At the beginning of 2019 i purchased this 1992 Nissan Pulsar GTiR!!!

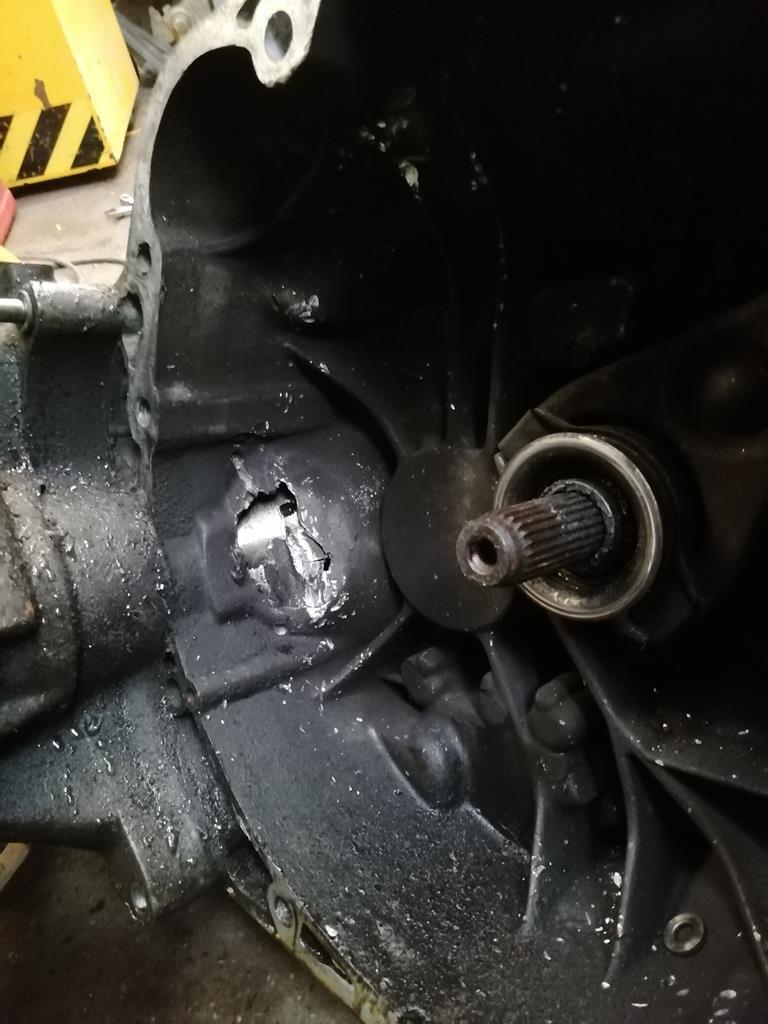

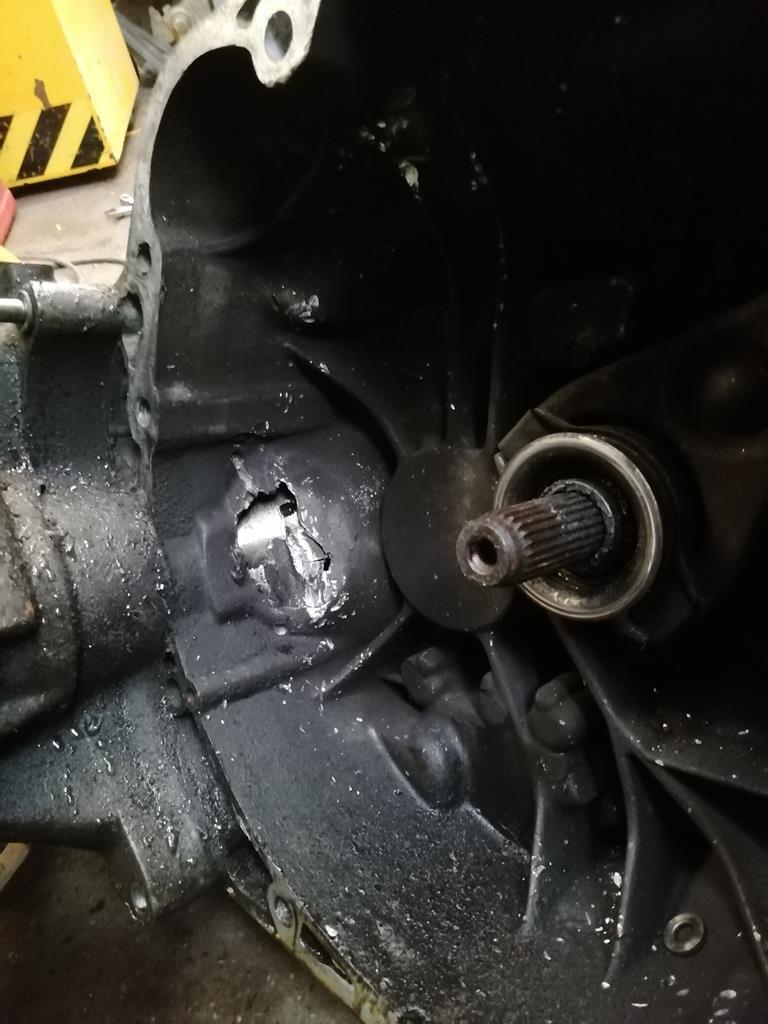

I purchased it off a friends dad who when he got it (10 years ago) it had rod knock, he replaced all the necessary parts when he rebuilt the engine and going through a few heat cycles on the engine it suffered the same fate (weird). It sat there for many years to come of which i found myself having a deep fondness for it, eventually he came round to asking me to rebuild the engine again so i stripped the engine down and gave him a parts list. 2 years later he asked me to rebuild it. I left the parts neatly laid out on a couple workbenches and when i came back to it they had curse word all over them and had been moved here, moved there and ultimately lost, it took a while to find all the parts to put it back together and once completed i put it through a couple heat cycles there was a rather loud snap and the engine stopped dead... then gearbox fluid started pee'ing out the bell housing.... turns out that whilst the clutch was laying on the bench something got caught inside it that i didnt see upon installing it (i suspect a nut or small bolt) and that got flung between the clutch and gearbox casing making a nice little window for the diff to say hello to all who wondered past, i did tell him to buy a new clutch but he said no so 50/50 on who's fault that was, i was hoping it would be a 6 month quick fix but with working away so much last year (way Way WAY too much) and being pre-occupied fixing everyone else's sh*t, 18 months later and I'm getting there (slowly)

This is where he pushed the f**k it button and offered it to me so i snapped it up, got it transported to my place and got set out on planning the build.

I knew when i got it that it needed a bit of attention to both rear arches, there was a small hole onside and bubbling on the other, both where the bumper meets the arch, arches are rarer than poor quality wobbly children's play pony poo so i settled with a set from a 4 door sunny and would "make them fit" as everyone else does. What i wasn't expecting was just how bad it was, it went from this

To this

I believe Drake would say "0-100 real quick"

So it wasn't going to be a case of making pieces of something that doesn't fit but making a whole thing that doesn't fit fit. Now I'm no master body beater or welder but i gave it a ruddy good go. This is where i found out it had a tap on that corner and a very botched repair, just look at all that filler , and rust

, and rust

I had a plan, strip it out, chuck a roll cage inside it, forge the engine and end up with many hundreds of BHP, so i stripped it out and found an awful and some what alarming amount of rust on the inside of which i cut out and slavered bird curse word all over attempting to put in new steel in the rear passenger foot wells and rear wheel well

After making a hash out of fixing it all i came across a previous fix from another owner, this then gave me a good idea of what i was yet to find, hackery and bodge jobs, don't worry, its only right bloody next to a seat belt mount, and i could see the tarmac from the inside. once this was covered i t was apparent i may have to cut out the plate they stuck on the inside of the arch and start again but would asses once i got there.

Once all the welding (birdshit) was done on the inside i set about wire brushing anything that looked vaguely suspect to inquire and address it, after all that was done it got 2 heavy coats of primer, 2 heavy coats of black and the 2 coats of bed liner. Also did the same on the underside.

Now i turned my attention to the drivers side rear arch as that only needed a small area taking care of in the corner

Again, how wrong i was, the bit thats covered by the bumper with vents in it was utter toast, so i patched the rear arch and set about trying to fix what was lay infront of me with again, the wrong panel for the job ( just remember my previous comment, poor quality wobbly children's play pony poo)

As i was looking into the previous bodge up i notice another complete lash up in the front section of the arch, what i found was beyond shocking, if you look they welded some of it in and then just finished the rest of with a mastic, words couldn't describe how angry i was but i was also overcome with joy from laughing at it.

I had no option but to cut it all out and start again, just look at what they thought was a repair, it is utterly shameful

So, i had a task on my hands, stupidly i thrown out the rest of the repair panel which had the sill section on it so with nothing but flat sheet i "attempted" to repair and replace what i had cut out, it could of gone better but i was happy enough with it, after all, this is what body filler was made for right? i had to rebuild the inner sill, the closing plate for that, the outer sill and the closing plate for that.

Next up was the front of the sill panel and the lower section of the wing, both rusty and holed

Now onto another complete lash up by a previous owner, for some reason unknown to man they decided it would be a good idea to route the inter cooler charge pipe through the lower radiator support and from what i could tell they did it with an axe

A couple hours later and it looked a lot neater and ALMOST like no one had been there (from a distance)

Where they had attacked the other side and cut out steel they had managed to cut one on the headlight support mounts off so the passenger headlight flopped about like a fish out of water, i wasted no time in repairing that too.

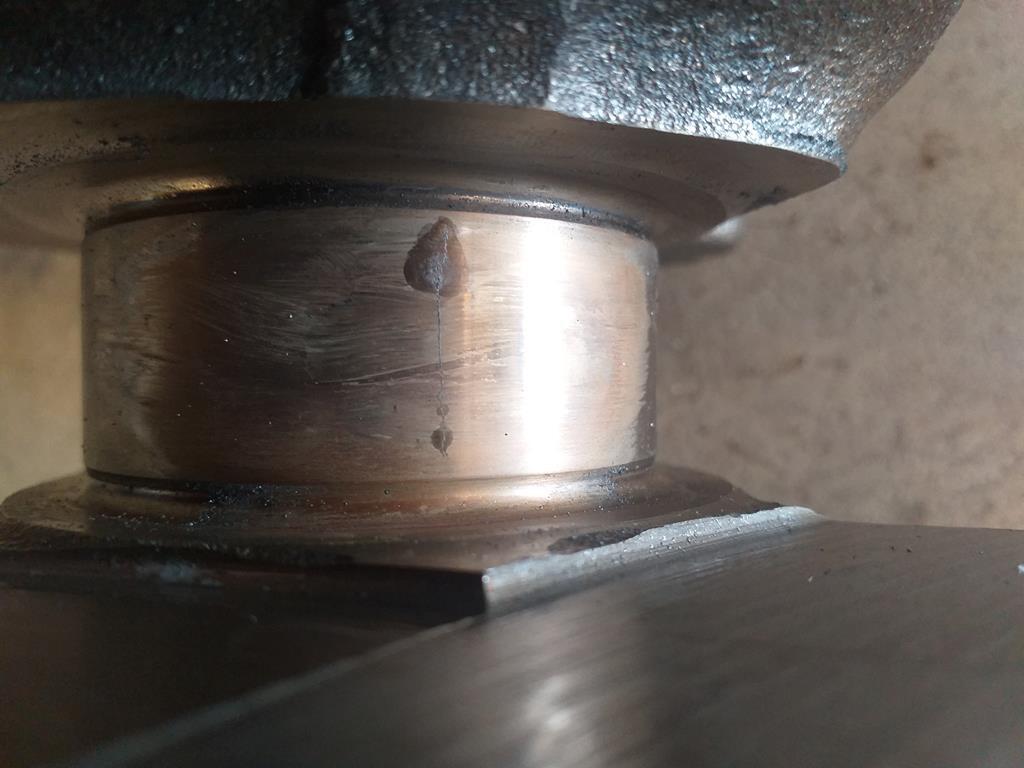

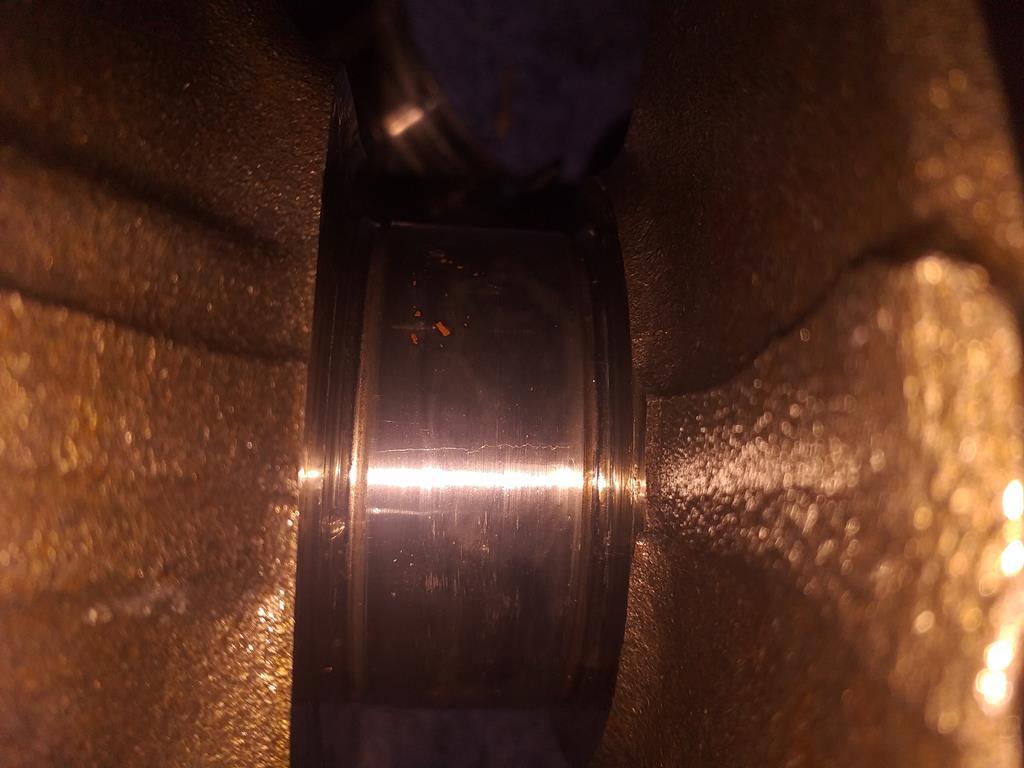

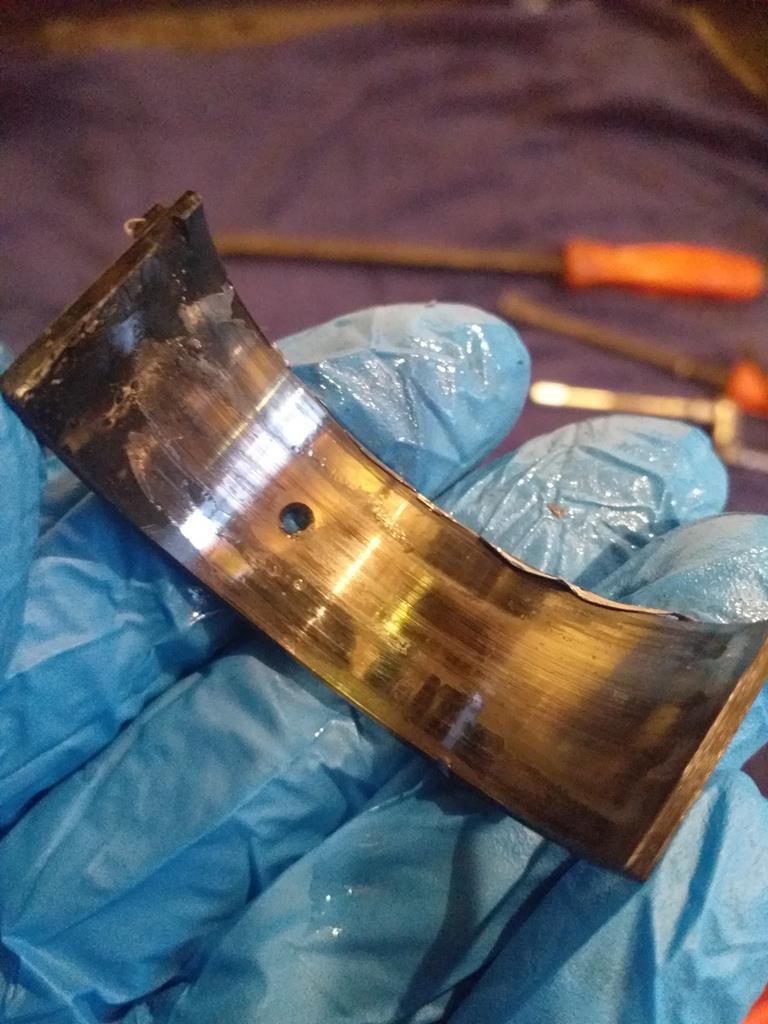

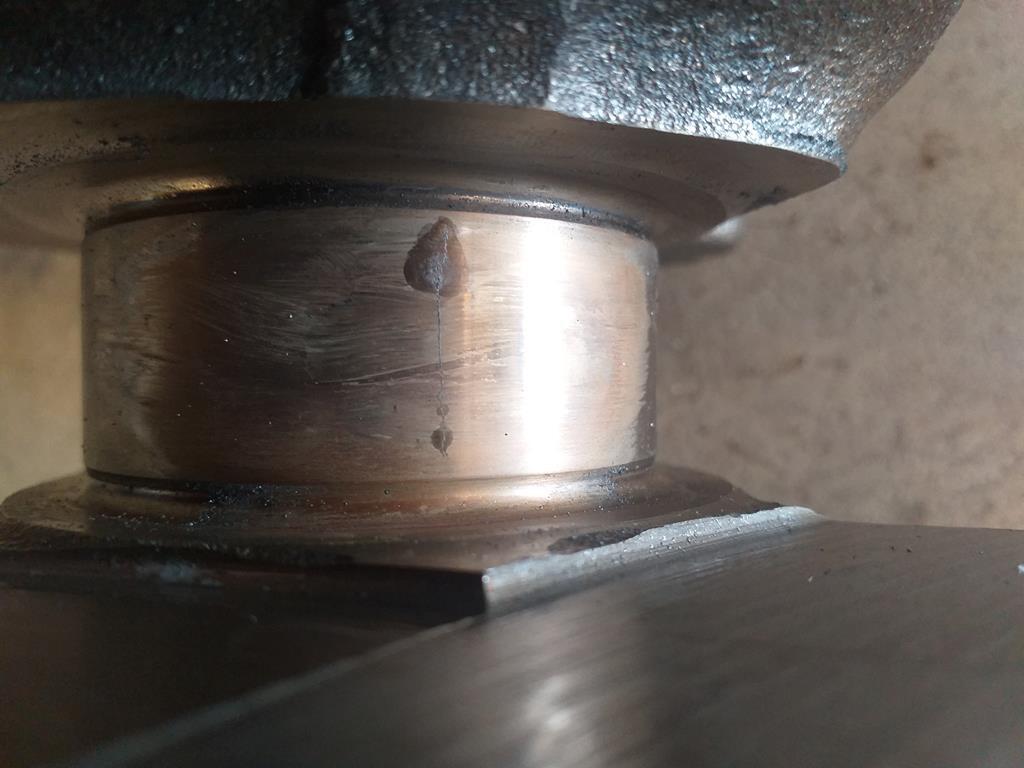

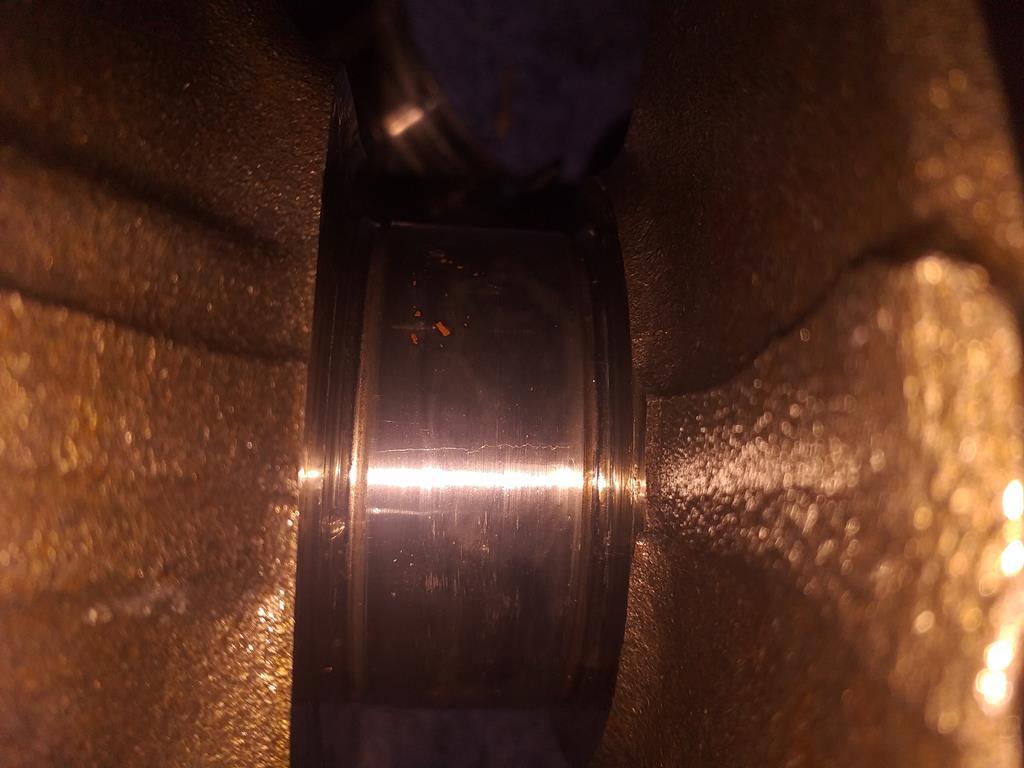

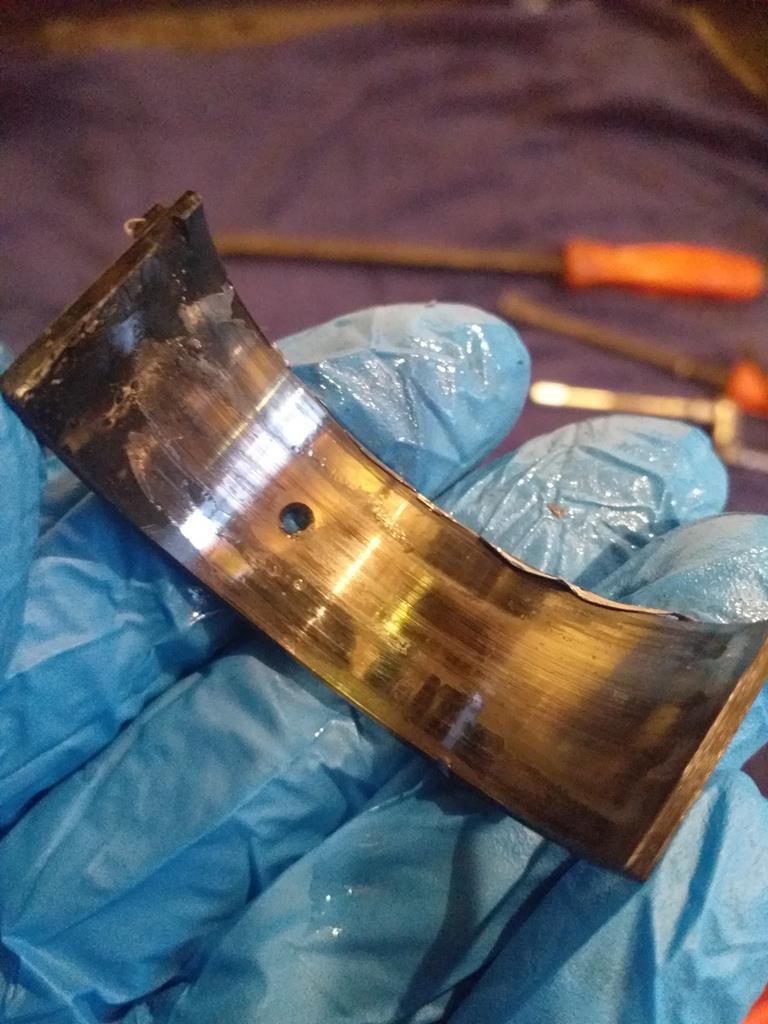

Now, because I'm a bit of a silly sausage i took the intake manifold off to do some work to it but didn't cover the port holes up sufficiently so inevitably with that dirty girt top mount vent in the bonnet and typically wet Cornish February weather some rain got into the cylinders, i had purchased a new oil pump, water pump, cam gears, cam chain, cam chain tensioner and sliders so i thought i may as well pull the engine, rip it apart and tidy up the engine bay, i wasn't expecting what i found, brand new shells completely shot and the crank i fitted to be cracked. never mind, it was all getting replaced.

So now i started on the engine bay, wire brushed primed and painted the front, fitted the new Cusco lower brace, anti roll bar, drop links, bottom ball joints, track rod ends, BC racing coil overs and then because I'm so bleeding clever i then decided once i had fitted it all to the wire brush back, prime, paint and add a few coats of bed liner to the front inner arches

Next was to adapt and fit the new Mishimoto radiator and twin fan shroud, i did have to mount the fans in front of the radiator as my waste gate port on the exhaust manifold was coming into direct contact with the fans, had to drill out some snapped bolts from in and around the slam panel, re-tap others that were cross threaded etc

Then i had to repair the front bumper support bar as some muppet had cut 60% of it away and i had nothing to hang my Mishimoto intercooler from, also now the bumper actually fits the car now the support had been straightened and was complete, also fitted the new horns, beep beep.

I set about straightening out the rear bumper support and fitting the new rear bumper i had obtained

Got some new boot struts too, just ordered two left hand ones by mistake so had to cut the brackets off the right hand one and very VERY carefully and slowly weld them onto the new one, first time that boot had held itself up without wood in over a decade

After getting my ex up the duff i had to reinstate the interior and cancel the rollcage i had ordered, more importantly i needed to make space to fit the interior as it had become a storage bin on the inside

I'll show you some of the parts that i have acquired for the build that where taking up the space on the inside

HKS boost controller

Kinugawa GTX3071R turbo

GFB waste gate

Thick walled stainless steel exhaust manifold (japspec i think) with turbo and waste gate fitted

Taarks hall sensor to delete distributor

Audi R8 coils for the COP conversion

Omex shift light

Cusco lower front brace

720cc rockfort injectors

AEM wide band

D1 snap off steering wheel hub

APR bolts, head, con rod, crank, flywheel and clutch

6" vibe door speakers

2 spare gearboxes, spare transfer box, spare diff

BC Racing coilovers

OMP front top brace

White gauge faces

Momo steering wheel

Hel braided brake hoses and EPman horns

Roose motorsport coolant hoses

anti roll bars front and back with new drop links, saddles and poly bushes

Twin race cooling fans with shroud

Bosh 044 fuel pump

poly bush billet engine stabilisers

Full cam kit, chain, gears, tensioner, sliders

mishimoto radiator

Front and rear carbon fibre doorcards

So now to fitting all the interior back in, what a pain in the it was finding all the screws, clips etc, door cards look good fitted though.

it was finding all the screws, clips etc, door cards look good fitted though.

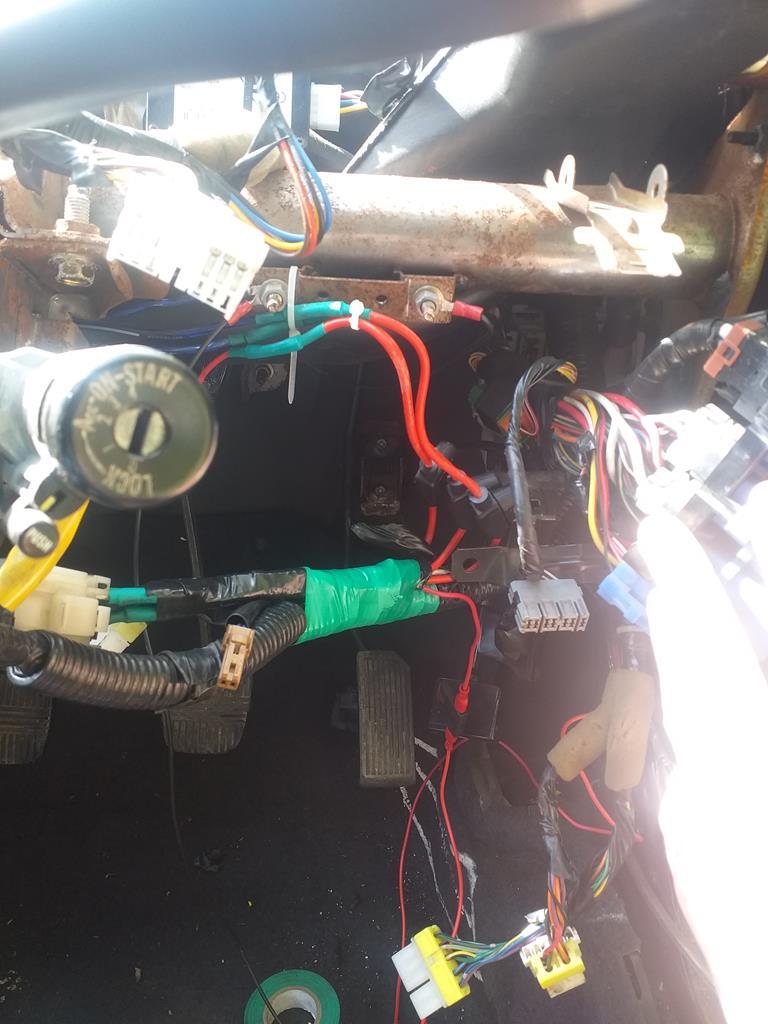

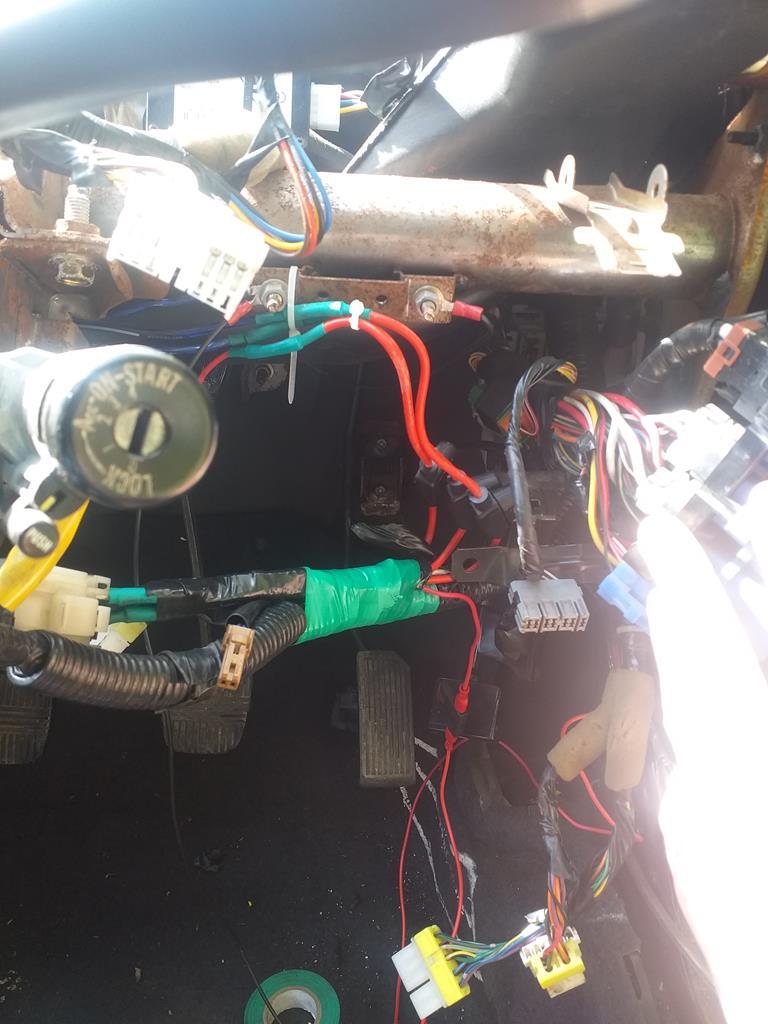

Then i had to take some of it back out as i needed to repair yet again more hash work on the wiring loom, had i of known it was such hash i would of repaired it before i put the stuff back in, main live in ignition wires cut into and just left bare 10mm from the steering column, and that's just the start of it, it was just a mess, had plenty of unqualified electricians making a good job of f**king it up. whilst i was there i noticed that all the foam surrounding the air vents across the whole heater system had disintegrated with age, luckily i had some draft exclude stripping for the house so i used it on all this.

THEN, covid bleeding 19 came along, obviously i have to be sensible with what money i have, i work offshore and a lot of that has come to a halt so until that all picks up again this puppy is on hold for a little while longer

I purchased it off a friends dad who when he got it (10 years ago) it had rod knock, he replaced all the necessary parts when he rebuilt the engine and going through a few heat cycles on the engine it suffered the same fate (weird). It sat there for many years to come of which i found myself having a deep fondness for it, eventually he came round to asking me to rebuild the engine again so i stripped the engine down and gave him a parts list. 2 years later he asked me to rebuild it. I left the parts neatly laid out on a couple workbenches and when i came back to it they had curse word all over them and had been moved here, moved there and ultimately lost, it took a while to find all the parts to put it back together and once completed i put it through a couple heat cycles there was a rather loud snap and the engine stopped dead... then gearbox fluid started pee'ing out the bell housing.... turns out that whilst the clutch was laying on the bench something got caught inside it that i didnt see upon installing it (i suspect a nut or small bolt) and that got flung between the clutch and gearbox casing making a nice little window for the diff to say hello to all who wondered past, i did tell him to buy a new clutch but he said no so 50/50 on who's fault that was, i was hoping it would be a 6 month quick fix but with working away so much last year (way Way WAY too much) and being pre-occupied fixing everyone else's sh*t, 18 months later and I'm getting there (slowly)

This is where he pushed the f**k it button and offered it to me so i snapped it up, got it transported to my place and got set out on planning the build.

I knew when i got it that it needed a bit of attention to both rear arches, there was a small hole onside and bubbling on the other, both where the bumper meets the arch, arches are rarer than poor quality wobbly children's play pony poo so i settled with a set from a 4 door sunny and would "make them fit" as everyone else does. What i wasn't expecting was just how bad it was, it went from this

To this

I believe Drake would say "0-100 real quick"

So it wasn't going to be a case of making pieces of something that doesn't fit but making a whole thing that doesn't fit fit. Now I'm no master body beater or welder but i gave it a ruddy good go. This is where i found out it had a tap on that corner and a very botched repair, just look at all that filler

, and rust

, and rust

I had a plan, strip it out, chuck a roll cage inside it, forge the engine and end up with many hundreds of BHP, so i stripped it out and found an awful and some what alarming amount of rust on the inside of which i cut out and slavered bird curse word all over attempting to put in new steel in the rear passenger foot wells and rear wheel well

After making a hash out of fixing it all i came across a previous fix from another owner, this then gave me a good idea of what i was yet to find, hackery and bodge jobs, don't worry, its only right bloody next to a seat belt mount, and i could see the tarmac from the inside. once this was covered i t was apparent i may have to cut out the plate they stuck on the inside of the arch and start again but would asses once i got there.

Once all the welding (birdshit) was done on the inside i set about wire brushing anything that looked vaguely suspect to inquire and address it, after all that was done it got 2 heavy coats of primer, 2 heavy coats of black and the 2 coats of bed liner. Also did the same on the underside.

Now i turned my attention to the drivers side rear arch as that only needed a small area taking care of in the corner

Again, how wrong i was, the bit thats covered by the bumper with vents in it was utter toast, so i patched the rear arch and set about trying to fix what was lay infront of me with again, the wrong panel for the job ( just remember my previous comment, poor quality wobbly children's play pony poo)

As i was looking into the previous bodge up i notice another complete lash up in the front section of the arch, what i found was beyond shocking, if you look they welded some of it in and then just finished the rest of with a mastic, words couldn't describe how angry i was but i was also overcome with joy from laughing at it.

I had no option but to cut it all out and start again, just look at what they thought was a repair, it is utterly shameful

So, i had a task on my hands, stupidly i thrown out the rest of the repair panel which had the sill section on it so with nothing but flat sheet i "attempted" to repair and replace what i had cut out, it could of gone better but i was happy enough with it, after all, this is what body filler was made for right? i had to rebuild the inner sill, the closing plate for that, the outer sill and the closing plate for that.

Next up was the front of the sill panel and the lower section of the wing, both rusty and holed

Now onto another complete lash up by a previous owner, for some reason unknown to man they decided it would be a good idea to route the inter cooler charge pipe through the lower radiator support and from what i could tell they did it with an axe

A couple hours later and it looked a lot neater and ALMOST like no one had been there (from a distance)

Where they had attacked the other side and cut out steel they had managed to cut one on the headlight support mounts off so the passenger headlight flopped about like a fish out of water, i wasted no time in repairing that too.

Now, because I'm a bit of a silly sausage i took the intake manifold off to do some work to it but didn't cover the port holes up sufficiently so inevitably with that dirty girt top mount vent in the bonnet and typically wet Cornish February weather some rain got into the cylinders, i had purchased a new oil pump, water pump, cam gears, cam chain, cam chain tensioner and sliders so i thought i may as well pull the engine, rip it apart and tidy up the engine bay, i wasn't expecting what i found, brand new shells completely shot and the crank i fitted to be cracked. never mind, it was all getting replaced.

So now i started on the engine bay, wire brushed primed and painted the front, fitted the new Cusco lower brace, anti roll bar, drop links, bottom ball joints, track rod ends, BC racing coil overs and then because I'm so bleeding clever i then decided once i had fitted it all to the wire brush back, prime, paint and add a few coats of bed liner to the front inner arches

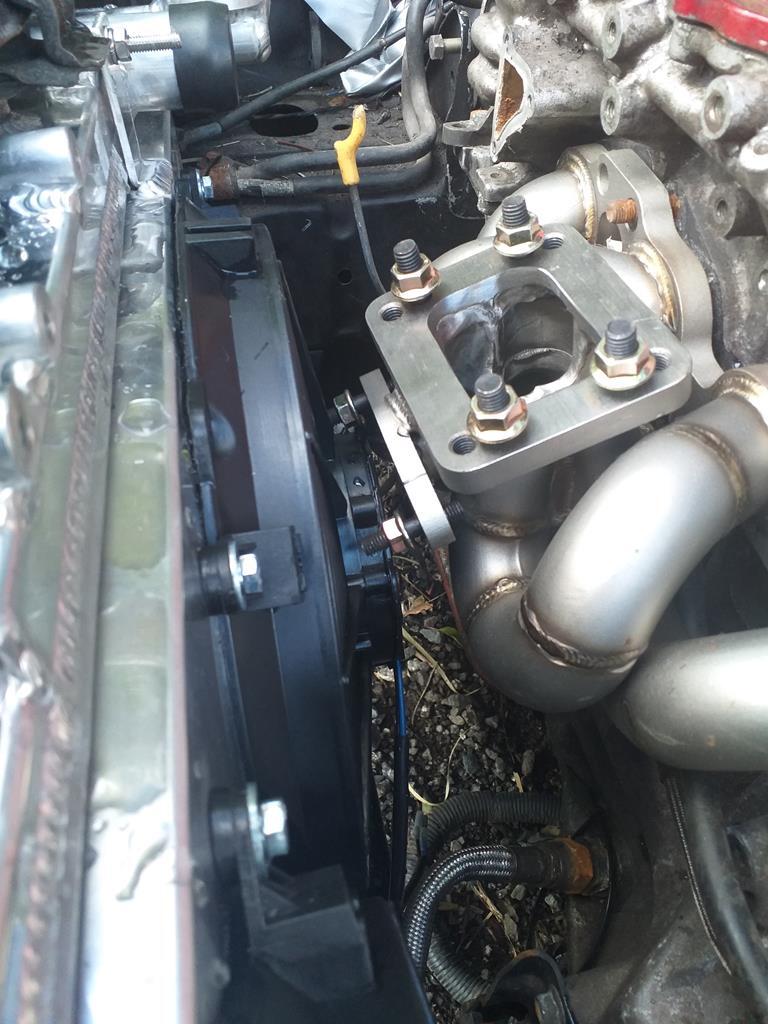

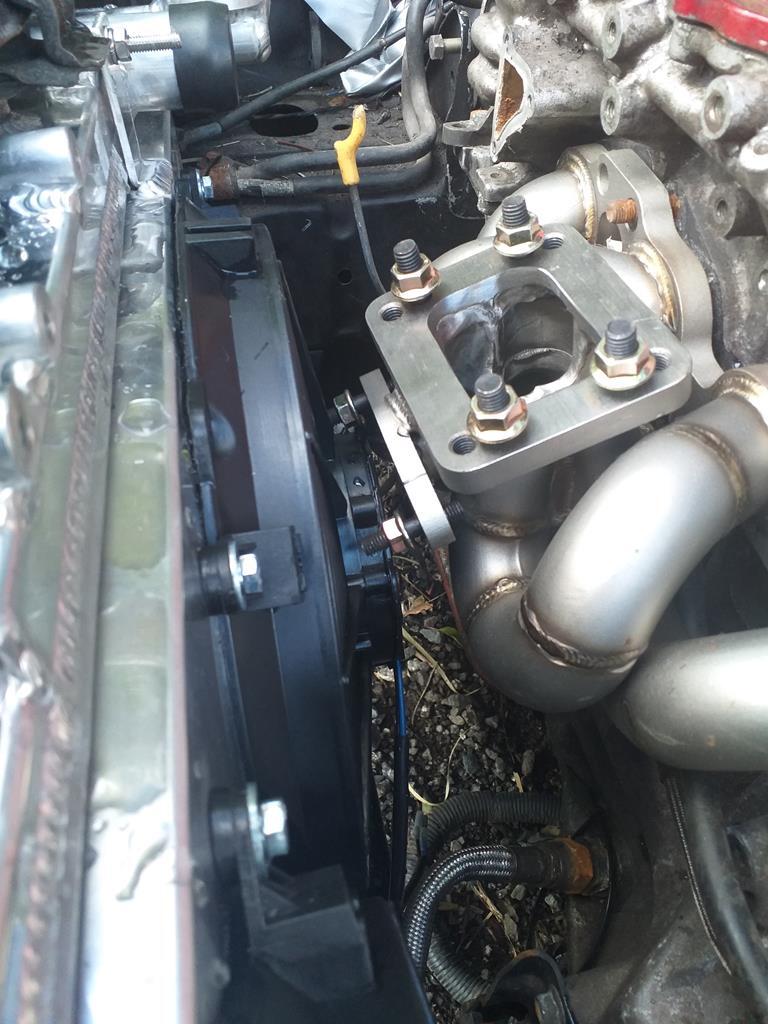

Next was to adapt and fit the new Mishimoto radiator and twin fan shroud, i did have to mount the fans in front of the radiator as my waste gate port on the exhaust manifold was coming into direct contact with the fans, had to drill out some snapped bolts from in and around the slam panel, re-tap others that were cross threaded etc

Then i had to repair the front bumper support bar as some muppet had cut 60% of it away and i had nothing to hang my Mishimoto intercooler from, also now the bumper actually fits the car now the support had been straightened and was complete, also fitted the new horns, beep beep.

I set about straightening out the rear bumper support and fitting the new rear bumper i had obtained

Got some new boot struts too, just ordered two left hand ones by mistake so had to cut the brackets off the right hand one and very VERY carefully and slowly weld them onto the new one, first time that boot had held itself up without wood in over a decade

After getting my ex up the duff i had to reinstate the interior and cancel the rollcage i had ordered, more importantly i needed to make space to fit the interior as it had become a storage bin on the inside

I'll show you some of the parts that i have acquired for the build that where taking up the space on the inside

HKS boost controller

Kinugawa GTX3071R turbo

GFB waste gate

Thick walled stainless steel exhaust manifold (japspec i think) with turbo and waste gate fitted

Taarks hall sensor to delete distributor

Audi R8 coils for the COP conversion

Omex shift light

Cusco lower front brace

720cc rockfort injectors

AEM wide band

D1 snap off steering wheel hub

APR bolts, head, con rod, crank, flywheel and clutch

6" vibe door speakers

2 spare gearboxes, spare transfer box, spare diff

BC Racing coilovers

OMP front top brace

White gauge faces

Momo steering wheel

Hel braided brake hoses and EPman horns

Roose motorsport coolant hoses

anti roll bars front and back with new drop links, saddles and poly bushes

Twin race cooling fans with shroud

Bosh 044 fuel pump

poly bush billet engine stabilisers

Full cam kit, chain, gears, tensioner, sliders

mishimoto radiator

Front and rear carbon fibre doorcards

So now to fitting all the interior back in, what a pain in the

it was finding all the screws, clips etc, door cards look good fitted though.

it was finding all the screws, clips etc, door cards look good fitted though.

Then i had to take some of it back out as i needed to repair yet again more hash work on the wiring loom, had i of known it was such hash i would of repaired it before i put the stuff back in, main live in ignition wires cut into and just left bare 10mm from the steering column, and that's just the start of it, it was just a mess, had plenty of unqualified electricians making a good job of f**king it up. whilst i was there i noticed that all the foam surrounding the air vents across the whole heater system had disintegrated with age, luckily i had some draft exclude stripping for the house so i used it on all this.

THEN, covid bleeding 19 came along, obviously i have to be sensible with what money i have, i work offshore and a lot of that has come to a halt so until that all picks up again this puppy is on hold for a little while longer

My buddy had one as a very early Japanese import back in the 90's, savage car when going right

My buddy had one as a very early Japanese import back in the 90's, savage car when going right