mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

I was going to suggest checking the signal line to the dump valve, but haven't seen one in any of the pics! No dump valve fitted. And to the best of my knowledge every little vac port and stuff that is spare is either blanked, capped or welded up.. plus I don't get any change in rpm from spraying brake cleaner round the inlet. But that's not to say I've not got a huggge leak under pressure |

| |

|

|

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

I know. I'm currently in process of trying to find a smoke tester to borrow to rule out any inlet leaks or owt daft. It's genuinely kept me awake last night (and then kids got up at 5!!) But don't worry when I figure it out il be sure to share the misery haha I have got a fog machine, as a smoke tester. Maybe if your close to Stafford I can lend to you...or cheap on Amazon/Ebay I'm up in rotherham but I do come that way for work regularly. That been said I can get a DJ smoke machine for 20 quid off eBay. So may just grab one and make a nozzle to fire it in. Thanks for the offer tho. |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

Could you hook some compressed air upto the inlet set on a very low pressure and see if you can hear where its escaping? Perhaps just use some gaffa tape and cardboard and set it at 5PSI? Thats next plan if the tissue test doesn't show anything today.. |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

So sadly only managed a quick look last night. I was nakerd from being up since crack of dawn with the kids. And it was raining horizontal. So now that's the excuses out the way haha It would appear I've several small exhaust leaks pre turbo. Nothing humongous I can see obvious. But it seems I've got small blows on the manifold to link pipe flanges, the wastegate is leaking were it meets the vband  and even tho the screamer is welded shut. The other end were the vband meets the gate is blowing too!! Is this combined enough to stop it spooling? Who knows. But it's certainly not going to be helping!! All this is before I've smoke and or pressure tested it! Or moved onto the inlet side. With this in mind I'm going to..... Do absolutely nothing about it haha. Well I am, but before I go any further I'm getting an exhaust made. My boss has ok'd me to have Friday off work, but go into work and make an exhaust. So that's the plan. I'm still trying to find/make a smoke tester locally. I had the thought about cobbling summat together using a party/DJ smoke machine. Then remembered my sister has one so I'm trying to get that from her (she's gone to hospital today to have a baby so said she was busy this mornin, some people don't know how to prioritise haha).. I'm going to try and make a start on the front pipe this week in the evenings at home if I can, I've also got my new used discs to chuck on and hopefully get rid of the awful vibration on the brakes.. More soon maybe. Cheers |

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,975

Club RR Member Number: 71

|

|

Aug 17, 2020 11:29:45 GMT

|

|

May have been suggested already but in concentrating on the hot side don’t forget the cool side can also lead to boost going missing - leaks on intercooler joints pipes or even the intercooler will bleed of boost very rapidly

|

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Aug 17, 2020 11:51:32 GMT

|

May have been suggested already but in concentrating on the hot side don’t forget the cool side can also lead to boost going missing - leaks on intercooler joints pipes or even the intercooler will bleed of boost very rapidly It's been mentioned and definitely considered. I'm going to work my way backwards from the turbo to she inlet with some smoke and pressure once I've got the means.. I will get to the bottom of it don't worry haha. Cheers |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Aug 20, 2020 19:53:10 GMT

|

|

So a bit of a check in. Just to say nowt exciting has happened since last time. Haha. I've been flat out at work, and busy at home so haven't really had chance to do much.

I did manage to have a quick go at "smoke testing".. by smoke testing I mean I grabbed some smoke pellets from Screwfix as there down road (I've no idea what there really used for haha)..

My test constituted lighting one of these and popping it in the exhaust then capping the end with a pop bottle and blowing up a piece of garden hose I'd taped along side the pop bottle 😂 (I'm sure that's not how it's really done) actually showed how bad the leaks were from around the wastegate.. when the smoke finally made its way as far the gate from the end of the exhaust, it billowed out.

I'm not a race car builder. But I'm sure that's not right. Hopefully with that issue sorted it will make boost.

Speaking of making boost I've been looking into wastegates some more and I "think" I've settled on a genuine turbosmart 50mm job. Not "cheap" but garaunteed to work properly from the get go with proper customer support.

Anyways, I'm off work but going into work tomorrow to make an exhaust. All being well I may have a usable exhaust by this time tomorrow.

Cheers

|

| |

|

|

|

|

|

Aug 20, 2020 19:57:48 GMT

|

|

I use smoke bombs at work all the time, testing flue draw and chamber sealing in solid fuel stove installations.

Hope you get to the bottom of your boost issue!

|

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Aug 20, 2020 20:03:00 GMT

|

I use smoke bombs at work all the time, testing flue draw and chamber sealing in solid fuel stove installations. Hope you get to the bottom of your boost issue! I figured they may have been chimney related haha. Most definitely not for checking for leaks in exhaust manifolds, but it's not stupid if it works least that's my theory. And cheers, so do I. I'm hoping once it's got an exhaust on it may be a bit more obvious/manageable to work out what's leaking were. Cheers |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Aug 21, 2020 19:12:38 GMT

|

So exhaust day. Would appear I picked a perfect day for it. Severe weather warnings in place across the UK for 7000mph winds and heavy rain. Ideal for rolling round under the shed making exhausts  Was all going well. Kids up and dropped off at nursery back home chucked my tools and owt I might need in the lexus to set off to work. Turned the key and it just clicked. Nothing more. Battery flatter than a flat thing (noticed a dimly lit interior light on, I've obviously cought it when I've been messing with interior).. perfect. Going to be one of them days is it. Grabbed my spare "massive" battery out the garage and fired straight up on the jump leads. Not trusting battery would do the job on way threw the battery and leads in car.. arrived at work to be greated with a list of jobs (the risk you take going into work on a day off)  So much later than anticipated I made a start with the job in hand. Just getting the car in the air high enough was a challenge in its self (and despite my boss suggesting we could use a forklift I resisted  )  As sketchy as that may look it was solid as a rock. So with access first job was drop the original downpipe off and shorten it down to where the 90 degree bend needed to go to fire it under the car.  Then weld on one half a 4 inch vband to connect the next bit. Also used the wrap I'd unwrapped off the original downpipe to go over my new shorter downpipe with another layer (every bit helps I'm sure)..  Next bit was the bit that goes under subframe, reusing the 4 inch pipe I welded a 90 degree bend on and the other half of the vband clamp. Meaning I can adjust the angle this pipe runs at using just the movement on the vband.  This is where things started going wrong. The heavens absolutely opened stopping job for a bit (my boss wasn't overly keen on me teaching the welder to swim).. and when it finally stopped the wind had gotten to silly levels making my usually bad welding look worse  think the wind was blowing the gas away as it was definitely better if I used my body to block it but cramped up under a car with my one good shoulder it wasn't always possible. Using my previously mentioned patent pending pipe ovaling jig (counterweight of a 3.5 ton truck  ) ovalled the black bit of 4 inch tube. Before welding on the 4 to 3 inch reducer cone. Heres a terrible picture taken under the car of the now oval tube...  Speaking of terrible pics this is about where my photos ended. I was conscious of time conscious of the weather and really wanted a useable exhaust before I called it a day. Besides. We've all seen some bends welded roughly together before now haha. Did grab this one before I slipped it back on tho  Before I packed up and shot home to get the kids. Back home on the drive in its rightful place hahah  Soooo. What's the verdict. Well it's precisely 80000% better. Don't get me wrong were not talking regular lexus levels of silence. It's still got a lovely burble to it. But at idle/low revs it's quite pleasant. Give it the beans and it goes full shouty. Which is what we like. It's taken the harshness out of the noise without losing the depth. But It now means I can start it once the kids are in bed! If needs be il put a mid box in too but I think it's going to be enough. (may make a quick release baffle just to make it silent for home starts).. Sadly didn't get a video but il try and get one over the weekend in-between parenting... Plan now is whip it back off and take the tops off a few of the welds, before I paint it and wrap the front section... But my next priority is I'm on a mission. A mission to find my missing boost  haha Cheers |

| |

|

|

|

|

|

Aug 21, 2020 20:09:45 GMT

|

|

Sounds perfect, I've never grown out of a rowdy exhaust.

|

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Aug 24, 2020 15:55:58 GMT

|

Sounds perfect, I've never grown out of a rowdy exhaust. Loud pipes save lives... Scientifically proven haha. Unfortunately the one that was on it was saving lives in other counties so not ideal This is an acceptable level of rowdy now. Least I say it is (Mrs says otherwise, what does she know) haha |

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Aug 24, 2020 16:01:29 GMT

|

|

So sadly no flypast video over the weekend. Infact not much of anything other than looking after kids.

I did manage to nip out for an hour Sunday afternoon and took my eldest daughter with me for her first go in it (she played in it for hours on end on the drive just never been in it driving).. judging by the big smile and her asking "what dat noise" when it started to make boost noises it looks like we have a fan haha.

Sadly the drive did also point out that the exhaust may be too low (not a lot I can do unfortunately for the time being). But least I've got summat to work from.

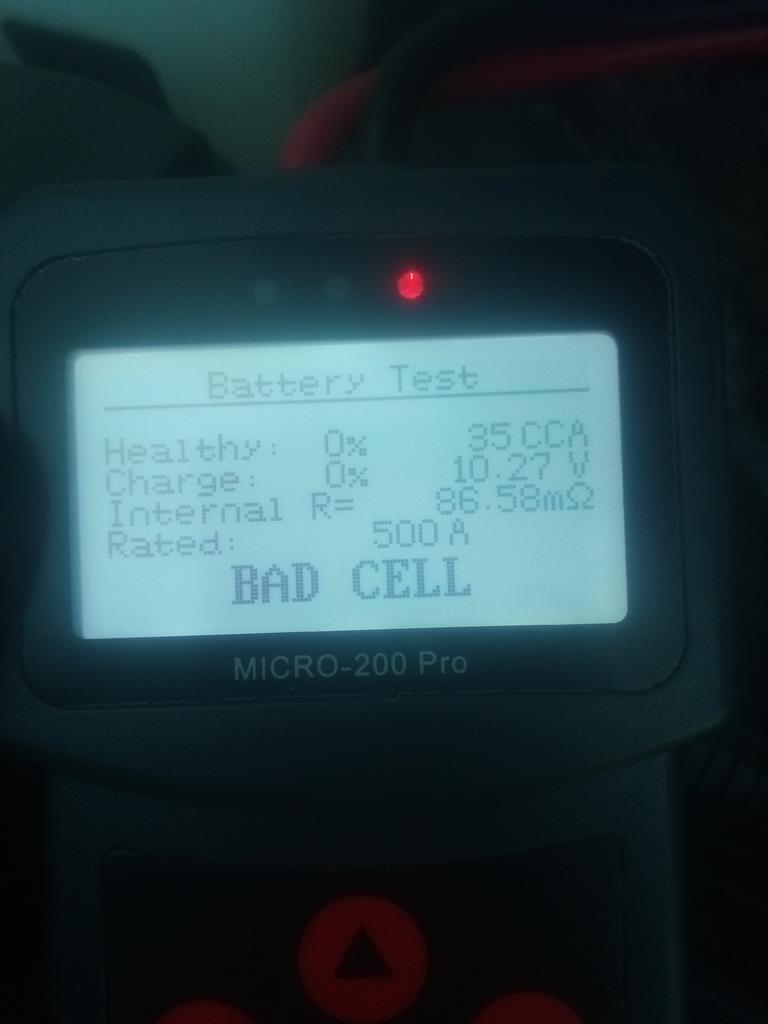

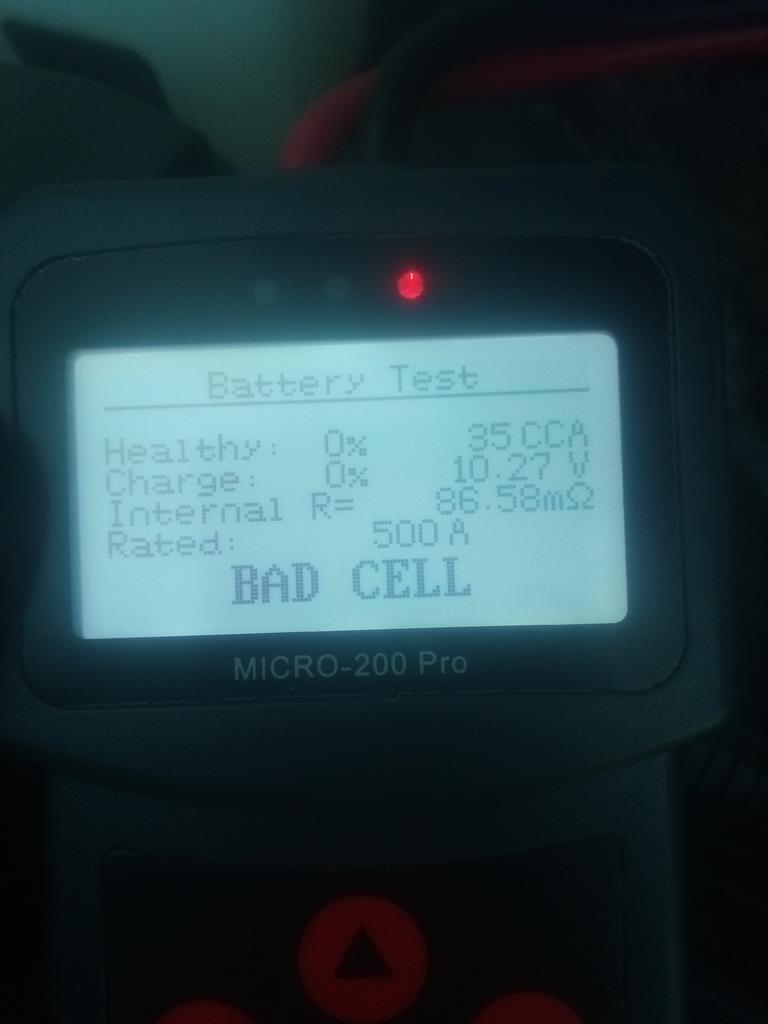

Oh and the battery was flat again, so I've either got a drain (possible) or the battery I aquired for free is infact dead (very possible). It's charging fine, il stick my load tester on it later to see what's happening.

Speaking of later, I've brought the welder home from work. So if I get chance I'm welding the wastegate hole shut in the exhaust. It will boost 😂😂

More soon.

|

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

Tiny little sneaking an hour update, complete with blood loss  ... First things first the flat battery. Is the battery as expected dead. Connected my tester up and sure enough. Well.. yeah.. it's nakerd! So it may be going to the boot sooner than I thought with a junction block under the bonnet. Can't complain too much as it was free.  So that out the way. The wastegate and its many flaws. Regardless I'm going to have to replace it. Regardless all the link pipe will have to come off to weld the new v band on for whatever new gate I choose. Decided that best way to rule out the gate altogether was to weld the hole shut in the manifold then sort it properly once its off.. As you can see it's been leaking badly across the vband face  So knocked up a little blanking plate to weld in and block it off.. I know it's slightly backwards way of doing it. I know I'm in a way making more work for myself. But I just want it to boost. And if I've ruled out the wastegate altogether it will either make all the boost or it still won't boost but il know it's not that...  This is where it went wrong.. my grinder is nakerd. You have to give it a shake to make it come on sometimes. My boss figured it was dangerous so ordered me a new bosch professional one.. which I duly left at work... Just about finished tidying the blanking plate up with my old one and it went off. Then came alive and fired out my hand trying to take end of my finger with it at same time (before landing on garage floor and continuing to chuck itself about)... Once I'd restrained the runaway grinder I looked at my finger and thought Oh cock haha.  Put my big boy pants on. Rinsed the blood away. Quick running repair and were back at it  With finger repaired and plate made I welded it into the outlet on the exhaust. It wasn't pretty (turns out having the trigger finger taped up makes welding difficult) but it should be air tight. Gave it a wipe of exhaust paste on the outside for good measure. And that's your lot. All that's left to do now is give the car a test drive and see if the boost has returned from its holidays. Was too late to try last night so all being well when I get in from work today il give it a try (I'm sure torrential rain is the perfect weather for testing a rwd v8T with no traction control and potentially limitless boost haha) Cheers |

| |

|

|

|

|

|

|

|

I wouldn’t weld directly onto the exhaust, you’ve got a flange, I would invest in a V clamp. Then cut a circular disc out that is the same size as the waste Port and clamp it on, that way you can easily take it off. You wouldn’t have to grind it off when you find that is the problem. Can you hear the turbo spool up, it should start at around 3k. Then start to get boost around 3 1/2 k unless you’re on high load, when it will start boosting at about 2 1/2 k . We have got roughly the same sort of set up, I wouldn’t delete my Waste gate but there again I know mine is boosting. As this way there is no way to reduce the boost. Even though mine is still in development stage I’ve seen 17 psi boost at 4000 rpm, even a light throttle you see 7 psi at 3 1/2 k and that builds very very quickly. If you were to completely blank off the wastegate and this was your problem, taking out for a drive will boost extremely quickly. Might build too quick for you to take your foot off the throttle and damage your engine. There again if you have a decent dump valve, ie Forge, thats Capable of dumping that volume of air, then that should, should, stop or at least limit any damage to the engine. With my original set up I had a branded normal dump valve, but this couldn’t dissipate the volume of air quick enough. So every time the car saw any boost and I change gear, it couldn’t do anything with the volume of air and as a result it always blew a hose off.

After doing some quick maths I realised what was happening, and the only way to solve it was to get a bigger dump valve. So looking round the best one, and the best price, was the forge 52 mm dump valve. This operates very quickly and as it is 2 1/2 inches in diameter it has the capability of getting rid of the massive volume of air that the turbo can produce, even when we are hitting the 17 psi of booze. |

| |

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

|

|

|

It's a bit late now.. it's welded haha. I know it's not the "right" way of doing it. But it's the only way I've got of knowing it's sealed without spending any money. The clamp that comes with the chinagate is awful so even if I made a disc that was big enough, perfectly circular and chamfered to match the shape of a vband I couldn't be sure it seals.

Not sure if I've made it seem like this is my new solution. It's not. It's purely to test it. If I drive off my road jab the throttle and I see boost on the gauge that's it. Test complete. I can order a proper turbosmart gate, pull the link pipe and turbo back off. Weld the new smaller vband on (going for a 50mm over the 60mm that's on it) and jobs done..

If I take it out and I've still got no boost. I can rule out the gate altogether and carry on digging (smoke test is next).. but regardless I know I've got no leaks pre turbo this way.

And I can hear boosty noises. Il try and get a vid next time I drive it on my private road. But it doesn't make any boost until around 5k rpm and even then it's only making 3psi. Which isn't right regardless

Thanks tho for the warning. I'm aware if I go and jump on the go peddle with no thought I could very quickly see rod removing levels of boost before I've had chance to shut the throttle. I've not got a dump valve on it at the minute. But it's on the list of things needed.

Cheers

|

| |

|

|

shyam

Part of things

Posts: 162

|

|

Aug 25, 2020 12:14:27 GMT

|

|

Hi mat88, awesome build dude, that's a big curse word OFF turbo aint it haha.

As for the troubles you are seeing with boost, I'm no expert but you checked for boost leaks? Also, have you tried 'spinning' the turbine shaft inside the turbo to see how 'freely' it moves?

Are you seeing any oil leaks?

Do you have a boost controller installed?

Any smoke from behind? if so, what color?

I'd also do a spray test to see if you have any leaking gaskets...

|

| |

|

|

mat88

Yorkshire and The Humber

Posts: 1,542

|

|

Aug 25, 2020 13:13:45 GMT

|

Hi mat88, awesome build dude, that's a big curse word OFF turbo aint it haha. As for the troubles you are seeing with boost, I'm no expert but you checked for boost leaks? Also, have you tried 'spinning' the turbine shaft inside the turbo to see how 'freely' it moves? Are you seeing any oil leaks? Do you have a boost controller installed? Any smoke from behind? if so, what color? I'd also do a spray test to see if you have any leaking gaskets... I've checked everything visible boost wise all clamps tight hoses in tact etc. Next plan is a smoke test/pressure test to confirm. Shaft spins lovely and free no play and zero smoke out the back (was out the front until I changed the exhaust Friday).. Boost controller is installed but all its values are currently set to zero in ECU so it does nothing (plus I tried it with it plumbed out and it made no difference) I've sprayed the hole top of the inlet with brake cleaner with it running. Does nothing at all to the rpm. That's not to say I've not got a leak. But it's certainly not leaking in vaccum. I'm really hoping all the issue I've had are wastegate related but the proof of the pudding will Be in the test drive later haha And cheers. It's been a bit of a long job. But it's getting there haha |

| |

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,883

Club RR Member Number: 39

|

|

Aug 25, 2020 14:14:06 GMT

|

|

If you have a system that requires a wastegate diameter capable of dumping large volumes of exhaust gas to prevent overboosting surely the small leaks you have discovered would have had no profound effect on the ability to produce boost if the turbo was 100% right. Could it be that exhaust/intake compressor wheel is wrong for the housing / your particular application? Can upstream exhaust gas pressure be used as an indication of the compressor wheel/housing match being right?

|

| |

|

|

|

|

|

Aug 25, 2020 16:05:29 GMT

|

If the turbo is an HX 50 holset then you might not see sufficient boost occur before about 6000 rpm. As these turbos with design for about 12 L truck. The turbo I’ve got fitted to my Lexus V8 was for a 8 L truck. Where you see boost start about 1 1/2 thousand rpm. Bearing in mind that the car engine is half the size of the truck, so the gas flow will under be half the amount. You expect to see the boost start at over twice the RPM of the truck. A 4L engine revving twice as high it should give more or less the same gas flow as the 8L engine at half the revs. mine does start to spool at about 3 1/2 of rpm and boost is on by 4000 rpm. Looking at the holset Data, they recommend that the HX 50 turbo is suitably up to 15 L engine, so with that in mind, an average of 12 L then your engine would have to be revving three times is high. So this would be around 6000 rpm to start the boost. A lot of people do use a holset turbos but I’m sure it’s normally the HX 35 as it is a smaller and produce boost low down the rev range. Remember this is not an exact science, as the gas flow on a diesel engine is far higher than a petrol engine due to their design. www.myholsetturbo.com/holsethx50.html |

| |

Last Edit: Aug 25, 2020 16:09:18 GMT by Bullstarz

“It Doesn’t Feel Pity, Or Remorse, Or Fear, And It Absolutely Will Not Stop, Ever, Until You Are Dead!”

|

|

and even tho the screamer is welded shut. The other end were the vband meets the gate is blowing too!! Is this combined enough to stop it spooling? Who knows. But it's certainly not going to be helping!!

and even tho the screamer is welded shut. The other end were the vband meets the gate is blowing too!! Is this combined enough to stop it spooling? Who knows. But it's certainly not going to be helping!!

)

)

think the wind was blowing the gas away as it was definitely better if I used my body to block it but cramped up under a car with my one good shoulder it wasn't always possible.

think the wind was blowing the gas away as it was definitely better if I used my body to block it but cramped up under a car with my one good shoulder it wasn't always possible.

haha

haha

... First things first the flat battery. Is the battery as expected dead. Connected my tester up and sure enough. Well.. yeah.. it's nakerd! So it may be going to the boot sooner than I thought with a junction block under the bonnet. Can't complain too much as it was free.

... First things first the flat battery. Is the battery as expected dead. Connected my tester up and sure enough. Well.. yeah.. it's nakerd! So it may be going to the boot sooner than I thought with a junction block under the bonnet. Can't complain too much as it was free.