Not one of mine this time but helping out a fellow mr2 club member and friend.

The car has seen alot of roads, 255,000 miles of them in fact.

Its is suffering with one of the afflictions that plauges most old cars, commonly seen on british layland but occasionally crosses barriers to our japanese machines.

.

.

Oil leaks

.

.

Lots of them.

A garage had the car and decided that the engine was knackered and needed replacement after a slightly low reading on compression test, he also said it had a few other rather improbable issues hence the car was removed from that particular garage.

Since he had taken most of the engine apart i havnt had it running and have decided that the best option is to do some tests and drop the engine for inspection.

So down it goes.

Seperate and mount...

Cut out the sniggering you lot at the back, I'm still on the engine.

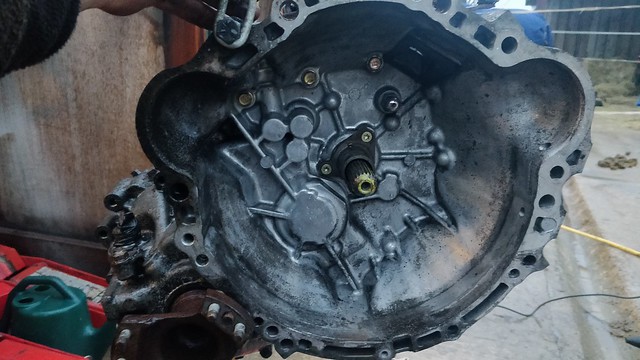

Hmm i think there is a leak in here.

No sign of the oil on the clutch or flywheel so my guess would be that its the input shaft seal on the gearbox. Easy fix.

A leak down test was performed and results came in at

Cylinder 1 @ 5-10% leakage

Cylinder 2 @ 5-10% leakage

Cylinder 3 @ 10-15% leakage

Cylinder 4 @ 5-10% leakage

The general concensus is that anything below 20% leakage is fine.

All leaks could be heard coming out of the dipstick tube and block - head oil ways which indicated that all leakage is in the piston rings and at 1/4 of a million miles thats a pretty good result.

Plugs all looked good and what i could see of the piston CROWNs shows very little deposits.

Intake is clean.

I want to do a pressure test on the block and head coolant system as the garage made comment about coolant in the oil. As everything had been drained when it got here i couldnt confirm this but there was no mayo in the oil cap. Since the system is totally disconnected i think making some block off plates will be a good start, either that or try loop the pipes and see if i can get some pressure into it.

Coolant system looks spotless though. I suspect this is a good sign that the engine has been well looked after and allways filled with the correct stuff.

A few minor issues to fix on the wiring loom

Oil pressure sensor

Dodgy repair to the dizzy connector

Cracked manifold to replace.

Christmas day arrived and i snuck a few hours down in the shed to apply some gunk and pressure wash the thick muck off.

Ports stuffed up with paper and dizzy wrapped to keep it safe.

Much better and i did the gearbox too.

Hope you all have had a great chrtistmas

The car has seen alot of roads, 255,000 miles of them in fact.

Its is suffering with one of the afflictions that plauges most old cars, commonly seen on british layland but occasionally crosses barriers to our japanese machines.

.

.

Oil leaks

.

.

Lots of them.

A garage had the car and decided that the engine was knackered and needed replacement after a slightly low reading on compression test, he also said it had a few other rather improbable issues hence the car was removed from that particular garage.

Since he had taken most of the engine apart i havnt had it running and have decided that the best option is to do some tests and drop the engine for inspection.

So down it goes.

Seperate and mount...

Cut out the sniggering you lot at the back, I'm still on the engine.

Hmm i think there is a leak in here.

No sign of the oil on the clutch or flywheel so my guess would be that its the input shaft seal on the gearbox. Easy fix.

A leak down test was performed and results came in at

Cylinder 1 @ 5-10% leakage

Cylinder 2 @ 5-10% leakage

Cylinder 3 @ 10-15% leakage

Cylinder 4 @ 5-10% leakage

The general concensus is that anything below 20% leakage is fine.

All leaks could be heard coming out of the dipstick tube and block - head oil ways which indicated that all leakage is in the piston rings and at 1/4 of a million miles thats a pretty good result.

Plugs all looked good and what i could see of the piston CROWNs shows very little deposits.

Intake is clean.

I want to do a pressure test on the block and head coolant system as the garage made comment about coolant in the oil. As everything had been drained when it got here i couldnt confirm this but there was no mayo in the oil cap. Since the system is totally disconnected i think making some block off plates will be a good start, either that or try loop the pipes and see if i can get some pressure into it.

Coolant system looks spotless though. I suspect this is a good sign that the engine has been well looked after and allways filled with the correct stuff.

A few minor issues to fix on the wiring loom

Oil pressure sensor

Dodgy repair to the dizzy connector

Cracked manifold to replace.

Christmas day arrived and i snuck a few hours down in the shed to apply some gunk and pressure wash the thick muck off.

Ports stuffed up with paper and dizzy wrapped to keep it safe.

Much better and i did the gearbox too.

Hope you all have had a great chrtistmas

[

[

as they like to seize on and there is no room for a regular puller against the oil pump housing.

as they like to seize on and there is no room for a regular puller against the oil pump housing.