits like a glove!

|

| |

78 Kadett C 2.0 8 valve turbo, holset, rust&other stuff..

|

|

|

|

|

|

|

Dayyyym! Amazing work dude - that adapter fits like a glove! Thank you  To the block it does, I am less happy about the fit to the box, so I`ll remove the front section of gearbox and measure it properly soon. Then I`ll do the same again but in Alloy, with some fine thread steel inserts to get the bolt pull out torques required Cheers for looking as always |

| |

|

|

|

|

|

Jul 13, 2015 14:41:00 GMT

|

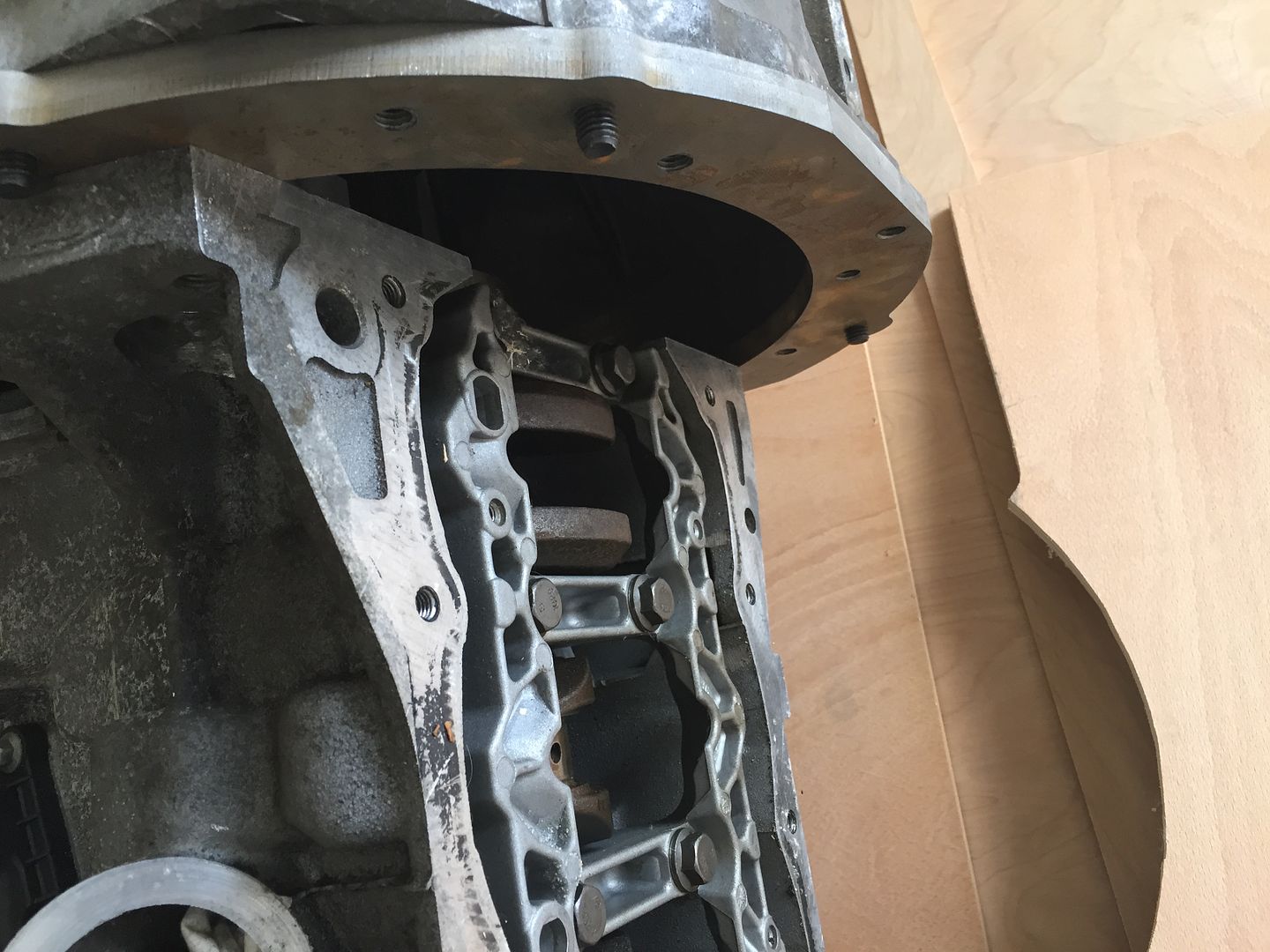

Well I picked one of the warmest days to do it, which wasn't that much fun !! But I got the front end off the RX8 Box with much swearing and gearbox oil everywhere  One bolt which a selector locates on was a pain, and I had to resort to welding the internal hex up, then welding a nut on the outside of it so the heat would break the locktite seal and I could get a big breaker bar on it.  But with that finally out of the way, I could get the front end of and cleaned up ready for measuring accurately on the CMM / FARO Arm at work.     So brought it in to work today, hopefully have it measured up tomorrow, and then I can adjust the cad model to suit as well While it is separate, I`ll have it mated to the block again and see what clearance I need to make for the starter motor too. Then I can chop out and weld up a new starter section. I`ll make some blanking plates up as well and generally tidy it up. The new adaptor plate will probably be aluminium with some proper steel thread inserts, and fine thread M10 bolts to hold it all together. I`ll also drop down to 10mm plate rather than 12mm to give some additional engagement to the input shaft and spigot bearing. So it is all progressing. As its unlikely to be done this year (Being realistic) I may have just brought another trackday toy too........which means I can have some fun on track while remaining inside the law on the roads.   Cheers for looking as always Dom |

| |

|

|

|

|

|

Jul 13, 2015 17:30:58 GMT

|

Looks like you chose wisely on the toy  brilliant  Cross member has a great finish, looks like we are at similar points in the project  |

| |

|

|

|

|

|

Jul 13, 2015 17:50:40 GMT

|

|

LOL yeah, 180ish Hp from an effectively standard blacktop crate engine (Which is fitted now, rather than the silvertop in the photo) on TB`s and Management, should be plenty fun enough on track.

|

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,971

Club RR Member Number: 71

|

|

Jul 13, 2015 19:08:38 GMT

|

|

Oooh liking the new toy - bringing it to Snet on Wed?

|

| |

|

|

|

|

|

Jul 13, 2015 19:37:41 GMT

|

|

10 mm alloy plate is what I made my adaptor from. And then I machined steel inserts with large shoulders that I pressed in from the back. Metric fine thread. Not a problem so far so you'll be fine.

I had 5 mm radius difference between flywheels so machined the locating step on the v6 starter offeet by 5 mm in a four jaw chuck and managed to get that sweet. But you have more difference and less starter material to play with yeah? Could you split the starter down, build up the locating face with a tig welder and then re- machine it?

|

| |

Last Edit: Jul 13, 2015 19:39:34 GMT by yoeddynz

|

|

|

|

|

|

|

10 mm alloy plate is what I made my adaptor from. And then I machined steel inserts with large shoulders that I pressed in from the back. Metric fine thread. Not a problem so far so you'll be fine. I had 5 mm radius difference between flywheels so machined the locating step on the v6 starter offeet by 5 mm in a four jaw chuck and managed to get that sweet. But you have more difference and less starter material to play with yeah? Could you split the starter down, build up the locating face with a tig welder and then re- machine it? Yeah that was the plan  Flywheels - I am using the Billet steel TTV Sigma flywheel and the Sigma Starter motor, so its not a problem I may look at a custom hi torque starter later on to fit the RX8 position, but I only need that if I need the sigma starter space for the Lysholm charger in phase 2  |

| |

|

|

|

|

|

|

|

Oooh liking the new toy - bringing it to Snet on Wed? Hasn't been delivered yet, but I`m hoping to be there. Are you going in the LC ? |

| |

|

|

|

|

[*]

[*] [*]

[*]