|

|

|

Sept 23, 2021 16:09:05 GMT

|

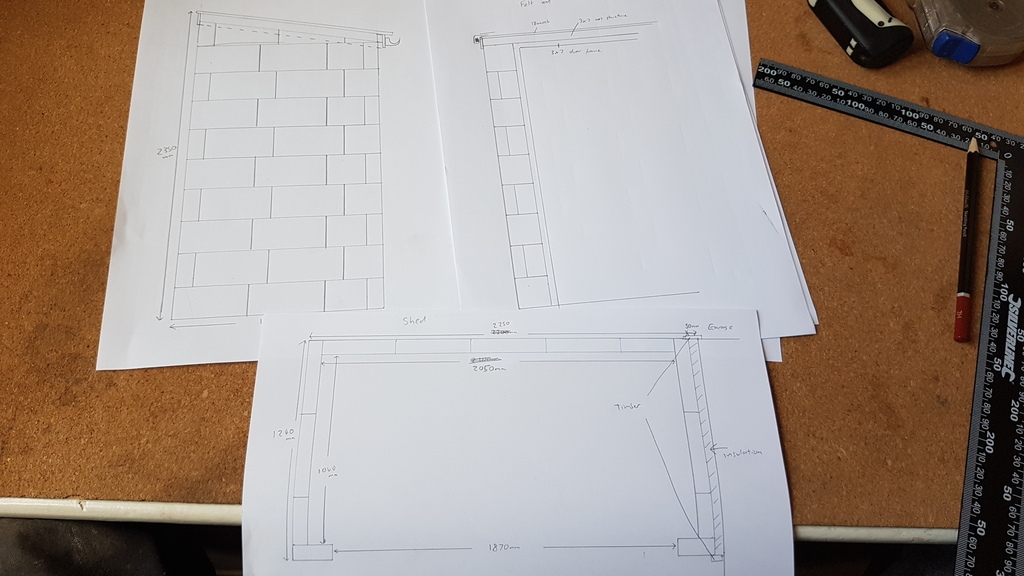

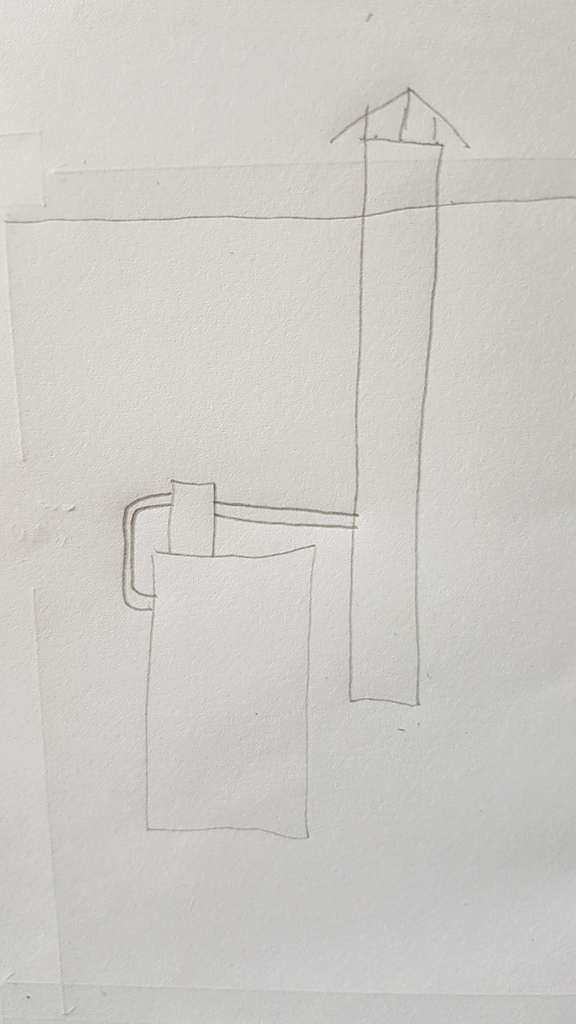

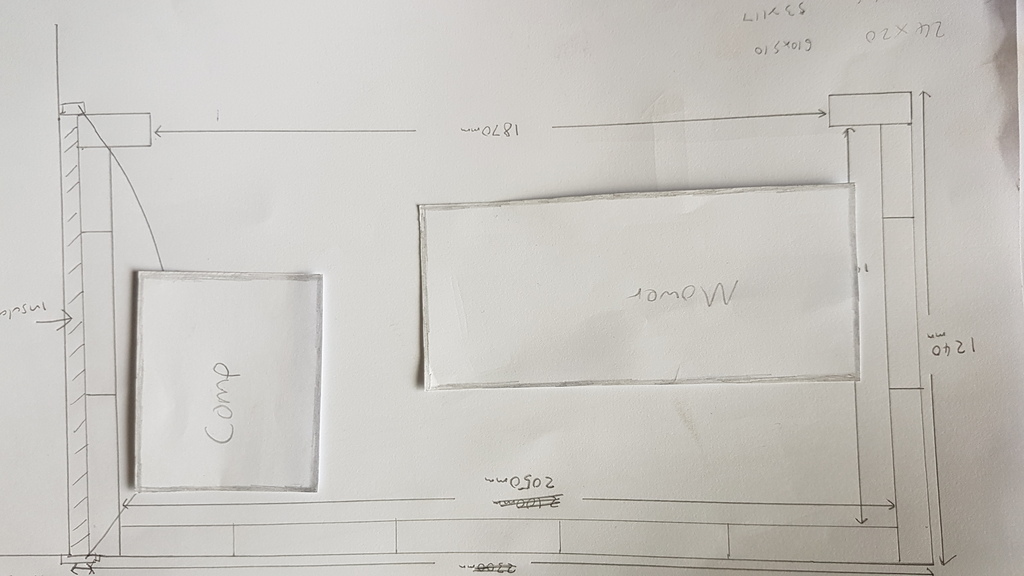

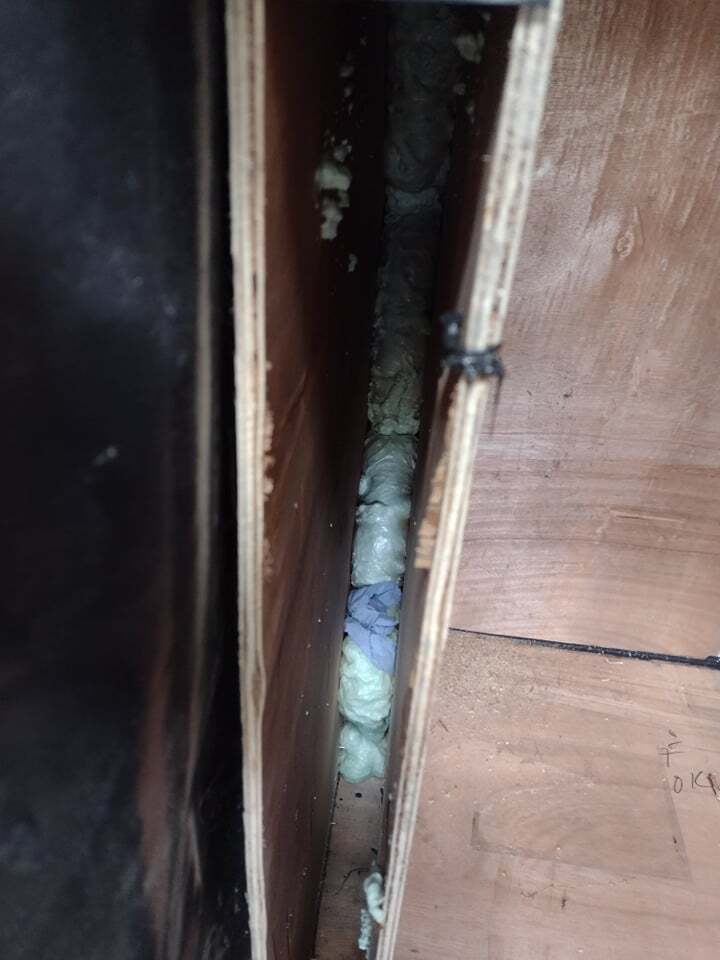

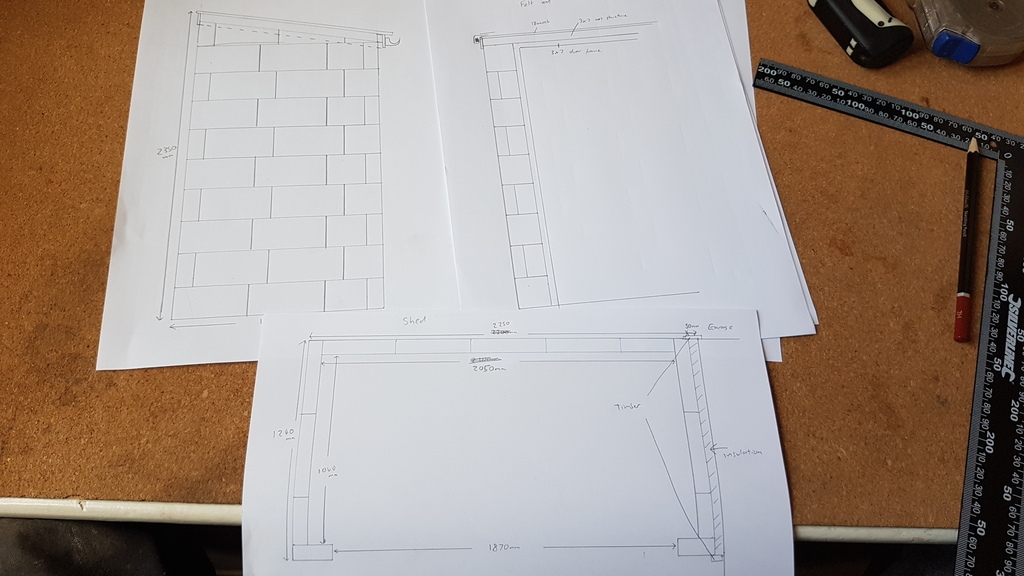

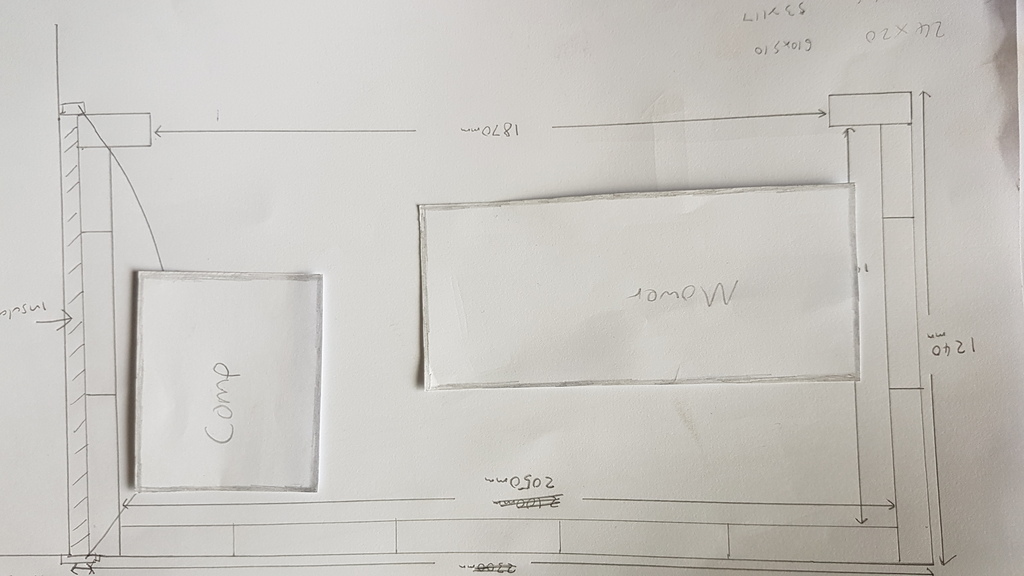

About 7 years ago I built this  I am now at a stage where I have to be careful with what space I have, ive run out! Not even any cars in it (no access). Not easy to extend at the rear as it's 3 foot down in the ground at that end. I did think about putting another 2 meters on the front but don't really want to restrict access from the side of the house. Still an option though. However, I put a coal bunker and water but here   I've never used the coal bunker! So my plan is to use that area to build a compressor shed and somewhere to put the lawn mower. A couple of shelves up top and I'll be able to move alot of house stuff out of the workshop. Can put parts in there too. The base area is 2300mm x 1240mm. I plan to utilize as much as possible, only down side is it will be just a little too big for one 8x4 sheet to do the roof. Quick sketch of the plan  I need to check how i did the roof on the garage, ill do this the same but with 3x2 timber. As I've drawn it I don't think the doors will clear the gutter 😂 I plan on just dumping the workshop run off onto the shed roof, then running a gutter on the shed and relocating the water butt at the end. I don't really see a need for a lintel as there is no blockwork above the doors. Frames will be concrete bolted into the walls and door frame will be tied into the roof structure, which in turn is also screwed into the walls. Should be fine right? Also, I'm thinking no piers. Half block returns at the door openings should be enough right? Back wall will be 2250mm long and 10 blocks high. Think it will be ok? The workshop is the only building I've ever built so I'm willing to be told I'm doing things wrong. Workshop is still up though and no cracks in the walls! A few things I'm unsure about though. I was going to build it separate, with a 50mm gap to the workshop that i can put insulation in. I'll join the shed roof to the workshop wall though. This is purely so noise doesn't just go through the wall into the main building. Good idea, or not needed? Every bit of internal space will help! I plan on insulating the roof and the doors purely for noise benefits. I will sit the compressor on a small floating floor insulated from the slab. I also think ill box the compressor in, in its own insulated cupboard, to protect it from lawnmowers and to keep the noise down. But, I'm conscious that heat needs to get out and air needs to get in. Any ideas on that? Air will be piped in copper, probably around the outside of the garage at roof height, then in through the wall in the middle of the garage. That is mainly so the air can cool. I'll put a slight fall on the pipe so any condensing water ends up at the drop before the water trap. I'll have 2 separate air systems when this is done. The filters have auto drains that I'll run through the wall. The 2 receivers and the 2 drops at the regulators will probably have auto drains. Anyone tried any of the cheap ones? I've seen manual float type, which appeal. The timer type, which for some reason I don't like. Or, I am considering putting solenoid valves on them all and running them to one momentary switch that when pressed opens all the drains. I'll dump all the drains straight outside. Also plan on having an internal switch for the compressor in the shed So I haven't got to go out and turn it on. I'll have a second pressure gauge before the reg so I can see what's in the receiver. Both air systems, all regulators, all filters and a switch for all drains will then be in one neat place in the main workshop. The second compressor is tiny, and quiet, so that will live inside. I'm still thinking this all through though, materials may be here in a week or two. If anyone has any ideas, can see any issue with any of this, or spots a better way, feel free to chip in! |

| |

|

|

|

|

|

|

|

Sept 23, 2021 16:11:07 GMT

|

|

Doors will be made exactly the same way I made the main doors so hopefully it will all look ok.

If it's not clear from the drawings, I plan on double doors, same as the workshop, so as much of the side opens as possible.

The hedge will swallow most of the building up pretty soon anyway 😂.

|

| |

Last Edit: Sept 23, 2021 16:12:00 GMT by VW

|

|

|

|

|

Sept 23, 2021 16:40:21 GMT

|

|

Do you think, if I dumped any compressor water into the hedge behind the shed and the flower beds in the garden, I'd end up polluting the ground?

It won't be alot, not like it's running every day. I'd be surprised if it runs more than a 100 hours a year.

Edit on this, ive been reading.

It's not allowed to just dump this on the ground. Seems I'll either need to collect it, or let it evaporate, or pipe it into the foul drain.

|

| |

Last Edit: Sept 23, 2021 17:01:04 GMT by VW

|

|

|

|

|

Sept 23, 2021 16:44:01 GMT

|

|

The first question that I would ask is, who owns the hedge along the side wall of the garage, as seen in photograph no.1? I am also assuming that your workshop is not built right on your boundary line either?

The hedge will not be doing your building any good what so ever, and in opinion needs to be cut back away from the side of the building, in order to allow air and light in.

The present situation is only asking to exacerbate problems with damp, and particularly seeping through that wall of the workshop.

With regards to the compressor-shed, have you given consideration to build this structure out of timber? In the past I have had similar buildings constructed out of 3" X 2" timber, and then clad with 1/2" plywood, which was cut into strips of 6" (or similar), attached to the framework to look like overlapping boards. Worked very well and other than creosote/or similar, did OK. The structure could be mounted onto a single brick high, dwarf wall, which would also keep rain/etc... out.

|

| |

|

|

|

|

|

Sept 23, 2021 16:58:50 GMT

|

The first question that I would ask is, who owns the hedge along the side wall of the garage, as seen in photograph no.1? I am also assuming that your workshop is not built right on your boundary line either? The hedge will not be doing your building any good what so ever, and in opinion needs to be cut back away from the side of the building, in order to allow air and light in. The present situation is only asking to exacerbate problems with damp, and particularly seeping through that wall of the workshop. With regards to the compressor-shed, have you given consideration to build this structure out of timber? In the past I have had similar buildings constructed out of 3" X 2" timber, and then clad with 1/2" plywood, which was cut into strips of 6" (or similar), attached to the framework to look like overlapping boards. Worked very well and other than creosote/or similar, did OK. The structure could be mounted onto a single brick high, dwarf wall, which would also keep rain/etc... out. The hedge is shared and on the boundary. I cut back as far as I could, then built the workshop so id guess the walls are maybe 12" of the boundary. No chance of removing the hedge. I know it's not ideal (I normally cut it back to 2' above the roof and in line with the wall, but I've been slack this year), but it was the best I could do at the time. For the record, and surprisingly on a few levels (No barrier between earth and walls etc) I get no damp issues in this building. None at all! Bare steel won't go rusty, even over winter and I've never seen a single drop of condensation in it. No idea why! Still, it is what it is, and the comlressor shed will be built in exactly the same way, bang up against the hedge. As for building it in timber, it's easier, quicker, cheaper and stronger to do it in block. Edit... There is no ventilation in the building at all (will be soon though) and no insulation over the last 7 years. Roof is being done now though. It has a damp membrane under the floor and a damp course in the walls. Inner walls below ground level were painted with bitumen paint. I've no idea why it's so dry in there! Edit 2... Other end of the garden I have a timber shed, also burried into the hedge. The side in the hedge is the only side that hasn't rotted, 7 years later! Reminds me, I need to replace the bottom boards on the side that's open to the garden! I wonder if the protection it offers from the rain and wind helps as much as the lack of air movement doesn't. Maybe it creates a 6 of one, half a dozen of the other type situation? |

| |

Last Edit: Sept 23, 2021 17:12:06 GMT by VW

|

|

|

|

|

Sept 24, 2021 9:09:47 GMT

|

The first question that I would ask is, who owns the hedge along the side wall of the garage, as seen in photograph no.1? I am also assuming that your workshop is not built right on your boundary line either? The hedge will not be doing your building any good what so ever, and in opinion needs to be cut back away from the side of the building, in order to allow air and light in. The present situation is only asking to exacerbate problems with damp, and particularly seeping through that wall of the workshop. With regards to the compressor-shed, have you given consideration to build this structure out of timber? In the past I have had similar buildings constructed out of 3" X 2" timber, and then clad with 1/2" plywood, which was cut into strips of 6" (or similar), attached to the framework to look like overlapping boards. Worked very well and other than creosote/or similar, did OK. The structure could be mounted onto a single brick high, dwarf wall, which would also keep rain/etc... out. The hedge is shared and on the boundary. I cut back as far as I could, then built the workshop so id guess the walls are maybe 12" of the boundary. No chance of removing the hedge. I know it's not ideal (I normally cut it back to 2' above the roof and in line with the wall, but I've been slack this year), but it was the best I could do at the time. For the record, and surprisingly on a few levels (No barrier between earth and walls etc) I get no damp issues in this building. None at all! Bare steel won't go rusty, even over winter and I've never seen a single drop of condensation in it. No idea why! Still, it is what it is, and the comlressor shed will be built in exactly the same way, bang up against the hedge. As for building it in timber, it's easier, quicker, cheaper and stronger to do it in block. Edit... There is no ventilation in the building at all (will be soon though) and no insulation over the last 7 years. Roof is being done now though. It has a damp membrane under the floor and a damp course in the walls. Inner walls below ground level were painted with bitumen paint. I've no idea why it's so dry in there! Edit 2... Other end of the garden I have a timber shed, also burried into the hedge. The side in the hedge is the only side that hasn't rotted, 7 years later! Reminds me, I need to replace the bottom boards on the side that's open to the garden! I wonder if the protection it offers from the rain and wind helps as much as the lack of air movement doesn't. Maybe it creates a 6 of one, half a dozen of the other type situation? At least you are aware of the potential issues. Property boundaries are such a mix bag of issues, especially hedges/trees. Keep up the good work and continue the updates, please. |

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,971

Club RR Member Number: 71

|

Compressor shed buildbstardchild

@bstardchild

Club Retro Rides Member 71

|

Sept 24, 2021 11:28:19 GMT

|

|

Watching this as I am considering similar to get my compressor out of the garage but also to add a second receiver to it

|

| |

|

|

|

|

|

Sept 25, 2021 10:50:26 GMT

|

|

i moved my compressor into our shed, its near next door, although they have never complained, it gets hot in there in the summer, and i am conscious of its noise. I am thinking of doing it simple, get one of those garden plastic storage boxes , lining it with some foam to keep it insulated and help with the noise, and drilling the side to take a drain pipe and take it upwards with a china mans hat on the top...

not 100% decided yet, but they are noisey and make vibrations too.

|

| |

|

|

|

|

|

Sept 25, 2021 12:09:46 GMT

|

i moved my compressor into our shed, its near next door, although they have never complained, it gets hot in there in the summer, and i am conscious of its noise. I am thinking of doing it simple, get one of those garden plastic storage boxes , lining it with some foam to keep it insulated and help with the noise, and drilling the side to take a drain pipe and take it upwards with a china mans hat on the top... not 100% decided yet, but they are noisey and make vibrations too. Good idea on the pipe for ventilation. I may even be able to 'borrow' some insulated flue from work, hoping having insulation in everything will keep noise down. The other reason I'm going with block is Hoping the mass will help with noise. I may try different linings inside, maybe hanging carpet but 1" away from the walls. Anything to stop vibrations and sound waves from reaching the outside walls. This is all reliant on my new (to me) compressor actually works well enough when I get it back in one piece. I'm going to start on clearing that area this weekend, then maybe order materials next week. I've been owed some money for quite some time, so all the materials for this will be put on the debters builders mech account, so it will basically feel free 😂 |

| |

|

|

|

|

|

Sept 25, 2021 12:17:27 GMT

|

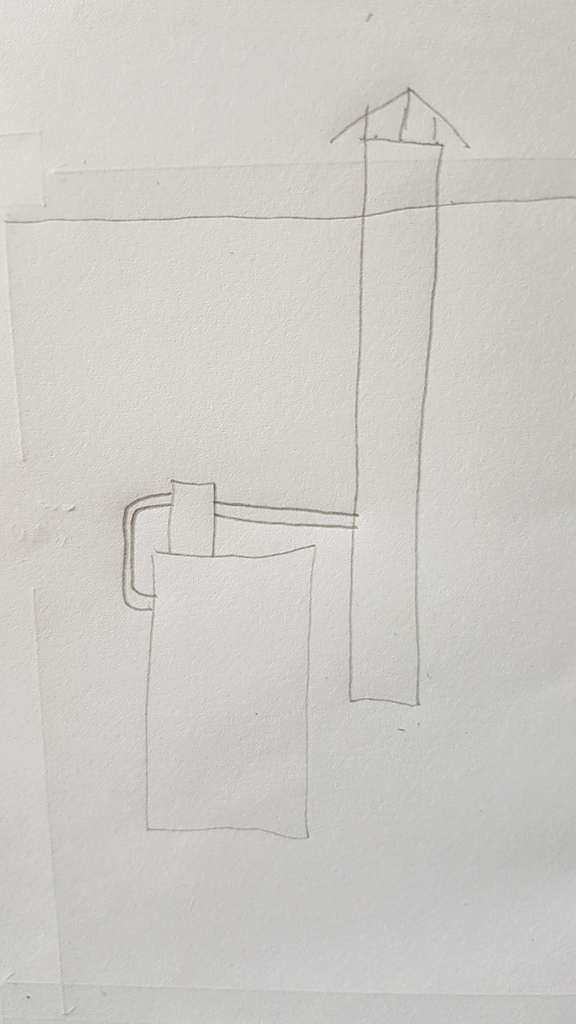

I could use some insulated twin wall flue as an external air source for the compressor, might quieten it down some too.  Also had to check the compressor and mower will both fit! Benefits of a vertical receiver!  |

| |

|

|

|

|

|

|

|

Sept 25, 2021 13:47:01 GMT

|

|

I was thinking of using a "t" on the side of the box , the straight bit going into the floor to mount the pipe and up with the hat on ,

|

| |

|

|

|

|

|

Sept 25, 2021 13:54:08 GMT

|

I was thinking of using a "t" on the side of the box , the straight bit going into the floor to mount the pipe and up with the hat on , Makes sense. If I had a suitable outside wall, I would too. But I don't, so would have to go through the roof. Probably have all the stuff needed, even if an 8" flue and a proper roof mounting collar is a little overkill 😂 |

| |

|

|

|

|

|

Sept 25, 2021 16:52:24 GMT

|

|

i think if you stuffed some foam in the pipe too it would dampen the noise down too.. I was looking for a tool box on ebay but there is non big enough, but at work we have a lot of off cuts of the wisadecking, i could make a box out of that and put it on 4 legs to keep it dry.

only thing I'm worried about is condensation getting into it.

|

| |

|

|

|

|

|

Sept 25, 2021 17:24:00 GMT

|

|

Keeping it dry inside would be helpful.

I guess that's one benefit of having the compressor draw air from inside, it will dram any damp air out where it can be caught in the water trap.

I'm hoping the fact mine will be alot bigger than the compressor will help with things.

I may be wrong, but my gut feeling is the smaller the box around the compressor, the harder it will be to maintain conditions inside the box.

|

| |

|

|

|

|

|

Sept 25, 2021 18:50:32 GMT

|

|

yes yours being much bigger will help. I was thinking about insulation, and looking on ebay , and me being a bit tight fisted, it all seems expensive for what it is. So thinking of making the box, then another box say 2" smaller inside, and then using expanding foam to insulate it and make it quieter. Will seal the pipe on the side too

now thinking of using some pallet wood i already have and some roofing felt to cover the outside of it. I think a vent in the bottom would be usefull also, let any water out...

|

| |

|

|

|

|

|

Sept 25, 2021 20:34:24 GMT

|

yes yours being much bigger will help. I was thinking about insulation, and looking on ebay , and me being a bit tight fisted, it all seems expensive for what it is. So thinking of making the box, then another box say 2" smaller inside, and then using expanding foam to insulate it and make it quieter. Will seal the pipe on the side too now thinking of using some pallet wood i already have and some roofing felt to cover the outside of it. I think a vent in the bottom would be usefull also, let any water out... Having made similar structures before, you'll struggle to fill it with expanding foam without it blowing itself apart! Even with holes for expansion. Maybe just make the inner and outer walls, No top or bottom, and just fill those first. I have insulated 3/4 of my 30sqm workshop so far and it hasn't cost me a penny. All in kingspan type pir insulation boards. Keep an eye on Facebook for free offcuts and keep an eye on skips. It's surprisingly easy to pick up free insulation. There is normally a place nearby that does seconds too, 25mm insulation board can be had for £20 for an 8x4 sheet if need be. I think if I was doing one the size you are, I'd frame it in timber, tongue and groove the outside, put 25mm insulation board on between the studs, then pin carpet to the inner frame, so it has an inch or so gap between the carpet and insulation. Put some insulation on the floor with a piece of ply on top to sit the compressor on to keep it off the base. All guesswork, but should keep it dry and quiet. |

| |

|

|

|

|

|

Sept 26, 2021 16:57:53 GMT

|

|

|

| |

|

|

|

|

Compressor shed buildballbagbagins

@ballbagbagins

Club Retro Rides Member 164

|

Sept 26, 2021 19:08:09 GMT

|

|

To block the noise you need mass. Get some 2nd hand heavy duty rubber floor mats or similar rather than carpet, carpet isn't dense enough. Sound proof plasterboard is an option but when I've used it I've done for two layers of it with offset joints. Sound proofing only works if done properly, absolutely no gaps for the sound to pass through.

|

| |

|

|

|

|

|

Sept 26, 2021 19:48:02 GMT

|

To block the noise you need mass. Get some 2nd hand heavy duty rubber floor mats or similar rather than carpet, carpet isn't dense enough. Sound proof plasterboard is an option but when I've used it I've done for two layers of it with offset joints. Sound proofing only works if done properly, absolutely no gaps for the sound to pass through. My thoughts with carpet, especially with what I plan to build, is to try and take the energy out of the sound, by making it have to move the carpet, before it gets to the mass. It's just guesswork though. |

| |

|

|

|

|

|

Sept 27, 2021 7:42:45 GMT

|

|

Remember most compressors are air cooled, you need a decent amount of air fresh flow around them and over the fins to keep them cool.

Mine are in a dry pit under the garage floor, I have an extractor fan pumping fresh air through a 4" pipe to keep things cool.

|

| |

|

|

|

|