jamesd1972

Club Retro Rides Member

Posts: 2,921  Club RR Member Number: 40

Club RR Member Number: 40

|

1987 Fiat X1/9 Turbojamesd1972

@jamesd1972

Club Retro Rides Member 40

|

Apr 21, 2021 12:03:35 GMT

|

|

Nice write ups of the trials and tribulations !

Some musings on stuff. On heat and fans etc. Not sure if moving the fan switch location will do much more than the simpler option of putting in a lower temp cut in fan switch? The hot water will get to the switch shortly with the engine running anyway? Did this on my old Skoda and it did help but the bottom line with a front / rear set up is that the system can lag like you find, if it doesn't boil then its OK really, stop watching the dial !

Not sure what antifreeze you are running but I was told to be slightly wary about antifreeze % / condition my understanding is that pure antifreeze boils at a hotter temp but has less specific heat capacity to move the heat from engine to radiator so running at the correct % can help a little bit.

Oh and your experience is why the LR chassis hasn't been waxoiled - its at a point that you know its going to need an odd repair and better to do that without any fires and weld contamination !

James

|

| |

Last Edit: Apr 21, 2021 12:04:13 GMT by jamesd1972

|

|

|

|

|

|

|

|

|

We have an afterrun pump on our S4, makes a noticeable difference to temps but we do also have 3 cooling fans as stock, 1 mechanical and 2 electrical. Turbo engines produce a lot of heat that needs to be dissipated. Oh interesting, so an electric pump in series with the mechanical pump? Or in parallel? Was wondering about what the best setup might be.. Yes, its an electric pump in series with the mechanical. It runs for 10 minutes once the car is switched off if the thermoswitch has been closed by the coolant temperature. The B5 has watercooled turbo's as standard so helps to prevent localised boiling. Not in the best location though as it is buried in the V of the engine under the inlet manifold, this leads to the pump going brittle. The 2.7TT in the B5 is tightly packaged and needs all the help it can get.  |

| |

|

|

|

|

|

|

|

I'll just leave this here  / |

| |

|

|

big02

Part of things

Posts: 62

|

|

|

|

I'll just leave this here  / I think it’s on for £16k - lovely car but yikes, the price. |

| |

|

|

|

|

|

Apr 24, 2021 17:11:03 GMT

|

|

Looking at others for sale, that doesnt seem too bad. Lovely looking car

|

| |

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

Apr 28, 2021 13:08:22 GMT

|

Nice write ups of the trials and tribulations ! Some musings on stuff. On heat and fans etc. Not sure if moving the fan switch location will do much more than the simpler option of putting in a lower temp cut in fan switch? The hot water will get to the switch shortly with the engine running anyway? Did this on my old Skoda and it did help but the bottom line with a front / rear set up is that the system can lag like you find, if it doesn't boil then its OK really, stop watching the dial ! Thanks man! Not finished updating them yet, but getting there now  Good idea on the lower temp fan switch. There is a fair bit of stoplight angst and gauge-watching, although its not overheated yet (since sorting all the problems anyway). The only thing that's worrying me is that I haven't heard the fans cut in either, although the new modern fans are much quieter so could be muffled by general traffic around. Perhaps what I need is just a fan override switch. It's one of the things I wanted to make sure was foolproof before taking it out on track, but perhaps just a switch I can flick on as I roll into the pits is the solution... Not sure what antifreeze you are running but I was told to be slightly wary about antifreeze % / condition my understanding is that pure antifreeze boils at a hotter temp but has less specific heat capacity to move the heat from engine to radiator so running at the correct % can help a little bit. Another good point. I've been running it with 50/50 mix as it's alloy head/iron block. Each time I've changed the coolant it's come out very orange so I think it's been run on a lot less in the past, but it's been getting a bit better after the ~10 coolant flushes I've wound up doing!  Oh and your experience is why the LR chassis hasn't been waxoiled - its at a point that you know its going to need an odd repair and better to do that without any fires and weld contamination ! James Yeah I've got thoroughly mixed opinions on it. Two of my old cars were waxoyled (presumably pretty early on in their life), and they're definitely in much better nick than any of the others. On the other hand it does make them a royal pain to repair. Ideally I think I'd get some form of dipping and electrophoretic epoxy-coating done, but need to scrape the pennies together to do that! Yes, its an electric pump in series with the mechanical. It runs for 10 minutes once the car is switched off if the thermoswitch has been closed by the coolant temperature. The B5 has watercooled turbo's as standard so helps to prevent localised boiling. Not in the best location though as it is buried in the V of the engine under the inlet manifold, this leads to the pump going brittle. The 2.7TT in the B5 is tightly packaged and needs all the help it can get.  Ah gotcha. The Fiat has a watercooled turbo as well, but it's set up as a draw-through system so the movement of boiling water in the turbo to the reservoir pulls more water through it to cool it down after shutdown. I'm sure an electric pump could be set up to help that as well! Personally I'm a great fan of watercooled turbos and I'm not sure why quite a few modern frames seem to be going for oil cooling only. There's a couple of T22 turbos that might just work for an upgrade but they're all just oil cooled. I'll just leave this here  Yeah I spotted that! My initial reaction (after audibly saying 'neat!') was 'yikes'  It's probably more that I got my one for an absolute screaming deal as they do seem to be worth quite a lot now (provided they're not rotboxes). Classics in general seem to have got more expensive over the past year or so. Not sure how much of it is driven by the dwindling supply and how much to do with them being seen as tax-free investments. The green one looks in a bit better nick rust-wise than mine, although photos can be deceptive (and these cars do tend to hide it in places). The twincam swap is a fair bit trickier than an Uno Turbo engine as well, although not massively difficult still. So it's a bit higher spec than mine (although if all you're aiming for is 130bhp then a UT swap is both lighter and simpler). -------------------------------------------------- Linkage fixing - 3rd August 2020So, I went to test the Fiat after its suspension repairs and I noticed that the gearstick was behaving strangely. It was returning to centre in different places depending on what gear it had come out of. Initially I thought the cable was slipping in the end I crimped on. Took everything apart and crimped it again in a different place, but that didn't change it at all so something else must have been happening. Eventually, after I'd taken everything apart and poked around I found out what was happening. The steel wire that reinforces the rubber outer lining of the cable was migrating inside the sheath! You can see it poking out here.  That would explain the worsening shift quality. Also, because I assume it's been trying to force a gear in when it's just outside of its gate, the linkage housing has bent as well. Not surprising seeing as I've chopped so much out of it.  So, I bent it back into shape and did a bit of reinforcing to stop any flex in the housing.   I also pinched the smaller bellcrank from a spare set of linkages I have as I'd shaved down the other one to fit properly and tried to shim it out to fit the little bronze bush. As I don't have a lathe the shims were never perfectly the right size so there was additional play that wouldn't have helped. Turns out the whole exercise was unnecessary as it works perfectly fine without the modification.  I also found that the linkage was catching on itself when getting into reverse, so I clearanced that a little.  For the cables core movement issue I figured that the standard MG cable ends must have an end-stop inside them. Initially I thought of a spacer to bolt down against the wire reinforcement, but that would involve precise measuring and cutting. Then I found you can get M16 grub screws so I can bolt those down against the cable ends, then use the actual bolt to clamp the cable end to the bracket. Like so:  Had a couple of iterations drilling through the grub screws. Initially drilled a 7mm hole so the cables could draw all the way back, but it turns out that was too wide to act on the wire reinforcements. Drilled a smaller hole through, but that meant I didn't have enough travel. So what I ended up with was drilling a big hole for 4mm depth, and then a smaller one for the remaining 2.5mm (the one on the left).  I also took the opportunity to try and drill the centre-hole through the bolts a bit straighter using a method I'd seen on youtube with two chucks on a pillar drill. Worked quite nicely, although there was still runout and it took qite a bit of fiddling to get it straight. Having a short starting drill bit would help, as would having a good drill press that you don't need to shim quite so much to get everything square.  Lastly I lengthened the lever-arm on the gearbox-side so there's a bit more side-to-side travel which should lessen the force on the cable a little. With all of that done I now have a linkage that works again properly! I will say that it's still not the best gear shift in the world (by a long way). I think access to a lathe so I can drill stuff dead straight (and do things like make up little nylon bushes for the cable ends to run along) would do wonders. As would remaking the cables and cable ends as the former have got a bit mangled with repeated removals of the swaged ends and the latter aren't welded on straight enough. Oh, and I think the issue with the clutch slave cylinder leaking (now resolved) has caused accelerated wear on the synchros as it's not quite as smooth going from gear to gear as it used to be. Unless it's just a fluid level issue as it's developed a bit of a leak... But it works! Just a cracked coolant hose to replace then the Fiat's roadworthy again  |

| |

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

|

|

So, we're pretty much up to date now. The only thing I haven't mentioned is the iffy running. When I got the car, I noticed that the idle was set quite high (and given that the idle screw came loose as I was driving it home I reckon someone was fiddling about with it before I bought it). These SOHC engines do have a relatively high idle as standard, but not 1500rpm. I'd also noticed that it breathes quite a lot, so something's not healthy with the pistons/rings/bores. A quick compression test showed this: Cylinder 1: 9 bar Cylinder 2: 8 bar Cylinder 3: 9 bar Cylinder 4: 9.8 bar Not sure what they typically are on these engines, but I'm not a fan of the difference between cylinders... To try and confirm I bought a leakdown tester, but didn't read the instructions so managed to junk the bellows (dolt). Luckily, my aircraft mechanic mate came to the rescue and lent me a set they use to test piston engined aircraft (with firm direction to read the instructions!). Put 80psi into the cylinders and got 76psi (cyl 1), 68psi (cyl 2), 66psi (cyl 3) and 78psi (cyl 4). So leakdown percentages of 95%, 89%, 83% and 98% respectively. Apparently while they wouldn't necessarily be happy with the spread between 98 and 83, the absolute figures would still be airworthy. No particularly loud hisses from the inlet or exhaust, and couldn't hear any bubbling from the coolant tank so don't think it's valves or headgasket to the water jacket. Did sound pretty hissy from the crankcase so best bet is rings. Also tried listening to the sparkplug hole in the adjacent cylinders but decided it wasn't really possible to distinguish between two sets of leaky rings and one dead headgasket. So, it'll need a bit of a rebuild at some point. Unfortunately, it's been my only working car for about a year now so it'll have to wait until the Jag's done to have its time (just as well I'm not doing many miles!). Seeing as the plan was always to squeeze a bit more power out of it, I figured I'd do a bit of research into turbo options. I've seen people run T25 framed turbos on Unos before, and at least one chap with a GT28 that made 233bhp! The only issue I have with those is that because it's a 1.3l you end up with a fair bit of surge low down and need to limit the boost until, say, 5000rpm to stop flutter. Might not be that bad of a thing, but ideally I'd like a turbo that's sized right for the application. Unfortunately, high-boost low-flow turbos seem to be quite rare for anything smaller than 1.4l! The only one I've managed to find a map for so far has been a T3 45 trim (and that's still only making full boost at 4000rpm):  It's still a bit close to surge as it's climbing at low VEs, so I think a well ported head would be an absolute must. I took a punt on a couple of R32 GTR turbos as a guess that they'd roughly match up as half of an RB26 would be 1.3l, but I think the 4-valve head must flow much better as I've later found out that the compressor wheel on those is a T3 50 trim one (which doesn't quite work, as above). The only newer framed turbo I could find that would even nearly work is the GT2259, but even then it's only marginal at higher VEs:  So T3 it is! At least they're cheap  shame you can't get a T3 wheel on a newer framed turbo (shaft diameter is 6.3mm for the T3 and 6mm for pretty much all the other Garretts). |

| |

|

|

|

|

|

|

|

|

Not sure of your timeline on these posts, but are the last two not mutually exclusive? Worn engine with possible ring issues on one hand and wanting to push it harder with a bigger turbo on the other?

Especially as it's the only form of transport. My son wants me to get the wrx mapped, bigger turbo, better flowing cat etc etc but it's my daily, so stock power is fine .....

|

| |

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

|

|

Not sure of your timeline on these posts, but are the last two not mutually exclusive? Worn engine with possible ring issues on one hand and wanting to push it harder with a bigger turbo on the other? Especially as it's the only form of transport. My son wants me to get the wrx mapped, bigger turbo, better flowing cat etc etc but it's my daily, so stock power is fine ..... Ah, that's my poor explanation I think! My thought process was that if I need to tear the engine down, it seems like a waste of effort and money to rebuild it as standard when the plan is to go for more power anyway. I might as well get the head done while it's off and everything's apart, and that leads onto the other mods. But yeah, won't be happening until I've got reliable alternative transport sorted! Hence the Jag being the main project at the moment  |

| |

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

May 11, 2021 10:10:28 GMT

|

Right! So now we're up to date here's some stuff that's been done this week! MoT's rolled around and there was a fair bit to do. First off is a rust hole near one of the front suspension tie bars. Don't have a before pic, but here's the after:  Excuse the welds. The car's been waxoyled at some point in its history. Probably why it's survived as well as it has, but it does make welding a pain in the backside (especially upwards!).  Next step was a hole in the driver's floorpan. Pulling the carpet up I found there were 2 layers of sound deadening that were well past their best. First was this:  Followed by this:  A lot of this stuff was still stuck, but did chip off quite easily and is pretty thick so I took the lot off which uncovered some more crustyness.  Choppy choppy...  First panel was quite straight forward. No nasty curves, and used the press and two big sockets to form the little dropped-down drain, copied from the other side.   The next section by the side was a tricky compound curve. The actual curving went quite well, but I made the mistake of not leaving a good inch excess around the edge of the panel to take account of the curvature moving the edges around as its formed. Had to cut a bit off and reposition it to get the hole closed.   Painted on both sides. Alloy wheel paint on the underside as that's what I had at the time (and I'm doing a bit of a tester of the longevity of different rattle-cans), and a brief dusting of etch primer followed by proper 2k epoxy primer for the floor pan (again, a tester to see how well it works...I'm thinking jsut a light coat of etch might help the epoxy stick if the surface is less than ideal).   plop finish, but I prioritised getting good coverage over finish as it's going under dynamat anyway...  And everything back together  the dynamat even saved 1.2kg over the old sound deadening so I might do it on the other side too!  |

| |

Last Edit: May 11, 2021 22:34:48 GMT by biturbo228

|

|

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

May 12, 2021 14:16:32 GMT

|

Next up was to try and sort the sump plug so I can change the oil properly. After I fitted the X1/9 sump I wanted a magnetic sump plug, which was simple enough, but unfortunately it's a taper-fit thread. I'm sure it would have worked fine on a steel sump plug, but it truly mashed the threads on my alloy one. It mostly sealed with only little drips, but I didn't fancy its chances the second time around. First job was to buy a rather pricey helicoil kit, and then drill out the old threads:  To try and have a chance of getting the hole straight I got a drill bushing (which didn't fit quite as closely as I'd hoped, but hey ho). Unfortunately the wishbone mount was right in the wrong place to get a drill in there, so I cut some flats onto the drill shank and very carefully used a ratchet.  Then carefully tapped it out, very carefully threaded the helicoil in (was tricky getting it started!) and cut it to size.    It seems to seal about as well as the previous one did (that is to say not perfectly, although I'm not sure how much is oil forced out of the dipstick tube getting blown by the bottom of the sump), but at least I can remove and refit the plug without worrying about stripping the threads  |

| |

|

|

|

|

|

May 12, 2021 16:22:26 GMT

|

|

gt1752 off a saab turbo ?

|

| |

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

|

|

gt1752 off a saab turbo ? You know...depending on which estimated compressor map is accurate or not (doing some research there was a hotly contested debate on Honda D-Series forums in 2008 about what the map looked like!), that might be bang on what I'm after... Just 'smaller than a T3 50 trim' is about what I'm looking for, if anything else. It even looks like it's water cooled! Thanks man  |

| |

|

|

|

|

|

May 13, 2021 10:00:37 GMT

|

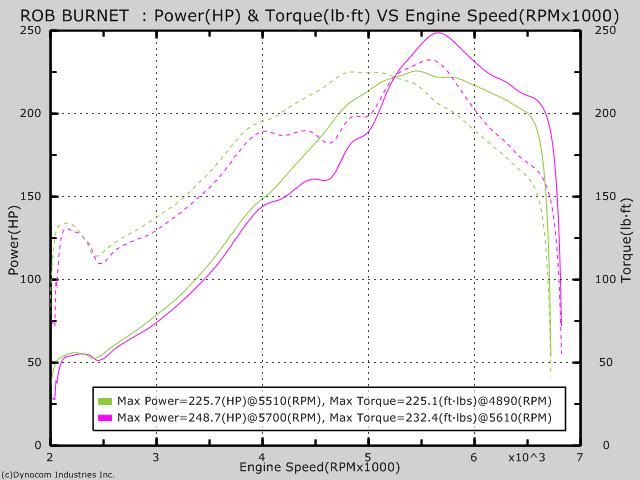

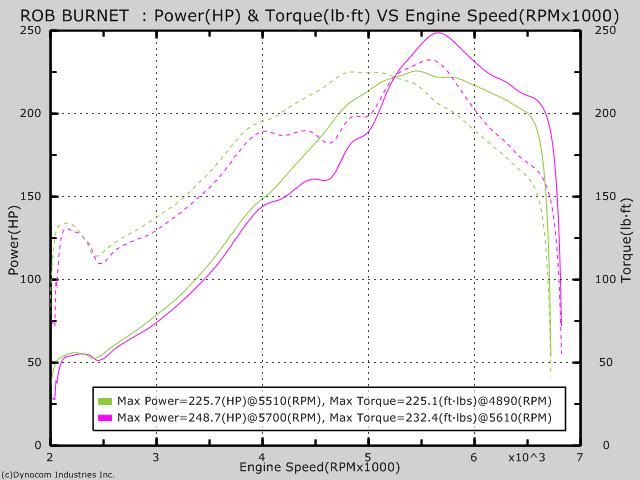

here is the original gt17 thread .. www.turbominis.co.uk/forums/index.php?p=vt&tid=10263on my Austin mini 1310 5 port head i got this on the dyno,  21 psi spike then tapering to 18 psi. i think that dyno over read a little but not a huge amount . i had 190 odd bhp on 16 psi at NMS whose dyne agreed with mine , and i thinn is pretty spot on . the 620 kg car has run , on old falkens and a none lsd dif , 112 mph in the quarter and a 13.1 s . on 19 psi.(wheelspinning to 3rd , and also on the 3rd to 4th shirt ) they work very well , the map is not out there , but i settled for a gt2056 map with a few percent off the airflow to account for the area change of the smaller wheel inducer . regards robert |

| |

Last Edit: May 13, 2021 10:01:20 GMT by ivanhoew

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

May 14, 2021 10:49:22 GMT

|

|

Interesting thread! Did I read right that it's a T2/T25 flange? If so then it's easier for me to get a tubular manifold in there. I've found a more affordable T3 cast manifold, but the tubular one would save a bit of weight.

21psi should get me handily around the 200bhp mark, depending on efficiency.

Did you need to have a boost solenoid to delay full boost down low at all, or was it sized nicely enough that you could just let it run on the wastegate?

|

| |

|

|

|

|

|

May 14, 2021 12:40:22 GMT

|

yes t25 , 21 psi would have got you a fair bit more than that i would imagine  on my car i had a simple bleed valve on the wastegate line , triggered by a switch on the dash . i used a saab 5 psi wastegate cannister , then bled to 19 psi when i flicked the switch . i came off the line t 5 psi , then flicked to high boost on the 1st to 2nd gear gearchange ,this was really too much , i should have run a much faster time if i had run 3 levels , say 10 psi in 2nd then max boost in 3rd and 4th . this turbo is normally fitted to a 2 litre , so no worries about low end surging. |

| |

Last Edit: May 14, 2021 12:42:15 GMT by ivanhoew

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

May 14, 2021 13:05:45 GMT

|

yes t25 , 21 psi would have got you a fair bit more than that i would imagine  on my car i had a simple bleed valve on the wastegate line , triggered by a switch on the dash . i used a saab 5 psi wastegate cannister , then bled to 19 psi when i flicked the switch . i came off the line t 5 psi , then flicked to high boost on the 1st to 2nd gear gearchange ,this was really too much , i should have run a much faster time if i had run 3 levels , say 10 psi in 2nd then max boost in 3rd and 4th . this turbo is normally fitted to a 2 litre , so no worries about low end surging. Ah interesting. So it was fine with no fluttering pulling through the higher gears on boost? Did you ever run it on the street at all, say planting it from low down in 4th say? The issue I've found with turbo sizing is that for most of the ones that will flow what the engine needs at a relatively high boost level, when the turbo comes on full boost at, say, 3500rpm the low amount of flow puts it off the left hand side of the map (which from what I uderstand is where you get flutter). Looks like if you were running low boost until you got up to the right rpm, you might have been able to avoid that with your switch setup (but for ease of street use I'd need to run a boost solenoid so that if I planted it from low rpm in 4th, it would pull cleanly through the rpm without surging). Bet if flew with that much power in a mini! |

| |

|

|

|

|

|

May 14, 2021 13:20:21 GMT

|

|

i always used it on the street , it looks pretty stock , and often planted it at 1000 rpm in 4th , boost would start at 1400 , and 5 psi by... 2200 i think it was , no surging , generally , if you have not built a hybrid , with a larger compressor on a smaller turbine , surging is rare in my experience . i have a t25 on a 500cc bike , that went from 52 bhp to 135bhp , on 15 psi boost , and that does not surge at all .

i rally would not worry about it at all , i can put the mini in 4th , on a 3.1:1 diff , and pootle along , in fact it makes over 100 lbs ft at only 2800 rpm.

|

| |

|

|

lebowski

Part of things

Hillman Avenger, Clan Clover

Hillman Avenger, Clan Clover

Posts: 488

|

|

May 14, 2021 14:15:07 GMT

|

|

I think Ivanhoew is right, in that you most likely won't run into surging problems on a standard reasonably sized turbo. If there isn't much flow, the turbine won't have much flow either, and therefore probably won't spin the compressor enough to take you into the surge region.

BTW, that Mini must've had a good cylinder head to make 250bhp at just 5700rpm from 1300cc!

Regards the boost solenoid, you can run a low rated wastegate actuator to set your base boost level at say 5psi. You can then bleed off to whatever level you require, but you'll need some kind of controller. Mine is done this way but its mapped in the Megasquirt, from a base of 7psi upto 15psi. I'm not sure if standalone boost controllers can do this. The good thing about this solution is that you can map the boost against throttle angle, so you can have low (base) boost levels when you're driving gently.

In any case, I'd be surprised if a 45 trim T3 had surging problems on your engine.

|

| |

|

|

biturbo228

Posted a lot

Posts: 1,868

Member is Online

|

|

|

|

Thanks guys! Looks promising  What I was aiming for was to try and find a turbo that doesn't need a boost solenoid (partially to control cost, but also complexity). It's not really a major issue if I do have to have one, but the thinking was that surely they must be a turbo out there that would do the job  looks like the GT17 might be it! Or a T3 45 trim, so it's nice to have two options. Oh, and just to continue with the update for a moment, there were two last rusty sections to exorcise before it would pass an MoT. Neither are structural, but they are within 12" of the front suspension tie rod mount.  This side had been 'repaired' before with just a patch stuck over the rust hole to hide it, so of course it had just disintegrated behind it.  It was hard to get a good picture of the metal removed, but this is the underside and it spread about 12" up the inner wing.  Bit of CAD templating, some head scratching, tentative metal bending, and careful trimming later I had the replacement patch sorted.   Carefully welded it in one spot at a time and ground the welds flat, managing not to set too much cavity wax alight! Painted it with a light dusting of etch primer to help it key, and then proper epoxy primer before underseal.   Rinse and repeat on the other side and that's one of the major crusty spots done on the car   Feels good to have it done as I was otherwise putting off much rust work until the whole thing gets stripped down for a full resto at some point in the future. This car's an interesting mix of 'perfectly fine because of the cavity wax' and 'very rotten where cavity wax hasn't got to'. It's also interesting to think about the rust prone-ness of X1/9s having poked around one for a bit. You can tell they were really thinking about rust resistance when the car was designed as there's drain holes everywhere on the car, and cleverly designed to prevent water ingress through the drain hole itself. I think they're mainly let down by the same sort of multi-layered construction you get a lot in French cars. Where on, say, British cars you'd get increased thickness of a box section where strength is needed, on French cars (and X1/9s apparently) you tend to get multiple pressings of a single thickness of steel spot-welded together to give strength. I wonder if it's a reflection of the capabilities (or perhaps just working practices) of each country's steel pressing industries. Both of them rust, and often quite nastily, but it's interesting to think about. I'd quite like to have a poke around a couple of retro German cars to see how they tend to be put together, and American and Swedish while I'm at it! |

| |

|

|

|

|

21 psi spike then tapering to 18 psi.

21 psi spike then tapering to 18 psi.