adam73bgt

Club Retro Rides Member

Posts: 4,994

Club RR Member Number: 58

|

|

Jan 28, 2024 20:23:27 GMT

|

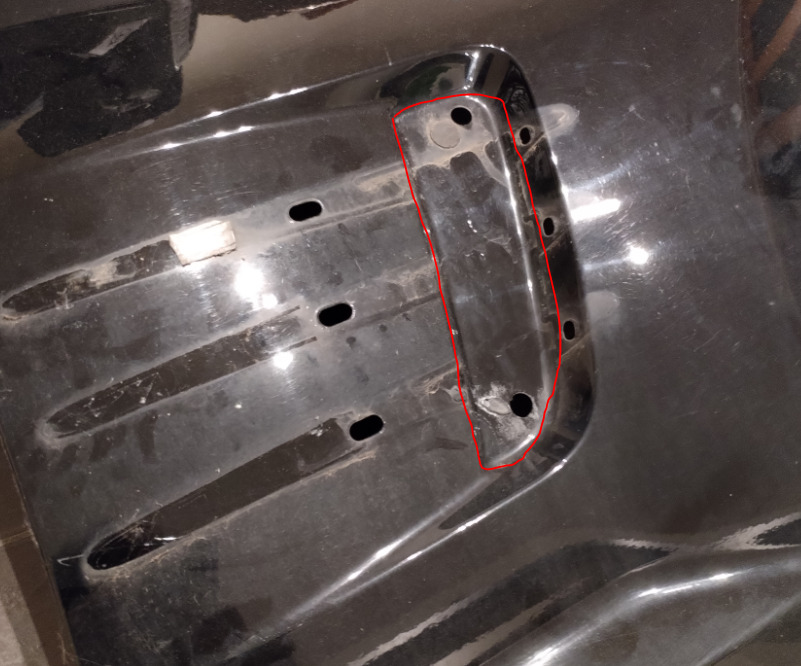

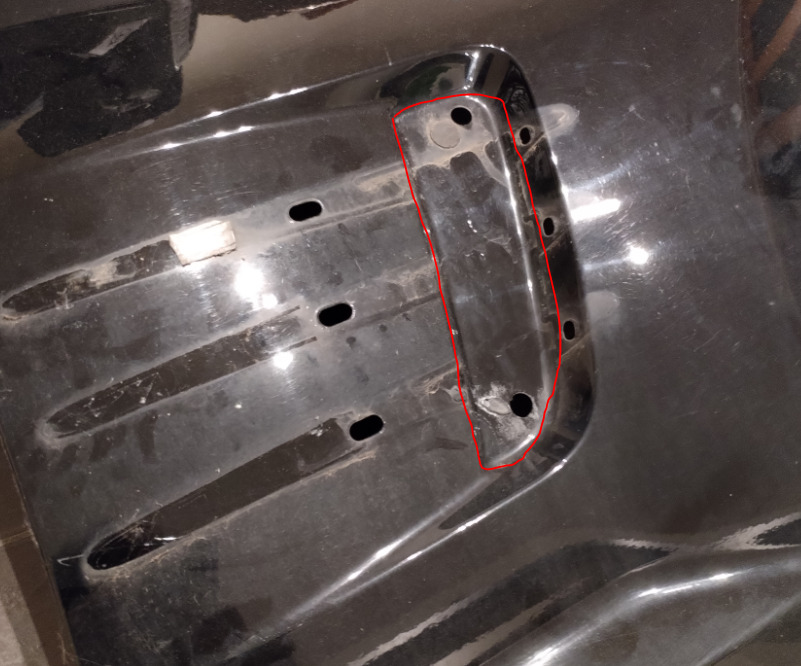

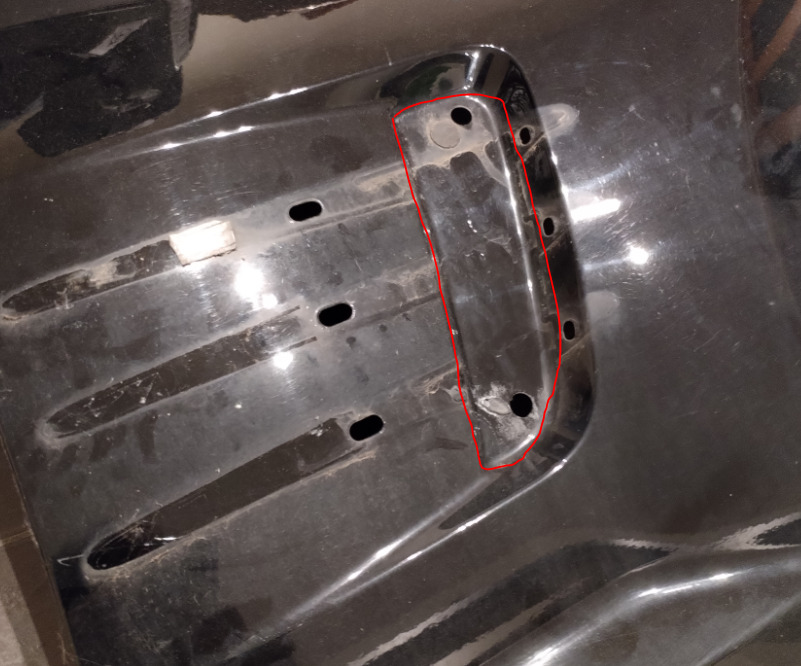

I have a Chrysler Crossfire which I've been doing a few styling tweaks on, one of the things I'm not a fan of is the fake vent/strake things on the front wings  I've currently got the wings off to repair some rust (not the holes I'm suggesting filling with fibreglass...) and I've taken the vent/strakes off which leaves some holes and a depression in the wing  I'd like to keep the scallop in the wing so I'm just thinking of filling the 6 mounting holes, and the inner area circled in red  I'm trying to avoid welding them up, I do have some fibreglass and stainless mesh left over from previous projects. I'm thinking for the holes I could mesh over the back of the hole then fibreglass and sand back, fill etc. but would the deeper area be too much to fill with fibreglass or would it work as well? Is there a better alternative I could do? |

| |

|

|

|

|

|

|

|

Jan 28, 2024 21:53:41 GMT

|

Could you cut the sunken part out and make something like this (seems someboy made functional ones from stainless)  |

| |

|

|

adam73bgt

Club Retro Rides Member

Posts: 4,994

Club RR Member Number: 58

|

|

|

|

|

I could, I had heard of people making them functional vents but there isn't much behind there to vent out anyway haha

I could cut the stakes off the fake vent and somehow use that to fill the sunken area but I'm aiming for the smooth look really

|

| |

|

|

|

|

|

Jan 29, 2024 10:49:13 GMT

|

|

I would think you would be better off sticking pieces of painted steel on the back with panel adhesive then filling over it.

|

| |

|

|

adam73bgt

Club Retro Rides Member

Posts: 4,994

Club RR Member Number: 58

|

|

Jan 29, 2024 15:07:59 GMT

|

|

That's a good shout for the holes, I hadn't considered that before.

|

| |

|

|

|

|

|

Jan 29, 2024 17:10:33 GMT

|

|

I did this to lose the side marker holes in the wings of my range rover, cleaned up the back face, epoxy painted the back of the wing and the patch then stuck it on with Araldite (to tight to spend £40 on the proper stuff) then filled over the top and painted, still fine now after 5 years.

|

| |

|

|

|

|

|

Jan 30, 2024 12:58:09 GMT

|

|

When I removed the boot spoiler on my Grand Am, I used JB Weld (because that’s what I had on hand for a spur of the moment Sunday afternoon project) to stick the metal patches on and fill the holes flush, then some fine filler, primer and paint to finish off. That held up well enough, no cracking, for a couple years before I sold it on.

|

| |

|

|

adam73bgt

Club Retro Rides Member

Posts: 4,994

Club RR Member Number: 58

|

|

Jan 30, 2024 18:39:21 GMT

|

I was looking at the price of proper panelbond, and wasn't sure, but Araldite and JB Weld? I have those both on hand so that's good enough for me  |

| |

|

|

|

|

|

|

|

I was looking at the price of proper panelbond, and wasn't sure, but Araldite and JB Weld? I have those both on hand so that's good enough for me  There is not a lot of difference between the epoxy adhesives, unless you are using them in stressful situations. Your situation isn't one of these :-) Just make sure all mating surfaces are clean and roughed up with 80 grit to help the adhesive to grip (increases surface area). |

| |

|

|

adam73bgt

Club Retro Rides Member

Posts: 4,994

Club RR Member Number: 58

|

|

Feb 23, 2024 20:32:10 GMT

|

Excellent, that's pretty much what I've ended up doing in the end, used JB Weld to stick in some filler pieces (parts of the original plastic trim cut down) then will fill over the top  |

| |

|

|