I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I must not poke crusty bits

I poked....................

curse word

My day in pictures

I waxoiled the chassis rail and then noticed a bit of waxoil oozing out of a scabby bit on the chassis rail - well I couldn't leave it like that!!!

I'd hit it hard with a zip wheel when I was cleaning up the underside before painting and underseal and it didn't turn to dust but it obviously wasn't as sound as I thought

Chop chop

Glad I did - had to go a fair way over till I got to good steel

Grind grind - shiney steel

I'd had me cornflakes so the box came in handy - make a card template

Transfer to 1.5 mm steel

Cut, sand, hammer and splash a bit of weld thro primer on it

Same with the chassis rail that remained

Had a few hard drive failures over the years - recently liberated a few magnets out of the dead ones - make great fixings for butt welding - even better when you can find more than one of them - bloody mini in the garage seems to have eaten them all

Don't try to weld near one does weird sh!t to the arc!!

I know it looks a bit "gappy" but with multiple curves I find it easier to weld it in where it touches and then go round beating it into the shape that closes up the gaps - works well with chassis sections - not so well with bodywork!!!

Yes it did catch fire - but I was ready for it - I knew that the wax oil would flame up quite nicely

First piece in

Grind it back

Cornflake box and scissors I have plenty so knock the next bit up (holes are for a few puddle welds - spot welds with a MIG) My Portamig was appreciating the break as it's not been on power 5 out of 12 for a while - minis don't like anything more than 15 amps

Splash a bit of weld thro on it

Hit it with the sparkly stick

Upside down welding - yeah that's my strong point - NOT

Grind it back (just the weld so as not to thin the metal)

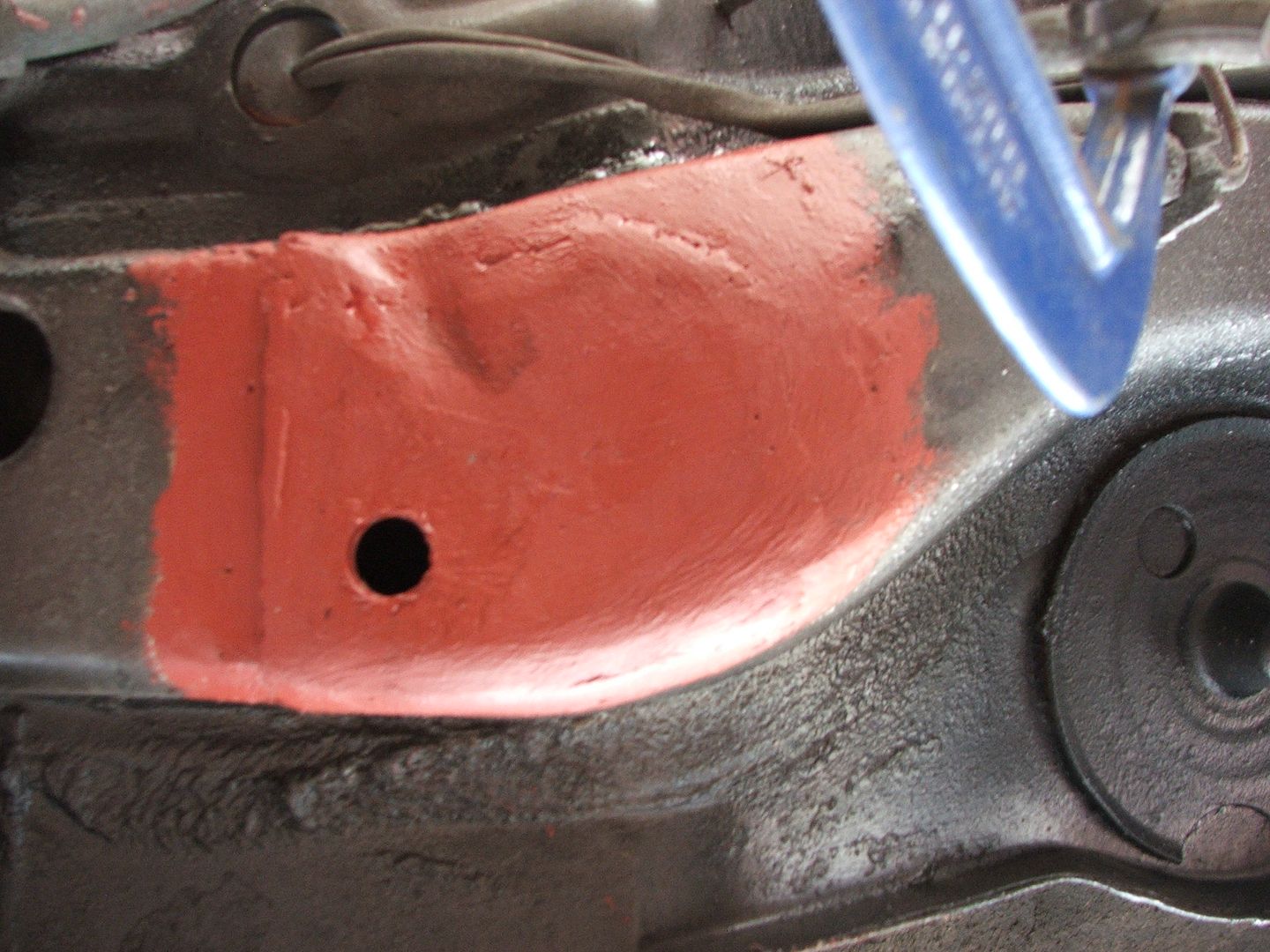

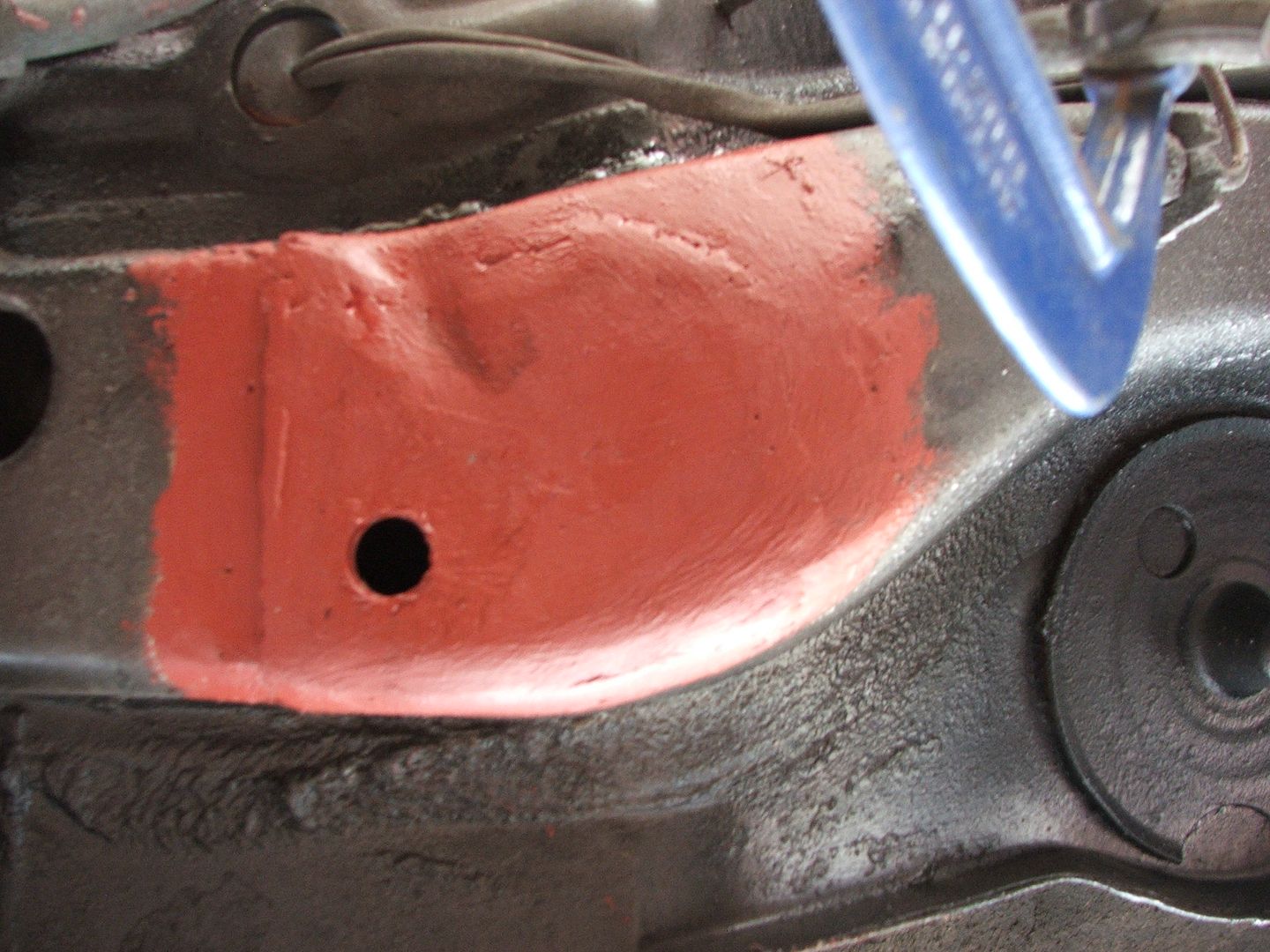

Bit of Red (Pink) Oxide - I remembered to drill a new drain hole

Am I happy with that......

Well a blind man on a galloping horse would be so

Slap some chassis black on it then

There I did it I posted pics of my not so invisible repair and "functional" welding - who'd have thunk it!!!

Subframe can go back up tommorrow

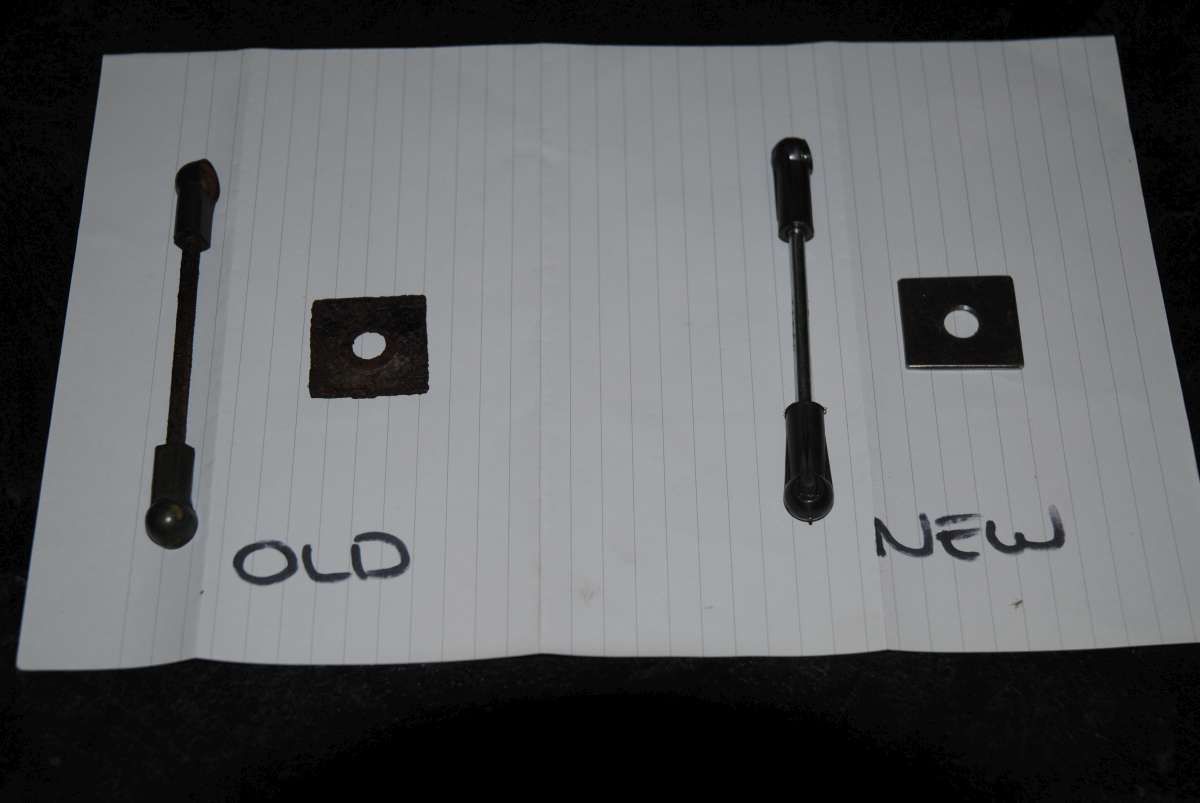

Following day still with burns from upside down welding so I thought I'd do some other stuff which had to be done

Sneaked out while Lisa was in the bath to finish painting the Diff........

Sorry No pics but it's black and pumpkin shaped - shouldn't be too hard to visualise

. Keep it up

. Keep it up