Before starting on the Canta yesterday, I had a few small jobs to do indoors.

After which I went out to the shop, moved stuff about and started to look for somewhere to mount and power the 200W LED spotlight my lodger, Andy who previously lived here and helped with the welding and hole digging when I built the carport, had liberated from a skip at work. Crazy world we live in, it was mounted, then found to be in the way of works going on, removed and put in the skip. The cost of repatriation on building sites exceed the written off value of items.

Andy went home this week, to see his wife and for an interview with Rolls Royce, which seems very positive. So he may be gone sooner than planned.

As a consolation he brought some large, salty pretzels 🥨

Back to the work light.

So a suitable length of 3 core wire and a plug added, light mounted on a beam, thanks to

nickwheeler who popped in and held it in place for me to fasten.

Sally was waiting patiently for me to get done so we could go walk Bonnie on the outgoing tide down at the River Thames.

Testing.

This thing is deceptively bright.

In position.

And at 10.30pm last night when I got home.

This certainly, along with the strip lights will make the space super light for working in winter when it gets dark at 3.30pm

Once the light was fitted, I closed shop as Sally was patiently waiting for me to to go walk the dog……

Always fun walkingBonnie, as she is such a hyperactive dog.

Interesting sight passed us on the footpath.

Back at home, I got back to the Canta, a few small jobs in mind.

My motivation is kinda low with all the cr@p and insecurity at work.

First job was to clean out all the aluminium swarf from last weekends drilling rivets.

Then found some of the nylon webbing used for the Rezin Rockit roll bar wrap and measured, cut it to size, followed by hearing a piece of welding rod to burn the holes through for the rivets.

Result.

Riveting progress.

Done.

Both sides now retained, hopefully preventing over extension and damage.

Next job was a bigger one, and had been bothering me since day one.

The bonnet/hood supports had been damaged by the engine bouncing around while the front engine mount was broken

This left everything catching, mal-aligned and of course the hood latch needing to be forced.

After fixing the cable operated release last weekend, the obvious next job, which I could no longer avoid, was this.

Shown more clearly in the video……. This was the process.

So I tried to manually pull it into position using a length of trucking webbing the pavement gods had blessed me with at some time.

I failed………

So it was onto “Plan B” that should have been “Plan A” to prevent wasting time.

Using a hydraulic jack, and my large ball pein hammer handle, I just lifted it and pushed it back up to the position it needed to be.

Simple solutions often deliver the best outcomes.

Looking at the bonnet before, it was way out of alignment.

After.

And stepping back.

Just so much better.

Buoyed by my success, I put the tools down, went for a pee and made a coffee.

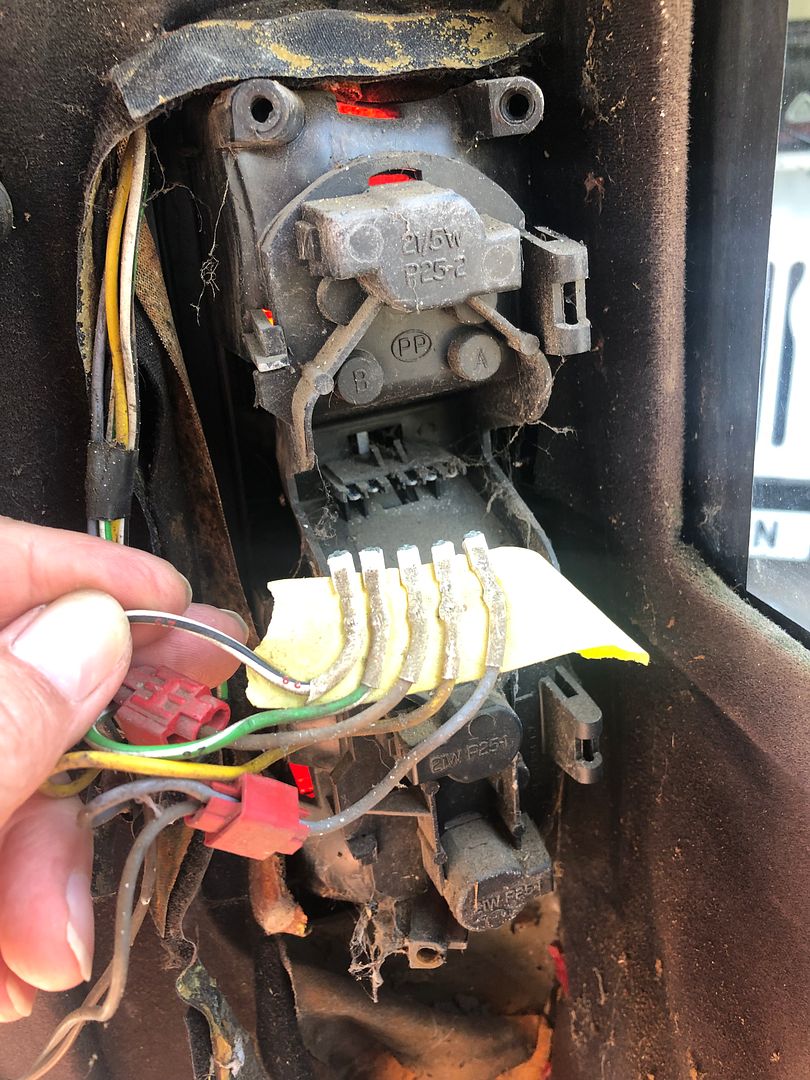

Then back to the last job of the day, another eyesore.

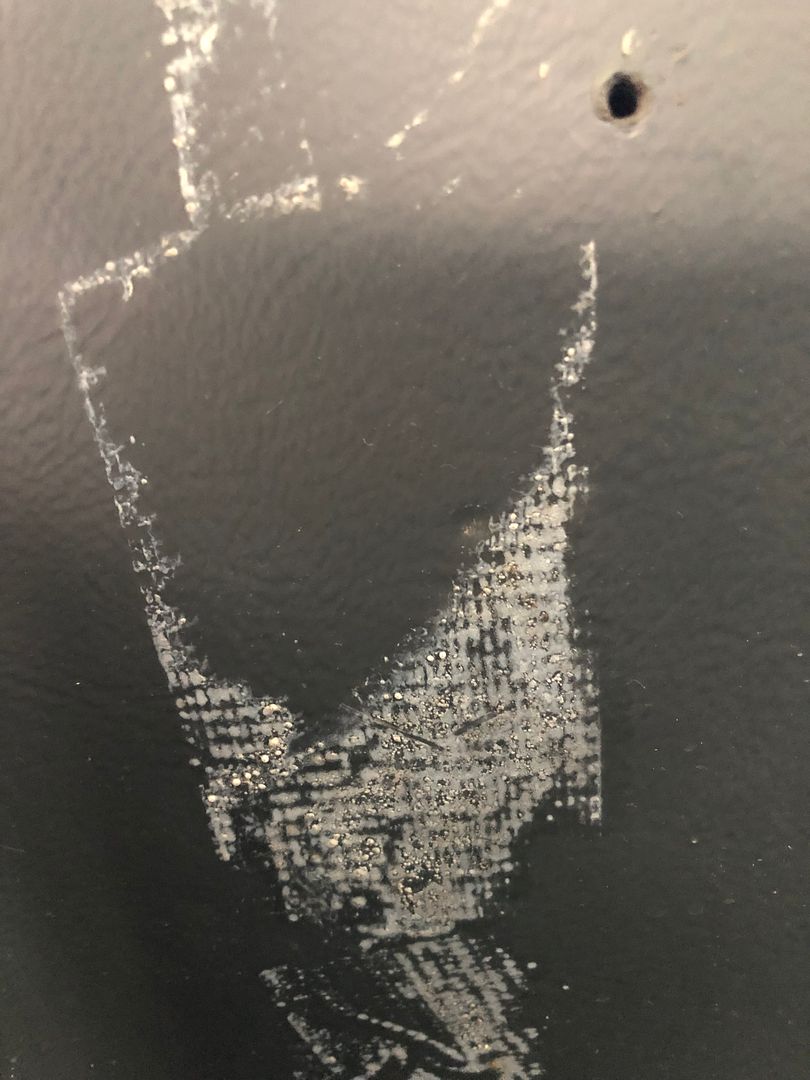

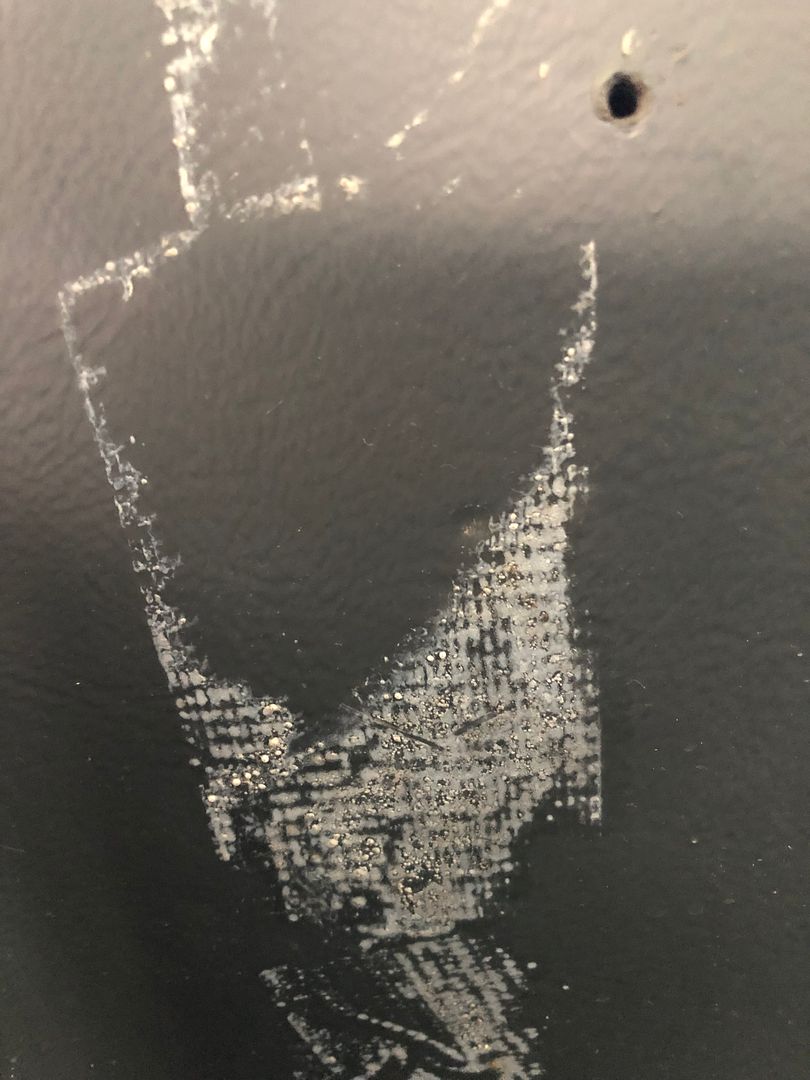

Duck tape is godly stuff, but man it can leave a mess years later.

My guess is that the radio-tape had come unscrewed/broke away from the dash, and some genius used (as it should be when stuff moves that should not move) duck tape to secure it all……. Till it was removed by a subsequent fixer.

So armed with some blue garage paper towel and washing petrol/gas I cleaned this mess.

And the result was satisfying to say the least.

Closed up shop, came indoors and sat editing the bits of footage from the day for an hour or more.

Showered, went to Sallys place to upload on her decent Wi-Fi, the YouTube video.

VIDEO LINK:

Sunday today, need to go next door and cut Mickey’s lawn as it is looking rubbish.

Then maybe some more Canta Time.