|

|

|

|

|

Morning all, my question is as the subject line, but first some background...

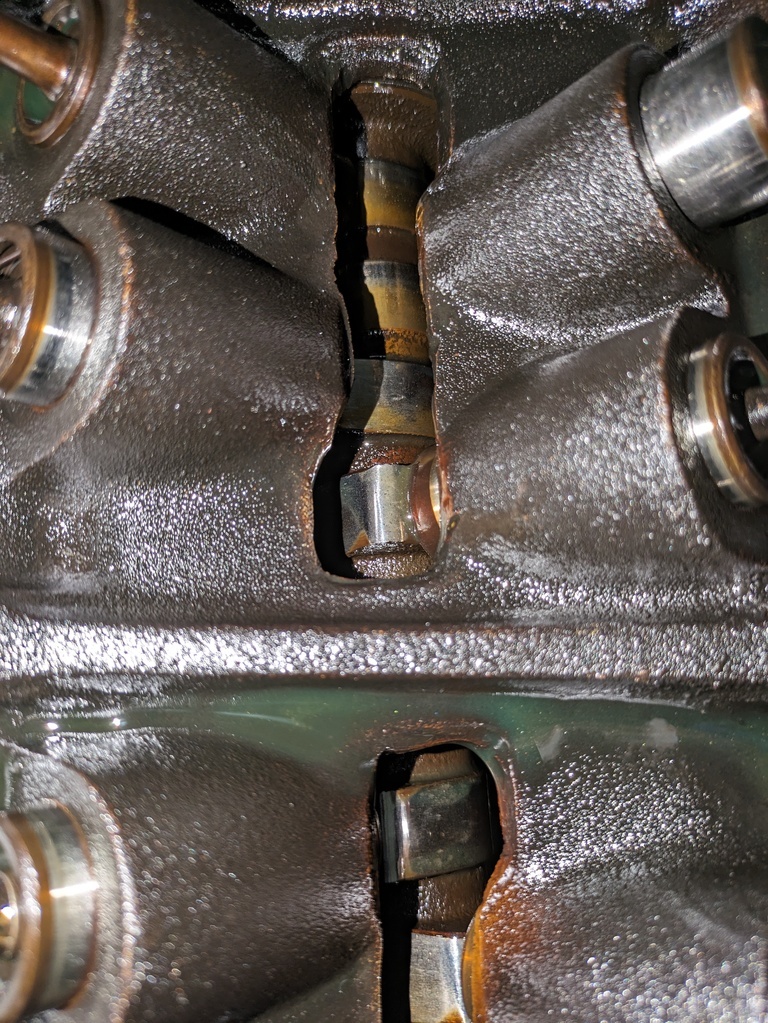

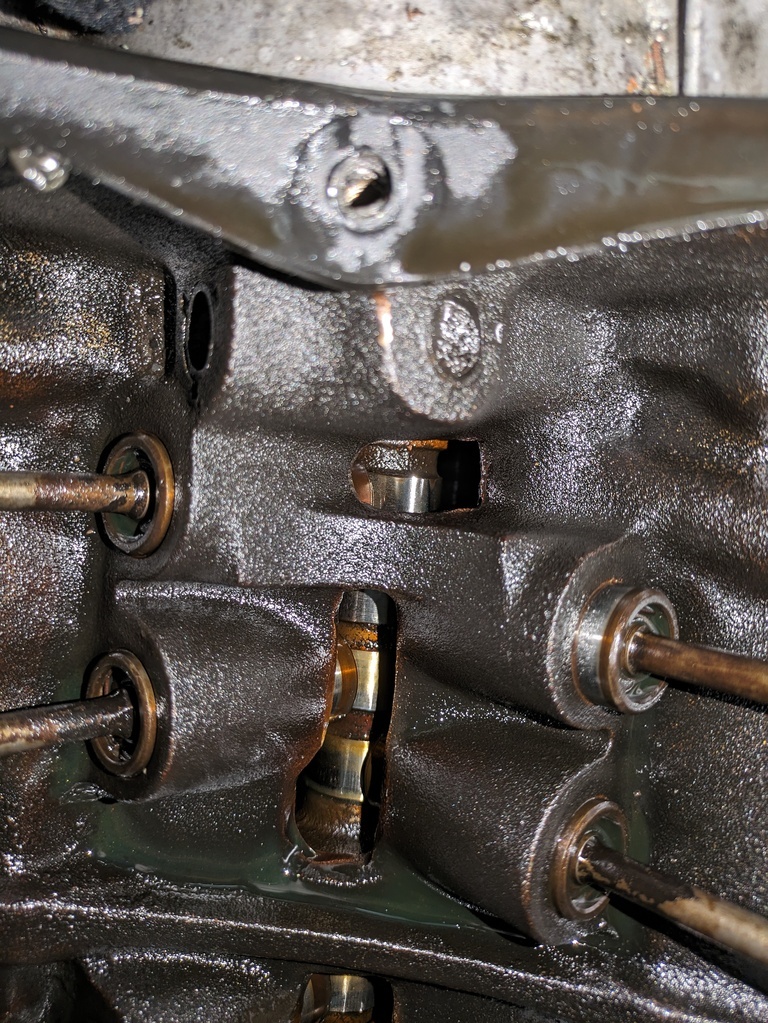

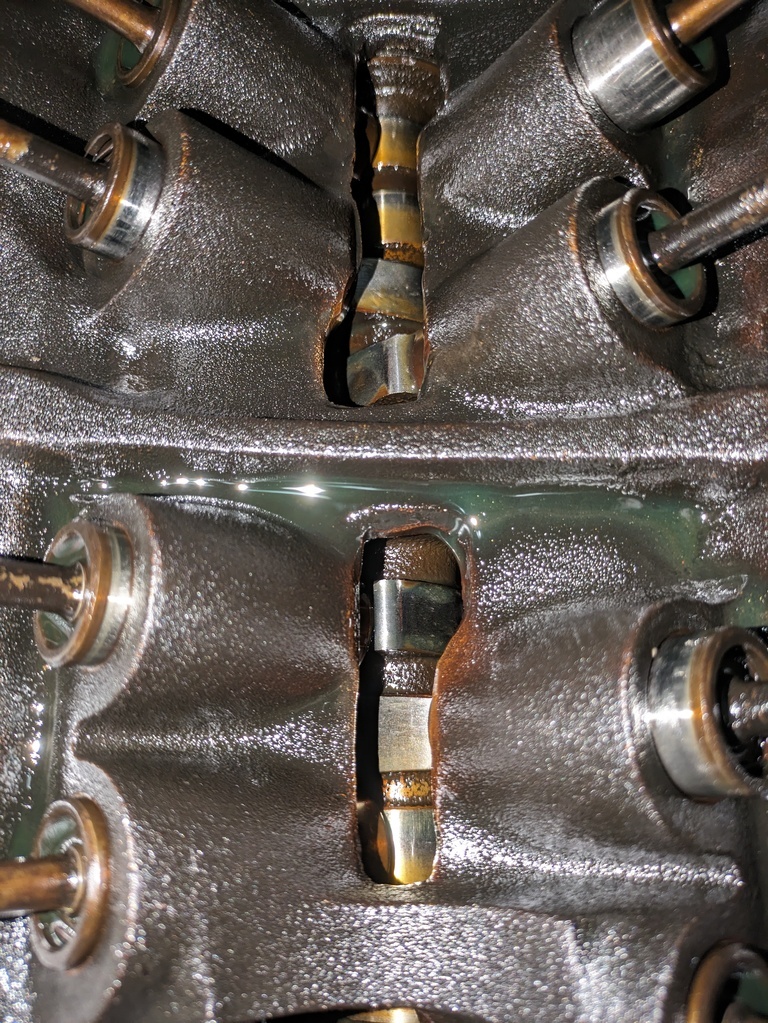

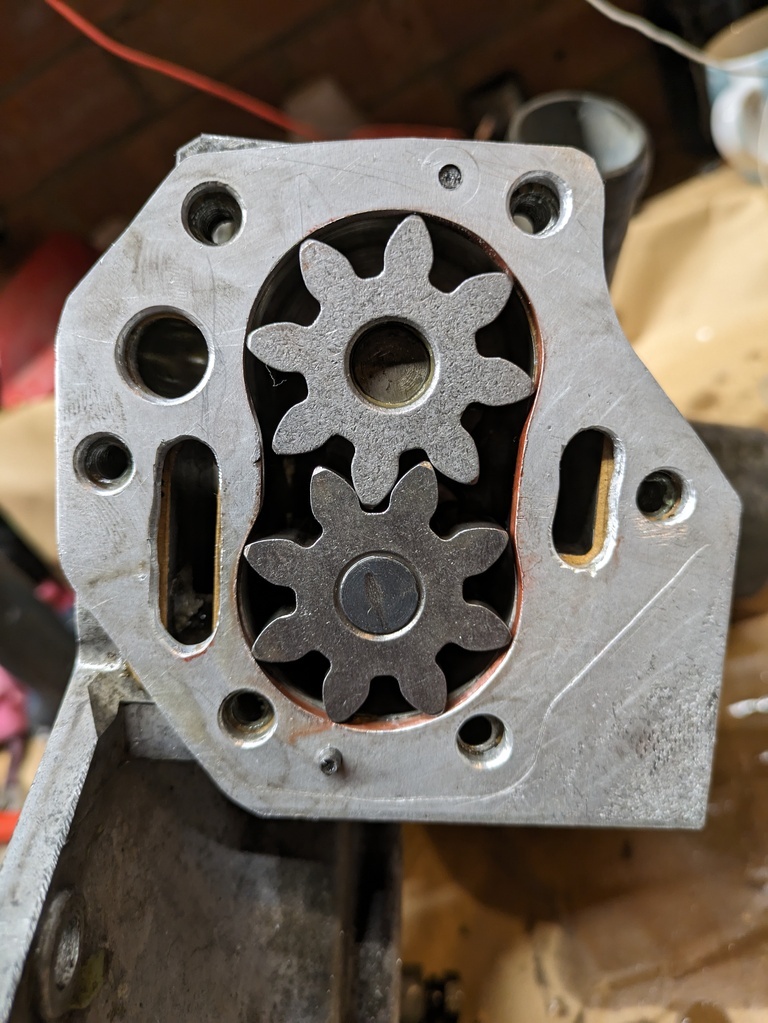

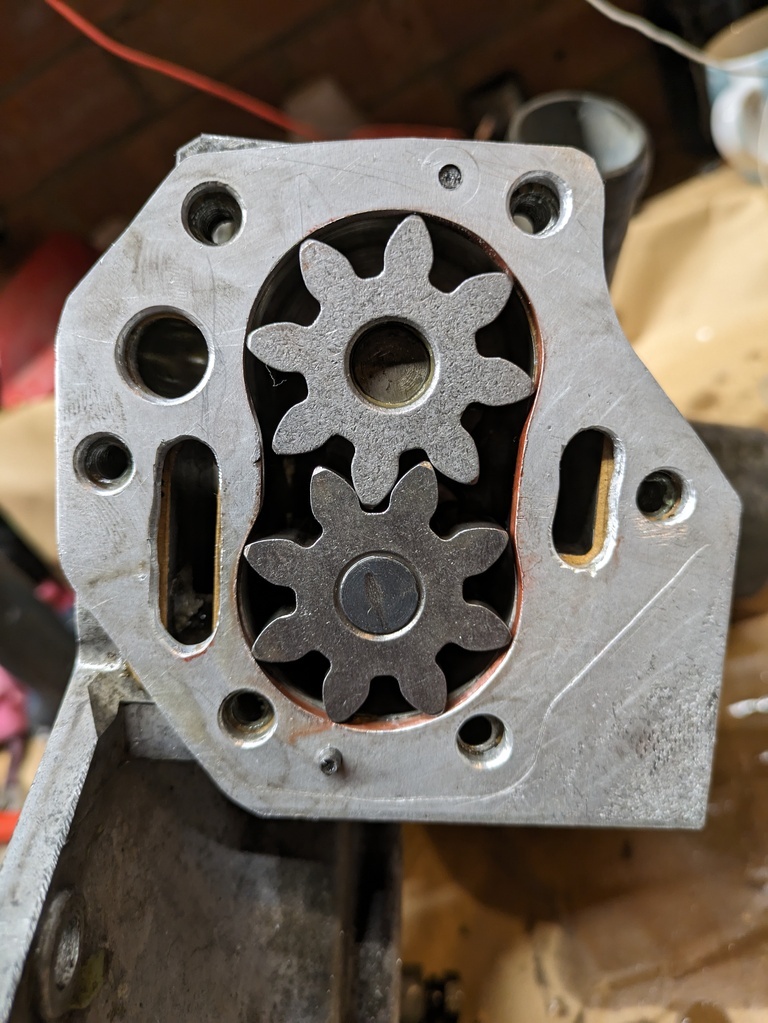

A while ago the 3.5 in my Rover 3500s decided to lose oil pressure, as I was on a dodgy A-road with my kids in the back not far from home I decided to swing about and get home (about a mile and a half) at minimal revs. By the time I got back the top end was rattling but no bad bottom end noises were heard. On investigation I found this:  So I pulled the sump and checked the big ends and mains. The big ends were all worn and showing copper, but there was no scoring on them or the crank. The mains were similar, but I'd say not quite as worn. I chucked in new big end bearings, was gonna do the mains but realised that although getting the top bearings out was fiddly but doable, fitting new ones was near impossible without damaging them. In the end I stuck with the old mains.  The pump gears were a set of "high volume" ones that I fitted a number of years ago. Not wanting to trust them again I ordered of standard SD1 gears from a decent supplier and went to fit them, only to find that they are shorter than the high volume ones by around 2mm (here compared with "high volume" one):  So I ended up ordering some ally plate and making my own thinner spacer plate to accommodate the SD1 gears in the p6 timing cover:  On priming with the drill initially I must have cocked up my measurements for end float as the pump was locked, swapping for a thicker gasket the pump now turns. Priming with either my cordless or mains drill gives around 2 bar (it did show 2.5 bar at one point when cordless was on max charge). So my question is, is this high enough?  My concerns in order of concern are: 1. In my haste to see it just work, I have put in too thick of a pump gasket and opened up the end float too much. 2. My spacer plate is not tight enough to the gears (see photo above, top-most gear at the 4:30 to 6:00 position, where I went a bit too far) 3. The top end may be knackered. 4. Maybe I really do need to change the mains. Your thoughts would be appreciated! Cheers Quagmire |

| |

|

|

|

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,220

|

|

|

|

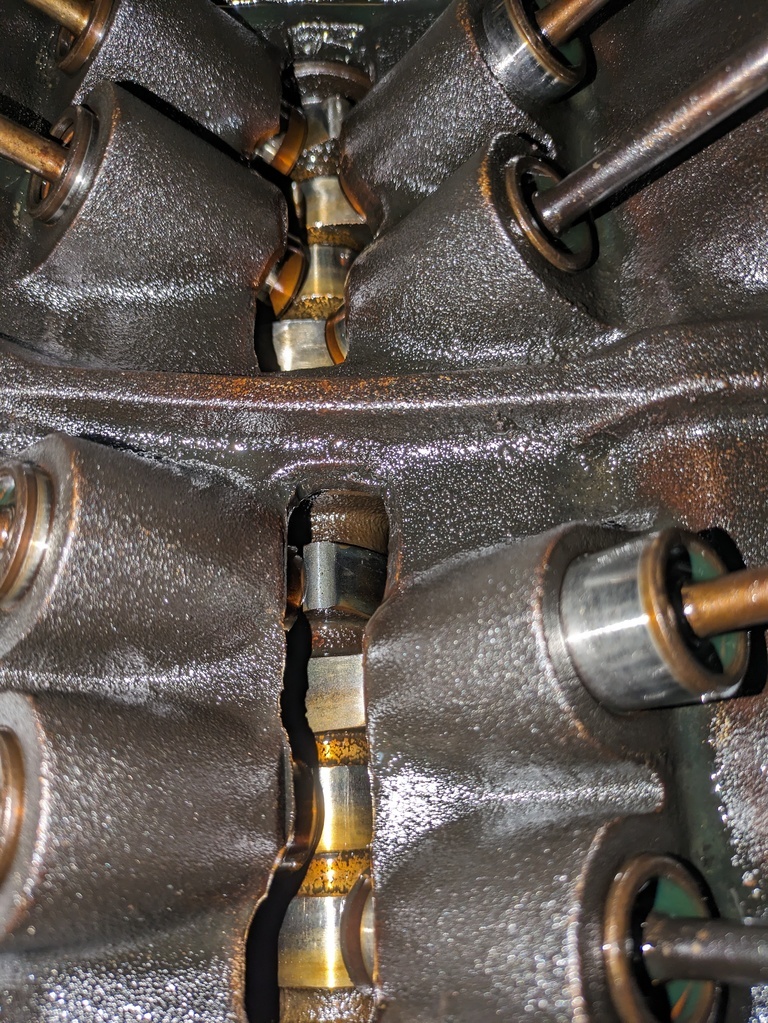

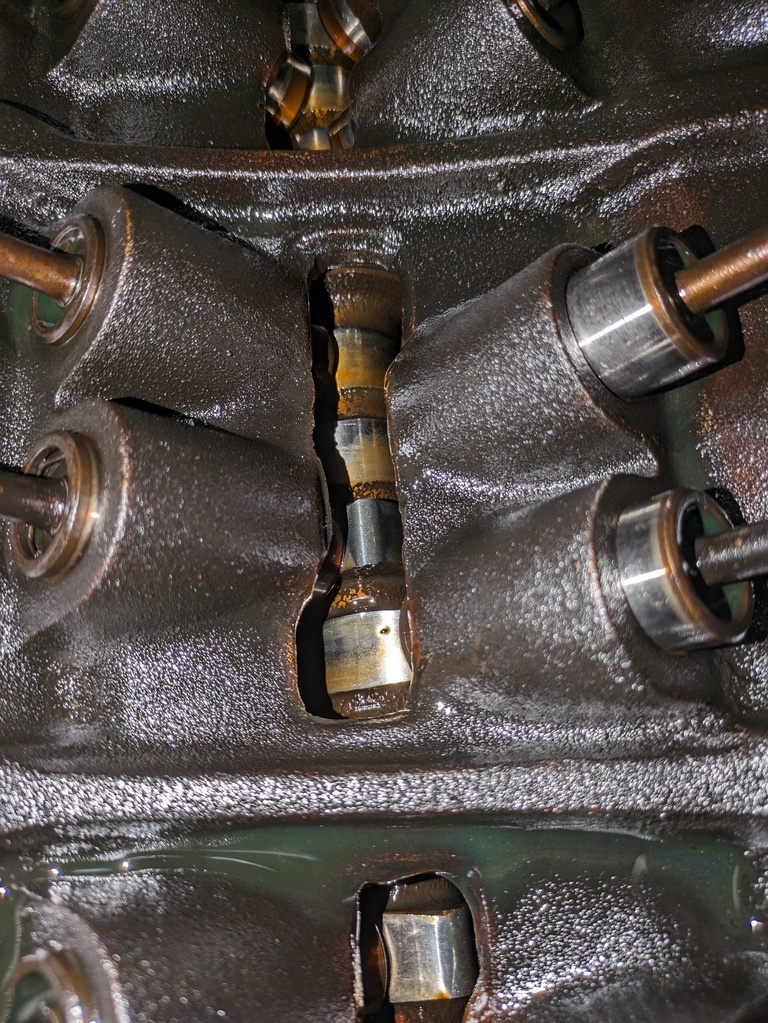

I'd say that 2 bar is OK, I think it's more important that the oil has gone everywhere. Hot pressure is about 2 t0 2.5 bar anyway. The Rover V8 engine relies on volume not pressure to lubricate. Yes, the top end may be knacked, what did the cam look like, it's the wear point on these engines  If it looks like this, it's time to change. It wouldn't hurt to change the mains, but then you're into a complete rebuild, so expense and the cars off the road. Maybe get another engine ready and hope this one lasts long enough! |

| |

|

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,220

|

|

|

|

|

Thinking about the top end, no pressure means the hydraulic lifters lose their clearance and will rattle. Not sure if that'll cause damage or just noise. It's a quick job to lift a rocker cover and look.

|

| |

|

|

|

|

|

|

|

|

The ally plate in the oil pump will wear as its too soft, don't mess around, just buy a new pump. Far cheaper then a new engine.

Personally I'd drop the crank and fit new shells as well, no point in doing half a job on something so important.

Normally you don't prime rover pumps, you pack them with vaseline as they don't have the suction to draw oil otherwise.

|

| |

|

|

|

|

|

|

|

|

I've always vasalined and then primed mine, 2 bar is fine for priming your really just looking to get oil around everything, the real answer is what you get when it's running, at idle they run fine with less than 10 psi, idealy should be up at around 35-40 above 1500rpm when hot.

The original front cover the gears run in is alloy so I can't see why an alloy spacer would be a problem.(the gears only contact each other not the case on the sides).

|

| |

|

|

|

|

|

|

|

Thanks for the replies everyone, to answer some questions: Yes, the top end may be knacked, what did the cam look like, it's the wear point on these engines Cam looked ok from underneath when I had the sump off, which was surprising! As you say, 20psi hot idle would be nice- so I guess I am concerned that on the drill whizzing around at however many rpm with cold fresh oil I am only seeing ~30-35ish psi. The ally plate in the oil pump will wear as its too soft, don't mess around, just buy a new pump. Far cheaper then a new engine. Personally I'd drop the crank and fit new shells as well, no point in doing half a job on something so important. Normally you don't prime rover pumps, you pack them with vaseline as they don't have the suction to draw oil otherwise. Ideally I would have the engine out and sort things properly, but this is my daily – and the only car I have that can take both kids (my other vehicles are both SWB Land-rovers), so I need to get it back on the road ASAP. If I can do that then I would like to get hold of another 3.5 or 3.9 and build that up in the comfort of the garage ready to be dropped in at a more convenient time. The reality is that I am probably going to have to fit a proper forward-facing seat in the 90 first, which would allow me to take the P6 off the road for a while as she does need more TLC in general. Regarding the ally spacer being too soft, I figured that the oil pump housing is ally (it’s part of the timing cover), the pump base is ally too, so to my mind an ally spacer wouldn’t be an issue, I could be wrong though! The only way to remove the home-made spacer plate would be: • Revert to the short P6 gears and find a replacement dizzy (the old one had the end chewed off when the pump jammed). • Find an SD1 front cover – these are hard to come by unless they are attached to an engine. • Buy and fit another “high volume” kit – but having had this failure, and since finding a post from someone else on classicroverforum.net with the same issue after using the high volume gears I’d rather stick with standard later gears if possible even if they are a shade shorter. As for priming – the pump was packed with Vaseline, but rather than spin over on the starter, I prefer to run the pump off the drill first to get the oil moving about. When pressure is up you just drop the dizzy in and away you go. The car runs fuel and spark on MS and the old dizzy was a cut down stumpy job so you don't even need to faff about getting it in the right place and timing it up after removing it. Having slept on it, and prompted by Andy’s comments on hot pressures I think I am going to do two things as the next steps: • Remake the spacer plate so that it has good tight clearance all the way around. I could do it in steel this time, and whilst it would take longer to work than the ally, this could be a good thing when trying to get tight clearances around the gears as its harder to go too far. • Double check gasket thicknesses (I have a few different brands in my gaskets box) and see if I can get the end float tighter/correct this time. With that done i'll see what pressure I get - and l also need to check the rocker gear. Thanks all James |

| |

|

|

|

|

|

|

|

|

I did not realise the casing was ally, just make sure the ally spacer is on the upper face then as I think the lower plate is steel for this reason.

|

| |

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,960

Club RR Member Number: 174

|

|

|

|

|

If you're at the point of it been ready to fire up I'd just run it and see what happens. Won't hurt anything.

|

| |

|

|

|

|

|

|

|

Nope, pump cover is alloy as well.  |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,878

Club RR Member Number: 39

|

|

|

|

|

As the tall gear sits on the old short pin - how good is the fit? Has the damage been caused by the gear being able to rock on a worn pin and jam between the driven gear and the housing.

30PSI seems low - but its an RV8 and they still go on for ever with the oil light shining away at idle.

|

| |

|

|

|

|

|

|

|

|

|

|

The RV8 is very tolerant of low oil pressure.

|

| |

|

|

|

|

|

|

|

|

If you can get the main caps off in situ then you can change the main shells without damaging them if you are careful. Cut yourself a plastic strip just thinner than the bearings and just narrower. Piece of filler spreader works well. Must be kept spotlessly clean at all times. Use this to push on the non-tang end of the bearing and roll it out. You may need to give the end of the bearing a tap with wide bladed screwdriver and hammer to get it started. If reluctant to come out once started, you can roll the crank over in the same direction to help. Refit is more or less the reverse. Oil the new shells before fitting.

Have successfully done this on several Triumph engines, including once in a London street. Don’t recommend that.

|

| |

1967 Triumph Vitesse convertible (old friend)

1996 Audi A6 2.5 TDI Avant (still durability testing)

1972 GT6 Mk3 (Restored after loong rest & getting the hang of being a car again)

|

|

|

|

|

|

|

Thanks for all the replies, here's the latest: Based on stealthstylz comment about trying to start it, I thought I'd give it a go. The engine was back together but with no cooling or PAS installed but I thought a quick 30 second run to see what's what wouldn't hurt. It started but the top end sounded horrendous, and pressure was around 1.5 bar at idle. I switched it off promptly... As per my last post I had decided to remake the spacer plate, so I took the timing cover off again so I could check clearances properly on the bench. When I took the filter off I found the oil was aerated: I think (hoped) that may be a symptom of clearances being too large in the pump, so cracked on:  I got the plate sorted and this time clearances were nice and close, I basically kept installing the plate checking for witness marks and slowly removing material until things moved freely with no marks.   I then set to checking the end float on the pump gears, I had three types on gasket, and eventually got the combination right to give me about 4 thou. Yesterday I chucked the timing cover back on, after cleaning all the duralac off the bolts again. It's a bit of a pain in the  to do, but the stuff is absolutely magic at preventing them corroding themselves stuck and snapping when you need to undo them. Instead of vaseline this time I squirted a load of fresh oil into the pump from one of the ports using a syringe. Priming on the drill gave me some hope, the drill noticeably slowed down a lot more as the pump loaded up, and low and behold I was getting 3.4 bar (~50psi) on the gauge!  Carried on assembling and went for a start.... Poo- still the same, engine running badly, shaking and wobbling and still making a terrible clatter (but not as bad as before) from the top. I hoped I'd messed up the order of the HT leads, but no. Time to take the top apart then...  Rockers on drivers side were dripping a small bit of oil, the passengers side seemed pretty dry. Nothing felt odd when trying to wiggle rockers in place. I backed off the passenger side and tried the drill again, and sure enough oil came spurting out. On removal of the rocker gear that side no play can be felt on the shaft (giggidy) but perhaps the pads look a bit worn. You can see circles on them, but these can't be felt with a finger nail, so I will ignore for now.  I tried the drill again with passenger rockers off and confirmed that oil shoots out- this was with the cordless just ticking along at minimum revs, it would have shot out across the drive if i'd gone full pelt.  At this point it was 22:30 so I packed up. Will continue my investigations on my next "car night" which is Thursday. I guess cam and lifters may be toast after all.. |

| |

Last Edit: May 8, 2024 7:32:47 GMT by quaggers

|

|

|

|

|

|

|

|

Check the rocker shafts, slide the rockers along the shaft against the spring and see how much wear there is on the underside of the shaft. If so, fit new shafts.

Colin

|

| |

|

|

|

|

|

|

|

|

it can take quite a while for dry lifters to pump up could it just need running for longer?

|

| |

|

|

|

|

|

|

|

it can take quite a while for dry lifters to pump up could it just need running for longer? Yes I agree, I remember when I used to do a lot of rover K series engines it could take ages for them to pump up even when the car had only been apart for a few days.

If it runs and the oil pressure is ok then I would try running it for a little while longer to see if the lifters pump up.

|

| |

|

|

andyborris

Posted a lot

Freedom is just another word for nothing left to lose.

Freedom is just another word for nothing left to lose.

Posts: 2,220

|

|

|

|

|

Have the rocker shafts been disassembled at any time? I believe it's really easy to fit the rockers wrongly and mess up the oil flow to the rockers!

|

| |

|

|

|

|

|

|

|

Check the rocker shafts, slide the rockers along the shaft against the spring and see how much wear there is on the underside of the shaft. If so, fit new shafts. Colin Popped out to the garage in my lunch break and can confirm that although the underside of the shaft I have taken off is shiny and clean, there is no step or wear that can be felt. it can take quite a while for dry lifters to pump up could it just need running for longer? Yes I agree, I remember when I used to do a lot of rover K series engines it could take ages for them to pump up even when the car had only been apart for a few days. If it runs and the oil pressure is ok then I would try running it for a little while longer to see if the lifters pump up.

I ran it for about 2-3 mins and after the first minute or so gave it probably about 2500-3000 rpm for maybe twenty seconds (whilst gritting my teeth) before I let it settle, run a bit longer while I scampered about trying to see if I could see where the noise was coming from and then bottled it and shut it down. Pressure was great! I will continue checking everything including the other set of rockers, then the cam and followers – if I find nothing amiss, I’ll have to reassemble, try again and put my fingers in my ears while it runs... Have the rocker shafts been disassembled at any time? I believe it's really easy to fit the rockers wrongly and mess up the oil flow to the rockers! The rockers have been installed for a number of years (at least 4-5 years I would say) with no issues – I replaced the originals with a good second-hand set when a head gasket went randomly some time ago and I noticed some wear there. I used to commute 70 miles a day in the car all year round with no problems at all up until I changed jobs 2 years ago and now I have to get the train instead, which is a bit of a come down from the leathery-V8 goodness of the P6!  Prior to the oil pump failing the old girl had been utterly reliable... |

| |

|

|

|

|

|

|

|

|

|

| |

Last Edit: May 9, 2024 20:16:05 GMT by quaggers

|

|

|

|

|

|

|

|

Is there much oil now in the top of the engine after its been run?

A couple of things i've had before that were slightly similar:

1. Jaguar TDV6 where a main bearing shell had spun and blocked the oilway, the result was wiped out big ends loads of noise but good oil pressure.

2. A rover K-Series where the oil feed to head was blocked and it rattled like mad, still no idea what the blockage was or where it came from but my main thought was the oil filter breaking up as I removed a lot of soft material that was blocking the oil feed to the head.

If you have good oil pressure and it seems that oils is getting everywhere that it needs to then it might be a case of stripping it a bit further to see if there is any damage. If its run for a couple of minutes and been reved and its still noisy then I don't think the tappets are the culprit.

|

| |

|

|

|

|

to do, but the stuff is absolutely magic at preventing them corroding themselves stuck and snapping when you need to undo them.

to do, but the stuff is absolutely magic at preventing them corroding themselves stuck and snapping when you need to undo them.