|

|

|

Mar 17, 2021 21:21:19 GMT

|

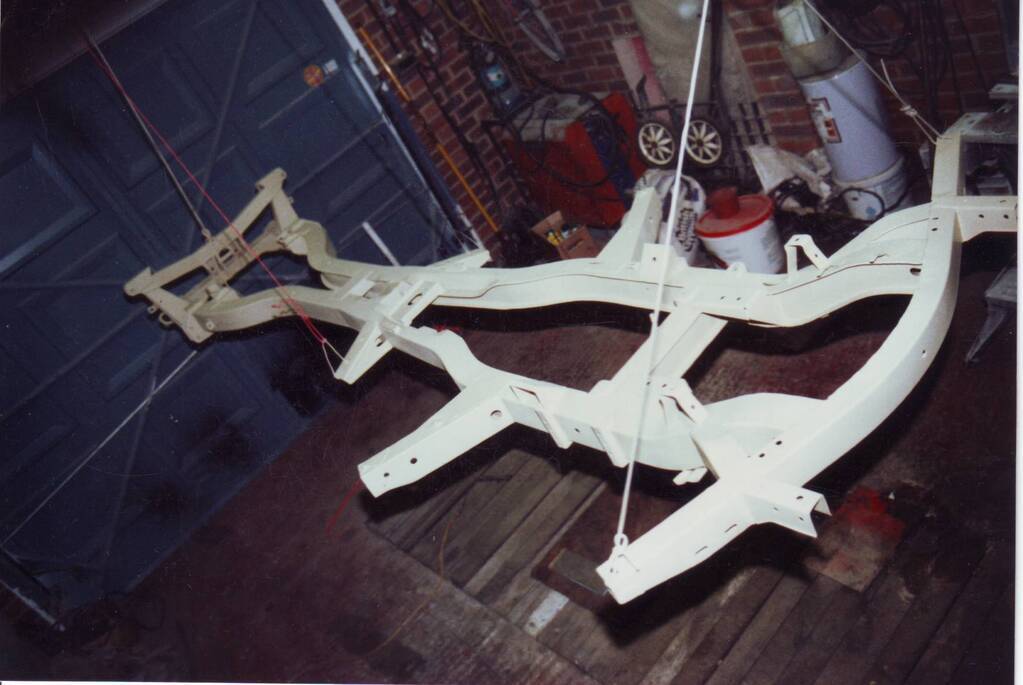

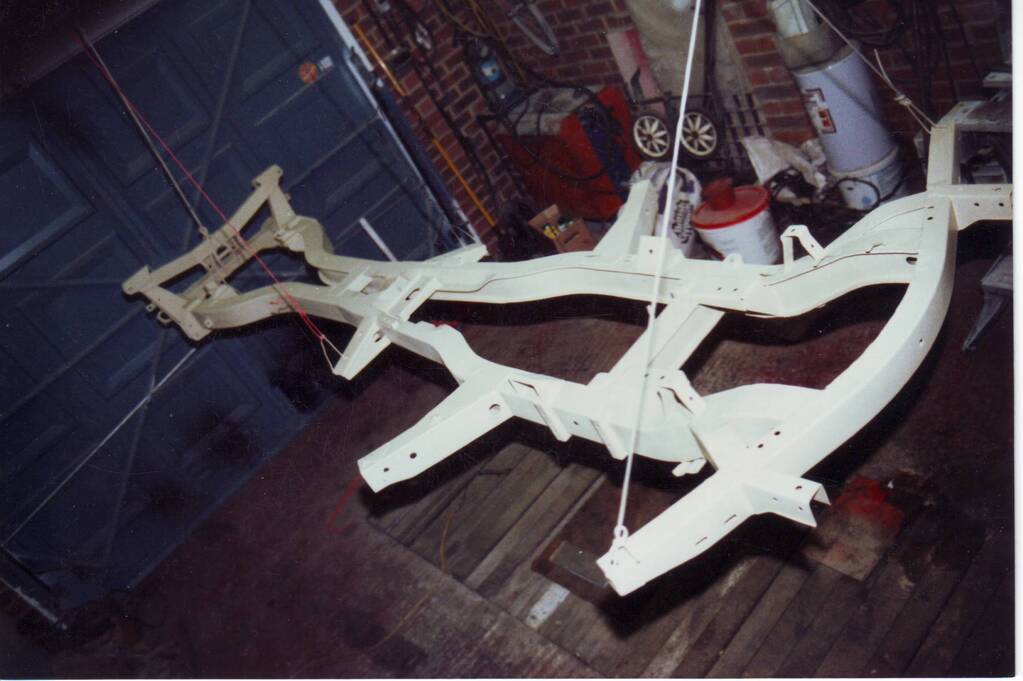

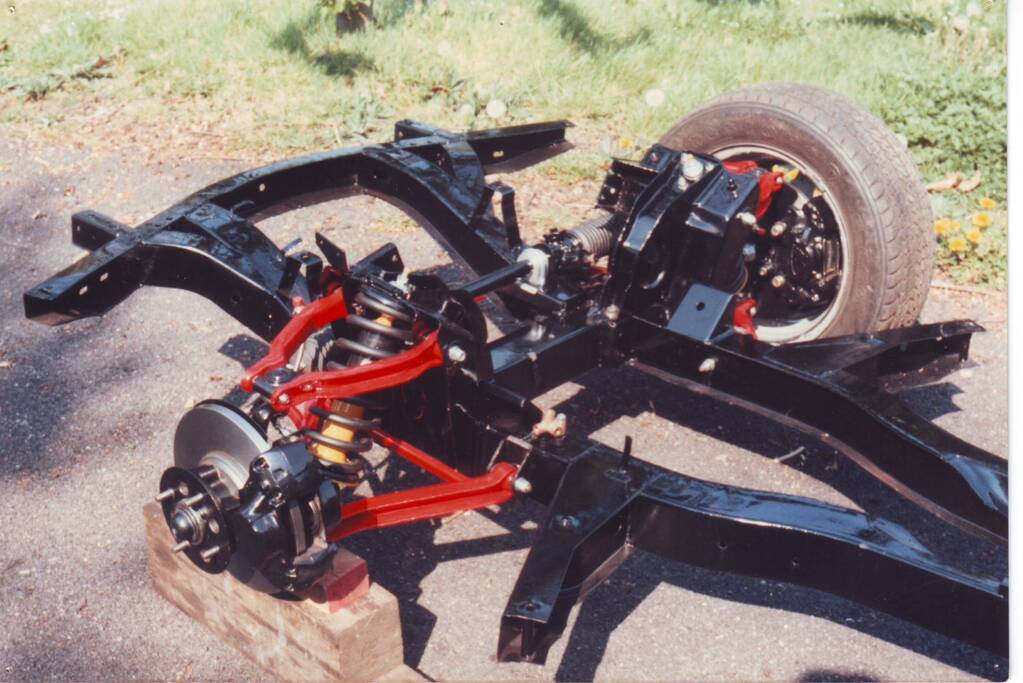

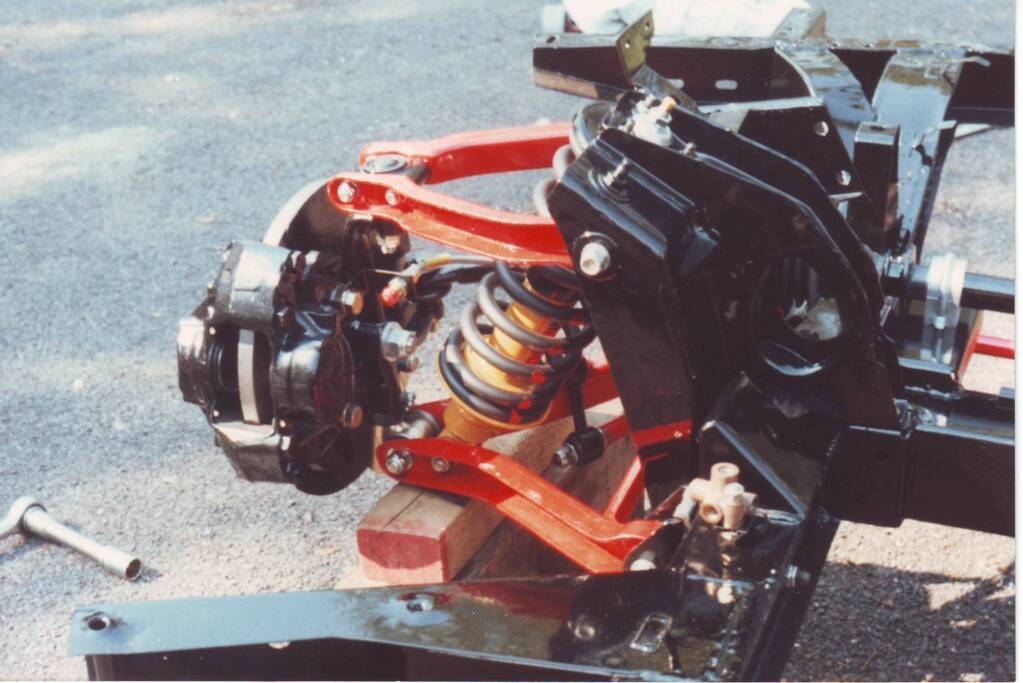

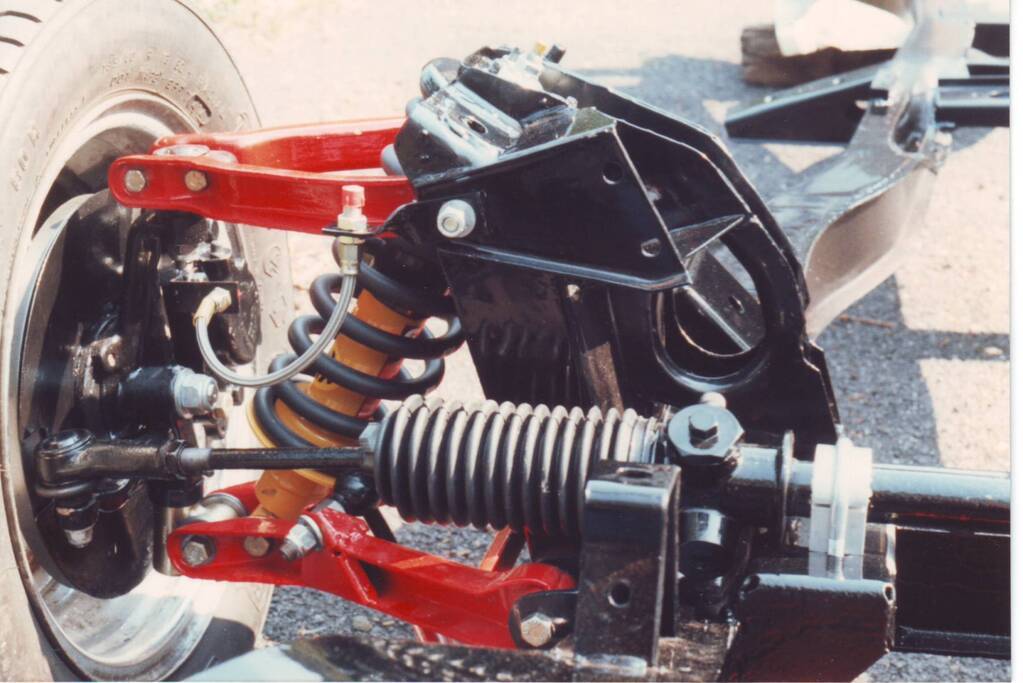

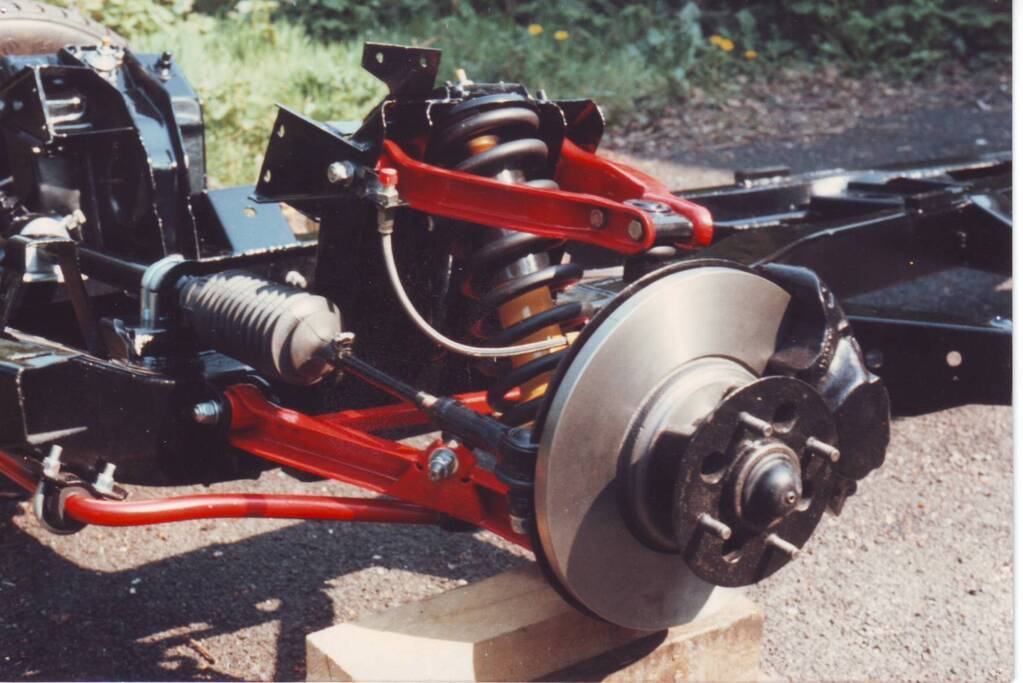

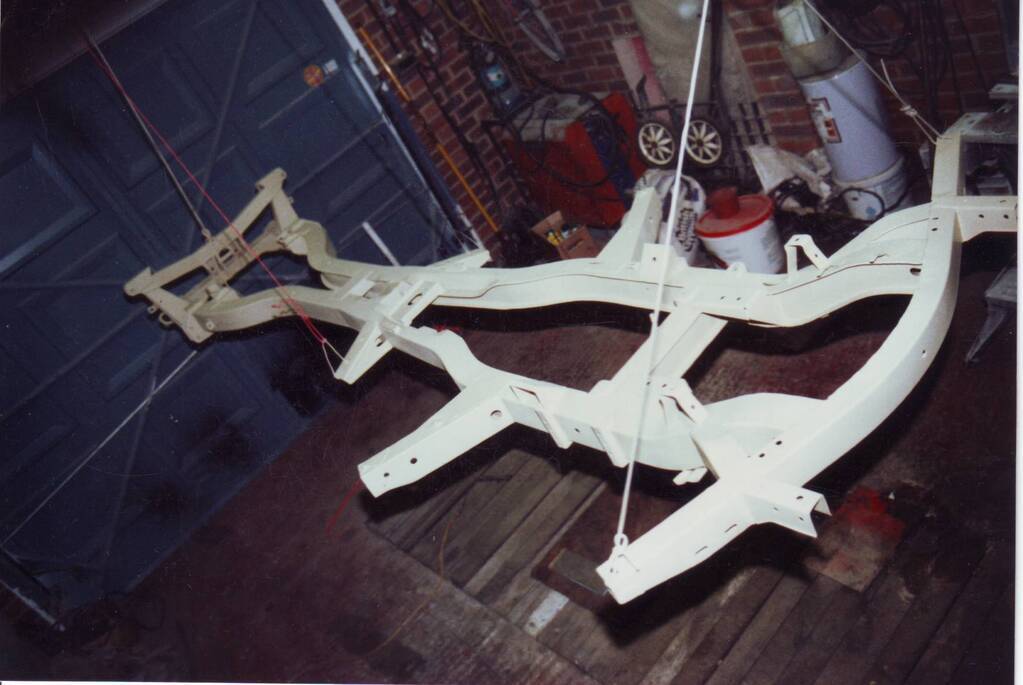

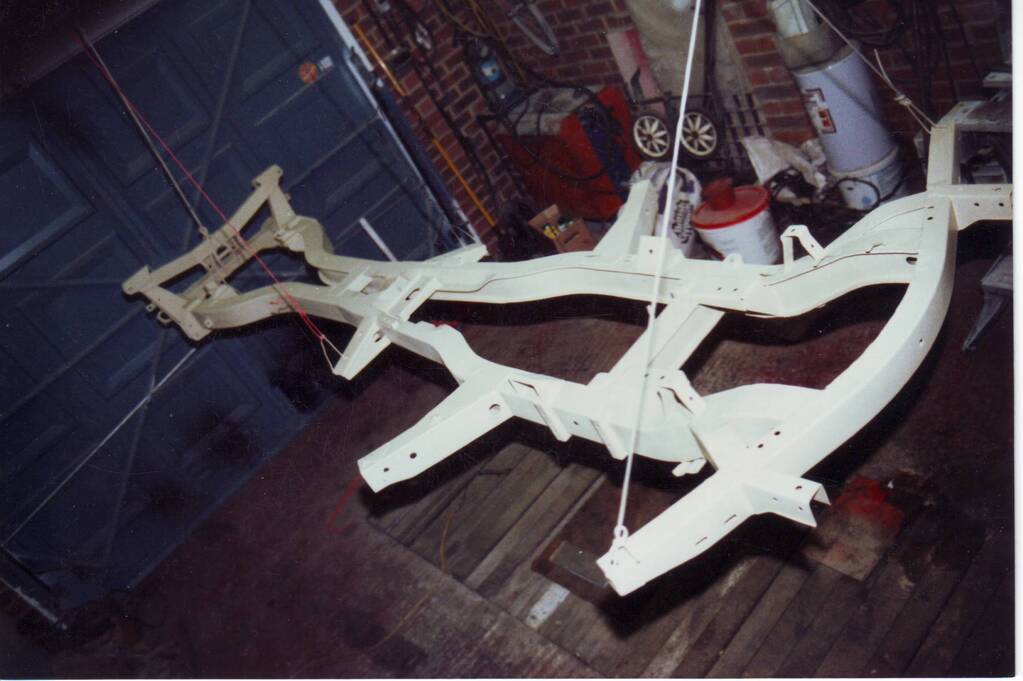

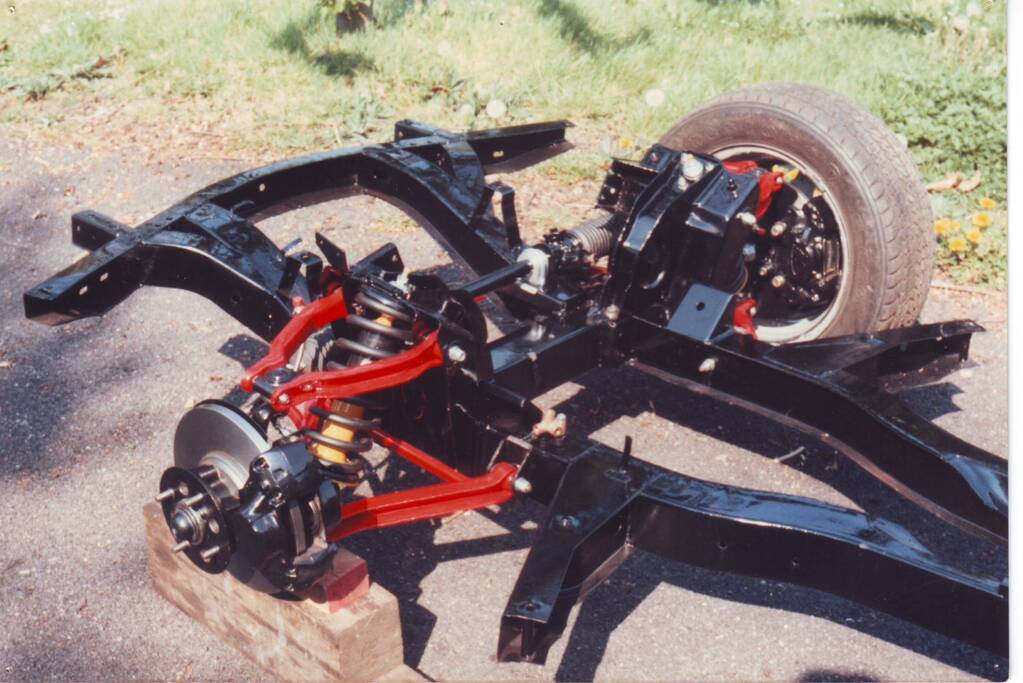

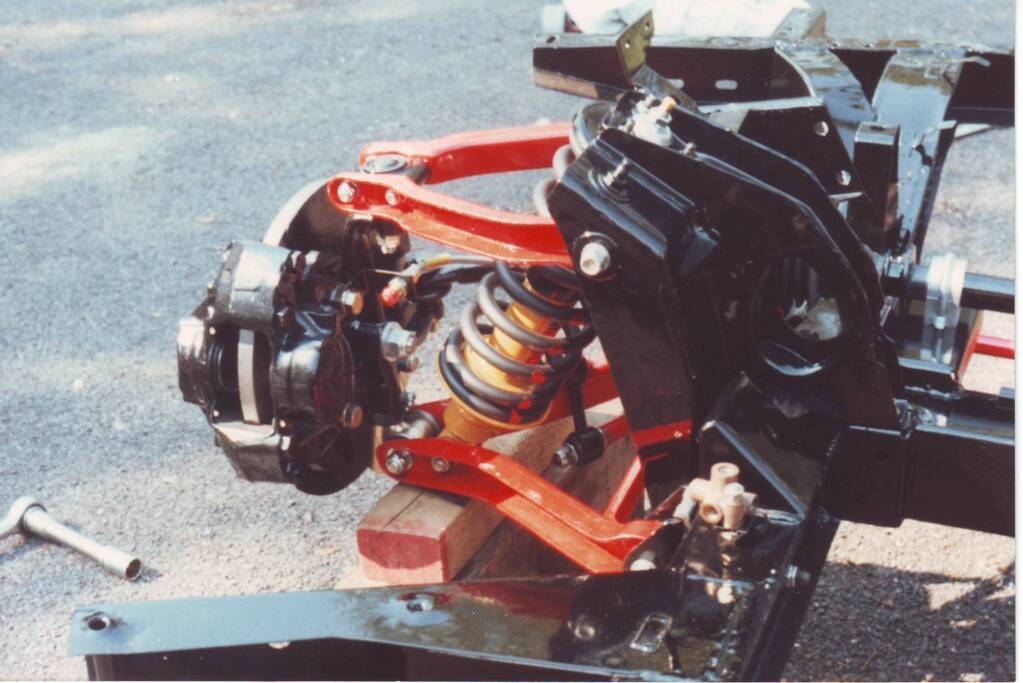

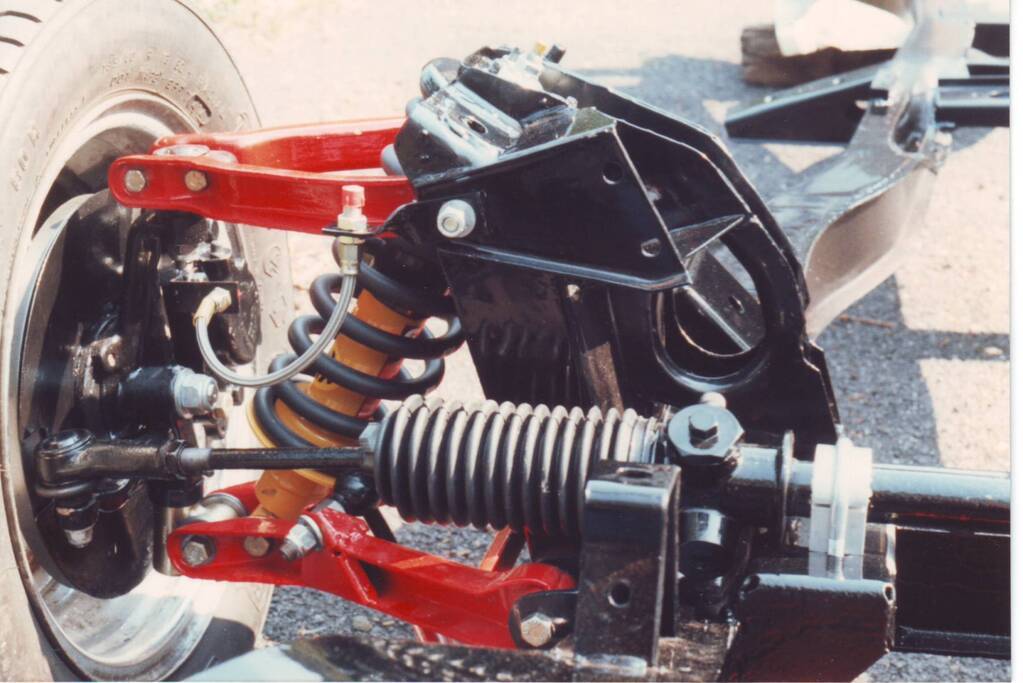

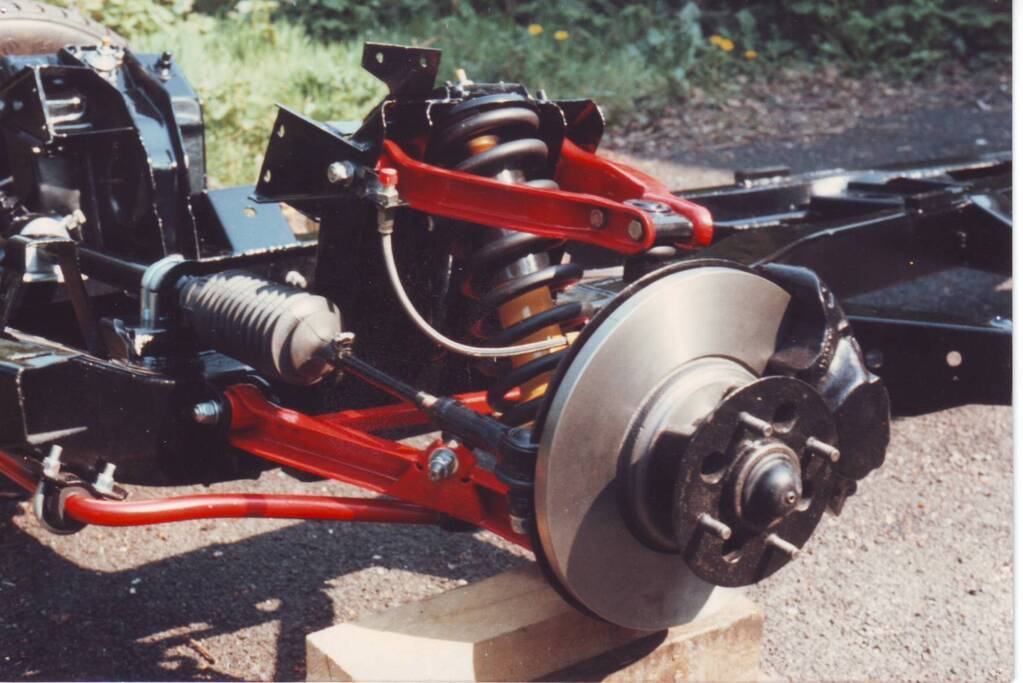

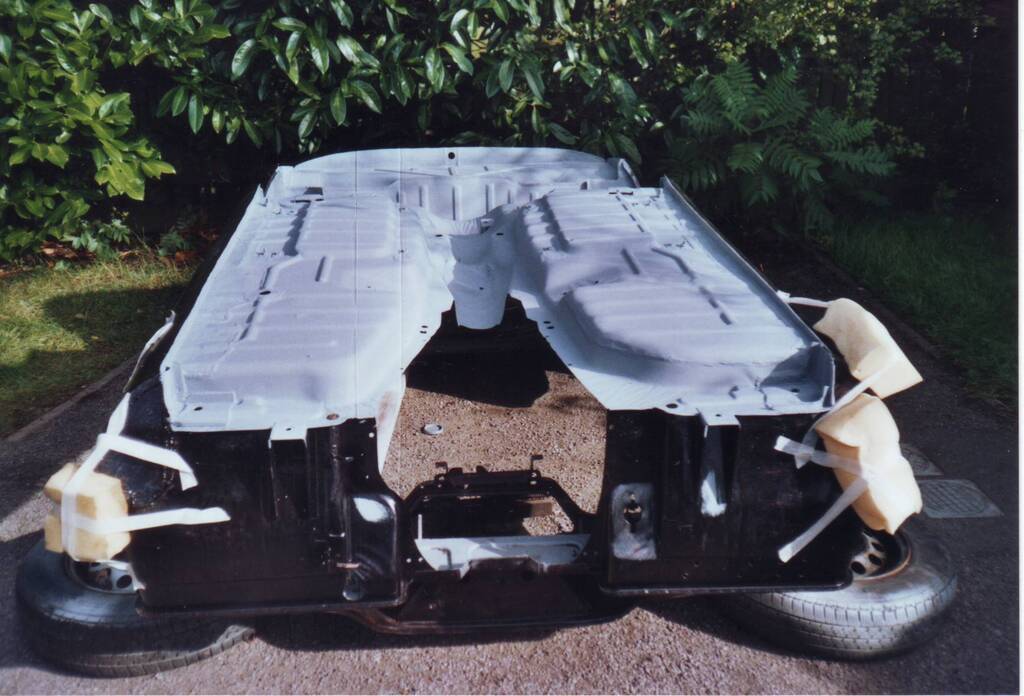

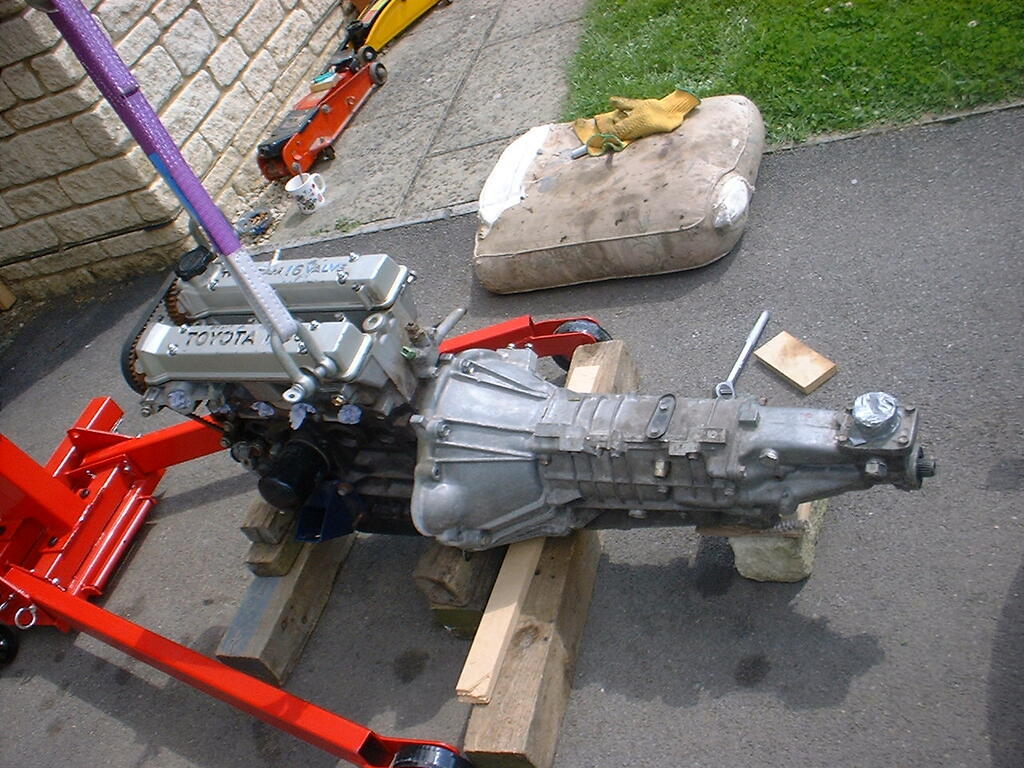

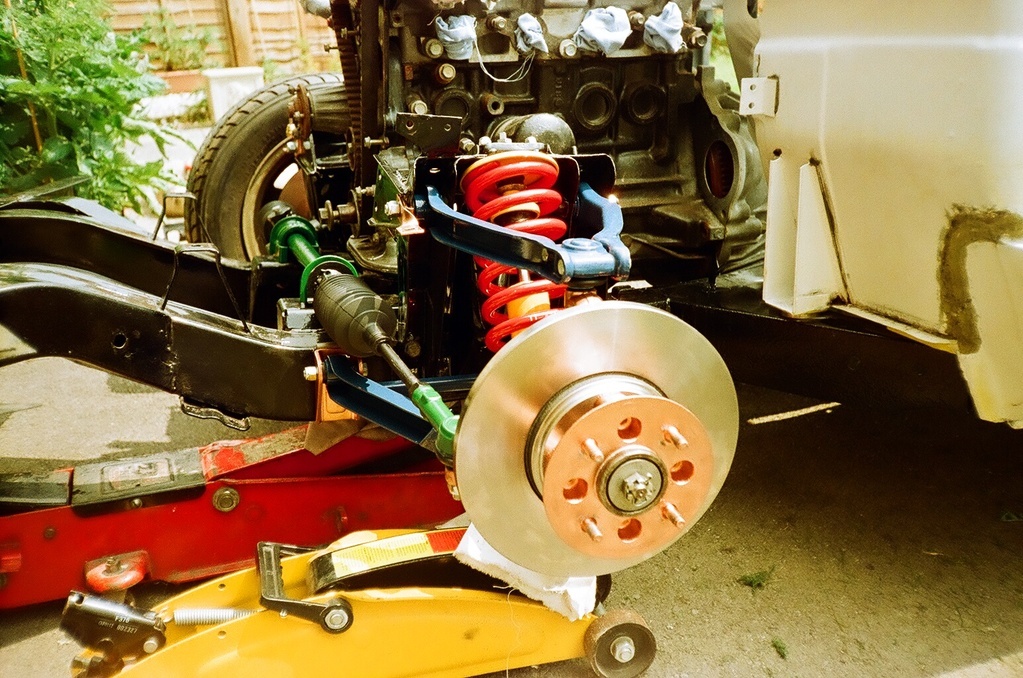

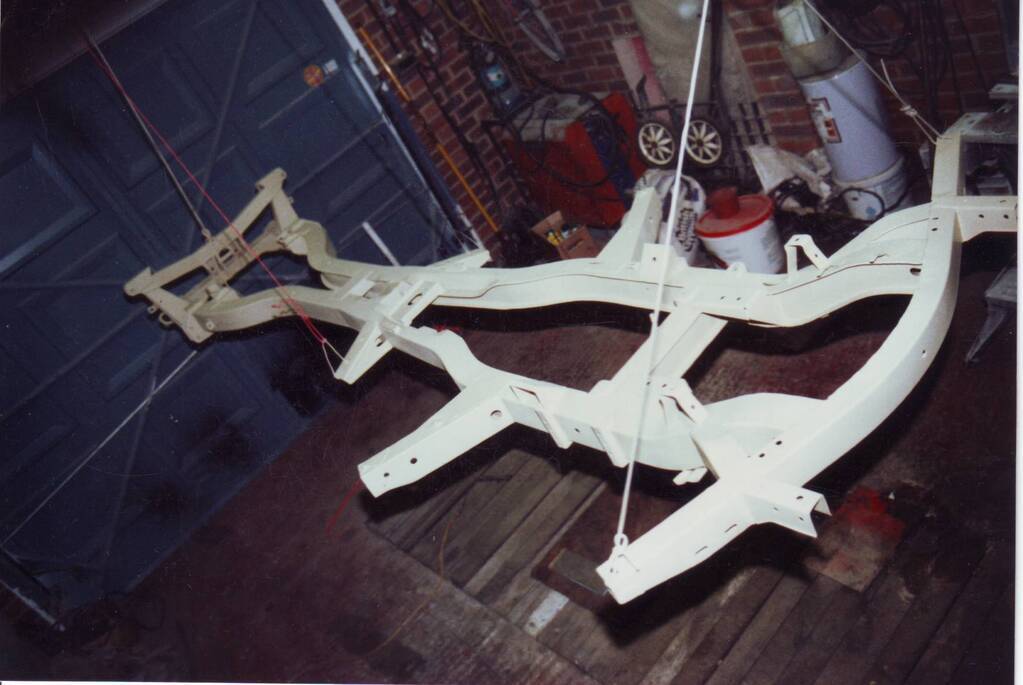

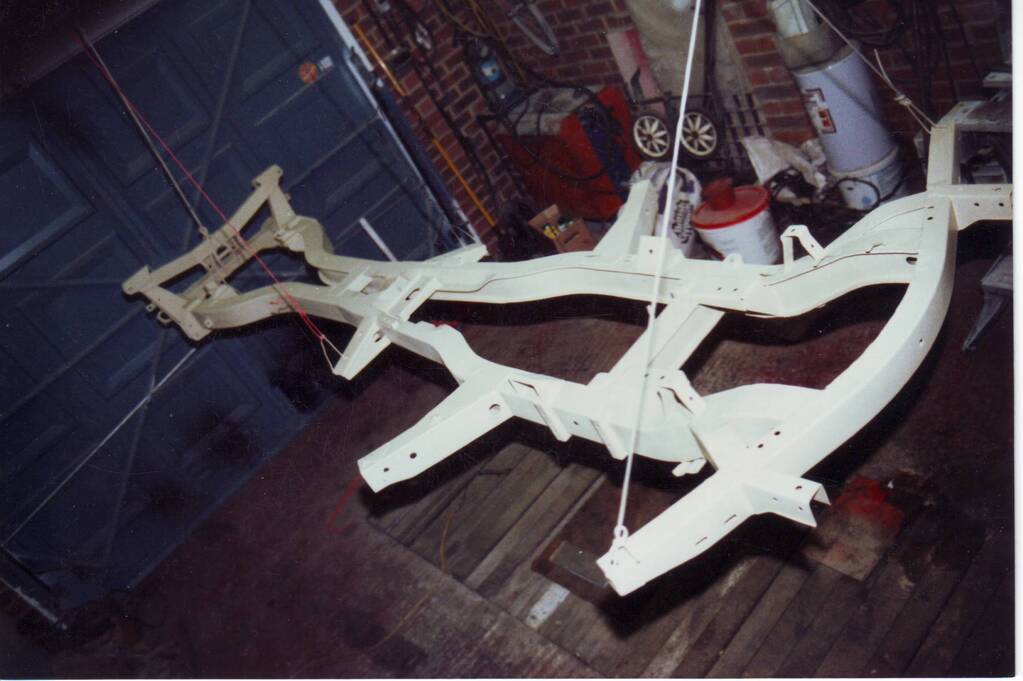

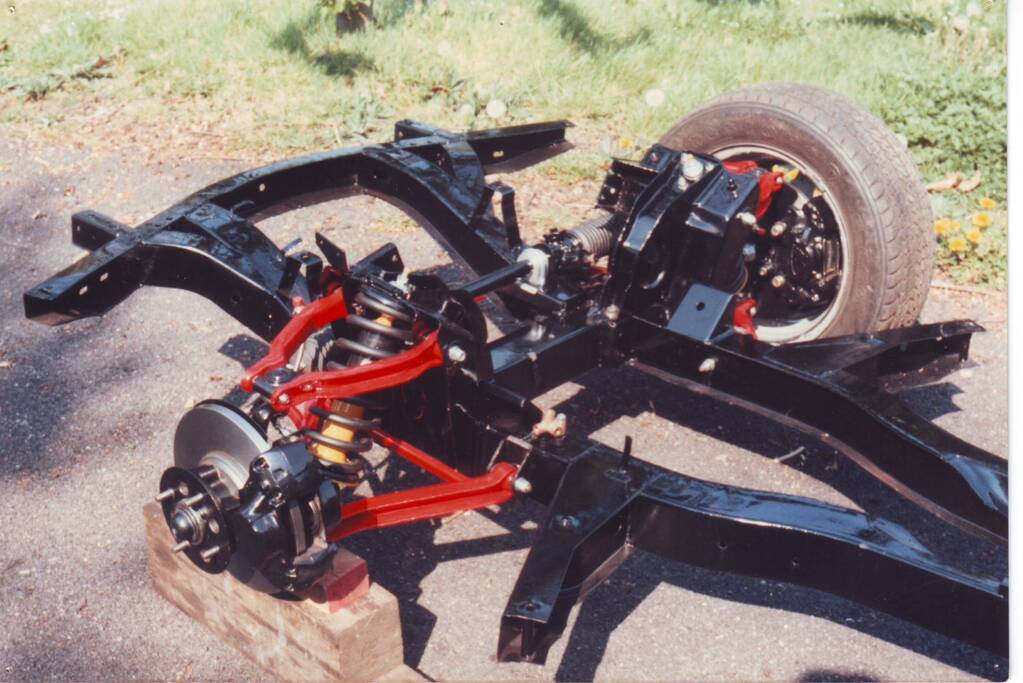

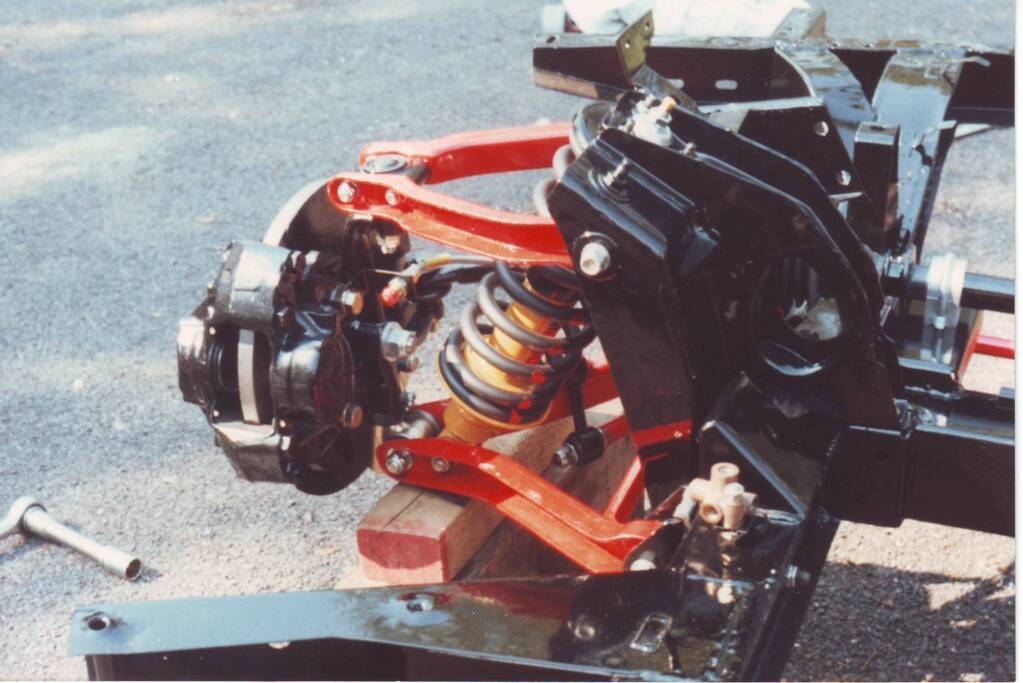

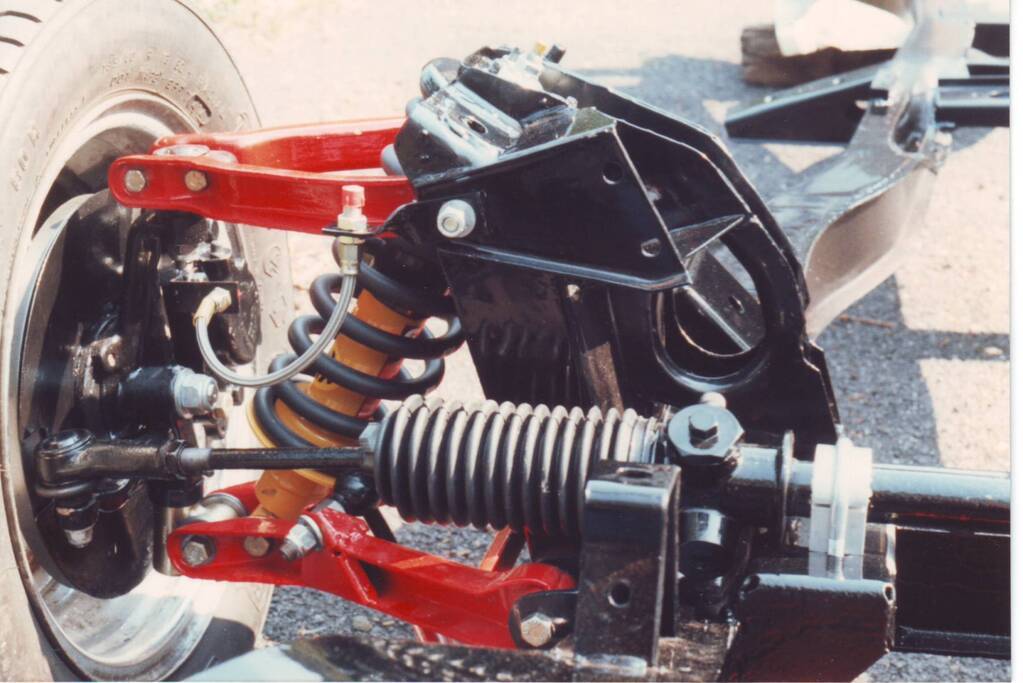

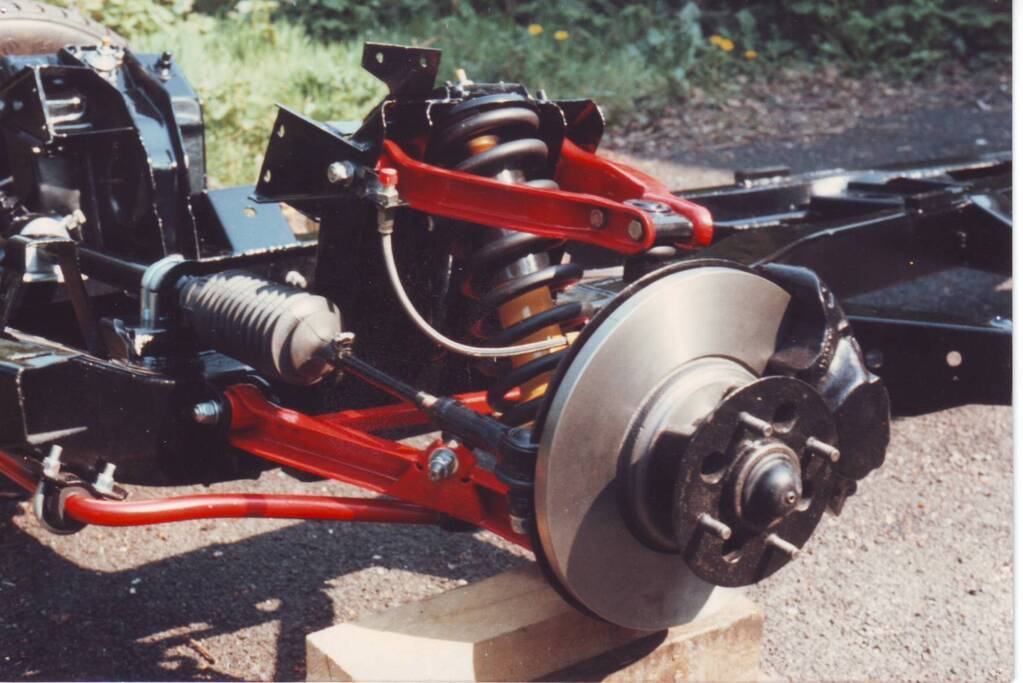

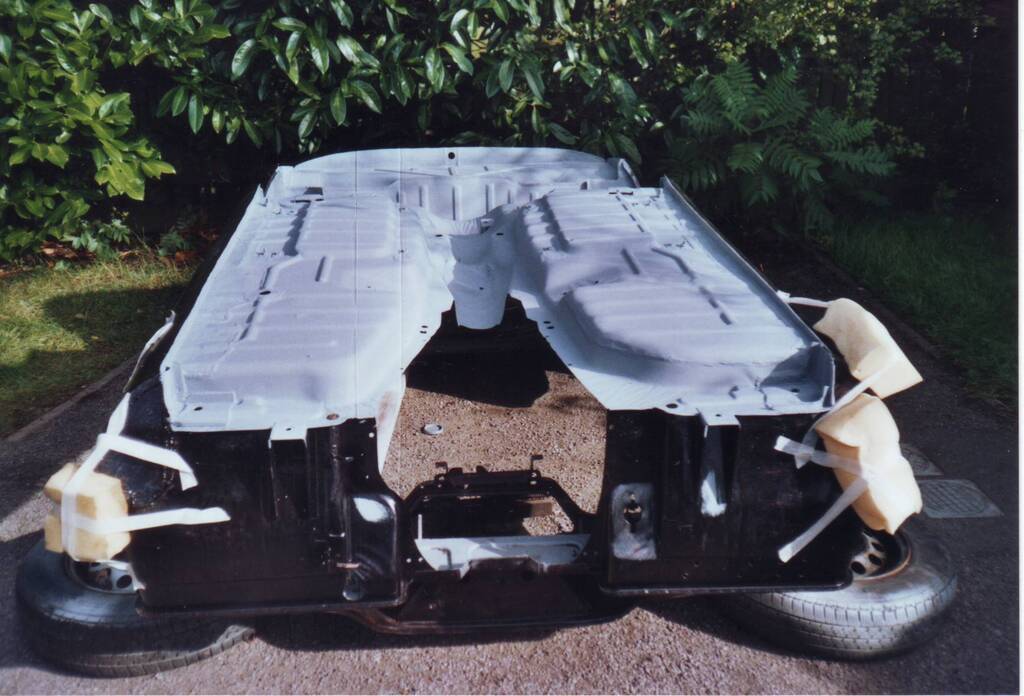

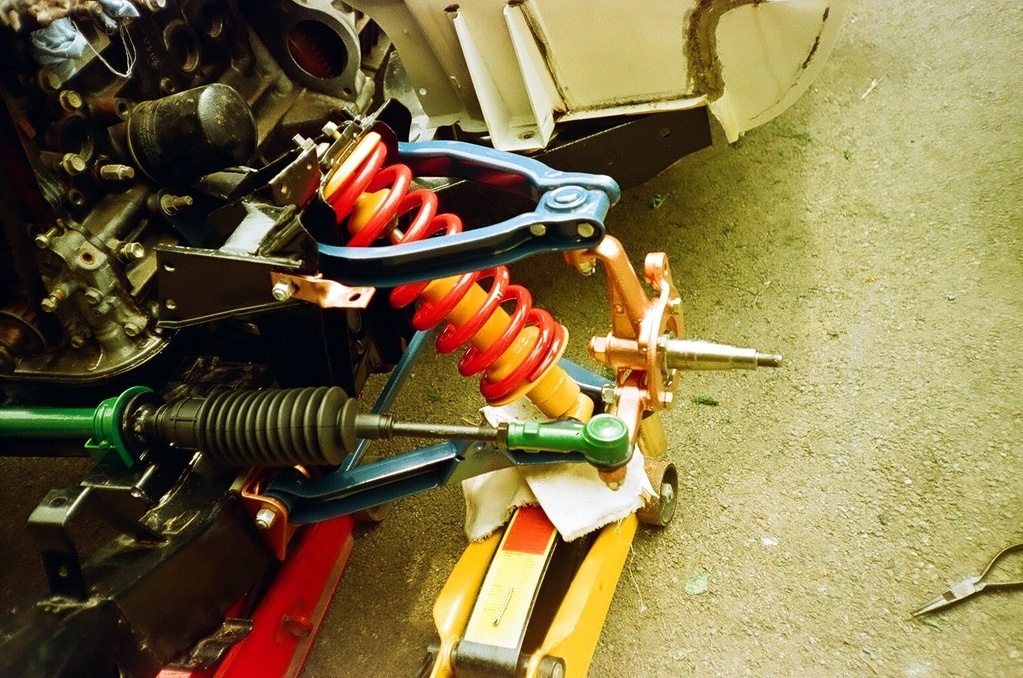

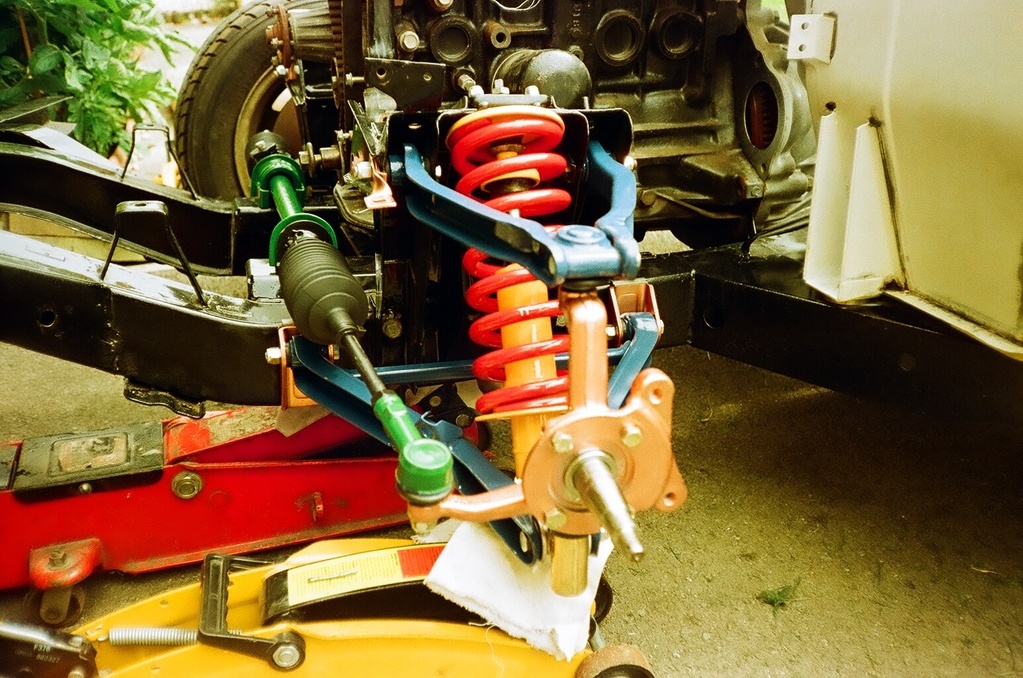

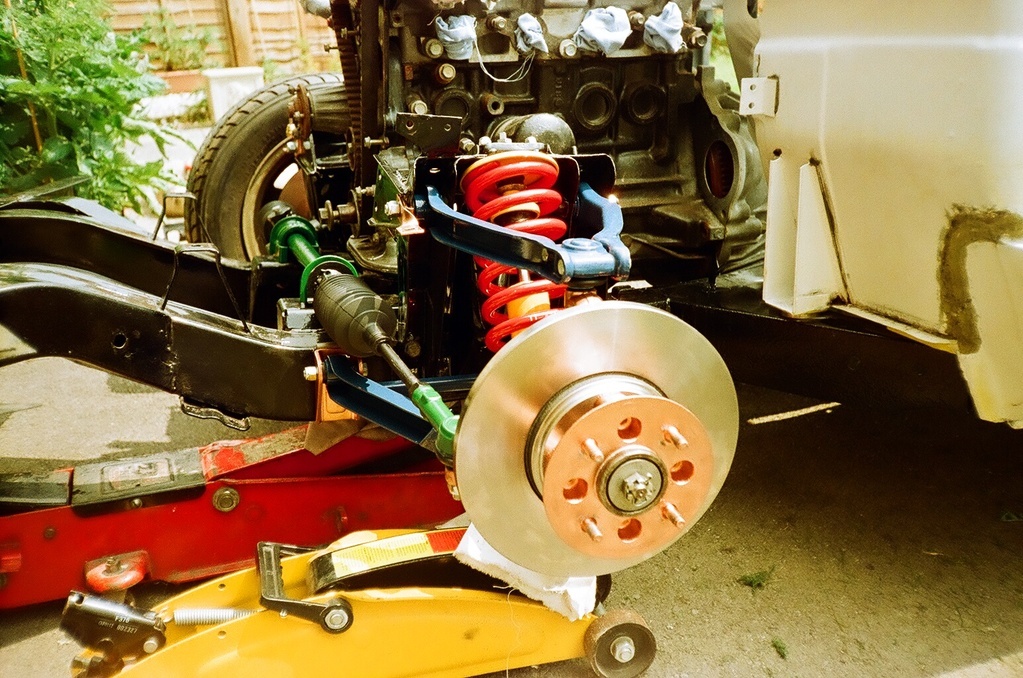

I found a picture of the custom GT6 rear wishbone bracket design that is welded to my chassis...  Anyhow, let's move on, still in 1989. Another local friend welded the various additions to the chassis i.e. the engine mount angle turrets, gearbox rear mount and rear wishbone brackets. My hobby MIG was not going to be up to the job, so this chap used his professional MIG set to achieve some excellent welds. He was a contractor on motorway barriers, so rather excellent at this sort of thing. With all the bits and bobs welded to the chassis, it got taken away to a company called Cleaning Consultants, who blast cleaned the chassis to bare metal.. It came back looking like this:  By this time, I had got to know a neighbour (called Alan) who noticed the Spitfire work going on in my driveway and happened to be restoring a Spitfire himself. We took the chassis straight over to his place after it got back from the blast cleaning. A couple of really minor repairs were required and then he did the full works of etch-prime, fine grain golf-ball stone-chip on the lower surfaces, 2K gloss black paint and finally internally sprayed it with 'waxoyl' type protection. Here are some photos: Etch primed....  Now you can see the 45 degree angled engine mounts, gearbox plate and rear wishbone brackets. The rear gearbox plate was designed and made by by me to accept the standard AE86/T50 rubber mount.    I then set about building it up with suspension items that I had blast cleaned and painted in Smoothrite. I hasten to add that those items are in a completely different colour scheme nowadays.     More updates will follow soon. Many thanks to all the folk who have responded to positively to this build thread. Chris |

| |

Last Edit: Mar 17, 2021 21:23:49 GMT by krissto: Typo corrections

|

|

|

|

|

|

|

Mar 18, 2021 21:41:14 GMT

|

|

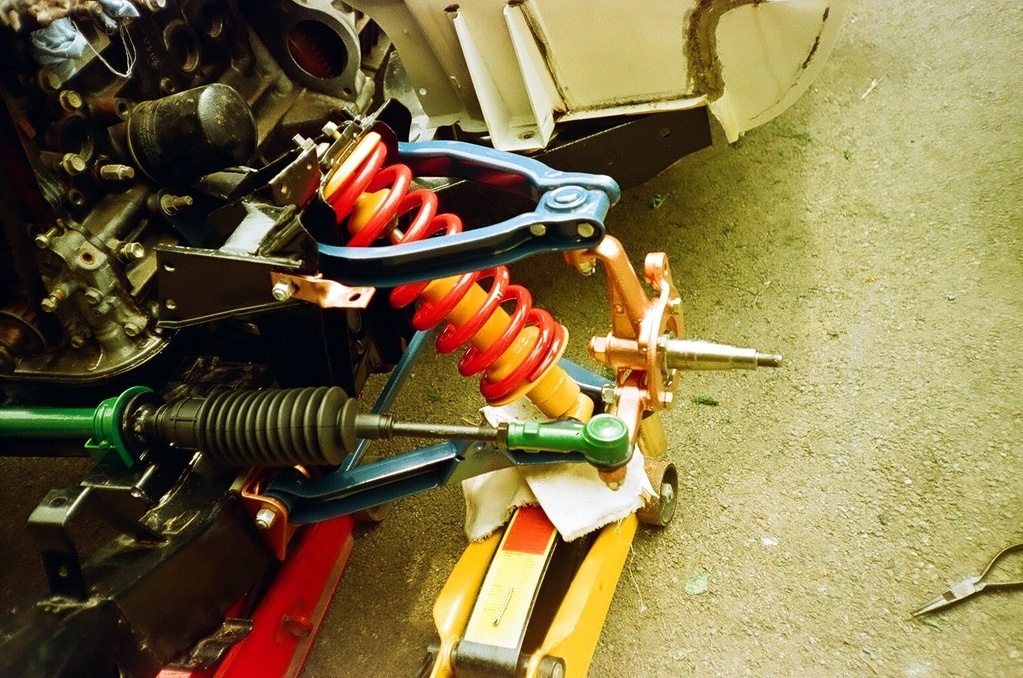

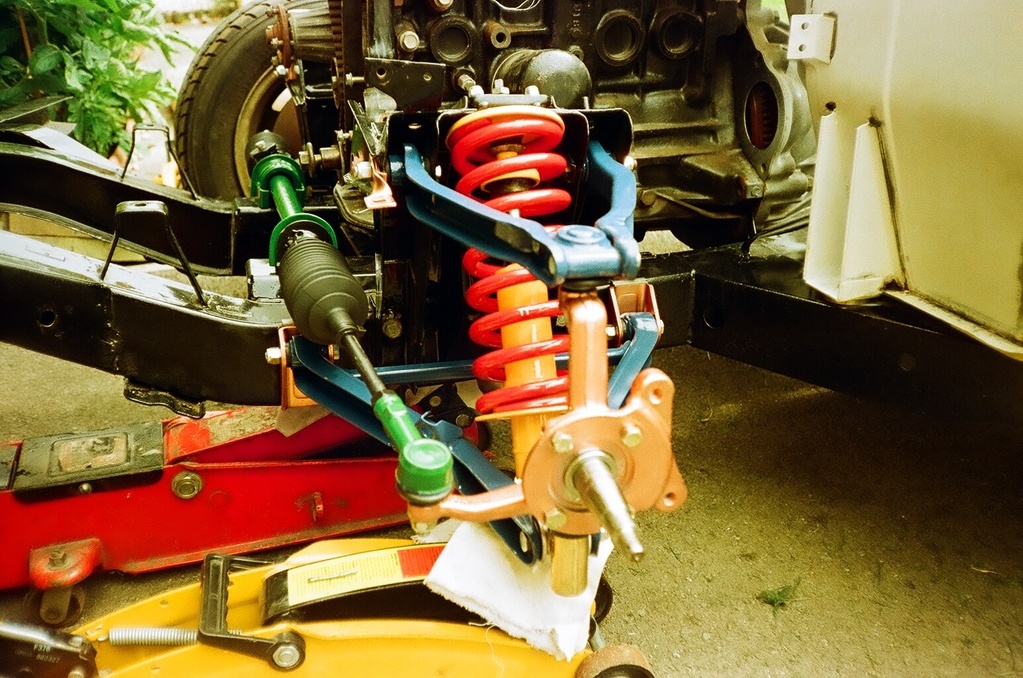

Those of you who know the Spitfre/GT6/Vitesse etc., will have noticed that the components fitted in the above pictures are not standard Spitfire Mk3. I forgot to mention that I bought a set of calipers, vertical links, hubs , steering arms, brackets, backplates, Mintex pads and new (at that time) discs. I rebuilt the used parts with new bearings, Goodridge hoses and more. Also in the photos are solid rack mounts, new/exchange steering rack, Spax dampers and TT4302 springs . 99% of what you see is long since replaced, but that's a story for later. One parting comment. It can be seen that the original Triumph engine mounts are no longer in place and that there is potentially nothing to stop the tops of the suspension turrets from moving around. The fit of the OE engine between the suspension turrets is supposed to prevent this - or maybe all the twisting and torque of the heavy cast iron engine makes them move even more than intended? In any case, rest assured that the turrets are now suitably connected with what we might loosely term a 'strut brace'. More of that when we eventually get to the 21st Century blog updates...

Enough waffle for tonight...

Thanks,

Chris

|

| |

Last Edit: Mar 18, 2021 21:42:55 GMT by krissto: Typos

|

|

|

|

|

Mar 19, 2021 10:23:28 GMT

|

|

Looks good!

I must say I've always been a bit skeptical of the engine bracing the turrets by any appreciable amount. If you can move the engine by hand (and you can just) it's probably not doing a great deal unless your chassis is very floppy indeed (and the Spit chassis is a bit floppy, but not there).

|

| |

|

|

|

|

|

Mar 19, 2021 11:50:43 GMT

|

|

Just found this, work looks great shall be looking forward to reading more! Bookmarked

|

| |

1975 Triumph Spitfire 1500

|

|

|

|

|

Mar 21, 2021 20:23:28 GMT

|

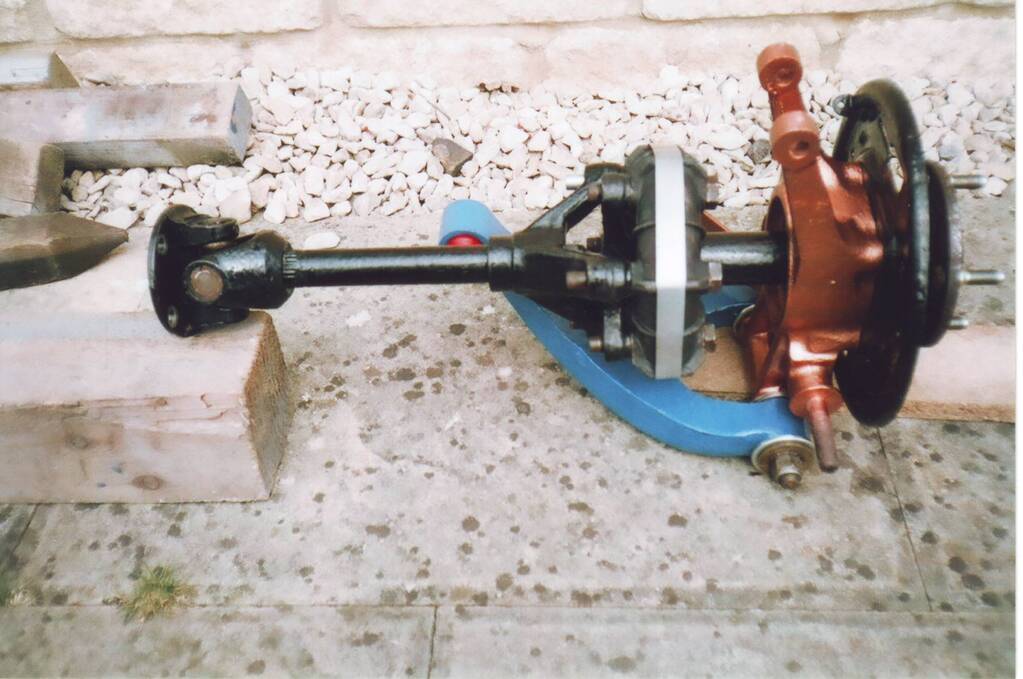

A quick update tonight, as I am struggling to find old photographs. We return to 1989/1990 and the body is reunited with the rolling chassis and the 4AGE minus many ancillaries but with the T50 gearbox fitted. The second photo is damaged and I have mislaid the negatives, but you can just about make it out....   I seem to have not taken any shots of the rear suspension at this time. So to describe instead, it was assembled with the following: - New late type 3.89:1 diff from John Kipping. - New GT6 Mk2 rear spring. - Completely rebuilt radius arms, lower wishbones, driveshafts, vertical links, wheel bearings, GT6 brake backplates, rotoflex couplings, Goodridge hoses and much more. - All new bolts/nuts/washers etc. At that time, it had no propshaft , which would of course need to be a custom design. More of that at a later date. When we got to the start of 1990 a lot of life changes took place. My career as an Electronics/Software Engineer at British Aerospace (Bracknell) came to an end due to site closure and I was not prepared to relocate to Plymouth. I also had to finish off all manner of other projects and get myself a new job. So the poor Spitfire came to a stall and I had to prioritise finding a new job, along with geographical move - and other matters. More of that to come on the next post...

Thanks,

Chris

|

| |

Last Edit: Mar 21, 2021 20:24:29 GMT by krissto: Typos

|

|

hagus

Part of things

Posts: 35

|

|

Mar 21, 2021 22:25:34 GMT

|

|

Still really enjoying this!

|

| |

|

|

|

|

|

Mar 22, 2021 15:03:01 GMT

|

|

Great story, excited to see how it comes out!!

|

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,975

Club RR Member Number: 71

|

|

Mar 22, 2021 16:40:44 GMT

|

|

I do like a good "historical explanation" thread to bring us up to date - especially when a car has a lot of history - please carry on - enjoying it

|

| |

|

|

|

|

|

Mar 22, 2021 18:53:32 GMT

|

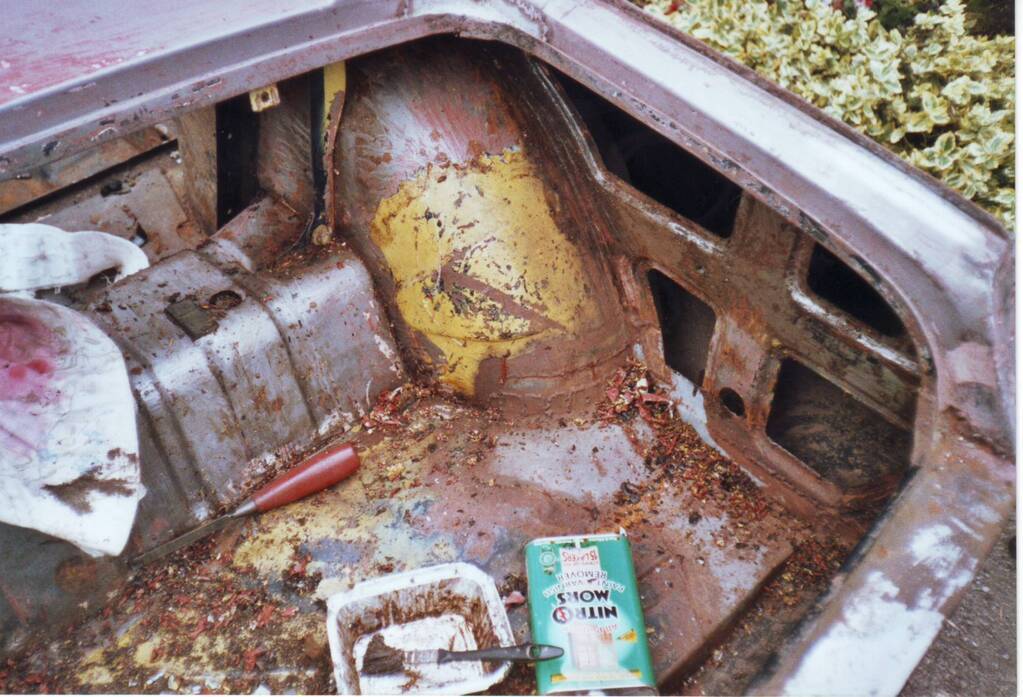

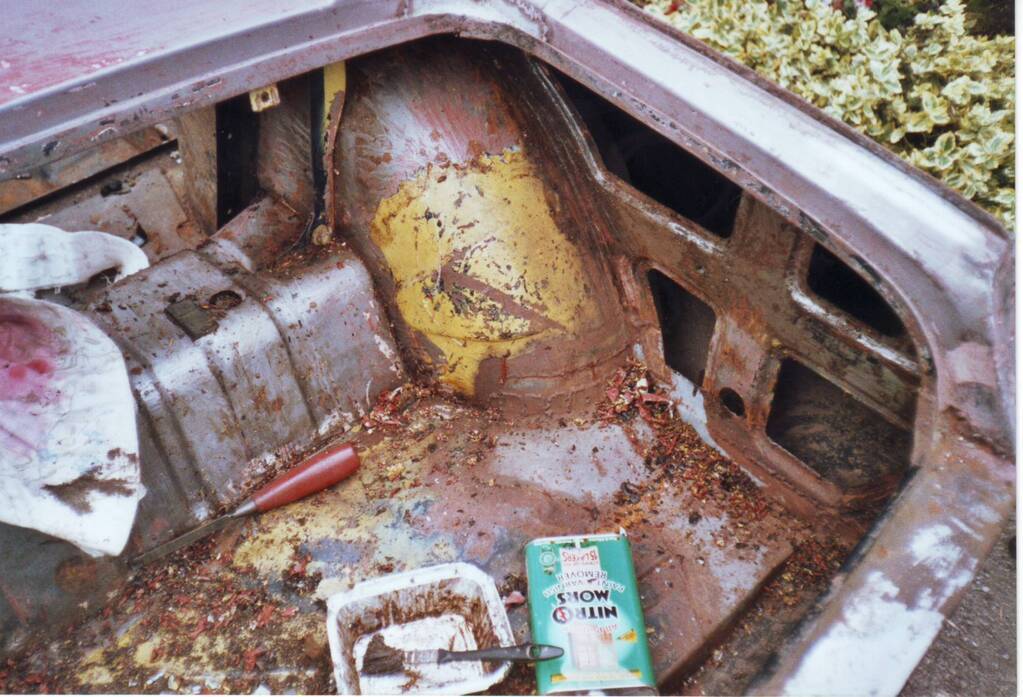

I'll not linger on too much history but between 1990 and 2004, the car got virtually no updates and was moved back and forth between Berkshire and Gloucestershire due to job changes, family commitments and more. Not to mention the rebuilds of a 2L Lancia Beta Coupe, Ginetta G15, modified 930cc Imp Sport, Clan Crusader (abandoned), Mitsubishi Colt, Mk1 Fiesta, LHD BMW 318i E30 and so on. House restoration and career spells at Smiths Industries and Tag-McLaren also took up most of my spare time. I think that in those 14 years, I made an upper bracket for the alternator (now superseded), a pair of downpipes for the OE 4AGE cast iron manifold and a few odds 'n' ends. Hardly progress. But in all that time it was always stored in a dry garage. Finally, I had some time to resume the Spitfire, so in spring 2004 I wheeled it out of the (tiny) garage, looking very sorry for itself...

Although it looked bad, the rust was only on the surface, so after many days (and lots of paint stripper, 3M scotch-brite wheels) I got rid of as much as possible and applied Kurust as I went...

Many weeks later...

After finishing all that lot, I took the tub off the chassis and did the same for the underside...

Then it got sealant applied to all weld joins and I hand painted the entire underside...

...in YELLOW!!!!

That was followed by my own attempts at painting the tub exterior, doors etc using cellulose and an electric (Wagner) spray gun. More of that in the next update.

Thanks,

Chris

|

| |

Last Edit: Mar 22, 2021 18:57:28 GMT by krissto: Typos

|

|

|

|

|

Mar 22, 2021 18:56:23 GMT

|

|

Please tell us that your dads arc welded sills remain. That's part of its heritage. Also I hope the chromed wellers stay as a feature

|

| |

|

|

|

|

|

|

|

Mar 22, 2021 19:05:24 GMT

|

|

Sorry to say that the only remaining arc weld is on a patch in the N/S boot floor. I still have the Weller type chrome wheels but they are very rusty and cannot be used on the car due to the size of the brakes. Now I have given away a teaser there...

|

| |

|

|

|

|

|

Mar 22, 2021 19:19:20 GMT

|

|

Ooh, the plot thickens.....at least part of your fathers welds remain. It's like a signature when you weld a car for future generations to appreciate

|

| |

|

|

|

|

|

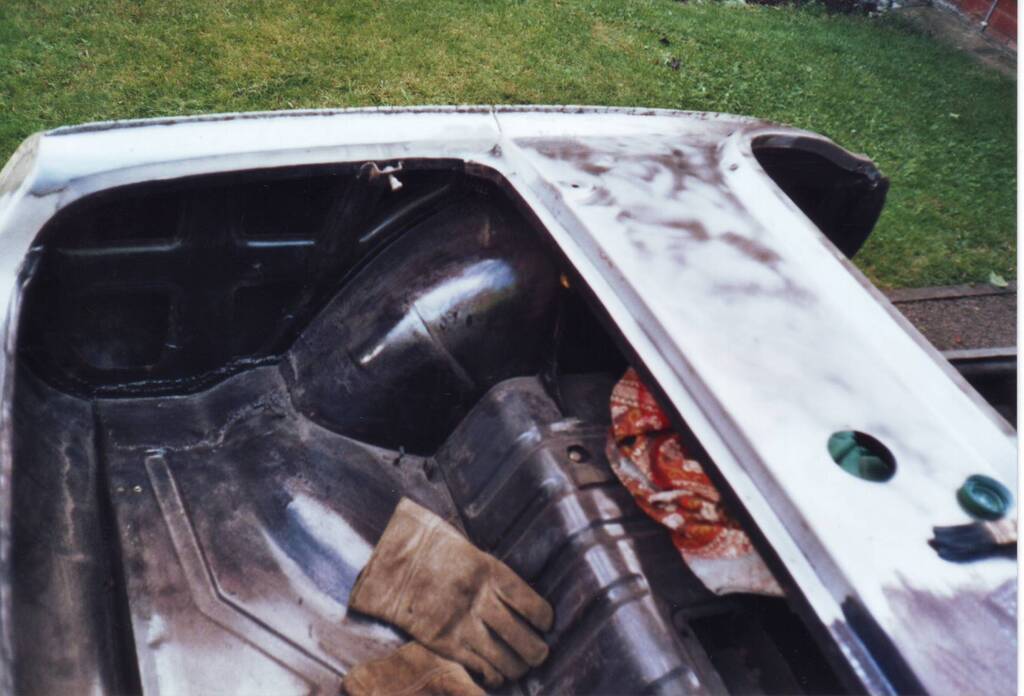

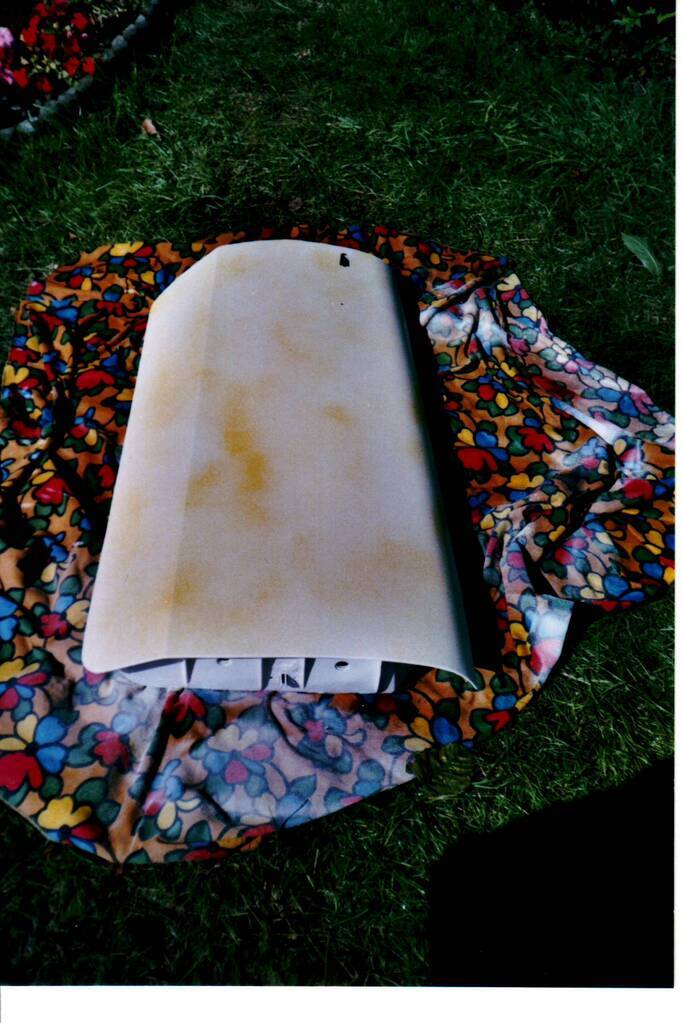

Mar 22, 2021 20:03:53 GMT

|

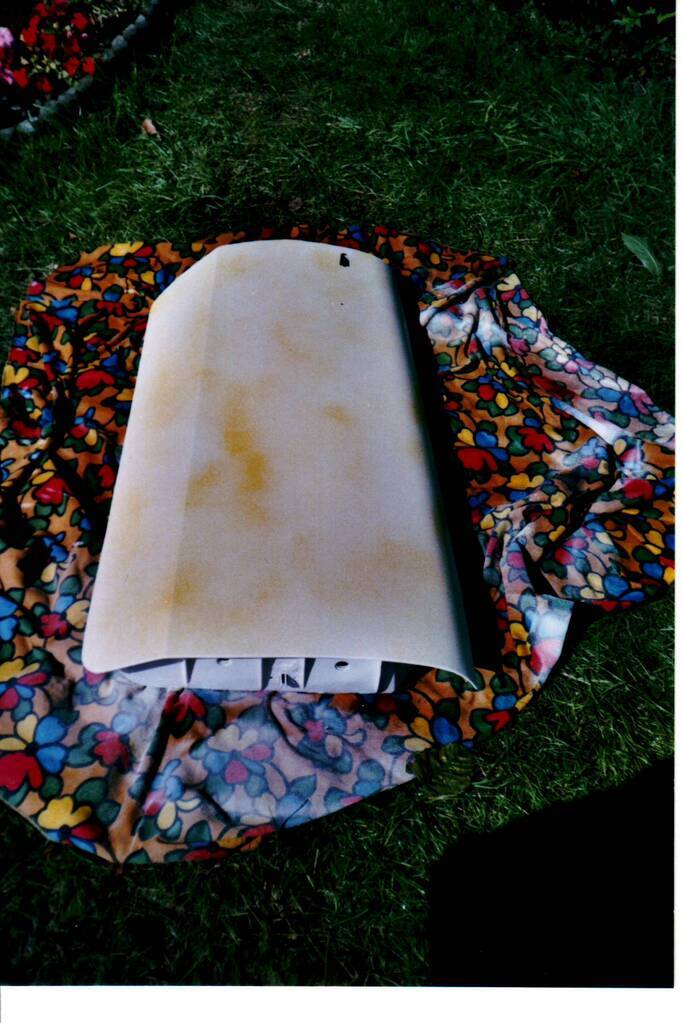

Whoops. Completely missed out the factory hardtop. This had grot in all the usual places i.e. the front underside where it meets the windscreen capping and the areas where it meets the rear wing tops. Duly welded up with lots of complex patches as there never have been and never will be proper repair sections to purchase. So, again in 2004 I repaired as best as I could and applied Kurust for long term protection while in storage...    Not my best welding by a long way, but it was all solid and will be hidden from view. The bitumen sound pads have since been replaced. Chris |

| |

|

|

|

|

|

Mar 22, 2021 20:40:13 GMT

|

|

Hello Stranger

Thought I recognized that rusty old spitfire. LOL

Have you still got my old imp??

Rod

|

| |

|

|

|

|

|

Mar 22, 2021 21:11:22 GMT

|

Phwaaahhhh... I never expected that! I'll PM you so as not to clutter this thread. Good to see you are still a car enthusiast, Rod....  |

| |

|

|

|

|

|

Mar 23, 2021 19:39:38 GMT

|

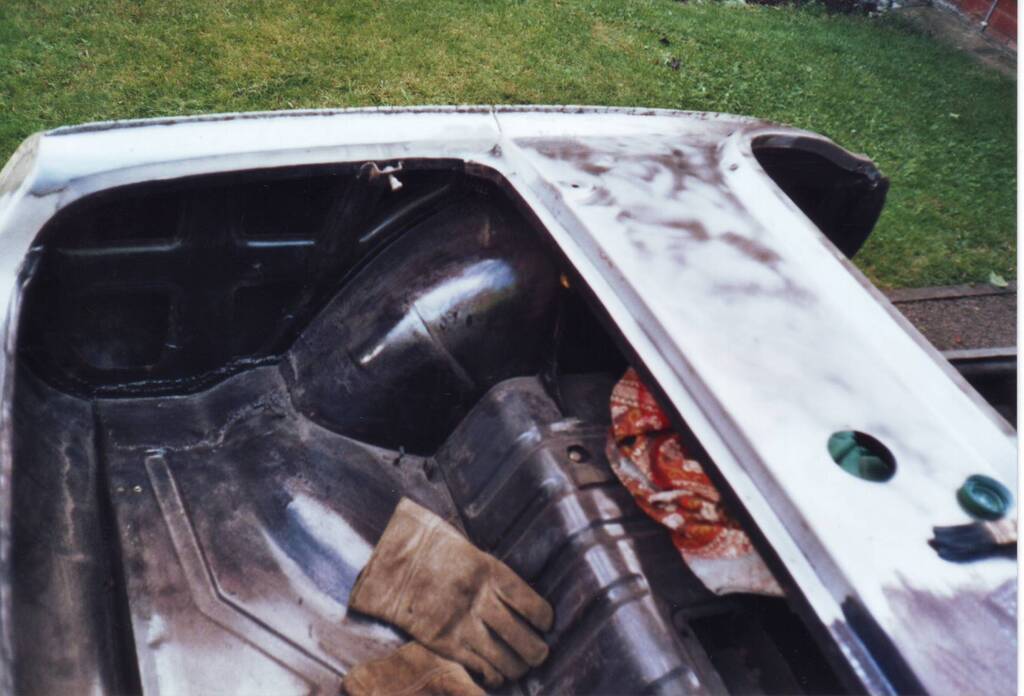

With the tub finished on the underside, time to paint the exterior panels. This was not intended to be a permanent solution, rather to give it some decent protection, as I knew that there was still so much development left to do on the car. All done outside and with a Wagner electric gun, so was never going to be very good! To be painted professionally at a later time... Etch primer:   Followed by grey cellulose primer:   Followed by white cellulose and a mist coating of yellow:   Windscreen frame:  Naff GRP bootlid (no longer used):  Doors:   By this time, the bonnet was declared beyond repair and was scrapped. The intention was for a lightweight GRP item to replace it. A couple of points to note on the bodytub: - The handbrake area was cut out and moved backwards by about 3 inches, in order to give room for the Toyota T50 transmission and new gear lever position. - There is a rebate in the top bulkhead panel to allow for the thermo sensors at the rear of the 4AGE cylinder head. That just about covers the bodywork progress in 2004. There followed yet another hiatus when my attentions were diverted to the full rebuild of my neighbours classic Mini convertible. That can wait for another thread. Next post will get more interesting with the engineering aspects. TTFN, Chris |

| |

Last Edit: Mar 23, 2021 19:43:11 GMT by krissto

|

|

|

|

|

Mar 30, 2021 20:12:46 GMT

|

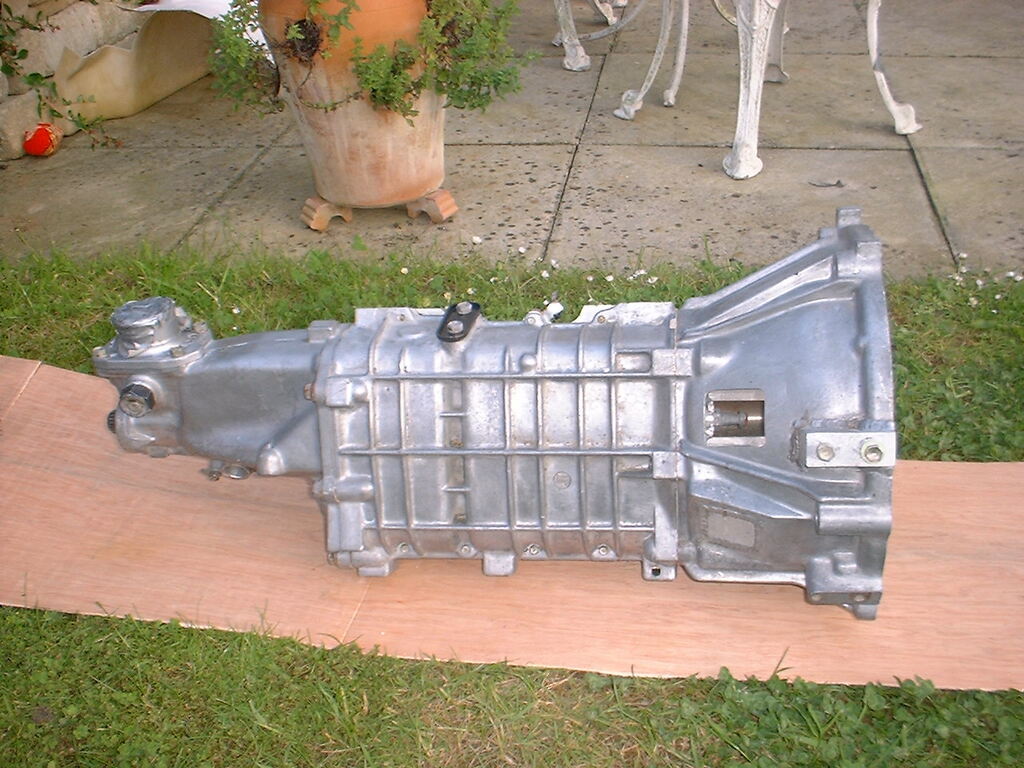

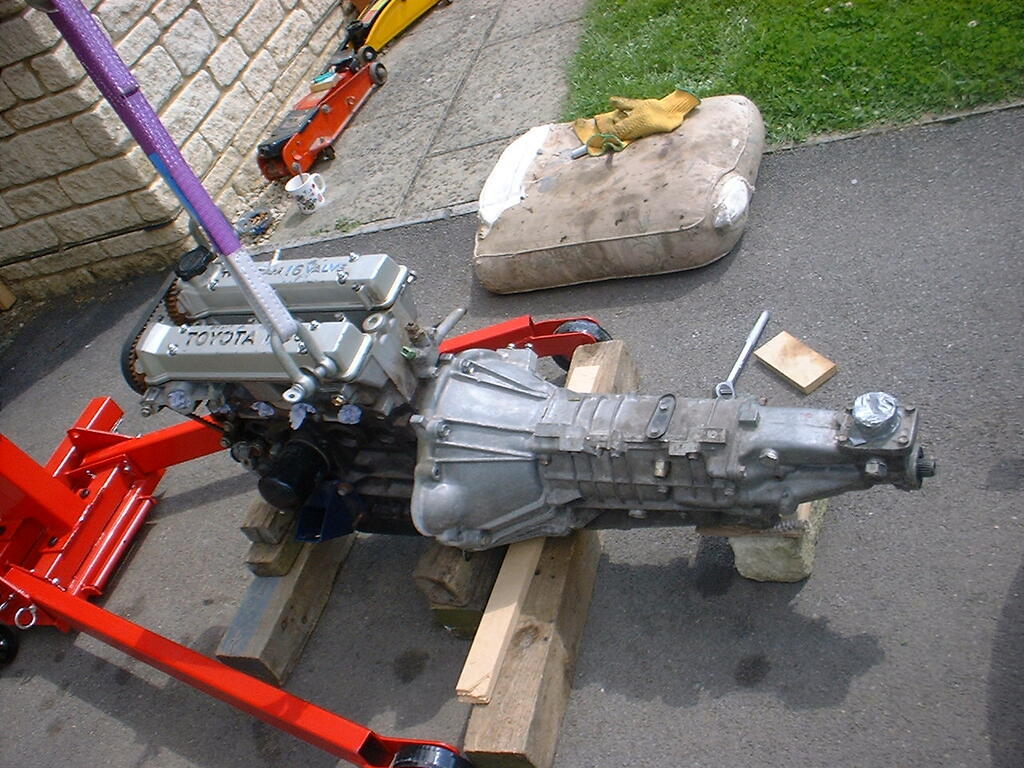

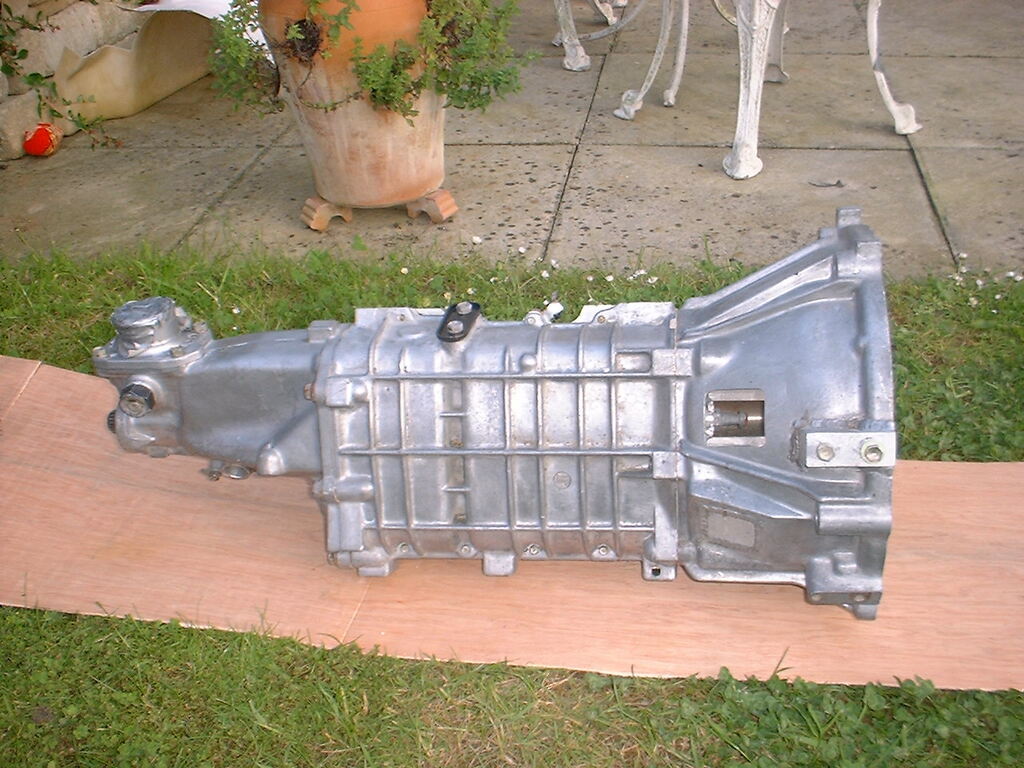

A minor update for tonight - and not particularly interesting from an engineering point of view (as was promised). It is now 2006 and a move back to Gloucestershire sees the Spitfire in its new home. The world's smallest integral garage. The comment from the removals company was something like "You'll not make any progress on the car in that garage..." - but I proved otherwise. Here is the poor car covered and surrounded in/with boxes when first arrived....  After a long while to settle into my new role as a consultant engineer and sorting out other car projects and so on, we see the Spitfire gain some progress a full two years (!) down the line... Engine and transmiision - time to be removed for some work:  Out with it:   T50 transmission separated from engine, showing clutch lever repositioning to higher up the gearbox. This has been superseded with a co-axial HRB, but I'll stick to the history:  Parting shot of the 4AGE-less Spitfire. Yes, yes, I have missed out loads of photos for the repainted suspension, brakes, rack etc., but that's all since been updated.  That will suffice for tonight.... Chris |

| |

|

|

|

|

|

Mar 31, 2021 19:25:05 GMT

|

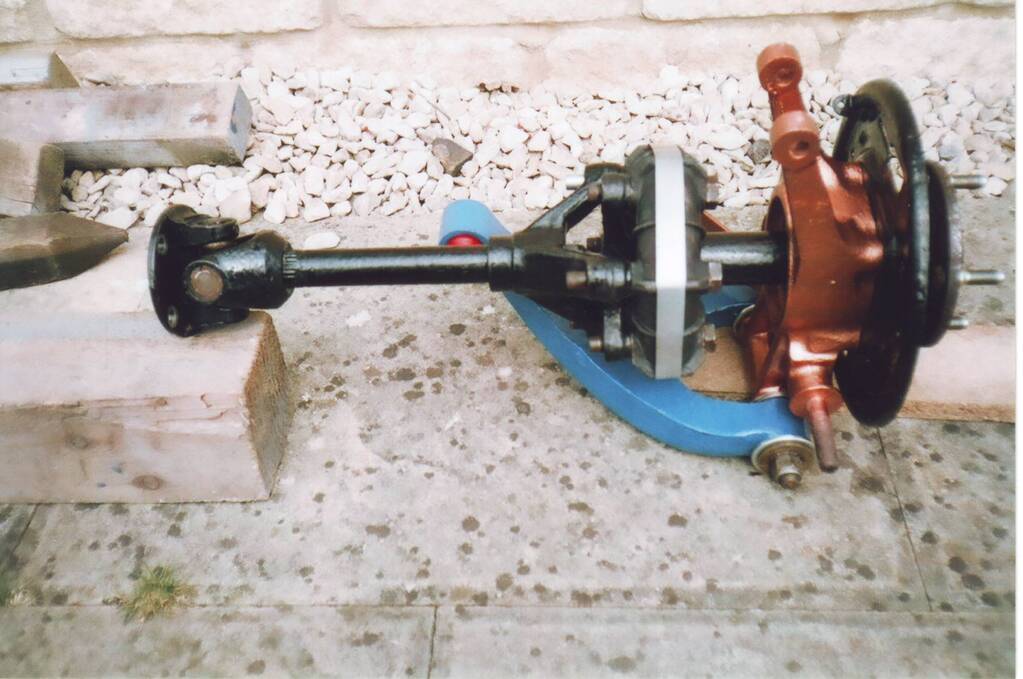

As per previous upload, I did strip all of the suspension of its late 80's paint, as it was getting chipped and was not really up to the job, being brush painted. I spent a lot of time prepping and spraying using rattle cans. Something I really should not have bothered with. I should have known better that the paint is simply too thin/soft/brittle. But it all looked good for a while (2008)...    Note yet another set of new GT6 front discs and wheel bearings etc., at this stage. Also, the eagle eyed may notice the cut out in the N/S suspension turret, just inside the two OE engine mount bolt holes. That was for the 4AGE alternator lower bracket (from a Carina E, remember?) to pass through. Now superseded (alternator is now mounted lower down) and welded back up with a substantial plate. I subsequently moved on and overhauled the rear suspension. Comprising diff repaint (in brushed blue!), vertical links in rattle-can copper, yet more rotoflex couplings, wheel bearings, trunnion bushes and a Spitfire Mk3 negative camber rear spring from Moss (nee TriumphTune). That spring at least gave me something approaching a sensible rear ride height, but....you guessed it... is no longer fitted to the car!  Spring lifting tool an absolute must when assembling GT6 rotoflex rear end....  In the above, you can see the Goodridge 'hard-line' pipes for the fuel injection supply and return. Whilst the car still has the same layout, the pipes have been replaced with more suitable bore sizes and are by Krontec. More of that in later posts. By this time, I had become more knowledgeable with JIC/AN hoses and plumbing and owe a great deal to Fay Fischer at Speedflow. Her advice put me on the right track for designing and building my fuel/oil/brake/clutch/cooling systems. More updates tomorrow when we get onto propshaft and drivetrain details. Thanks, Chris |

| |

Last Edit: Mar 31, 2021 19:32:57 GMT by krissto: More fox picture typos!

|

|

|

|

|

|

|

Here are a couple of parting shots of the rolling chassis from 2008...   In the above, the plate for the T50 rear gearbox mount can be seen, along with an extra bracket behind it to prevent the prop-shaft creating a 'pogo stick' - should the worse happen with front U/J failure. On the subject of the prop-shaft, it is obvious that a custom item would need to be developed. So I tack-welded together the AE86 splined front section to a Spitfire rear section in order to establish the nominal correct length. I then sent this over to Bailey-Morris for manufacture such that the O/D followed the Spitfire dimensions, but with competition rated U/Js at each end. Apologies, but I have no photos or sketches of this detail. Anyhow, with that all sorted, time to move on to 2009 and lots of work with the engine etc. To be continued.... Thanks, Chris |

| |

Last Edit: Apr 1, 2021 20:57:55 GMT by krissto: Missing info

|

|

|

|

|

Apr 11, 2021 20:26:44 GMT

|

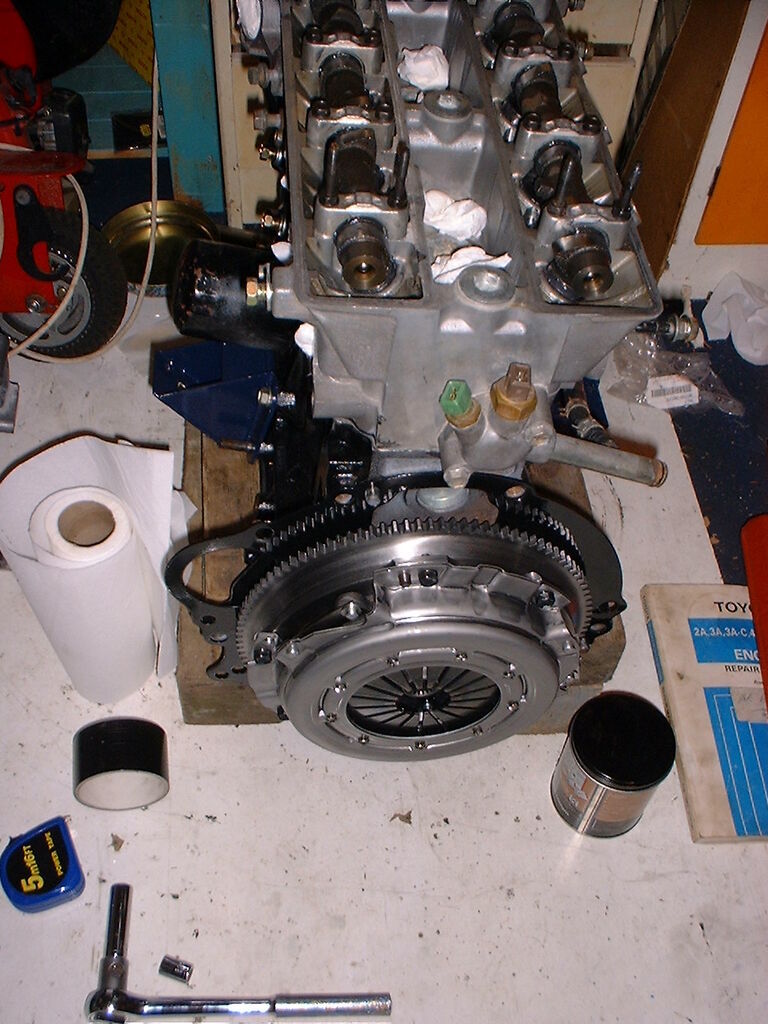

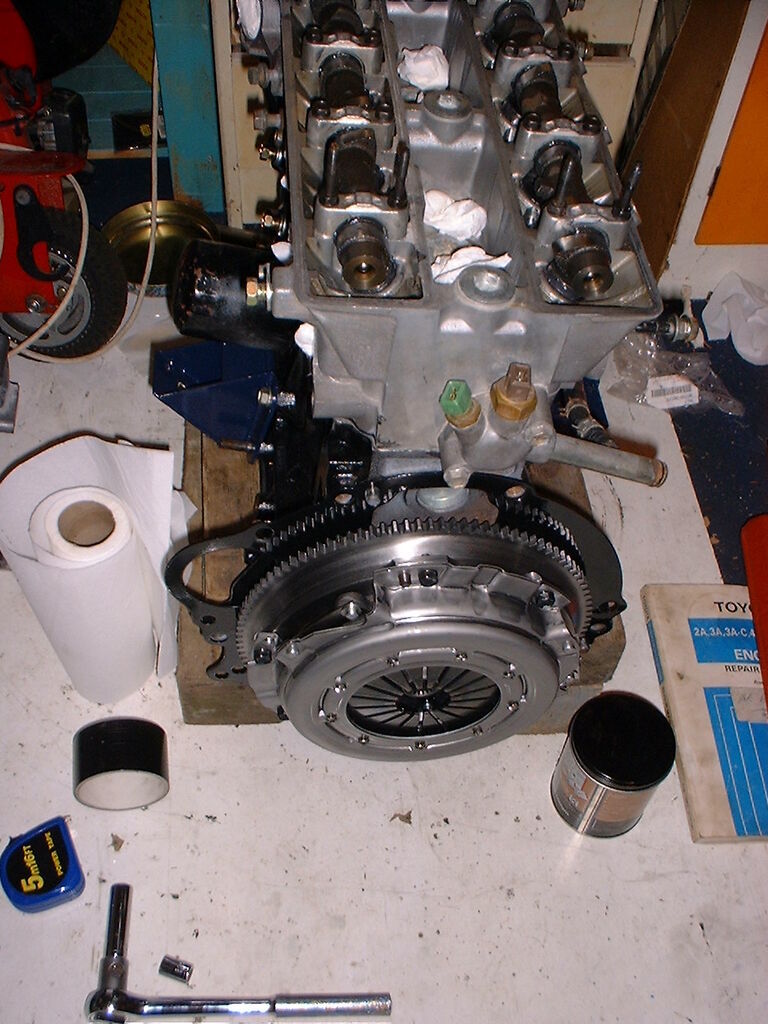

It has been a few days since my last post due to better weather and getting outside to do stuff. So here are a couple of shots of the tub in Summer 2008 and you can see the bulkhead 'notch' to clear the 4AGE rear cyl head sensors. Behind it are my first attempts at re-sculpturing a GRP gearbox tunnel, modified to accommodate the T50 gearbox but also to become a strong structure to reduce scuttle shake...   So then onto the engine. I removed all the ancillaries, cyl head etc., and painted the block in gloss engine paint. Comprehensively de-coked the head and pistons, checked the big ends and mains - no issues. Bought and fitted a TTV 4AGE lightweight steel flywheel suitable for the AE86 200mm clutch, with new ARP bolts:  New clutch assembly on TTV flywheel:  TRD competition engine mount rubbers:  Engine ready for cam covers etc...  Next update will comprise re-install of the engine. Thanks, Chris. |

| |

|

|

|

|