dom10a

Part of things

Posts: 184

|

|

|

|

|

Great cars. Had an FB with TWR kit, loved it. Glad you've got that nasty oil out of the engine. I do wonder how much longer the engines all would have lasted if they were maintained as Mazda intended! I've had 4 rotaries (10A, 12A, 13B, 20B) and all of them had what looked like crude oil in the sumps on the first oil change.

If you're thinking of changing the shocks, can definitely recommend fitting some Konis. Made a big difference to mine.

|

| |

|

|

|

|

|

|

|

May 12, 2020 19:17:39 GMT

|

Well today was a very disheartening days work. I was fairly optimistic that the rust wouldn't be 'too bad' but after letting loose with the wire wheel today, I've been disabused. The current goal is to get the entire rear end back to bare metal & then a coat of Electrox zinc rich primer to protect it while I carry out the repairs. I hate working on rusty, dirty and flakey metal, so I'd rather just get it all out the way now & then have a nice clean surface to work to. First though I had to get rid of the lower trailing arms, I did my best to get them out using normal means, but it wasn't happening. Angle grinder it is then.  I carried on the strip down of the rear end, almost got everything now. Handbrake cables look quite nice.  Fuel tank spider is also out, these fuel lines are seriously shot. Lots of rust.  Also attempting to depin my number plate lights resulted in this. That will need replacing so I just cut them off for the moment, I'll splice in new wires later.  The lower bumper / valance / trim panel needs work, it was coming away at the left, had some holes in it & generally needs sorting out. Since its just held on with a few spot welds and some tacks at the top I decided it was easier to remove it completely.    With it removed from the car I can do a much better job on it, as well as removing all the rust from the back side. It also gives me better access to other areas that need attention.  What you're seeing here represents probably half a days solid work, wire wheeling, grinding etc the rear bumper area back to pretty much bare metal. There are areas that need repairs, but its not too bad. Lots of box sections to trap water and salt though.   Finally I blasted it out with compressed air, hit it with brake cleaner & gave it a coat of electrox. Will dress it back in areas that need welding of course.  Finally I started on grinding back the wheel well on the nearside. This is where it got depressing, only got two photos, but they tell a thousand words.   Not only is the sill completely rotten, but some previous owner filled them with tons of goopy filler, you can make it out in the photo. I also started grinding back the rust along the back edge of the rear arches & that's pretty pad as well, not sure if the best approach is to cut off the outer or the inner. I'd rather not cut out any body panels until I have replacements, I spoke to the chap who does the panels but he won't be doing them until after lockdown. |

| |

|

|

|

|

|

Dec 12, 2023 20:22:44 GMT

|

Time to ressurect this thread, from the dead. Its kind of hard to believe that its been over 3 years since I last posted on this thread, I've no idea where the time went, other than, it flew by!

After the last update, I had pretty much decided that I needed some help with the metal work, I can't weld to sheet metal standard (or at all some would say), the car had a shedload of rust, and I was at a bit of a cross roads.

The engine was appalling on fuel, fun, but very slow, it was also getting towards the rebuild stage. Longer term I needed more power, but 13Bs are a small fortune now, and you really need a turbo to go fast, again lots of money, and then to get it to the ground I would need a bigger rear axle, bigger wheels in a stud pattern that is very hard to find, bigger brakes, etc. In the end I decided to go a completely different way.

I'd been toying with the idea of a more modern, fully independant, double wishbone setup for a while, and while I had the vision, I didn't have the fabrication ability, nor the workshop space and equipment to make it work. I spoke to a few companies that specialise in big fabrication jobs on cars, most didn't respond, a few did but didn't fill me with interest 'yeah we can do that, no problem', finally I was able to speak with a bloke as crazy as me, who had a workshop in Lincolshire.

A lot of to and fro ing and maybe too much inspiration from Project Binky, we settled on a scope of work:

Chop the rear out & fit a Mazda MX5 fully independent rear subframe and suspension, do some chopping at the front to fit an MX5 tubular subframe that I had already purchased from Claire at CrapEngineering.

By carefully jigging the suspension before it came off the donor MX5, we could ensure that we would get the geometry perfect when fitting it to the RX7. Or RX7.5 as it will hence be known. The MX5 as well as having great suspension already, had an identical track width, and nice features like Rack and Pinion power steering, thousands of wheel options, big brake kits, brake pads, lots of suspension options. The engine at this point was yet to be decided.

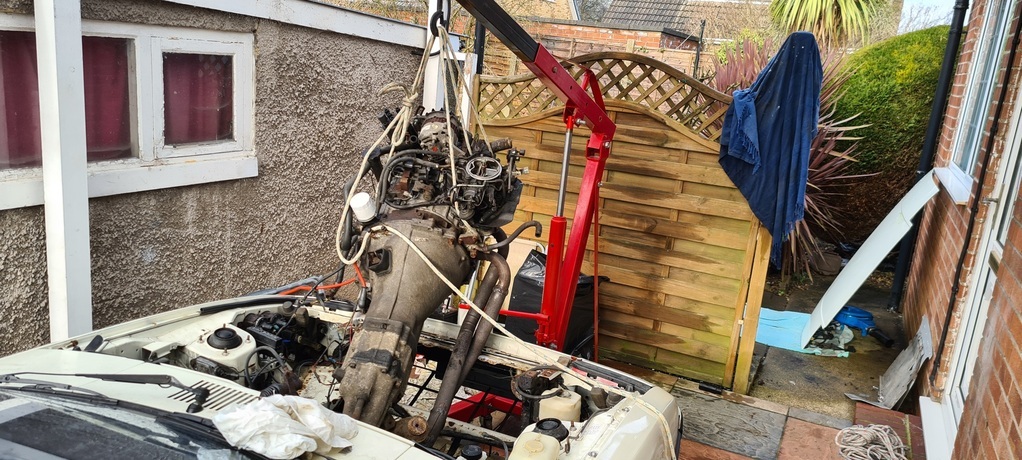

Anyway, the first step was for me to take out the old engine & arrange it to move to its home for the next 'year' (famous last words)  Sitting quite high! In its new home.

The first delay was the amount of rust, in true JDM fashion, there was a lot more than it looked like!

There was actually a heck of a lot more, but I'd be at it all day if I posted pics of it all.

So stage 1 was mostly just repairing the rot.

Again, not too much detail, this was all in 2021.

More to follow.

|

| |

|

|

|

|

|

Dec 12, 2023 20:47:22 GMT

|

To move forward, two things were needed.

- Donor MX5 - Engine For a donor, I sourced a MX5 NB2.5 that was rusting away, I think I paid about £600, most of which I recovered by selling the roof, engine and some other bits and pieces.

Since the 2.5 was the last iteration before the MX5 went to the newer NC model. it was the obvious choice, they had a bit more suspension travel, some trick bits like ABS (Which I hope to get working on the RX7) and semi decent brakes.

Next up was the engine, I dithered for ages. 13B, Renesis, RB25 etc.

In the end I went completely left field:     Its a 3.6 litre V6 LFX engine from a 2015 Chevy Camaro.

Despite being an American engine, its a really quite advanced powerplant, direct injection, all alloy, and producing 323hp and a load of torque. Safe to say, it should be enough to move this little RX7 at quite a pace.

Especially with a good exhaust and no cats fitted.

I managed to source it from an lithuanian breaker, with 40k miles on it, I think it was around £1400, sadly I got smashed by HMRC when it got imported, the engine was off an auto, which means I needed to source a gearbox seperately.

It may also cause me a wiring headache later on, but I'll come back to that.

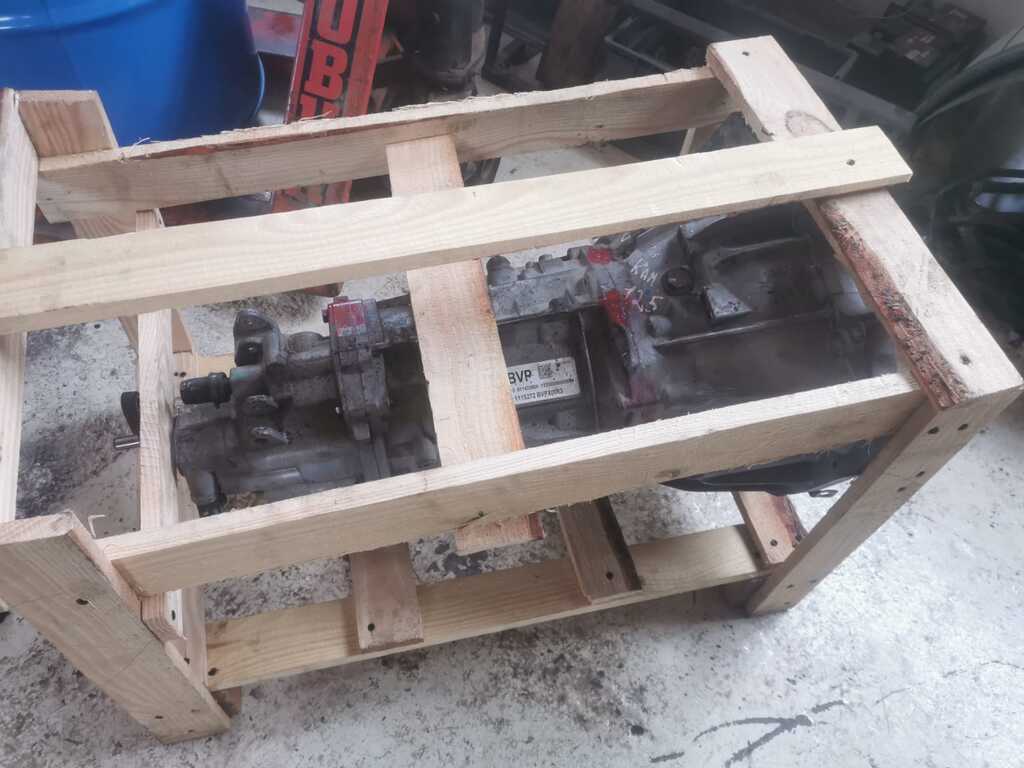

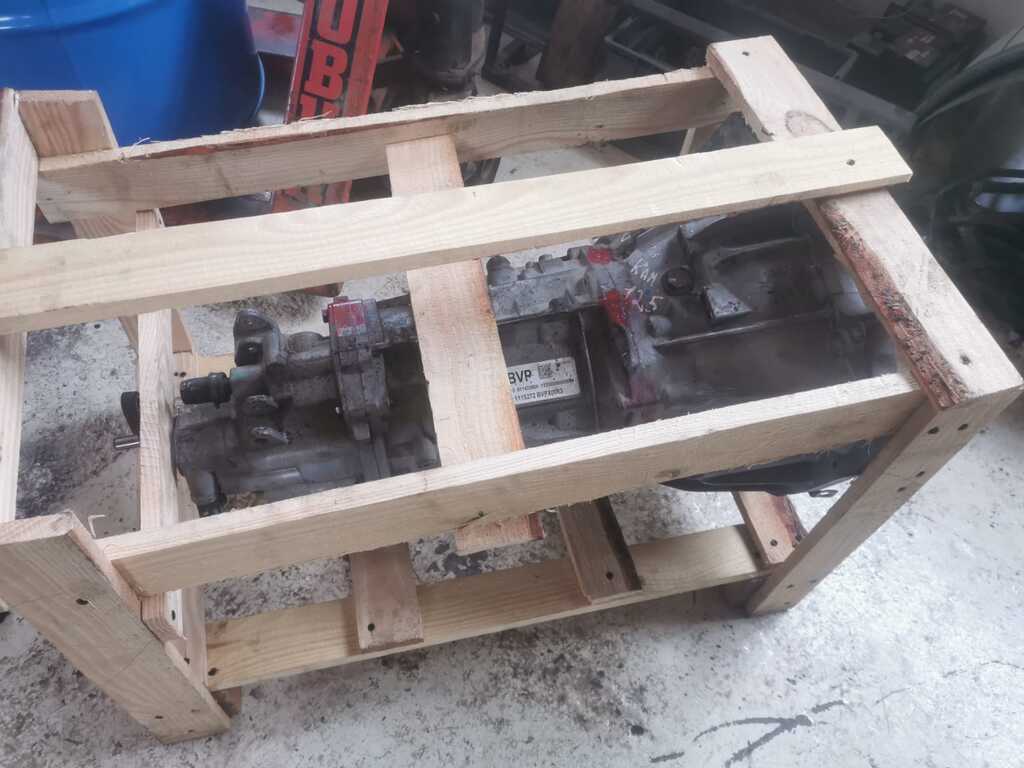

For the gearbox, the standard for this was an Aisin MV5 or MV7, apparently they are awful boxes, but as it turned out, I couldn't find one.

In the end, & thanks to a lot of advice from some helpful American owners, I sourced a Tremec 3160 transmission, which with some different parts, should fit the engine nicely.

For the sake of continuity I show it here, but the engine and gearbox were bough a year and a half apart.

So all being well, the end result will be a 323hp V6 RX7, with a proper independant suspension that can put down the power, 6 speed gearbox and somewhat decent economy.

I know to some that taking out the rotary is sacrilege, but the 'purity' of this car is long gone anyway!

|

| |

|

|

|

|

|

Dec 13, 2023 14:22:02 GMT

|

|

My first post.

The GM high Feature line of motors are very under rated. They are light, give a fair bit of HP and torque and are not that complex. I have installed a LY7 (port injection) into a Porsche (now that is sacriledge) with a few mods and stand alone ecu and expect around 240kw at the flywheel.

They sound and feel a bit incipid in the Holdens, Chevs, Pontiacs, SAABs, Suzukis, Opels, Alfas etc they were built for but with long tube exhaust manifold, 3" exhaust and a bigger throttle body and intake sound and feel far more sporty. I also put in a lightened flywheel which helps as the standard is better used as a boat mooring.

If you need any help with the electrics pm me as there is not alot of info around. Took me a fair while to sort it all out.

Cheers.

|

| |

|

|

|

|

|

Dec 13, 2023 19:38:48 GMT

|

jaffar Thanks for the kind offer, I may have to pick you brains, although I'm not sure how similar the LFX is to the AY7, direct injection,returnless fuel setup, cam phasing etc. There's some good info online, but of course being in the UK, its always a pain finding parts etc. Just a note, I keep using 'we' when I write this, but if its fabrication then its mostly the guy I have doing the complicated stuff.  First up, quick sanity check too make sure that it all will fit.

Ground clearance should be OK, I won't be slamming the car, and I have the option of a shallow sump if it presents an issue. Other than hood height, there's a surprising amount of room in that bay, note how power steering & AC pumps can be preserved.  Off camera a chassis jig was made, it involved a perfecly flat & square base, and then various bolt on bits that would copy the pickup points for the MX5 suspension in order to transfer them to the RX7.

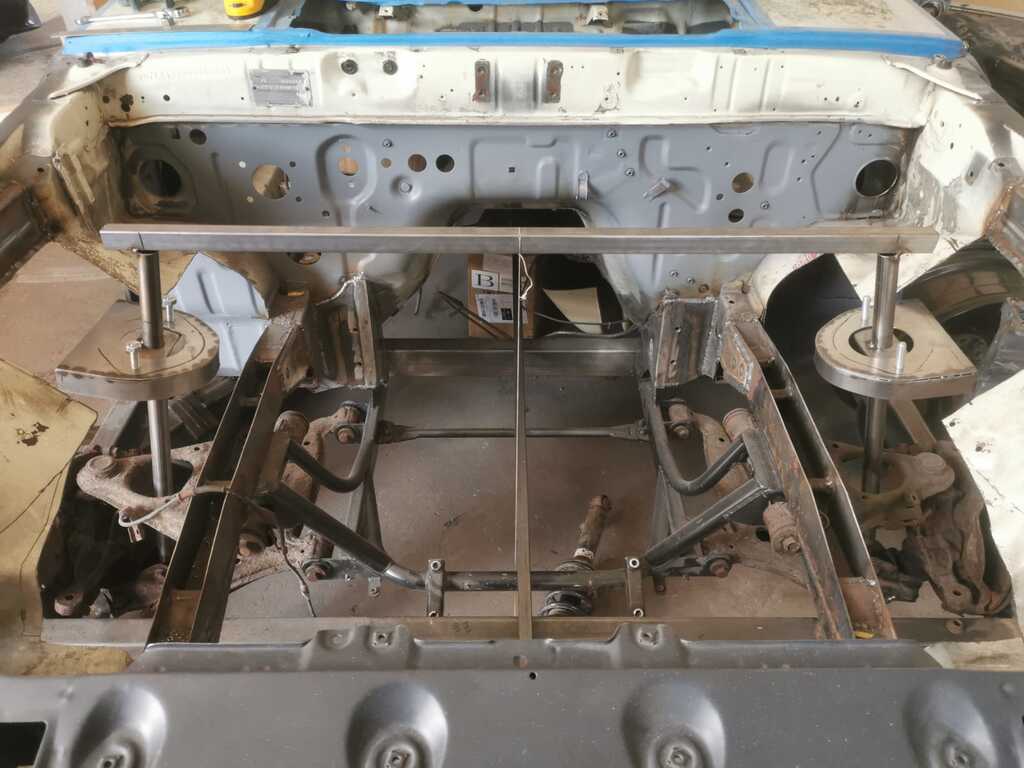

This would allow the subframes & other pickup points to be in the exact geometry that Mazda intended them, including front in relation to back, esentially allowing the suspension to be located into the RX7 & then the monocque adapted to fit. Time to look at the rear suspension, first off, we go past the point of no return, by cutting a rather large hole in the boot.

You can see the chassis jig will locate the rear subframe.

Unfortunately as you can see in later pics, although we actually can lower the boot floor a litte, we do loose the rear seats, as the subframe encroaches on that space.

Not that any adult could fit in them, so no real loss.

You can start to see how this will all work.

Strut tops are surprisingly low on an MX5.

Maybe later we will see if we can increase suspension travel (or at least shock travel), but for now, we have enough to be getting on with & can leave well alone.

The points will be reinforced later on in the build.

|

| |

|

|

bstardchild

Club Retro Rides Member

Posts: 14,975

Club RR Member Number: 71

|

|

Dec 13, 2023 23:50:38 GMT

|

|

Well that didn't go in the direction I expected when I originally read the thread - Interesting project twist - good luck

|

| |

|

|

|

|

|

|

|

Well that didn't go in the direction I expected when I originally read the thread - Interesting project twist - good luck You and me both! I've got to be honest, if I could start again, I probably wouldn't do it. Its been an over 2 year slog. In hindsight, I would have been better building a large garage that I could work in, at the moment all the work I do at home is on the driveway or under the carport. I'd like to learn to weld properly, and somewhere inside in winter would be great! Anyway its getting close to driveability, and I think its turning out good. (I'm still catching up with photos) |

| |

|

|

|

|

|

|

|

|

All the same including 4 cam VVT and return less fuelsupply. The only difference is PI v DI and the LFX has one exhaust port rather than the normal 3.

You appear to have more room in the engine bay particularly around the heads. I had to trim the sump and pickup to get it all to fit due to height restrictions.

|

| |

|

|

|

|

|

Dec 20, 2023 19:42:41 GMT

|

I had intended to do a post a night, but I got sidetracked. Anyway, moving on.

With the rear end in place as it needed to be, the front was next.

To accomodate the engine & free up space, instead of using a standard subframe for an MX5, I got a tubular one from Claire at Crapengineering.

It came without engine mounts.

Unfortunately Mazda had designed some frame rails in the way, so they had to go.    With that done, the new frame rails could start to take shape.

Various sheet metal constructions were made to get it all to fit nicely, this is just a few photos, but it of course represents a lot of work. (months in fact)    With the rough height of the suspension set, its obvious that the existing shock towers are too high, so they also had to get chopped.

This is very much an 'oh curse word' no turning back moment.

|

| |

|

|

|

|

|

|

|

Dec 20, 2023 19:49:16 GMT

|

Again, this is months of work, quite compressed.

With the frames in place, reinforcement in (off camera), the new strut tops and sheet metal work could start to take place.

Andy did a really fantastic job here, the welds can be smoothed in when the engine bay is painted, but i'm happy with how it went, as I wanted a relatively stock look.

Still additional reinforcement to follow in the area inside the wheel well.

Nice to see wheels on the car and the car on the ground!

Reinfocement tubes were welded into the rails. The rails will eventually be capped, but for now it was really starting to take shape.

|

| |

|

|

79cord

Posted a lot

Posts: 2,617

|

|

Dec 20, 2023 21:14:34 GMT

|

|

Lots of impressive work, though using complete MX-5 floorpan looks tempting afterward!

|

| |

|

|

|

|

|

Dec 23, 2023 11:18:31 GMT

|

Lots of impressive work, though using complete MX-5 floorpan looks tempting afterward! As much as I'd like to take credit, all of the fabrication is done by someone better at it than me! I'll be taking over for the final finishing, brake / fuel lines, electrics, etc.

We had considered the floor pan, but it wasn't really suitable, it made more sense to jig the suspension in the correct location & then build out to it.

|

| |

|

|

|

|

|

Jan 19, 2024 14:27:22 GMT

|

|

cracking route your are going with the car, and the fab.

was reading the other day there is some platform sharing and componentry between the NC mx5 and RX8. so in a tenuous kind of way, seems fitting

|

| |

|

|