|

|

|

|

|

|

I remember going in school French exchange and the family I stayed with had a Twingo in that colour. Quite liked it’ll though I remember looking at the rear seat and it looked really comfy and sculpted So I sat down waiting for a nice supportive squish. Wrong. Sculpted seats but rock hard. The French are strange.

|

| |

|

|

Paul

Posted a lot

Posts: 2,014

|

|

|

|

My vote goes to more poke but even smaller wheels so tyre diameter is less than the arch could reach. I'm thinking the same thing...ideally some dinky 13s. Surprisingly hard to come by reasonably priced ones though... |

| |

|

|

|

|

|

|

|

My vote goes to more poke but even smaller wheels so tyre diameter is less than the arch could reach. I'm thinking the same thing...ideally some dinky 13s. Surprisingly hard to come by reasonably priced ones though... Yes all the cool 13” stuff seems to be 4x114.3 and too low offset for adaptors |

| |

|

|

Paul

Posted a lot

Posts: 2,014

|

|

|

|

So I raised the rears 1/2" up the spindle this morning, went for a proper drive. Now the rears only catch slightly on the worst bumps and potholes...I can take that.  Death rattle at 55ish totally gone, minor wobble at 75 akin to wheels being slightly out. Tracks slightly right, which will be down to me doing the tracking by eye and comparison to the old rods as best I could. Plan is to replace the CV joints next week then get it professionally tracked next week. All in all a successful test! |

| |

|

|

Paul

Posted a lot

Posts: 2,014

|

|

|

|

So this morning's mini-project was twofold... 1) Fix the 12v socket at the front. Since I'm still using the speedo on my phone (I can't do kmph/mph conversion in my head and there are lots of cameras around here) I really need a 12v socket to keep the phone topped up.   I tried to clean up the corrosion as best I could, but to no avail...I wasn't too fussed though as I knew I had a spare 12v socket in the garage from another project. Not the most elegant solution, but it works.  2nd job was to fit a rev counter - these never came fitted with one but a) I had one in the shed from my old K11 Micra project (there's a thread on it somewhere in RR). So it wouldn't cost me a penny. b) I was curious as to what the engine was doing.  Identify the negative wire from the ignition coil, quick test - result! Now I've seen a rev counter fitted to one of the vents so I'd like to investigate that...I wasn't keen on drilling holes in the dash to fit the wires, so here she is on the shelf over by the passenger side, wires fed through a pre-existing hole in the speakers.  It'll do for now and - like I say - didn't cost a penny! |

| |

|

|

Paul

Posted a lot

Posts: 2,014

|

|

Aug 11, 2020 19:01:24 GMT

|

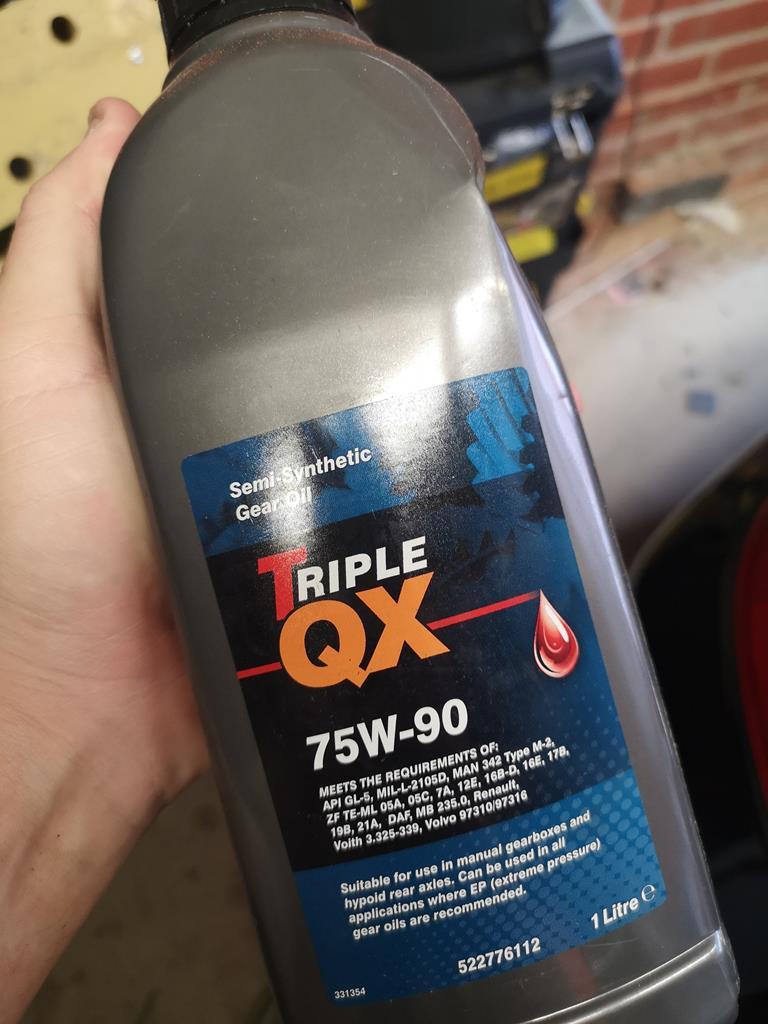

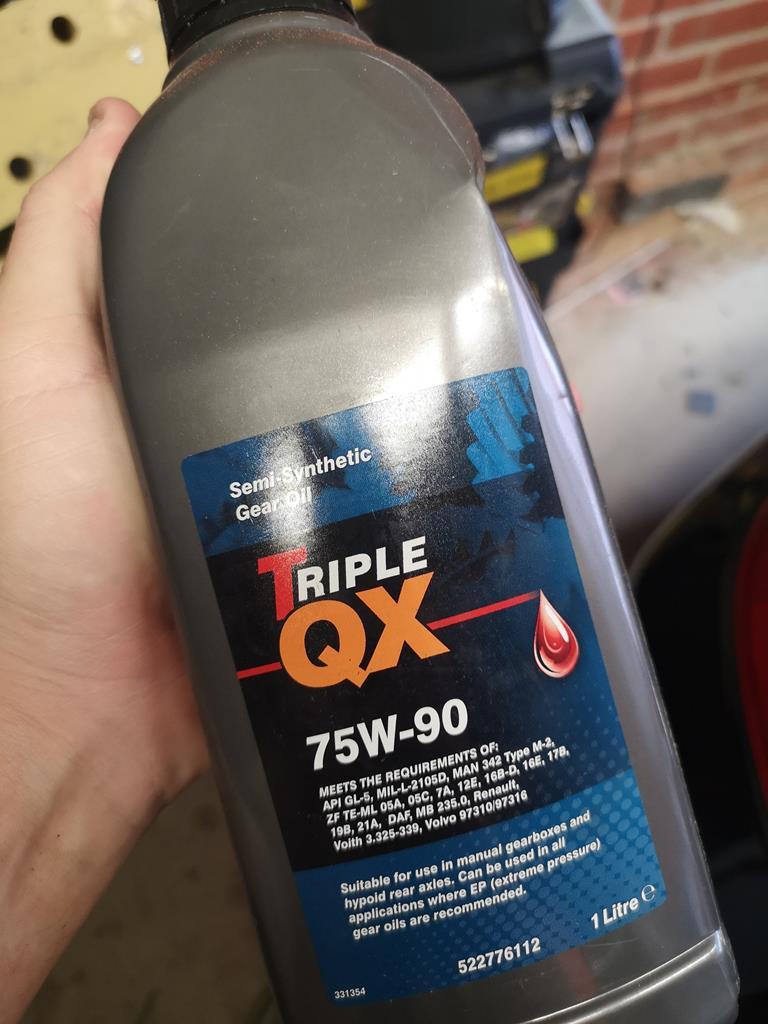

So today was devoted to changing the driveshafts as this looked like a lot less hassle than changing the CVs Now Twingo parts were about £100 and had to come from Germany...I didn't like the sound of that. Renault Clio Mk1 parts, on the other hand...£32 the pair 😁  Beautiful. ECP probably paid that for the two separate DHL deliveries they used to get them here. Disassemble the suspension knowing that it's all new and only just bolted together, so came apart easy. Driver side is held in with 3 13mm bolts and a weirdly reusable housing, and Google suggested I might lose a little gear oil.  Balls. If you don't know, well used Gallic gearbox oil stinks. Everything I've touched stinks. I stink. The drive stinks. Also, these boxes hold 3.5l of oil, so off to ECP in the afternoon...  Undeterred, passenger side just slid right off the splines on the gearbox...which it isn't supposed to do. There was a split pin missing 🤨 Reassembled with the new split in, bolted back together... I'll get her down in the morning and tighten them hubnuts good. Also got some new bolts for the Borbets, they'll make a whole world of difference to the appearance I know... will update tomorrow 😊  |

| |

Last Edit: Aug 11, 2020 19:02:13 GMT by Paul

|

|

Paul

Posted a lot

Posts: 2,014

|

|

Aug 24, 2020 12:26:07 GMT

|

Decided to add a bit of negative camber to the back wheels as the arches were still catching the tyres despite my arch rolling, bashing and hammering. So off with the rear hubs, 4x13mm bolts on each side. Doddle.  curse word. In total 5 out of 8 of the bolts snapped. Clearly they've been locktited in and whilst I could get the wire brush and oil on the back of the top ones the bottom ones were inaccessible.  This was last Thursday...3 of the 5 left a lot of thread so I ordered a stud extractor for those.    This is what success looks like.  Oh come on. eBay return initiated. Buy Bluespot, buy twice. Ordered a Draper one now at twice the price. Now I've also wanted to learn to weld, never a better time than the present. The two really short ones haven't got enough meat for a stud extractor but will take a 13mm nut. So it looks like my first welding job will be sticking a nut to those threads. Managed to snap a lug on the back of the lights for my 911 after taking them out for a polish and it's not even lunchtime yet. FML. |

| |

Last Edit: Aug 24, 2020 12:45:31 GMT by Paul

|

|

Paul

Posted a lot

Posts: 2,014

|

|

|

|

Bolts removed, a little bit of rear camber added, and did somebody say 3 spokes?  |

| |

|

|