It's not old, but the technology is certainly retro

Well,

I've had this a while, but I didnt want to post it up until I knew it was back 100% driving. I bought it last October/November with a noisey bottom end, and it turned out it needed a gearbox rebuild too. Found it by accident when I was in the UK, and the condition knocked me back. It was only after I drove it that we discovered the problem, so after a bit of bartering it was mine!

The car is a 00 Mini Cooper, half leather interior, 55k on the clock and it is IMMACULATE. Cant find any rust on the yoke.

Here are some pics of the car:

After I got it back to Ireland, I eventually brought the crank to Howard engineering for them to reground. Once that was done, a friend, Albert fitted it all back together with another gearbox which I'd sourced. Turns out this gearbox was a crapper and the diff pin sheared in half leaving the car with absolutely no drive.

So I was nearly back to sqaure one, but didnt want to pay someone to do all the work again. Due to some inspirational talk from Neil, I decided to get the old gearbox rebuilt (just had a slightly crunchy 2nd, I've seen much worse stay on the road) and fit it myself.

Got the rebuilt gearbox back from Simon Evans (Rallies Minis) on Friday and started work on the car friday night in Neils garage. We disconnected everything underneath and called it a night.

Arrived in on Saturday late enough and started disconnecting the rest of the stuff. Gary, a mate, arrived at around 3, and Neil headed off. We made amazing progress, managing to get the engine out, and flywheel housing off. Couldnt go any further without flywheel pullers.

Sat morning:

Sat evening:

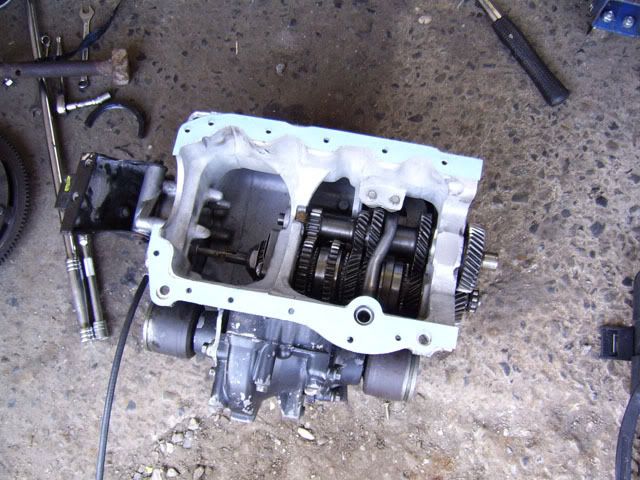

Sunday afternoon, I headed over to Albert to grab his pullers from him, and then pulled the flywheel off and got the old box off. It looked like this:

Nice!

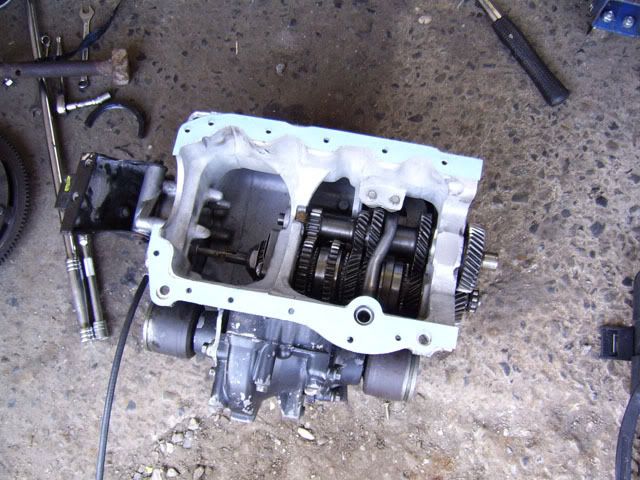

This is the new box to replace it:

Lining up the block with the box:

Neil arrived at this stage with some much needed gasket sealant, and all the gaskets were put on and the engine and box, and clutch/flywheel connected.

The two of us got the engine sitting back in and lined up and a few of the ancilleries connected and decided to call it a night.

Today, after work, I headed up to finish it off. Got quite a bit done, then Gary and Alan, another mate, arrived to give me a hand with all the fiddly stuff.

This is how it looked just before we put back on the bonnet and airbox:

Took it for a spin and everything seems grand. Need to stick on its new alloys and give it a good wash and a polish before proper pics come!

Want to say a HUGE thanks to Neil for letting me use his garage, a big thanks to Gary who came out twice to help me out. I also couldnt have done it without Alans cable tieing skillz, and also Bert and Simon Evans for all the work they did for me. Finally, I'd like to thank the Mini for starting ;D Oh and Engine Cat - who helped loads

Well,

I've had this a while, but I didnt want to post it up until I knew it was back 100% driving. I bought it last October/November with a noisey bottom end, and it turned out it needed a gearbox rebuild too. Found it by accident when I was in the UK, and the condition knocked me back. It was only after I drove it that we discovered the problem, so after a bit of bartering it was mine!

The car is a 00 Mini Cooper, half leather interior, 55k on the clock and it is IMMACULATE. Cant find any rust on the yoke.

Here are some pics of the car:

After I got it back to Ireland, I eventually brought the crank to Howard engineering for them to reground. Once that was done, a friend, Albert fitted it all back together with another gearbox which I'd sourced. Turns out this gearbox was a crapper and the diff pin sheared in half leaving the car with absolutely no drive.

So I was nearly back to sqaure one, but didnt want to pay someone to do all the work again. Due to some inspirational talk from Neil, I decided to get the old gearbox rebuilt (just had a slightly crunchy 2nd, I've seen much worse stay on the road) and fit it myself.

Got the rebuilt gearbox back from Simon Evans (Rallies Minis) on Friday and started work on the car friday night in Neils garage. We disconnected everything underneath and called it a night.

Arrived in on Saturday late enough and started disconnecting the rest of the stuff. Gary, a mate, arrived at around 3, and Neil headed off. We made amazing progress, managing to get the engine out, and flywheel housing off. Couldnt go any further without flywheel pullers.

Sat morning:

Sat evening:

Sunday afternoon, I headed over to Albert to grab his pullers from him, and then pulled the flywheel off and got the old box off. It looked like this:

Nice!

This is the new box to replace it:

Lining up the block with the box:

Neil arrived at this stage with some much needed gasket sealant, and all the gaskets were put on and the engine and box, and clutch/flywheel connected.

The two of us got the engine sitting back in and lined up and a few of the ancilleries connected and decided to call it a night.

Today, after work, I headed up to finish it off. Got quite a bit done, then Gary and Alan, another mate, arrived to give me a hand with all the fiddly stuff.

This is how it looked just before we put back on the bonnet and airbox:

Took it for a spin and everything seems grand. Need to stick on its new alloys and give it a good wash and a polish before proper pics come!

Want to say a HUGE thanks to Neil for letting me use his garage, a big thanks to Gary who came out twice to help me out. I also couldnt have done it without Alans cable tieing skillz, and also Bert and Simon Evans for all the work they did for me. Finally, I'd like to thank the Mini for starting ;D Oh and Engine Cat - who helped loads

Spot on.......Whens it my go!

Spot on.......Whens it my go!