|

|

|

Oct 31, 2019 21:39:11 GMT

|

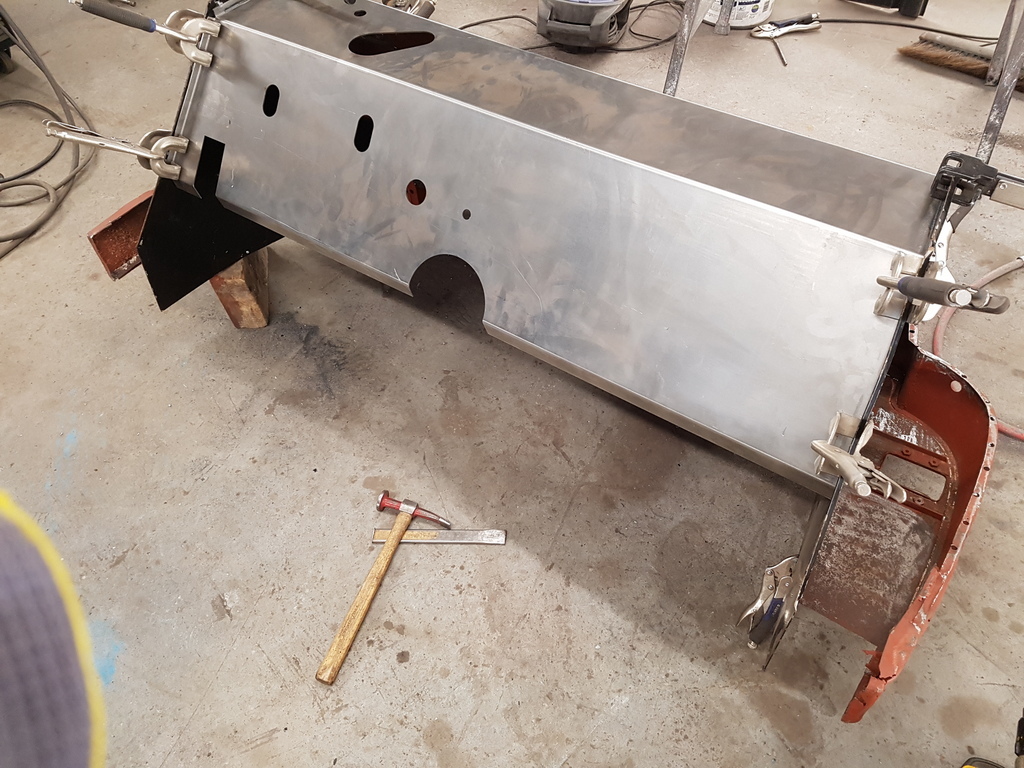

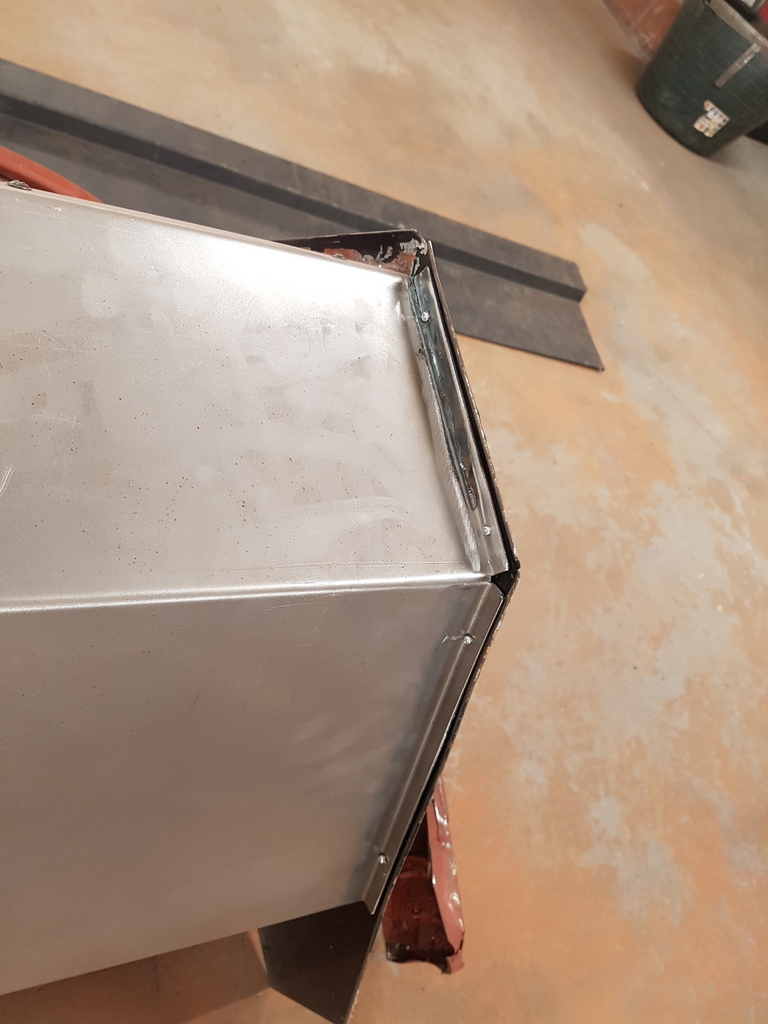

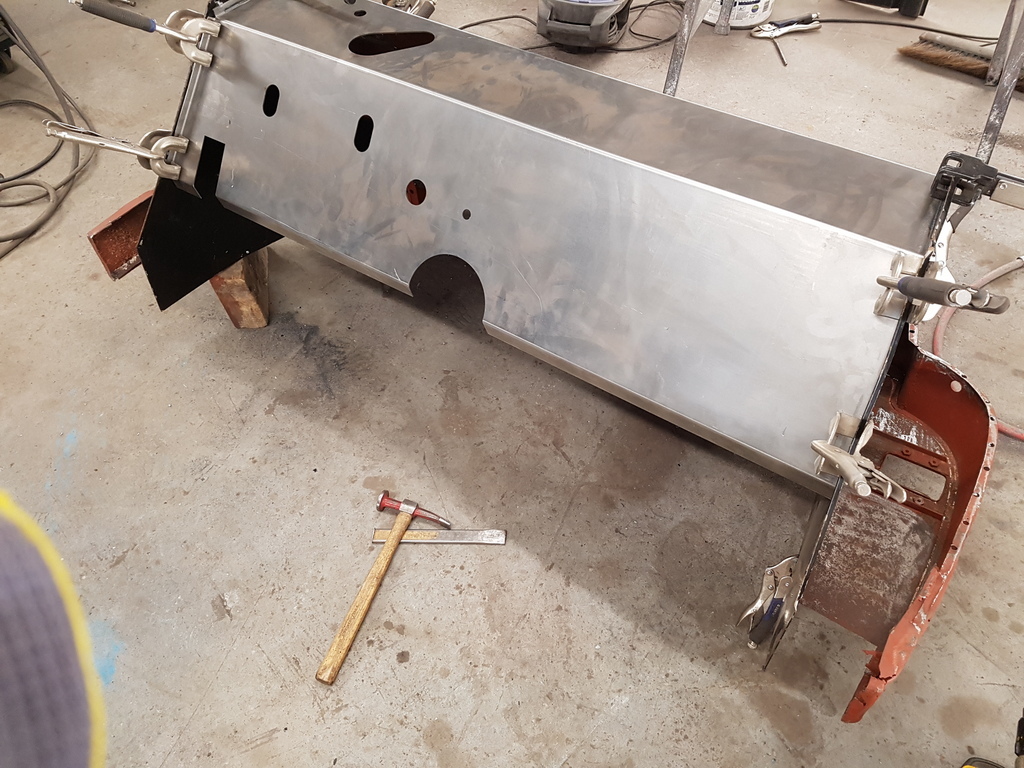

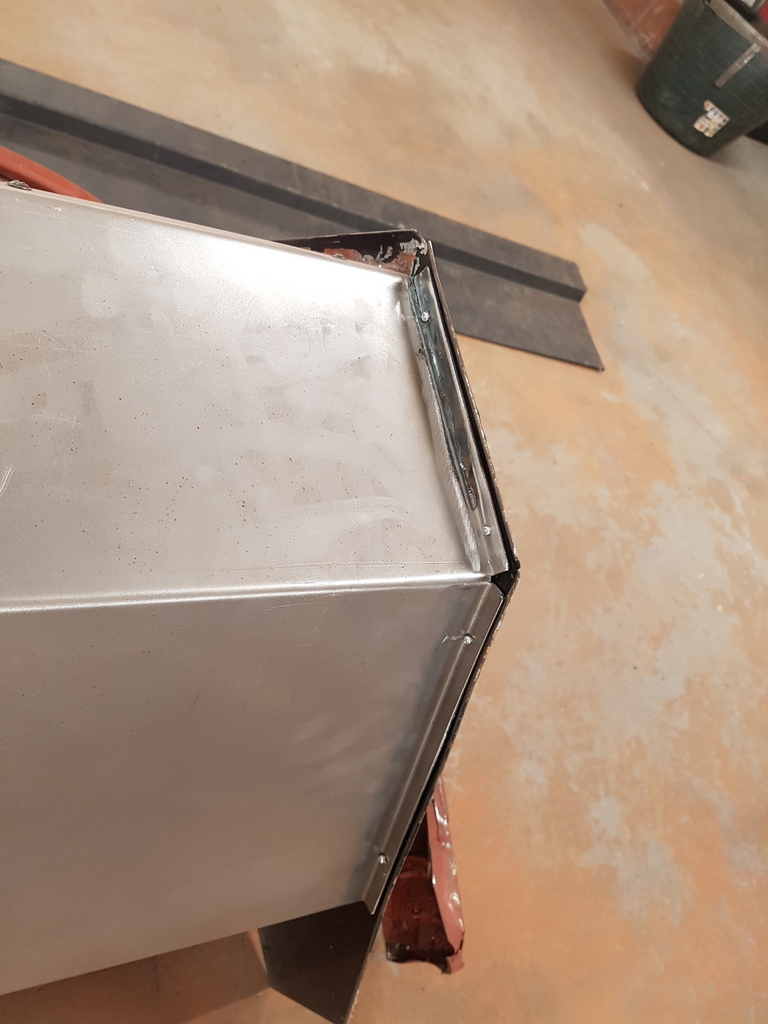

First piece of fresh metal let into the corner of he bulkhead panel where previous welds had burnt into the panel  It soon became obvious that I was going to have to remove the cross braces in order to get the side panels into position - so the spot welds were drilled out  First side panel clamped in situ  Then the second  Bulkhead face section going in  Lots of adjustments being made along the way - in some cases the panel is removed adjusted / trimmed and trialed again - but this may happen many times before you get every panel lining up with all the other panels - its easy to trim a little / make a minor adjustment and try again than what it is to become over ambitious and chop a lump out of the panel or hit it hard and distort it therefore just making the task a lot more difficult  Due to amount of panels involved and the fact that I wanted some rigidity to the bulkhead assembly I opted to do what the factory did upon original assembly and use pop rivets has temporary panel fastenings  Clamps - sometimes you just have to be inventive   Slowly but surely  I still need to make some adjustments to the floor panel to gain a better fit - todays exercise in trial fitting the panels represents several hours work - its not something that you can just throw together - The Jupiter was individually hand built and no two cars are the same - I am now within a 5mm tolerance - not bad for a bulkhead that has before today received a fairly hefty impact - however - I need to ensure that everything is true & square before anything gets welded up - the bulkhead is the critical point that dictates where & how every other panel on the car fits - get the bulkhead wrong and there is no chance of anything else lining up or fitting with the cars panels |

| |

Last Edit: Apr 6, 2020 20:36:16 GMT by Deleted

|

|

|

|

Darkspeed

Club Retro Rides Member

Posts: 4,882

Club RR Member Number: 39

|

|

Oct 31, 2019 22:54:22 GMT

|

|

Love watching the work you do but goodness me some of these projects you get involved in really serve to confirm my decision to stay playing with plastic cars.

|

| |

|

|

|

|

|

Oct 31, 2019 23:51:35 GMT

|

|

Wow !!!

|

| |

|

|

|

|

|

|

|

|

with eyes wide open.....

thats how I usually read through your posts, grumpy.

amazing...thanks for sharing one of the most important aspects of any metal work...get the initial shape wrong with an important assembly, and you will over complicate your life for the rest of the project.

the trouble is, experience, or lack thereof. Knowing when and where to take extra measurements, extra time with panel fit, extra disassembly with parts of the structure, ect, ect, ect.

Again, thanks for sharing your experience (s) ...it makes me feel so much smarter approaching the projects I have around here!

JP

|

| |

I know its spelled Norman Luxury Yacht, but its pronounced Throat Wobbler Mangrove!

|

|

|

|

|

|

|

with eyes wide open..... thats how I usually read through your posts, grumpy. amazing...thanks for sharing one of the most important aspects of any metal work...get the initial shape wrong with an important assembly, and you will over complicate your life for the rest of the project. the trouble is, experience, or lack thereof. Knowing when and where to take extra measurements, extra time with panel fit, extra disassembly with parts of the structure, ect, ect, ect. Again, thanks for sharing your experience (s) ...it makes me feel so much smarter approaching the projects I have around here! JP JP - Thanks for the comments - one of the critical points I keep missing off in my posts is having the guts / confidence to hack out several panels and start again - what I hope is that others can gain confidence through the threads of mine & the other talented owners of RR - Darkspeed quoting that he's happy that he sticks with plastic shelled motors but in my eyes underestimates his many excellent skills in working with the itchy stranded mat & resin stuff - Whilst I have rebuilt lots of steel bulkheads for classic sports cars before today I have never had a Jupiter bulkhead in this many pieces - so even with my experience I'm still learning - whilst I would not advise a project of this nature for someone just starting out in restoration there is no reason that once someone has gained some welding & panel fitting experience that they couldn't - the principles when listed remain the same and are quite simple - I don't really have any fancy bits of kit in my workshop either* - I was taught to work in old school methods with simple hand tools * Except for that fancy Cartar Glidemaster car lift that I now cant live without but every bloke should at least have one toy that they cant live without  |

| |

Last Edit: Nov 1, 2019 8:16:07 GMT by Deleted

|

|

|

|

|

|

|

|

Inspirational!

Hat is doffed.

|

| |

Proton Jumbuck-deceased :-(

2005 Kia Sorento the parts hauling heap

V8 Humber Hawk

1948 Standard12 pickup SOLD

1953 Pop build (wifey's BIVA build).

|

|

|

|

|

|

|

|

Great work as usual, the one thing I probably couldn't do without is also my 4 post lift, as I am getting older having the car at a comfortable work height and not rolling around on concrete floors is a great bonus.

Are you using some sort of jig?

When I did my series 2 landrover bulkhead I ended up building it up on the chassis to get it all square and aligned, off the car it just kept moving around (I was replacing the a pillars as well though). I'm wondering if there is some clever method you have developed?

|

| |

|

|

|

|

|

|

|

|

Fantastic to watch an expert at work- really enjoying reading through all your Jowett threads.

|

| |

1985 Volvo 760 "Jurbo"

|

|

|

|

|

|

|

Great work as usual, the one thing I probably couldn't do without is also my 4 post lift, as I am getting older having the car at a comfortable work height and not rolling around on concrete floors is a great bonus. Are you using some sort of jig? When I did my series 2 landrover bulkhead I ended up building it up on the chassis to get it all square and aligned, off the car it just kept moving around (I was replacing the a pillars as well though). I'm wondering if there is some clever method you have developed? Kevin - Its not worth using a jig due to the fact that the cars were hand built and the tolerances between the cars are too great to rely on a jig - hence my way is the same that you utilised for your Landrover - I will assemble the bulkhead structure but then use the chassis has the jig with the bulkhead mounted to it to true it up prior to welding but I also use many basic refences to get the structure to a 'Ballpark' prior to mounting to the chassis |

| |

Last Edit: Nov 1, 2019 19:59:10 GMT by Deleted

|

|

|

|

|

|

|

|

........and there's always the B.F.H in reserve... oh , or is that just me?

|

| |

'80 s1 924 turbo..hibernating

'80 golf gli cabriolet...doing impression of a skip

'97 pug 106 commuter...continuing cheapness making me smile!

firm believer in the k.i.s.s and f.i.s.h principles.

|

|

|

|

|

|

|

|

|

........and there's always the B.F.H in reserve... oh , or is that just me? Its probably just you but I have built quite nice reserve collection of such implements over the years - however this is a alloy clad / panelled car and you need to be careful - you cant just clatter away at it - but a length of 2" x 4" timber helps considerably  |

| |

|

|

|

|

|

|

|

|

Any word on when you get your preferred MIG back? John

|

| |

|

|

|

|

|

|

|

Any word on when you get your preferred MIG back? John John - They said 2 - 3 weeks and its probably that now so I will try to put a call in to them early next week - I have to say that its certainly missed - the difference between a transformer based machine (what I'm currently using) and an invertor based machine (being repaired) is very much night & day! |

| |

|

|

|

|

|

|

|

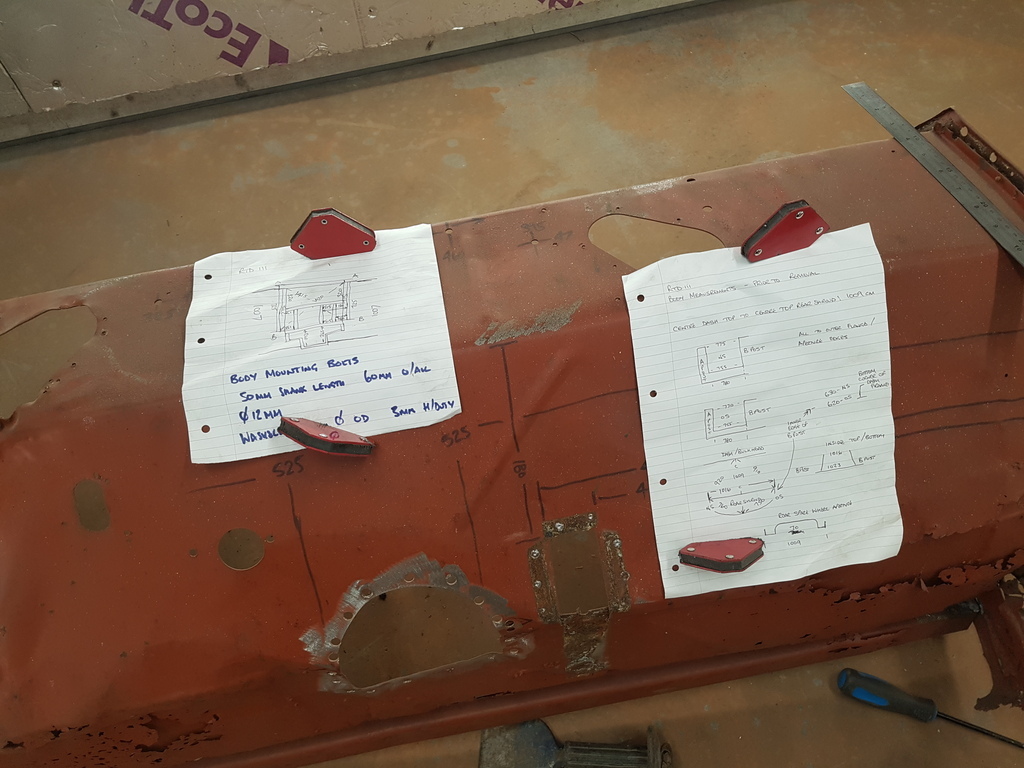

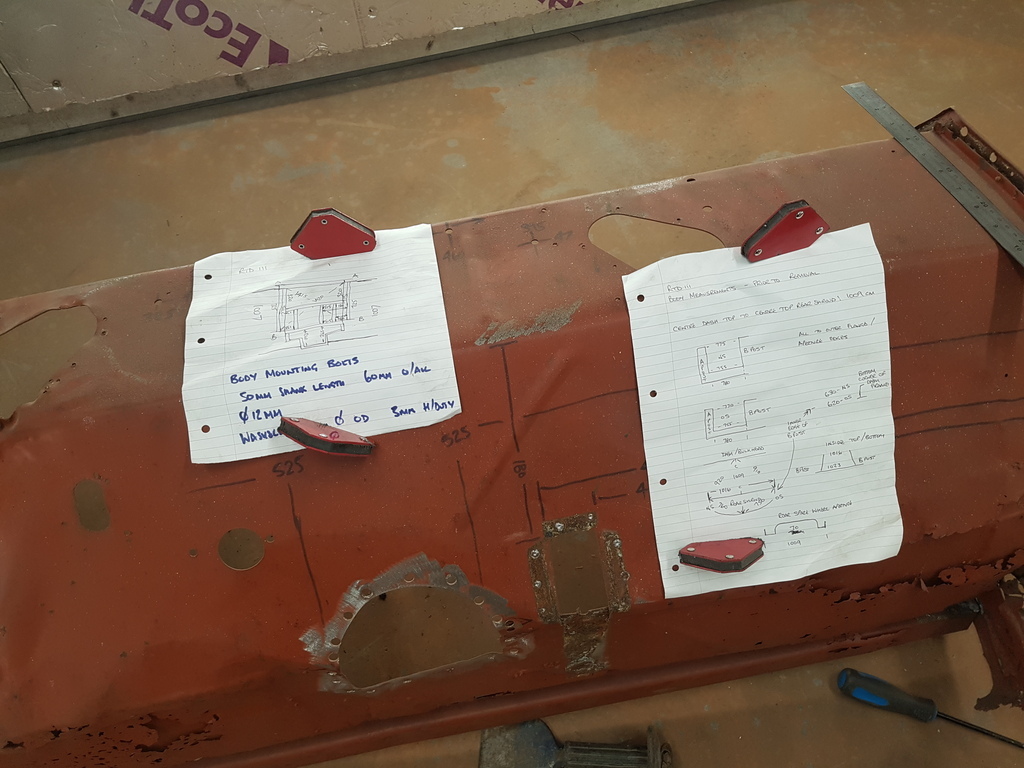

Sooo - Remember this one - well its still here and its next in the queue - I have been waiting for some additional panels to be made up & delivered but I now have everything to hand - onwards we go then  Need to get back on track  A few adjustments required before the floor section can be fitted  I'm using pop rivets & self tappers to trail assemble it has one structure  I made plenty of notes / measurements prior to pulling the defective panels off the assembly  Even marking the location measurements out on the original panel  It just needs to be neat & logical for you to refer back to - I also took hundreds of photos as it came apart  Floor panel adjusted slightly for fit  This is why we are not using the original one  A few pairs of long hand cramps are always useful  Now I just need to pull it square to get the diagonals equal in measurement  Then add some temporary bracing  Bracing complete  Measure  Measure  And measure again  Absolutely every other panel on the car relies on the bulkhead being correct - get it 10mm wrong and the net effect is that the body at the rear of the car will be 100mm out of tolerance - the bulkhead is the critical path for getting the bodyshell of the car to align correctly  Next job is make a new pair of body to chassis mountings up  The one on the nearside had completely dissolved in the dipping process  Fortunately I have a pattern - I shall make these up in the morning  I now have the rest of the panels that I require to advance the works - all supplied by the excellent Jowett Car Spares More tomorrow |

| |

Last Edit: Apr 6, 2020 20:41:36 GMT by Deleted

|

|

|

|

|

|

|

|

cushions plumped in preparation.....

|

| |

'80 s1 924 turbo..hibernating

'80 golf gli cabriolet...doing impression of a skip

'97 pug 106 commuter...continuing cheapness making me smile!

firm believer in the k.i.s.s and f.i.s.h principles.

|

|

nze12

Part of things

Posts: 193

|

|

|

|

Sooo - Remember this one - well its still here and its next in the queue - I have been waiting for some additional panels to be made up & delivered but I now have everything to hand - onwards we go then Then add some temporary bracing  It's amazing the uses you can put your old Meccano set to!  |

| |

1986 BMW E30 refreshed to original spec

1973 BMW E12 520 converting to Motorsport 530

1982 XJS V12 converting to 5 speed manual

Many landscaping projects overriding above!

Cogito cogito ergo cogito sum!

|

|

|

|

|

|

|

Sooo - Remember this one - well its still here and its next in the queue - I have been waiting for some additional panels to be made up & delivered but I now have everything to hand - onwards we go then Then add some temporary bracing  It's amazing the uses you can put your old Meccano set to!  Sure is - but doing it this way allows you shim / move a bolt hole / pack in / out any adjustment that you need to obtain the tolerances required  |

| |

|

|

|

|

|

|

|

cushions plumped in preparation..... Fresh cup of tea made, beer in fridge for later, settles in...  |

| |

|

|

eurogranada

Europe

To tinker or not to tinker, that is the question...

Posts: 2,556

|

|

|

|

|

No rest for the weary it seems!

But as a dedicated follower I don't mind...

|

| |

|

|

eternaloptimist

Posted a lot

Too many projects, not enough time or space...

Too many projects, not enough time or space...

Posts: 2,578

|

|

|

|

It's amazing the uses you can put your old Meccano set to!  Sure is - but doing it this way allows you shim / move a bolt hole / pack in / out any adjustment that you need to obtain the tolerances required  If that were proper Dexion it would look like a period repair! |

| |

XC70, VW split screen crew cab, Standard Ten

|

|

|

|