Project creep... Type it into Google and this is the definition...

Scope creep in project management refers to changes, continuous or uncontrolled growth in a project’s scope, at any point after the project begins. This can occur when the scope of a project is not properly defined, documented, or controlled. It is generally considered harmful. Wikipedia...

You know the score, set off changing a headlight bulb and suddenly there's a facelift front end going on, quick service and suddenly your doing an engine conversion.... Quick bodged MOT welding repair and your ankles deep in a concurs restoration...

So what am I waffling about now.. well... When engine number one became a v6.75, the plan was "quickly" throw new spare engine in and be on my way... But...

I've never been happy with how much juice the alternator throws out. 40amp is ok for a kit car with a 4cylinder pushrod engine on a carb.. but it struggles to keep up with a electronically fuel injected all singing modernish V8... I also want to fit electronic power steering and we'll... 40 amp is not going to run that aswell..

I'd got that 180 amp BMW alternator, but it certainly wasn't going to fit anything like with the standard manifold set up I have.. but while it's all out, may aswell try and make it work.. hadn't I

Made a start swapping all my modified timing belt covers and what not over,to see what sort of room I had.. also swapped the trigger wheel over to the new engine

Now with it summat like assembled I offered the alternator up, and one bolt looked like it may work, the bottom bolt may have worked. But the rear mounting lug was nothing like. Only one thing for it

With the extra mounting lug removed it sort of fits in sort of the right space.. I've seen people use this alternator before and the make it fixed and run a stretch belt... But that's too easy, and I'm not world's biggest fan of them tbh.. still looks like it could work..doesn't it

Now it's going to need a bracket for the bottom and some spacers (don't think big nylocs are suitable spacers haha), but were making steps. Called it a day at that, and since I had gotten bored of my knees hurting from working on the floor, took my hydraulic table thing down to work to work at a nicer hight. I'd also told my boss I wouldnt spill out into the workshop yeah about that haha

yeah about that haha

Probably need to reign the mess in a bit haha.

So the bottom bracket. Wasn't happy with it being fixed, using some bits of the old alternator mount, some random bolts and bits. Came up with this. Just bear in mind it's a work in progress rather than the finished product. But couldn't really be happier with how the concept works. Just need a couple 25mm spacers made from bar stock and some proper bolts.

Yep. That will do.. smallest size is 750mm (which is available as an off the shelf belt) and then I can tension it up..

So, with that sort of happy.. what about the manifolds, how do they fit, and the link pipe... Quick answer is they don't! Not close not at all not remotely... At this point it was either scrap it off put the little 40amp denso back on, try and modify the drivers side manifold and link pipe (there not even in right postcode tbh) or scrap the Manifolds and link pipe and start again with the lot...

So the obvious solution..... I'm starting again I needed to come up with a solution to get power steering on it, I needed more amperage, and I needed to get the exhaust over the subframe to get some ground clearance back.. and by remaking everything I can. With the added advantage of being able to do it inside at work inbetween jobs.

I needed to come up with a solution to get power steering on it, I needed more amperage, and I needed to get the exhaust over the subframe to get some ground clearance back.. and by remaking everything I can. With the added advantage of being able to do it inside at work inbetween jobs.

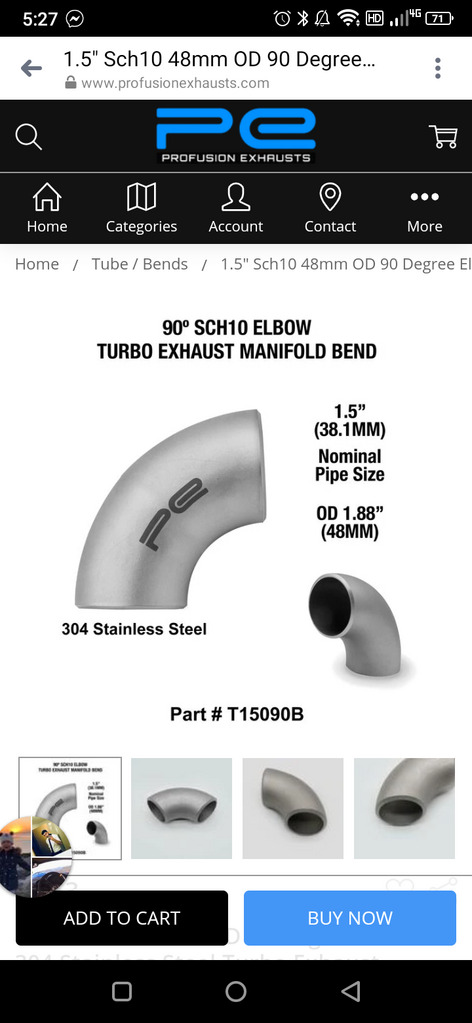

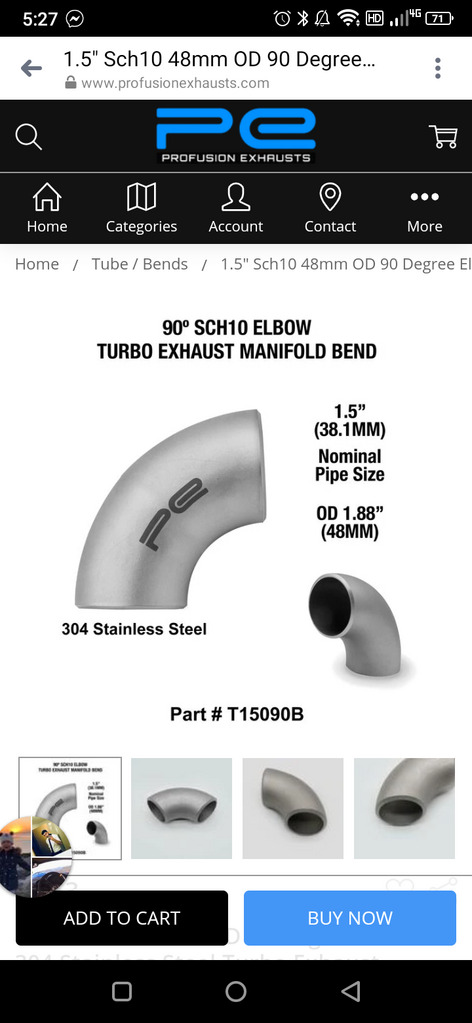

I'd already planned on making log Manifolds if i ever changed the set up in the future, I just didn't intend on being this soon.. only saving grace is I sold my stock wiring loom off this engine at the weekend so the Manifolds won't really cost me owt other than time.. as the massive haul of bits aren't here yet, these are the sort of things were talking about.. sch10 thick wall stainless tubes, T's and 90's..

I've also got some stainless manifold flanges on way, new turbo flange, vbands, lambda boss, etc etc. Now we understand "project creep"

But I can now get an exhaust over the subframe, and I can now get an Astra electric power steering pump so you can actually manouver the car without being Arnie (and catch it when it goes sideways which is probably more important)..

Carried on doing a few more bits, got the engine mounts on, oil feed and pressure sensor fitted.. sort of ran out of "stuff" that would be productive until I'd had some bits turn up.. I also need to grab some stainless wire for the mig, I've never properly welded stainless before so wel see how that turns out..

Anyways, more soon hopefully.. based on my current run of getting carried away, il probably be doing a full colour change paint job or reshell next time I check in haha

Cheers

Scope creep in project management refers to changes, continuous or uncontrolled growth in a project’s scope, at any point after the project begins. This can occur when the scope of a project is not properly defined, documented, or controlled. It is generally considered harmful. Wikipedia...

You know the score, set off changing a headlight bulb and suddenly there's a facelift front end going on, quick service and suddenly your doing an engine conversion.... Quick bodged MOT welding repair and your ankles deep in a concurs restoration...

So what am I waffling about now.. well... When engine number one became a v6.75, the plan was "quickly" throw new spare engine in and be on my way... But...

I've never been happy with how much juice the alternator throws out. 40amp is ok for a kit car with a 4cylinder pushrod engine on a carb.. but it struggles to keep up with a electronically fuel injected all singing modernish V8... I also want to fit electronic power steering and we'll... 40 amp is not going to run that aswell..

I'd got that 180 amp BMW alternator, but it certainly wasn't going to fit anything like with the standard manifold set up I have.. but while it's all out, may aswell try and make it work.. hadn't I

Made a start swapping all my modified timing belt covers and what not over,to see what sort of room I had.. also swapped the trigger wheel over to the new engine

Now with it summat like assembled I offered the alternator up, and one bolt looked like it may work, the bottom bolt may have worked. But the rear mounting lug was nothing like. Only one thing for it

With the extra mounting lug removed it sort of fits in sort of the right space.. I've seen people use this alternator before and the make it fixed and run a stretch belt... But that's too easy, and I'm not world's biggest fan of them tbh.. still looks like it could work..doesn't it

Now it's going to need a bracket for the bottom and some spacers (don't think big nylocs are suitable spacers haha), but were making steps. Called it a day at that, and since I had gotten bored of my knees hurting from working on the floor, took my hydraulic table thing down to work to work at a nicer hight. I'd also told my boss I wouldnt spill out into the workshop

yeah about that haha

yeah about that haha

Probably need to reign the mess in a bit haha.

So the bottom bracket. Wasn't happy with it being fixed, using some bits of the old alternator mount, some random bolts and bits. Came up with this. Just bear in mind it's a work in progress rather than the finished product. But couldn't really be happier with how the concept works. Just need a couple 25mm spacers made from bar stock and some proper bolts.

Yep. That will do.. smallest size is 750mm (which is available as an off the shelf belt) and then I can tension it up..

So, with that sort of happy.. what about the manifolds, how do they fit, and the link pipe... Quick answer is they don't! Not close not at all not remotely... At this point it was either scrap it off put the little 40amp denso back on, try and modify the drivers side manifold and link pipe (there not even in right postcode tbh) or scrap the Manifolds and link pipe and start again with the lot...

So the obvious solution..... I'm starting again

I needed to come up with a solution to get power steering on it, I needed more amperage, and I needed to get the exhaust over the subframe to get some ground clearance back.. and by remaking everything I can. With the added advantage of being able to do it inside at work inbetween jobs.

I needed to come up with a solution to get power steering on it, I needed more amperage, and I needed to get the exhaust over the subframe to get some ground clearance back.. and by remaking everything I can. With the added advantage of being able to do it inside at work inbetween jobs. I'd already planned on making log Manifolds if i ever changed the set up in the future, I just didn't intend on being this soon.. only saving grace is I sold my stock wiring loom off this engine at the weekend so the Manifolds won't really cost me owt other than time.. as the massive haul of bits aren't here yet, these are the sort of things were talking about.. sch10 thick wall stainless tubes, T's and 90's..

I've also got some stainless manifold flanges on way, new turbo flange, vbands, lambda boss, etc etc. Now we understand "project creep"

But I can now get an exhaust over the subframe, and I can now get an Astra electric power steering pump so you can actually manouver the car without being Arnie (and catch it when it goes sideways which is probably more important)..

Carried on doing a few more bits, got the engine mounts on, oil feed and pressure sensor fitted.. sort of ran out of "stuff" that would be productive until I'd had some bits turn up.. I also need to grab some stainless wire for the mig, I've never properly welded stainless before so wel see how that turns out..

Anyways, more soon hopefully.. based on my current run of getting carried away, il probably be doing a full colour change paint job or reshell next time I check in haha

Cheers

keep up the good work !

keep up the good work !