|

|

|

Aug 22, 2024 16:39:33 GMT

|

|

|

| |

|

|

|

|

|

|

|

Aug 22, 2024 21:11:14 GMT

|

|

With welders you get what you pay for.

Those are probably not very good I'm afraid. Gasless welding is not great and they will probably be useless on thin metal.

Better to buy a secondhand quality welder or save up to get a good one.

|

| |

|

|

|

|

|

Aug 22, 2024 21:43:47 GMT

|

|

A friend has a Static Arc from eBay will do MIG stick and lift TIG, he also has a posh welder, his welds look as good with the cheaper one and he says it welds nicely. Don't do gasless if you can avoid it.

|

| |

|

|

|

|

|

|

|

I suggest a trip over to www.mig-welding.co.uk/forum/and have a read. There's a wealth of experience and information on there. Just for information they are not MIG welders they are FCAW (flux cored arc welding) machine's. |

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

|

|

|

|

|

|

A better welder makes ALL the difference. I am not a great welder by any means, but the quality of welds I got from a Clarke 135 compared to a knackered old SIP (not known as a great piece of welding equipment anyway) was unbelievable.

I couldn't afford a more expensive bit of kit such as R Tech, but I also didn't really need one. Buy the best you can afford. But remember that a shiny new rubbish welder will always be rubbish.

|

| |

Last Edit: Aug 23, 2024 8:39:19 GMT by mrbounce

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

which Mig welderDarkspeed

@darkspeed

Club Retro Rides Member 39

|

Aug 23, 2024 10:41:46 GMT

|

|

Why would you have a brand called hitbox and a stylised "S" in the logo precede it ! - Hmmmmm.

|

| |

|

|

|

|

|

Aug 23, 2024 11:21:17 GMT

|

crockpot has the best advice. I joined The Forum ages ago and bought a second hand transformer based Portamig 185 which goes down to c.30amps and is lovely to use. I otherwise would have wasted my money on a gasless one. I borrowed a gasless one recently to make a little bracket as I had run out of gas. I damned near launched the thing out the door it was so horrible to use after the Portamig. Beware though - The Forum (note capitals) is even more of a Blokes' Net than this one!

|

| |

Last Edit: Aug 23, 2024 11:21:52 GMT by theoldman

|

|

fogey

Posted a lot

Posts: 1,623

|

|

Aug 23, 2024 12:53:25 GMT

|

|

|

| |

Last Edit: Aug 23, 2024 12:53:43 GMT by fogey

|

|

at200

Part of things

Posts: 90

|

|

Aug 24, 2024 11:55:25 GMT

|

|

|

| |

|

|

|

|

|

Aug 24, 2024 15:15:29 GMT

|

|

|

| |

|

|

|

|

elfman

Part of things

Posts: 399

|

|

Aug 28, 2024 19:30:10 GMT

|

|

|

| |

Last Edit: Aug 28, 2024 19:34:52 GMT by elfman

|

|

|

|

|

Aug 28, 2024 23:48:37 GMT

|

Well that didn’t take long, could say next day delivery, ordered Saturday night went through Sunday and bank holiday Monday so they worked Tuesday and it arrived here today (Wednesday)   It comes with a very flimsy welding mask, good enough to test out the welder but not for permanent usage, a couple of months back I was in Lidl and bought one of their welding masks I bought the one on the left  I bought some scrap metal today to practice on before I make my first project, a lawn leveller rake I’ve seen so many projects on YouTube I though I was able to make, till they get out their welder and I was stumped, I’ll see if there are any welding classes out our local tech collage to get me up and running elfmanThank you for the advice on the welder, the one you mention would of been more than enough for my use, I’ll have to see how I get on with my test runs on my scrap metals I bought, |

| |

|

|

elfman

Part of things

Posts: 399

|

|

|

|

i did a course in a local college years ago and found it a great help. Good luck, let us know how you get on ..  |

| |

|

|

|

|

|

|

|

mollydog1 are you using it as a mig or FCAW? Your location shows as N Cambridgeshire, are you near Peterborough? If you are I could pop over and give you some pointers.

|

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

|

|

|

Aug 29, 2024 19:27:43 GMT

|

|

|

| |

Last Edit: Aug 29, 2024 19:28:15 GMT by mollydog1

|

|

93fxdl

Posted a lot

Enter your message here...

Enter your message here...

Posts: 2,019

|

|

Aug 29, 2024 19:31:23 GMT

|

|

Put the rods somewhere warm and dry, they weld better if they are dry

Ttfn Glenn

|

| |

|

|

|

|

|

Aug 29, 2024 19:35:03 GMT

|

|

thanks for this tip 93fxdi it's much appreciated

|

| |

|

|

|

|

|

Aug 29, 2024 21:27:38 GMT

|

|

I have one of the R Tech welders as well - fantastic bit of kit.

You have the power levels wrong for welding so far - try upping and lowering the power levels to see what works better.

For practice it's better to just run some lines of weld on flat metal to get the general hang of it first.

|

| |

|

|

|

|

|

|

|

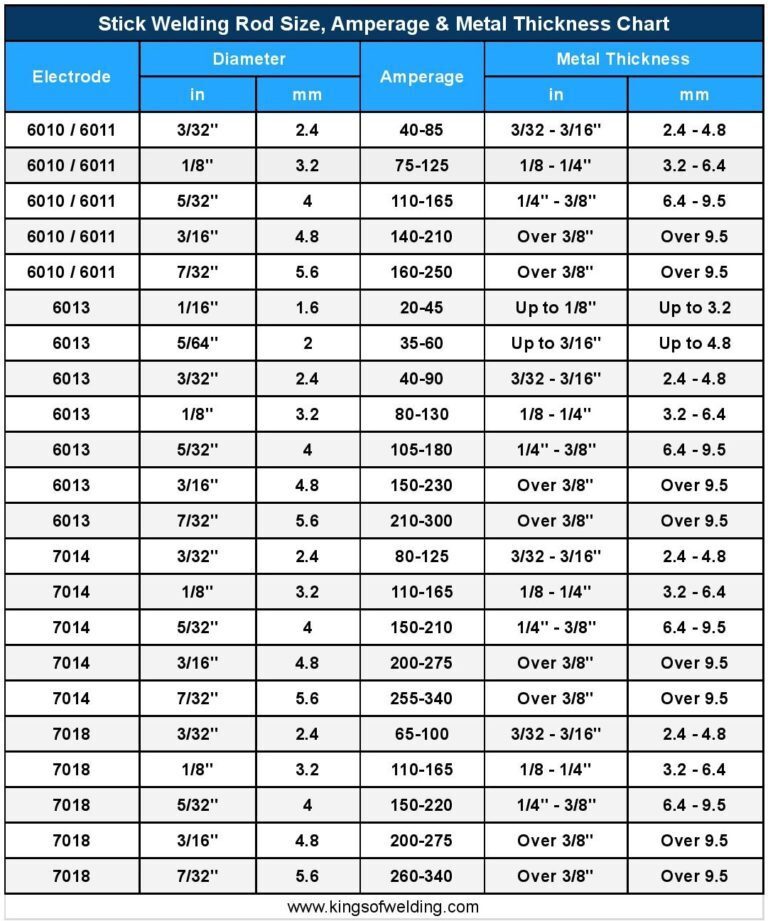

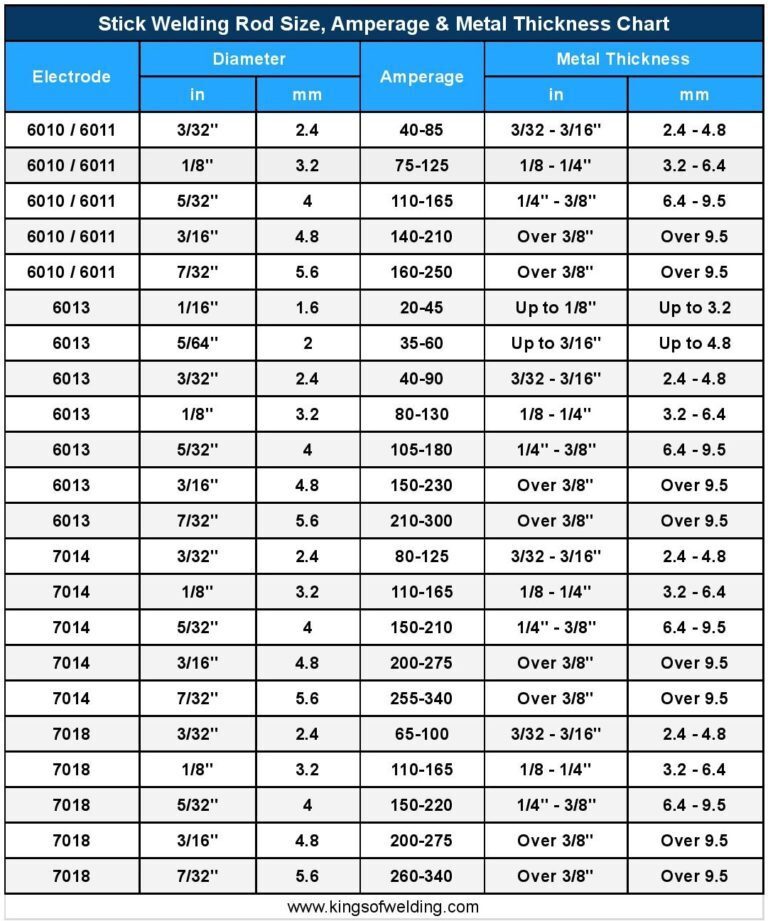

Fillet welds are not the place to start for arc welding. The secret to arc welding is rod control, maintaining a correct arc length and feeding the rod in at the same time and moving the rod along to give consistent metal deposition. Get some clean 3 or 5mm plate or flat for practicing on (not too thick, it will be easier to get heat into), no joints at this stage. You now have to practice until you can lay down a consistent weld bead without gaps or slag inclusions. When you have conquered this it's time for joining metal. First is a flat butt weld, same material. Leave a 2mm gap and cut your welds up to check penetration. I'll stop there as it will take some time to get to this point. Here's a weld current chart  You will see different welding rod numbers on the left. There many different types, some easier to use than others. 6013 is a good starting rod. Rod quality can be very variable and poor quality rods can make it harder when beginning. One tip is to cut rods in half for a kick off, this helps reduce "waggling"! |

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

which Mig welderDarkspeed

@darkspeed

Club Retro Rides Member 39

|

|

|

|

A note when welding plated bolts. Firstly, the BZP plating is pretty toxic when you turn it into a vapour. Well ventilated area is key. Secondly, Zinc plating does not weld ! It just contaminates, explodes and throws the weld pool at you. Not only must the weld metal be clean, all traces of plating must also be removed. All that Yellow/White powdery residue around the weld area is Zinc. Inhale too much of that and you will now about it. BZP plate - Zintec - Galv - all traces of the coating must be removed from any proposed weld area plus a fair bit more.

|

| |

Last Edit: Aug 30, 2024 8:02:49 GMT by Darkspeed

|

|

|

|