|

|

|

Apr 10, 2024 21:04:46 GMT

|

|

The cam runs in the block - no idea if it has separate bearings, the Haynes manual doesn't show any.

I did look up at the cams and they looked great though, no signs of wear or scoring on the lobes

|

| |

|

|

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,960

Club RR Member Number: 174

|

|

Apr 10, 2024 22:14:31 GMT

|

|

That oil pump looks well past the newness wearing off stage. Did you check for side to side play of the shafts in the housings?

|

| |

|

|

|

|

|

Apr 10, 2024 22:22:51 GMT

|

|

Not checked for side play yet. But yes, it does look quite chewed up. When I swapped sumps and pickups a year ago I wasn't looking that close, but I am sure I would have spotted the wear if was that bad at the time.

Fortunately, I have a spare front housing (which contains the oil pump) along with a spare set of pump gears. Not looked at it for a decade, but I will fish it out of the shed, give it a clean up and hopefully I can swap them over. The pump cap looks fine (a few circular marks but that is quite common).

|

| |

|

|

|

|

|

Apr 17, 2024 19:25:33 GMT

|

|

bearings don't look too bad but the oil pump is not great which would suggest the filter is doing a good job, any clue as to where the metal is coming from?

|

| |

|

|

|

|

|

|

|

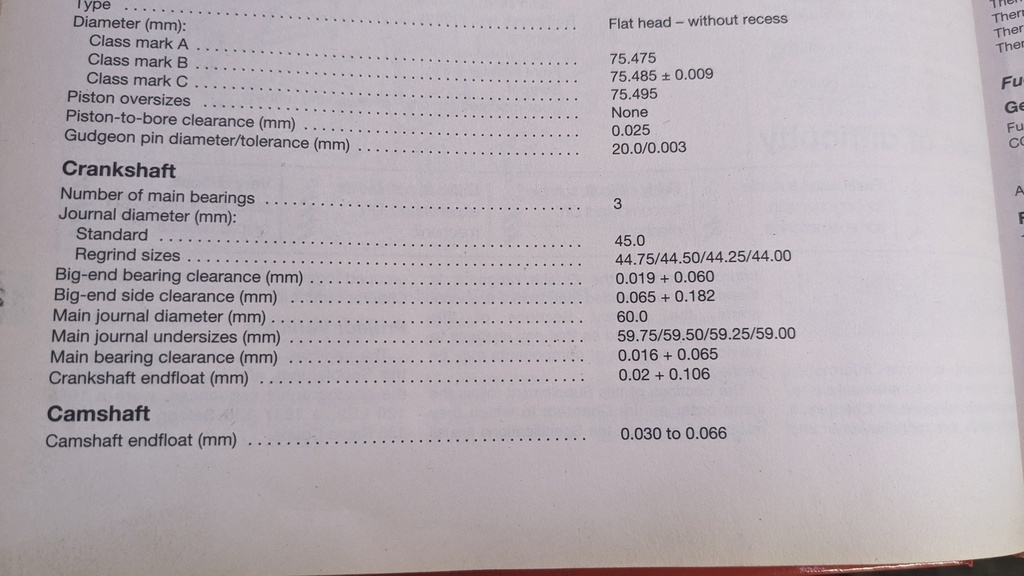

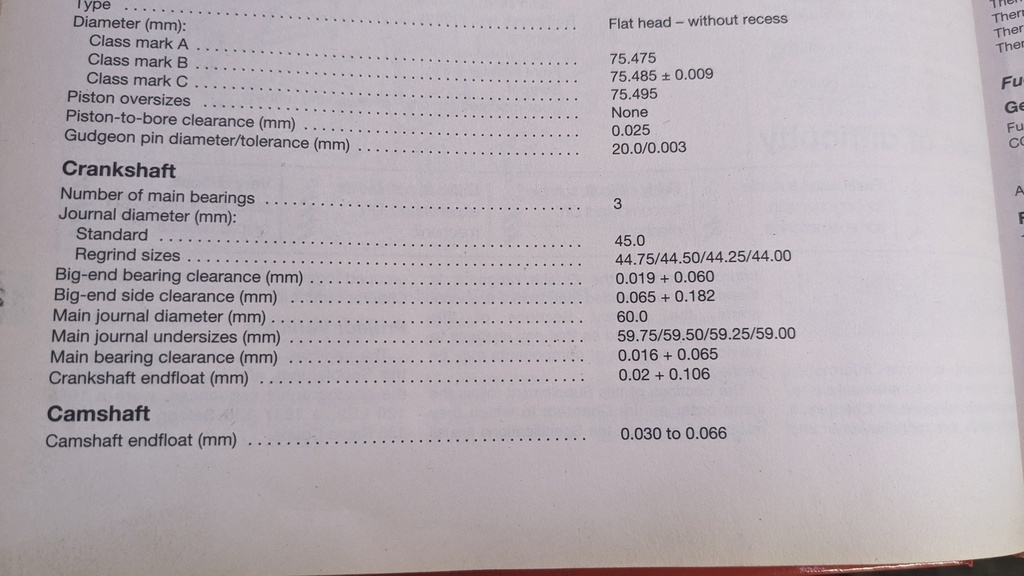

Update time Kevin - I have found a few culprits but no totally smoking gun. Engine is in bits in the shed ready for new bearings and oil pump. I ordered a load of parts from Germany, which arrived earlier in the week, but they sent me the wrong main bearings, so that has set me back a week while I ordered some from the Czech republic. I found some wear to steel parts in the fuel pump, and what looks like a delaminating pump diaphragm. I think I have had two issues going on 1 - fuel leaking into the crank case and messing up the oil causing bearing wipe, and 2 - steel fragments from the fuel pump going through the oil pump. I think the glitter is a combo of bearing material and aluminium from the oil pump. I can't see anything else wrong so that is my current working theory. I have a follow up question regarding bearing clearances. The haynes manual says that the main bearing clearances are 0.016mm + 0.065mm. I am reading that as minimum bearing clearance is 0.016mm, what is not clear is whether the max clearance is 0.065mm OR 0.016mm + 0.065mm giving a total max clearance of 0.081mm? Not sure it matters much as the clearance on the worn bearings was 0.04mm ish so within spec whichever way you look at it. I will re-check with the new bearings and don't expect the clearance to be any larger, but would like to know for sure what max clearance is.  Any help decoding the spec? Thanks |

| |

Last Edit: May 2, 2024 21:25:27 GMT by lewist123

|

|

stealthstylz

Club Retro Rides Member

Posts: 14,960

Club RR Member Number: 174

|

|

|

|

|

That spec is oddly written. On older engines I tend to aim for one thou of clearance per inch of journal as a maximum, so you'd be at 2 to 2.5 thou (.050-.065mm roughly) on a 60mm journal. It'd work at just over 3 thou clearance (0.081mm) but it'd be enough to show a noticeable drop in oil pressure when hot in my experience.

Fuel contamination of oil is the number 1 cause of engine failure that I see, so the fuel pump problems seems like a good diagnosis of the root cause of the damage you've experienced.

|

| |

|

|

|

|

|

|

|

|

Yeah it is weird. If it said 0.016 to 0.065mm I would understand!

Based on your numbers there, it would appear that perhaps 0.065mm is the max tolerance, and I will work on that basis.

Thanks

Lewis

|

| |

|

|

|

|

|

May 11, 2024 23:11:34 GMT

|

Well... good news and bad. Got the engine back together and back in the car. Took it for a bit of a run to make sure all was good. However, after a while it started acting a bit odd. Got it home, but have found that there is now a tight spot when rotating the crank and it is generally a bit stiff to turn as well. Damn! It rotated fine when I put it together. I used assembly lube on the new bearings, and cranked it with no plugs in to get oil pressure before starting it. Engine back out again I think and time to start again, Just hope there isn't any new damage as a result of whatever has gone wrong. If there is, it will probably be crank grind and appropriate new bearings  What a pain in the bum! |

| |

|

|

|

|

|

May 12, 2024 18:30:20 GMT

|

|

I spent some time today going over the engine and I think I found my mistake.

I pulled the sump and inspected each set of bearings in turn - all good, no marks or bad things.

What I think happened is that when I reassemble it I didn't check the crank end float - the haynes many says that you change the various shims to get it into spec. My logic was that it was fine before and so if I remove the shims and re-fit them in the same way it should still be fine.

However, and I think the haynes manual has the assembly order wrong, the main bearing caps are located radially by machined pockets in the block, but not located axially. Therefore, when re-fitting them they can be displaced from the bearing seat in the block by a fraction of a millimeter. I found that the front bearing was offset axially by a hair compared to the bearing housing the in the block and so when the main pulley is tightened, the misalignment takes away the end float in the thrust washers. If you follow the Haynes manual order of operations, you might end up shimming out the misalignment, meaning the thrust washers are only half bearing on their respective thrust faces.

Leaving No.1 main cap loose, I re-torqued the bottom pulley, then shunted the crank back and forwards to true up the thrust faces of the cap and block, and then re-torqued the cap. Doing it that way, I had the necessary crank float. After getting the engine up to temp it didn't get tight and no obviously tight spots.

No signs of damage in there, so I think I got away with it!

|

| |

|

|