|

|

|

|

|

|

I feel the same in my elan while it's more than capable of keeping up with the traffic, there are so many LHD lorries around here and the motorways are so crowded I just don't feel safe, staring at a trucks wheel nuts with their exhaust exiting at head height is no fun, if I ever go to Kent (pretty much only route is M25 via Dartford) I take a modern or the Range Rover.

I have done several similar courses including with a police instructor, many useful tips but observation awareness around you and planning a contingency are as you say the main thrust of it.

|

| |

|

|

|

|

|

|

|

|

|

No different to riding a motorcycle... Everyone is entitled to their own opinion on matters; however I would guess that you have not been tasked with scraping the remains of RTA's off the road? The disability vehicle subject of this topic was not designed for high speed use. Its client base were, as its name implies, those with a disability and deemed to be suitable for being given appropriate transport. Often the driver would also require the use of a wheel chair and this item would also be loaded aboard, once the driver was installed. With only one door, this then meant that in the event of an accident, the driver's only means of escape was blocked by said wheel-chair. Therefore you ain't getting out very quickly. This was why if 'Trumpton' turned up, that was goodbye to the roof. Quickest way to remove the occupant; that is if they hadn't been ejected when the thing fell apart, which it invariably would. Motorbikes involved in accidents invariably meant that the rider would not be attached to their steed, no matter what speed they had been travelling at. So yes, a motorcycle also gives no protection, other than that worn by the rider; the invalid carriage was not designed for speed, and don't you think that it is interesting that they were removed from service and replaced with the present scheme, where those who qualify are now driving modern motor vehicles. I am fully aware that there are many other, older motor vehicles, that come nowhere near meeting modern day regulations, and your Land Rover is a prime example. Why else was production stopped? I also am a Land Rover enthusiast, now being on my 12th. such vehicle over the last 50 years. My latest one being one of the last 300tdi's; I wouldn't be with out it either. So it takes all sorts to make the world go round; just that I have seen the end result of these contraptions being pranged, together with a plethora of motor bikes as well. Not for the faint hearted, but ideal as a restoration project in order to maintain the UK's social history. |

| |

|

|

|

|

|

|

|

Needed to venture out today to get some more dog food which meant a trip right down the the south edge of MK. The Jag is massively too hot in this weather as the air con isn't sorted yet, Xantia is still at the garage and the van needs fuel. Will be taking the Invacar then. Think it's fair to say that the last couple of runs have helped confidence as I didn't hesitate to take the quick (if actually slightly longer) route straight down the A5 to Caldecotte then across to Walnut Tree from there, and the same route back. Again no issues to report though as any other owners will attest to, the CVT belt section does make a horrendous din at speed. I think that's something which adding some soft trim to the cabin will help massively as it's just white noise which just reverberates around the cabin horribly.  Oh, finally got around to actually fitting the offside gutter infill strip that I cut to size months ago, started to fit then realised I couldn't reach the far end in the garage.  Think it's nice to have something to break up the otherwise solid block of blue. Not needing your feet for anything frees up a lot of floor as cargo space...  When we got home I decided to give her a much needed wash. There were still greasy handprints and such like all over the car plus no small amount of sawdust everywhere. Despite being careful we ended up losing a bunch of paint from the engine cover.  Once it started peeling off the engine cover I just kept at it until the whole thing was stripped back. I don't think this is necessarily a bad thing. The rattle can paint job is still immaculate under there it looks like and I always had a far better finish with that than I got from the spray gun.  The datasheet for the paint I used stated that I didn't need to prime this surface, apparently it lies. The paint came off in sheets, almost like a vinyl wrap being peeled off. We lost a small bit from the nearside door too, only a tiny patch though. Think my response to this is basically *shrug* and "so be it." I'll stick to rattle cans in future to touch other areas in. Will mean I need to do the work outside and will cost more but the results seem worth it. Plus my compressor having died makes the spray gun kind of useless just now. I think my poor results with the spray gun are probably down to an inadequate air supply to be honest. I'm not bothered to be honest as I knew the paint job was never going to be a long term result. At least it's a complete panel that's done this so it's not *massively* obvious at a glance. |

| |

Last Edit: Aug 9, 2020 22:02:57 GMT by Zelandeth

Current fleet: 73 AC Model-70. 75 Rover 3500. 84 Trabant 601S. 85 Sinclair C5. 06 Peugeot Partner 1.6HDi.

|

|

|

|

|

Aug 10, 2020 23:24:02 GMT

|

Been one of those days. Aside from seeing 34C in the shade in our lounge which is a surefire was to put me in a bad mood, the fleet have been misbehaving. Firstly the Invacar while still driving perfectly decided to drop the pin out of the gear selector linkage for the second time since she's been back on the road.  Hardly the end of the world, and I really should inspect the belt anyway and check the tightness of the pulley bolts given we've covered a couple of hundred miles since that lot was apart now. I really need to find a proper substitute for the original roll pin and R clip. I'd hoped that using a locknut on a bolt would do the job, but as we've now lost two it's obviously not. Thankfully we were in drive when this happened and as the car weighs about as much as a postage stamp I just pushed it a couple of feet back out of the parking space when I discovered that I was lacking in a gear selector. I'll see if I can summon the willpower to sort that out tomorrow. Given I lacked a reverse gear I returned to base and grabbed the van to complete the errand run I was out on. When getting home I noticed diesel dripping off several points and that the back of the van was soaked.  The oil drain pan there is catching the drips I'd spotted. As far as I can see there's no sign of any leaks underneath. My guess is that the ridiculous temperature here today has just heated the air in the tank up enough to generate sufficient pressure that it's just forced it back out of the filler (which attaches to the tank about half way up and has a poor venting arrangement). The seal on the cap doesn't look too clever so I'll get a new one ordered. Obviously I need to look at the tank vent too...that involves dropping the tank though, which currently contains somewhere in the region of 70 litres of diesel. Obviously she's going nowhere though until I'm sure that's been resolved. Wanting to get something useful done I decided to have a crack at sorting the offside door on the Invacar. The window runner is knackered, the weatherstrip the glass sits in is 50% missing, and the top of the door skin and frame aren't properly anchored to each other which means the door has as much structural integrity as soggy cardboard. You can see daylight under the window frame too. On the plus side I had a spare window channel in stock which while not perfect was a lot better than the one on the car.  I had seriously forgotten what a massive faff this job is since I did the other door. It's not really difficult as such...just incredibly awkward and requiring things to be done in exactly the right sequence. Especially when you're trying to get the glass back in. You have to get both panes seated in the top runner, then position them into the bottom one and slide it into place as one unit. After the best part of three hours we're now at this stage.  The window runner now has a thick foam pad under it, the remains of all the original fasteners have been removed so it can seat flush with the door too, and it's loosely bolted down at both ends. Next step is to feed my hand into the miniscule gap to reach the end of the bolts inside the door cavity (there's not an opening under the black rail, you need to reach up from the one in the middle of the door, up around the latch actuator rods, door handle assembly etc, to thread washers and nuts onto the bolts then tighten the whole lot up. Oh, and reattach the window catches. The channel is at least reasonably straight, the old one was utterly mangled.  Hopefully this should vastly reduce the degree to which this door rattles and vastly improve the weather resistance. Need to track down some more window catches (think they're early Mini ones) as all but one of mine are cracked, then also need to track down a replacement for the window edge strip which should sit on the rear edge of the front window to keep draughts out. I've got the one on the nearside by the offside one was so rotten as to be useless. Really not a fun job...even when it's a sane temperature. Will be really nice to have it done though as being able to see daylight through the door really bugs me - plus the whole door rattles horrendously. |

| |

Current fleet: 73 AC Model-70. 75 Rover 3500. 84 Trabant 601S. 85 Sinclair C5. 06 Peugeot Partner 1.6HDi.

|

|

|

|

|

Aug 11, 2020 21:45:09 GMT

|

After the better part of three hours and my nearly passing out from heat exhaustion twice this morning, finally got the offside window runner sorted.  Which at first glance looks very like the last photo from yesterday - if you look closely though you can see how the window rail has now been evenly clamped down to the door top which has helped remove the slight bend it had in it before. For the sake of completeness, here's a "before" photo looking at the bottom of the window runner from inside the car (photo is of the nearside door, but they had identical issues).  Looking at the same spot now at the front and rear of the door:   The only thing I still need to do there is to put a blob of sealant in the end of the stainless steel channel so that water is forced to drain through the dedicated drain holes rather then just running out of the front or back of the channel, straight over the inside of the door. A bit of paint wouldn't go amiss either but that's a bit further down the priority list. The channel rubber is pretty knackered but is far better than what was in there before which was about 40% missing. This does at least securely hold the glass now, whereas the window panes could rattle both in the frame and against each other before.  Very much hoping that this is a job I won't need to do again. Not content with having lost half my body weight in sweat in the morning, I ventured back into the garage in the afternoon. My willingness to do anything besides hide in front of an air conditioner when it's anywhere north of about 20C outside is next to non existent under normal circumstances. I'm trying to maintain momentum with this though so dragged myself back outside. I've really been enjoying buzzing around in this little car the last couple of days now I think I'm starting to get a better feel for it. I don't want to end up putting off sorting things and ending up another year down the line with it barely getting used. Having got the door back together it was time to reattach the gear selector to the gearbox. This job is most easily done from underneath, though jacking the car up would have meant taking the car out of the garage and working beneath the deadly ball of death that is the sun today. Not happening. I wanted to inspect the pulleys, CVT belt and check the oil levels in the gearbox and diff - all of these things want the rear service hatch in the cabin out, so figured I'd just work from above like last time.  When the new pulley set was installed a few hundred miles ago there was quite a bit of surface oxidisation on the primary pulley, I'm glad to report that just normal use appears to have resolved that. They've both got a lovely satin smooth texture now which is exactly what you want.  Belt also seems happy enough. The manual states very clearly that cracking between the teeth on the belt will happen early during its life, is absolutely normal and shouldn't be considered a sign of impending failure, so I'm not worried about that. It still seems nicely pliable and there aren't any signs of fraying around the edges or anything like that.  It's really noticeable that before the pulleys were replaced that this whole area used to get covered in finely atomised belt material during any run. No noticeable deposits anywhere since last time I was in here though so that behaviour seems to have been purely down to surface corrosion on the old secondary pulley. The gear selector was originally attached to the selector arm on the box by a roughly 1/4" diameter roll pin, held in place by a split pin. I was missing this because the replacement selector I fitted (the original one in TPA was totally siezed) didn't have it, and no amount of effort was able to shift the original one from the linkage. Originally I fitted a bolt in this location and used a locknut arrangement to try to stop it loosening itself over time. Apparently this didn't work as since then I've lost two bolts. Annoyingly the replacements I have, presumably because they're a metric size, don't fit. The smallest size I've got that fits drops straight through, the next size up won't fit. Adding an extra washer to the smaller one adds enough length that I can't then get the split pin in. So we will need to use a bolt then for the time being. It was at this point I had a bit of a brainwave. There are two pivot joints on the gear linkage of this type. The lower one (the source of my problem) attaches to a rod which acts as a see-saw before attaching to the gear selector on the gearbox itself nearer the top of the box. So I took the standard coupler out of the top pivot and installed that in the hard to get to bottom location. I then fitted a bolt and lock nut to the top one.  The fact that I can actually get to it makes it possible to easily do the locknut up *way* more tightly than I probably managed last time. I also put a blob of thead lock on it. At least if it does drop off again in future replacing the thing will be a five minute job as it's dead easy to get at. I do get the impression that I may need to look at replacing the gearbox seals at some point though...  Yes, I am indeed still out of gloves. The box has always been quite oily but never actually seems to drip anything so I'm not worrying about this too much in the short term but it would be nice to get that sorted. While I had access to the rear of the bulkhead because the service hatch was out I also replaced the self tapping screws that were holding the fire extinguisher bracket in place as they had (unsurprisingly) stripped their holes out so the thing wobbled around madly and rattled while driving. Bolts and nice big washers were instead employed which has made the extinguisher sit far more securely in place and far less likely to launch itself off the bulkhead if I were to brake too sharply. Given how loose the screws were I'm honestly surprised it hadn't already done so. I'd been literally dripping with sweat since about two minutes after leaving the house so called time at this point before I wound up passing out from heat exhaustion (showing 36C in the garage by the time I called it). I'll check the gearbox and diff oil levels tomorrow before I button the service hatch back up and call this round of work done. |

| |

Last Edit: Aug 11, 2020 22:19:04 GMT by Zelandeth

Current fleet: 73 AC Model-70. 75 Rover 3500. 84 Trabant 601S. 85 Sinclair C5. 06 Peugeot Partner 1.6HDi.

|

|

|

|

|

Aug 11, 2020 21:51:05 GMT

|

|

Just a thought, incase the CVT gives you too much trouble...

Since the rear suspension is early rear engined Fiat, and the engine is Steyr Puch, it should be pretty easy to convert the car to a regular 4 speed with a gearbox out of the Fiat 126 version of the Steyr Puch.

Same basic engine, but mated to a Fiat 500 gearbox.

Earlier Fiat 500 based Steyr Puch's used their own gearbox & rear suspension.

|

| |

|

|

|

|

|

Aug 11, 2020 22:17:54 GMT

|

|

There would be quite a bit of work involved in doing that. Basically everything forward of (and including) the flywheel would need to be swapped. The front engine mounts on this are also attached to the AC gearbox so those would need to be re-engineered. It's worth noting that the drive currently comes out of the CVT, goes into a chain drive and is then dropped down and into the Fiat diff, making the whole arrangement shorter. Not sure how the setup in the Fiat 126 is arranged, but I could see there being issues with the driveshafts winding up in the wrong place and things like that. If that's set up for a standard diff at the front, gearbox behind that, then engine at the back you would definitely run into issues with where things need to sit. Obviously there's no provision for a conventional gearshift in this car either so that would need to be worked out, plus some way to operate the clutch as there are currently no pedals present.

The CVT actually works pretty well it seems. The only thing she's not really fond of is picking up pace north of 40 or so if you pull away up hill, but I think that's more just to be expected when you're working with a 20bhp engine than any particular limitations of the drive system. On the level or downhill she picks up pace a lot more briskly than you would tend to expect from something like this, and maintaining speed on differing road conditions doesn't seem to be an issue.

The only real complaint about the CVT so far to be honest is that it isn't half noisy at speed!

There's really not much to go wrong with it really...unlike a lot of modern CVT systems which overcomplicate things with all sorts of feedback, electronics etc...Only thing I really need to do is find the exact specs of the original belts so I can pick up a couple of proper new ones rather than old stock that's been sitting around perishing for decades.

As for long term reliability...well we'll just have to wait and see won't we!

|

| |

Current fleet: 73 AC Model-70. 75 Rover 3500. 84 Trabant 601S. 85 Sinclair C5. 06 Peugeot Partner 1.6HDi.

|

|

|

|

|

Aug 11, 2020 22:34:31 GMT

|

Cool, if you are happy with it there is no reason to change it.  Just wanted to let you know there might be a good option available, if you were in a bind. |

| |

|

|

Rich

Club Retro Rides Member

Posts: 6,339  Club RR Member Number: 160

Member is Online

Club RR Member Number: 160

Member is Online

|

|

|

|

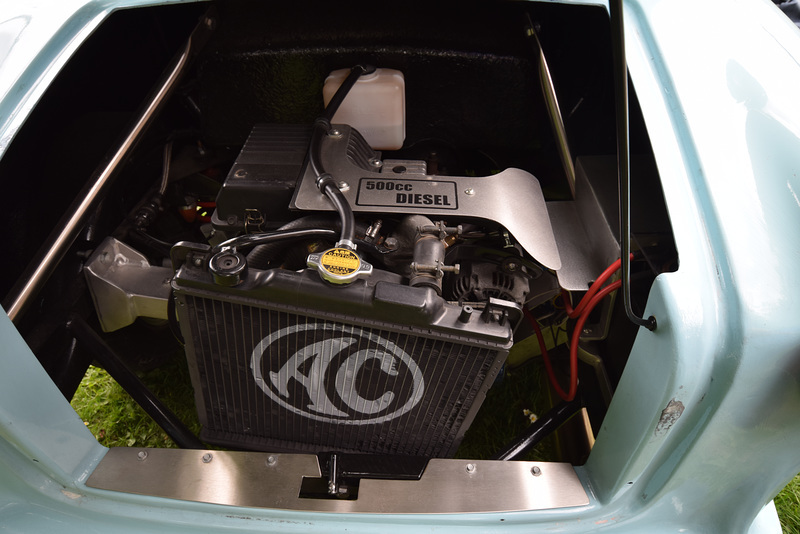

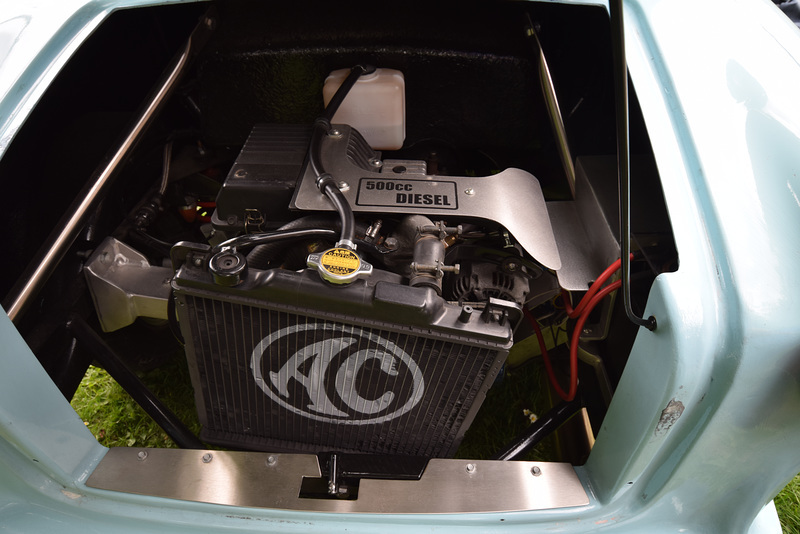

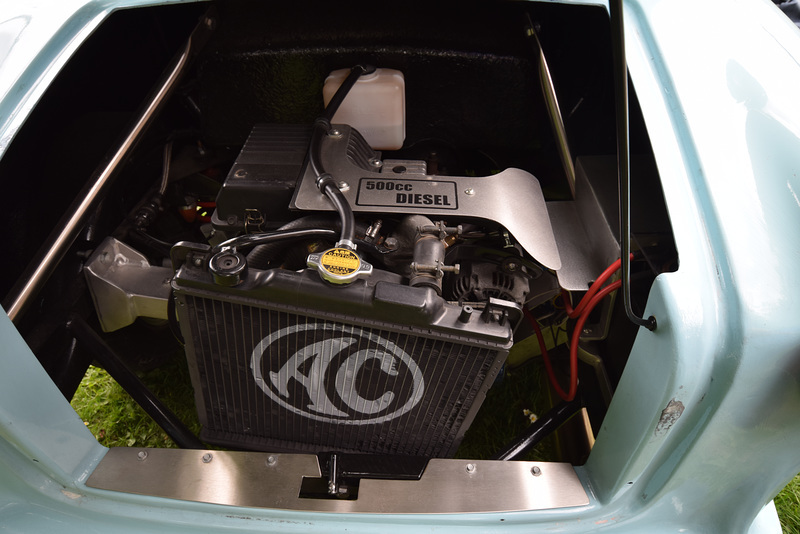

If you were desperate to fit a different engine in future I’d only recommend the engine and CVT from an Axiam Microcar. 2 cylinder Kubota diesel.  Fitted one in my dads ‘off-road’ buggy. Although you are doing fine with the OE engine so that’s moot.  |

| |

|

|

|

|

|

Aug 12, 2020 16:11:39 GMT

|

|

That CVT looks very like the Invacar's !!

|

| |

|

|

|

|

|

Aug 12, 2020 18:49:03 GMT

|

If you were desperate to fit a different engine in future I’d only recommend the engine and CVT from an Axiam Microcar. 2 cylinder Kubota diesel.  Fitted one in my dads ‘off-road’ buggy. Although you are doing fine with the OE engine so that’s moot.  would not be the first! heres one someone else did! although its coupled the original AC Gearbox and Salsbury CVT setup still IIRC   (its currently on the private plate VAV1L, its original plate is MPD553P) sadly I don't know the current whereabouts of it but one of the previous owners (or maybe current owner still?) posted about it on this very forum!  forum.retro-rides.org/thread/138513/1976-ac-invacar-model-70?page=1 forum.retro-rides.org/thread/138513/1976-ac-invacar-model-70?page=1 I'm curious to know why the engine was swapped, was it just cuz or was there an issue with the orignial engine or was there another reason?  (I do know of some videos of MPD553P shown running seemingly fine on her orignial Steyr puch flat twin engine) |

| |

|

|

Rich

Club Retro Rides Member

Posts: 6,339  Club RR Member Number: 160

Member is Online

Club RR Member Number: 160

Member is Online

|

|

|

|

If you were desperate to fit a different engine in future I’d only recommend the engine and CVT from an Axiam Microcar. 2 cylinder Kubota diesel.  Fitted one in my dads ‘off-road’ buggy. Although you are doing fine with the OE engine so that’s moot.  would not be the first! heres one someone else did! although its coupled the original AC Gearbox and Salsbury CVT setup still IIRC   (its currently on the private plate VAV1L, its original plate is MPD553P) sadly I don't know the current whereabouts of it but one of the previous owners (or maybe current owner still?) posted about it on this very forum!  forum.retro-rides.org/thread/138513/1976-ac-invacar-model-70?page=1 forum.retro-rides.org/thread/138513/1976-ac-invacar-model-70?page=1 I'm curious to know why the engine was swapped, was it just cuz or was there an issue with the orignial engine or was there another reason?  (I do know of some videos of MPD553P shown running seemingly fine on her orignial Steyr puch flat twin engine) That’s interesting as I’ve not noticed before, the engine isn’t orientated how it thought it would be, the crank runs front-back rather than side to side as I imagined. Neat conversion though. I bet you could brim the tank and run it for years with the diesel in  |

| |

|

|

|

|

|

Aug 13, 2020 20:51:13 GMT

|

|

...The alignment of that radiator is making my teeth itch!

Which is odd given everything else looks so nearly done. Guessing that there's a good reason for it.

What's the maximum running RPM on one of those diesels? If using the original drive system I could see that potentially being a big limitation...fine and good getting 300mpg, but if you're sitting on the rev limiter at 40mph you're hardly going to want to travel far!

I do wonder what the story is there, whether it was a case of doing it because they wanted to prove then could or if there were issues with the original power unit. I can't see me ever being temoted down a road like that as the stock power unit is both surprisingly capable and quite a charming little thing. The only possible thing that might happen if I ever did find myself needing to do a rebuild might be looking for a set of pistons and barrels from a 650cc engine as those are the only differences as far as I'm aware. Not really because I've any interest in going any faster, just figure the bigger power reserve you have the easier your life tends to be when negotiating city traffic.

|

| |

Current fleet: 73 AC Model-70. 75 Rover 3500. 84 Trabant 601S. 85 Sinclair C5. 06 Peugeot Partner 1.6HDi.

|

|

Rich

Club Retro Rides Member

Posts: 6,339  Club RR Member Number: 160

Member is Online

Club RR Member Number: 160

Member is Online

|

|

Aug 13, 2020 21:38:08 GMT

|

...The alignment of that radiator is making my teeth itch! Which is odd given everything else looks so nearly done. Guessing that there's a good reason for it. What's the maximum running RPM on one of those diesels? If using the original drive system I could see that potentially being a big limitation...fine and good getting 300mpg, but if you're sitting on the rev limiter at 40mph you're hardly going to want to travel far! I do wonder what the story is there, whether it was a case of doing it because they wanted to prove then could or if there were issues with the original power unit. I can't see me ever being temoted down a road like that as the stock power unit is both surprisingly capable and quite a charming little thing. The only possible thing that might happen if I ever did find myself needing to do a rebuild might be looking for a set of pistons and barrels from a 650cc engine as those are the only differences as far as I'm aware. Not really because I've any interest in going any faster, just figure the bigger power reserve you have the easier your life tends to be when negotiating city traffic. The microcar does more than 40. I am yet to actually unleash the buggy on tarmac but I’m expecting it to do 50mph or more. I suspect it probably would be slower than the stock engine but not by a lot. Hoping to actually find out soon! |

| |

|

|

|

|

|

|

|

|

Kubota 2 cyl diesels run up to 3600 rpm, with a peak power output of 11hp sae.

|

| |

|

|

|

|

|

|

|

Finally got around to getting something done today which had been bugging me since the day that TPA first started rolling again.  They're pretty cheap and nasty but will do the job just fine. It's not as though I'm going to be commuting daily in the dark. Hopefully somewhere down the line I'll come across a better quality more in-period set of 7" H4 headlights. They certainly look more at home in the car than the clear ones which I've had in here until now though!  Halfway there...  Done. Doesn't that look better?  Before I called it done on the offside door I wanted to get one last issue ticked off while I still had the drill and such out - that the upper runner channel (normally held on by several tiny self tapping screws) had pulled out of the door at the front.  I drilled a couple of new holes and secured it with proper bolts with large penny washers behind the panel to better spread the load. Hopefully that won't cause is any issues in the future. I'll need to "massage" the front of that rail back into shape just a bit but that's a lower priority that can just stay on the whiteboard to do list for now. Then once I'd re-secured the door seal in a few places where it had fallen off I called it good in that area for now.  That door is still a pig to get closed sometimes and doesn't run properly on the lower runner so I will need to pull the whole lot apart at some point. I think that the rollers are knackered or seized to the axle they sit on. While I was fiddling with door seals I reesecured the one on the nearside door which had started to peel off yet again. I've given up on gluing these in now after the third or fourth time and have just screwed it to the frame. Yes, I know that's not how the did it at the factory...but I'm sick of having to clean everything off and try a different type of adhesive every two months...and Sikaflex seems like overkill which is about the only thing I can think of I've not tried yet...Though I suspect it would just pull the gel coat off the fibreglass which is what I've already had happen in a couple places even with less powerful adhesives.  I do actually have a full set of new door seals for this car which I'll probably get fitted soon as these are a bit dog eared in places. It's a pretty low priority though. Before I put the rear service hatch back in I checked the oil level in both the diff and the gearbox and despite the visible leak they were both still showing as spot on. Before I actually put the hatch back in through I wanted to make an improvement to the fittings for that. Originally this was secured by moderately large self tapping screws which screwed into spring clips behind the panel - all but two of these had dissolved in my case and required me to drill them out to get the panel off. Trying to get the screws into the bottom two holes is also nigh on impossible given that I can't just pull the back of the seat off with two bolts because I'm not using the original seat. Even having replaced the spring clips in there I've found that the screws tend to loosen themselves off over time as well. My solution was to stick a bolt through from the back side, sandwiching the bulkhead panel between two big washers, essentially giving me studs attached to the bulkhead which I can then bolt the cover down onto.  This is the first time that I've ever actually had this really solidly secured in place I think. It made getting the thing in way, way easier as it just slotted onto the bolts rather than having to spend forever trying to wriggle it around until all the holes line up and I can get the screws in. I'll be curious to see if this has had any impact on the noise level in the cabin. Just need to finish tidying up my tools and such tomorrow and then we should be able to get her out and about again. |

| |

Current fleet: 73 AC Model-70. 75 Rover 3500. 84 Trabant 601S. 85 Sinclair C5. 06 Peugeot Partner 1.6HDi.

|

|

|

|

|

|

|

Kubota 2 cyl diesels run up to 3600 rpm, with a peak power output of 11hp sae. So not a great match to the original transmission then...replacing a 19.3bhp engine which can spin to around 4500 (from memory, I don't have the manual immediately to hand...it's not been transferred to my new phone yet and for reasons unknown I took the file down from my website). My gut feeling is you would be running out of revs somewhere in the region of 45-50. If you can get there with half the horsepower...though the diesel has more torque so would probably manage eventually. Quite prepared to be proven wrong and be told it works well, but the numbers just seem a bit off to my untrained eye. Especially with the additional weight onboard...I don't think one person would be lifting one of them in or out of the car by hand (which you can, admittedly with some effort, with the original engine. I have seen those little Kubota engines in generator and pump applications and they do seem like solid little units though. |

| |

Current fleet: 73 AC Model-70. 75 Rover 3500. 84 Trabant 601S. 85 Sinclair C5. 06 Peugeot Partner 1.6HDi.

|

|

|

|

|

|

|

|

Go one better and get the 17hp 3cyl version.

Mechanical injector pump, so ultimately you can dial it out over the design spec. You could probably pull 4000 rpm out of it.

|

| |

Last Edit: Aug 14, 2020 2:40:02 GMT by PhilA

|

|

Rich

Club Retro Rides Member

Posts: 6,339  Club RR Member Number: 160

Member is Online

Club RR Member Number: 160

Member is Online

|

|

|

|

Go one better and get the 17hp 3cyl version. Mechanical injector pump, so ultimately you can dial it out over the design spec. You could probably pull 4000 rpm out of it. That’s the thing we realised, you can bolt the microcar drivetrain to any cylinder number Kubota, it’s not fussy. Could go all Out with a 4 cylinder.  the 2 is certainly plucky, I knew they weren’t powerful but i suspect possibly more torque than the petrol in the Invacar? May be wrong though. |

| |

|

|

|

|

|

Aug 14, 2020 12:48:42 GMT

|

Go one better and get the 17hp 3cyl version. Mechanical injector pump, so ultimately you can dial it out over the design spec. You could probably pull 4000 rpm out of it. that is what I believe is fitted to VAV1L/MPD553P, at least I do recall reading somewhere it was a 3 cylinder jobby (I don't actually know exactly where its kubota engine came from originally, just shared it to show that someone had indeed done it LOL) as for the rev limit of the Model 70's Steyr puch engine, I don't actually know LOL, its one of those things I don't know that bugs me that I don't know! but I have not been able to find much on it sadly I do know it only makes peak horse power at about 5000RPM so you have to wind a Model 70 up to about 67-70Mph before you are even making peak horse power power  (according to the work shop manual the CVT holds the engine at 3500RPM, which is Peak torque all 22 foot pounds of it, up to about 45Mph, where it then goes into a fixed ratio mode and engine speed increased proportionally to road speed, with the engine doing 4500RPM at 60Mph) I do know also recently that when watching a Steyr puch guru talk about various Steyr puch flat twin camshafts, he mentioned that the one I'm pretty sure fitted to Model 70's goes up to about 6000RPM so maybe thats the RPM limit, but I'm not 100% sure doing some maths an RPM limit of 6000, gives us 80Mph in a Model 70 which does line up with their reported top speed of 82-85Mph, but I'm still waiting for someone to drive a healthy Model 70, like TPA, flat out and actually verify what the top speed is  |

| |

|

|

the 2 is certainly plucky, I knew they weren’t powerful but i suspect possibly more torque than the petrol in the Invacar? May be wrong though.

the 2 is certainly plucky, I knew they weren’t powerful but i suspect possibly more torque than the petrol in the Invacar? May be wrong though.