luckyseven

Posted a lot

Owning sneering dismissive pedantry since 1970

Owning sneering dismissive pedantry since 1970

Posts: 3,839

Club RR Member Number: 45

|

|

Oct 10, 2019 20:50:54 GMT

|

I never wear gloves when using an angle grinder. I've always been fairly complacent towards them until I had my first ever disc shatter the other day, which woke me up I can tell you! I've been meaning for ages to get myself a decent faceshield though. Now I'm old and blind and need glasses for close-ups it's a right pain, especially if I'm using a breathing mask too. Having a big Greek nose means they never seal properly along the top edge which means I just puff loads of warm moist air up inside my glasses so they steam up in seconds Wish I'd taken Daltrey's advice and died before I got old In other news, when I worked on site projects we were always told to not wear gloves with control or swing tools; so if you were using a pickaxe or mattock you could wear a glove on the forward sliding, hand but not on the heel hand that controlled the base of the stave because that was your grip hand. Gloves and, say, a billhook were a definite no-no unless you liked having a slick handle slip out of your gloved "grip" and embed itself inches into your tibia. The only thing we never took liberties with were the chainsaws, partly because of the NPTC inspectorate being quite happy to remove licenses back then and partly because chainsaw kickback was one guaranteed way to spoil your good looks for the old main drag  I had a mate whose chainsaw kicked back out of an undercut and because of the tree above, had nowhere to go but backwards. Caught him straight in the lovespuds, though his kevlar aramid trousers did their job and snarled the chain to a stop before it cut anything he wanted to keep. But when a chain travelling about 60mph stops dead, there's a lot of kinetic energy that has to go somewhere and it had no choice but to go into forcing the saw the opposite way. Taking it where he did must have been like being kicked in the nuts by a shire horse  We didn't laugh... until we realised he hadn't just disemboweled himself. Then we genuinely soiled ourselves laughing. Didn't get much out of him for the rest of the day |

| |

|

|

|

|

|

|

|

Oct 11, 2019 17:58:22 GMT

|

|

End of the week and we've been progressing well. Both rear crossmembers are done, both ends of the napoleon's hat are pretty much finished - just need a little fine tuning with the power file. Weld through primer next and the driver side floor pan is ready to go in. Passenger side needs trimming down and it'll be ready too, so potentially we're going to be done with welding the floorpan by the end of next week. Still thinking of IRS brackets, and maybe a gearbox mid mount too!

|

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

Oct 12, 2019 11:25:37 GMT

|

|

What's involved with replacing the floor pans? Do you need to line them up with the body?

Or can this all be done without having to refit the body before welding them on?

I fear I'm going to have to do this at some point on mine

|

| |

1967 Beetle

|

|

oldisbetter

Part of things

If it has a ECU it's complicated :)

If it has a ECU it's complicated :)

Posts: 478

|

|

Oct 12, 2019 19:36:50 GMT

|

What's involved with replacing the floor pans? Do you need to line them up with the body? Or can this all be done without having to refit the body before welding them on? I fear I'm going to have to do this at some point on mine I think if you own a beetle it will need to be taken to bits fully at some point, I am making room to do one of mine at some point so its all good info to see anything coming apart, the good thing is i am very slow but also very rough so its a good balance  |

| |

|

|

|

|

|

Oct 12, 2019 21:00:27 GMT

|

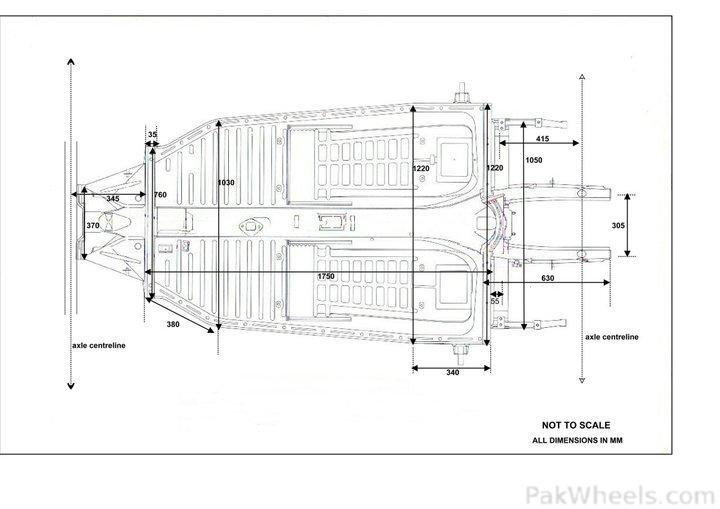

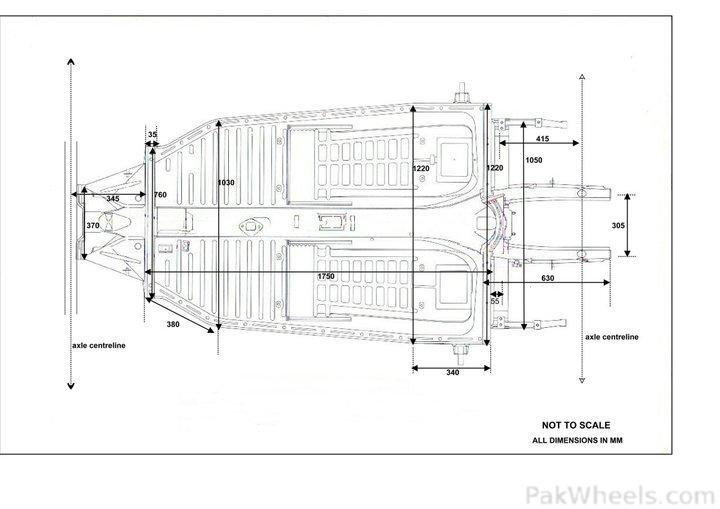

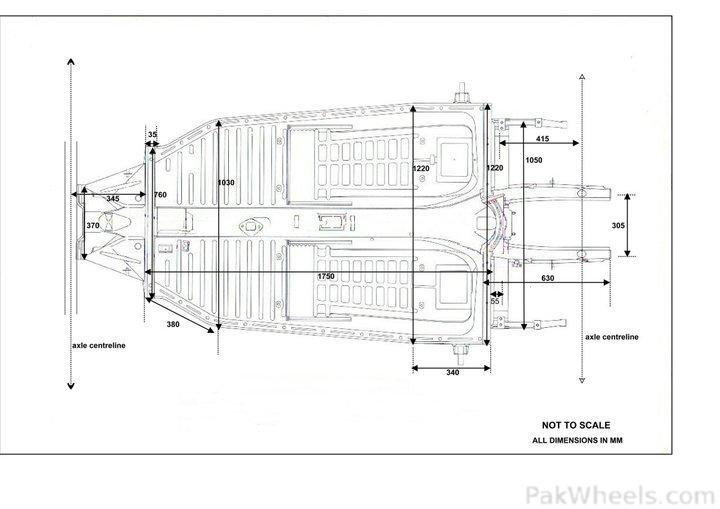

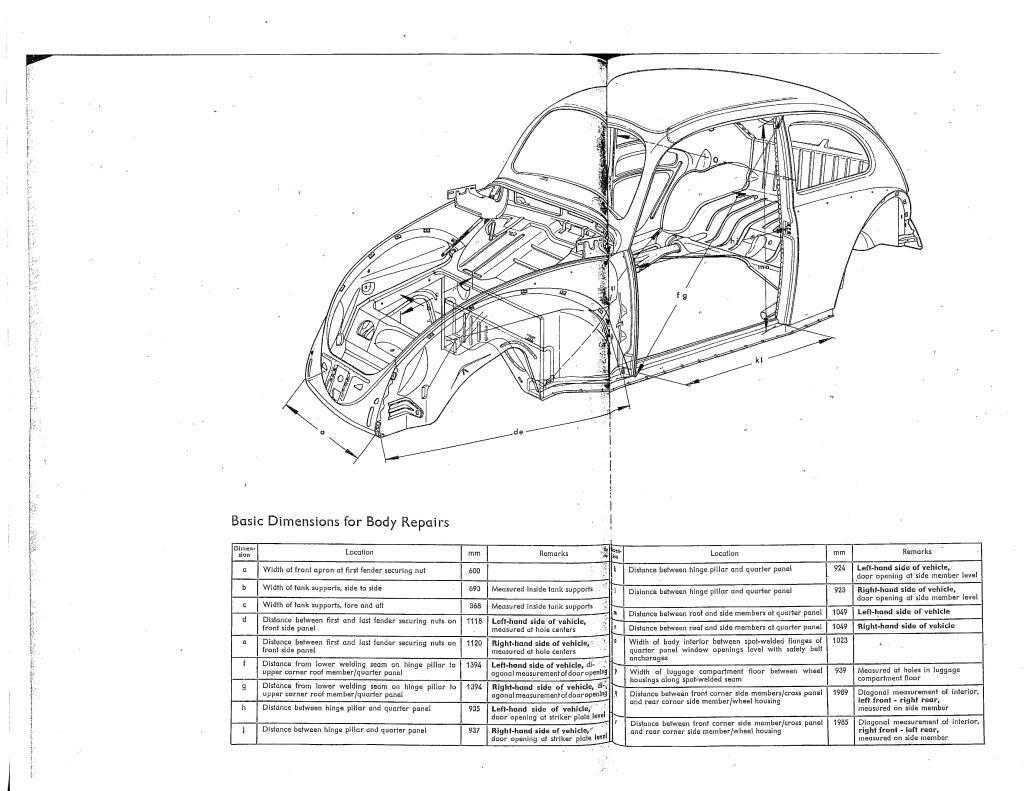

What's involved with replacing the floor pans? Do you need to line them up with the body? Or can this all be done without having to refit the body before welding them on? I fear I'm going to have to do this at some point on mine Ideally, you'd have either the floors or the channels solid enough to be able to replace the other, which is how I did my Ghia. On this car however, the passenger side channel was original but rotted out, and the drivers side was replaced, possibly due to the accident damage that caused the front quarter to be changed, and it was rotten too. The pans and channels were welded together too, so no chance of saving any reference points! I have found a few diagrams on the internet that give dimensions for the holes along the ends of the pan, so I used a sheet of 8x4 plywood and some wooden blocks to make a rudimentary chassis table with a couple of the holes marked out. This has let us position the floorpan half in exactly the right place relative to the crossmember at the back and napoleon's hat at the front. This phone is a bit rubbish so I might not be able to add the diagrams... |

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

Oct 12, 2019 21:02:59 GMT

|

Try again...  |

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

Oct 17, 2019 16:51:53 GMT

|

Try again...  Cheers that’s handy! Are the heater channels just as awkward? Or will you attach these to the pan once done and then sit the body on it to weld? They seem like a nightmare to fit from what I’ve read. But it’s something I wanna replace on mine at some point. |

| |

1967 Beetle

|

|

|

|

|

Oct 17, 2019 18:41:31 GMT

|

|

To be honest, there are a couple of ways of doing it. If the body is bad, chop all the rot out and see what you're left with, then assemble everything to the floorpan and plop the body back on, weld where it touches and fill the gaps. I did one about 15 years ago where I wasn't going to do the standard front and rear quarter panel repairs because although the channels were toast, the rot hadn't spread into the surrounding area. I drilled out the factory spot welds, ground out the seams around the inner a post and b post and cut the channel out in sections. Trickiest bit is at the back, where the crossmember joins the channel - if I remember right we unbolted the body and lifted it just a couple of inches so we didn't have to disturb too much, then slide the channel in, bolt the body back down and weld through the spot weld drill holes. Do one side at a time, obviously!

It did help that that particular car was pretty much original and unmolested other than a bad patch on the front bumper mount. It had been repainted once since 1970 and that was it - its the orange one that is in the pictures on the first page of this thread (I think!) - other than that it was untouched. Obviously I built a 1641 for it, lowered the front end and stuck it on fat and thin Empi Sprintstars, Cal Look all the way - but I did re-instate the chrome trim in the (new) window rubbers and even tracked down the correct original year rubber mat for the front to match the rear one. Sold it far too cheap, and still miss it now...

|

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

Oct 17, 2019 18:45:48 GMT

|

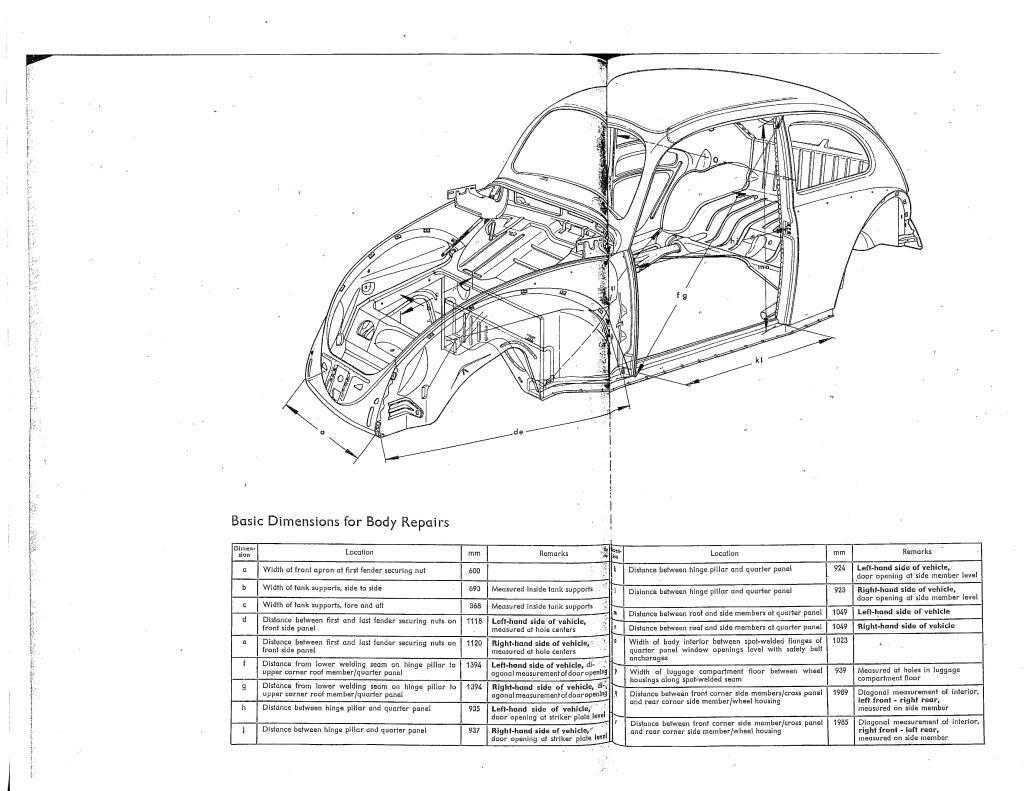

This might be useful to you...  I'm going to make door opening jigs as well, so I can brace the body square. I didn't do this one when it was on the original floorpan due to the accident damage - I don't know how square the body is. It'll be right once we've finished though! |

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

Oct 17, 2019 21:10:54 GMT

|

|

No to be a pain but, more photos please!

|

| |

|

|

|

|

|

|

|

Oct 17, 2019 22:18:21 GMT

|

No to be a pain but, more photos please! I'll see what I can do! It's quite tricky taking photos during lessons - I have to get photos of the students each carrying out the tasks, then I have to make sure that photos I post here don't identify them, as each student and their parents have to have photo release forms filled in, so it gets to be quite a task in itself! Today we did reach a bit of a mini-milestone, as the first pan half has started to be welded in. Used a bit of weld through primer, cranked up the welder and started to plug weld through the holes in the floorpan edge that the kids had previously punched in. Not every weld took (some of the students aren't confident with the welder so just filled up the hole) so we've got to grind back and redrill a couple, and a little bit of tapping the back corner down to fit the flange perfectly will be necessary, but we're getting there. Photos when it's done! |

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

|

|

Not entirely finished, but here's Fridays photo!  |

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

Oct 21, 2019 12:08:26 GMT

|

|

Great work.

I'd LOVE to have learned something (anything) of working on cars when I was a kid.......

|

| |

|

|

|

|

|

Oct 28, 2019 11:07:21 GMT

|

|

Half term update!

Well, with a bit of persuasion for the year 10s to have a go, we've got both pan halves welded in! Year 10 were a little bit grinder-happy, so trimmed a hit too much off the edge of the pan that welds to the spine, but there was still enough to weld to and keep it solid. Youthful exuberance and trimming to the wrong side of a scribed line...

After the holiday we've got to get the front of the drivers side pan half modified to take the reinforcing plate that picks up the pedal assembly in place, then grind down a couple of the bigger welds before a bit of epoxy primer and seam sealer. Then we're onto the body! Might get heater channels in by Christmas...

|

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

|

|

Second day back at school after half term and we're cracking on with the pedal box reinforcing plate. From 1967-ish onwards, VW used a new and improved pedal assembly, that while it didn't look as nice, allowed for a small bracket to bolt into the floor to keep it stable under hard braking. With 1500cc and 44 whole raw snarling horsepower, I guess they decided that the brakes would get a much more vigorous work out and needed beefing up... Early pedals:  Late pedals - note small bracket:  Now, just bolting it to the floor would never do; no, what was needed was a 5.5mm thick plate welded to the top of the pan, with holes tapped to accept two m8 bolts to brace the pedals! Overkill? Well, yes, but VW like to re-engineer things for fun, so the floorpan got a recess pressed into it for this plate to be welded into. You can see in this picture that the new floorpan doesn't have this pressing - it's a shame that these www.vwheritage.com pan halves, while excellent in every other respect, don't have the pressing, and it's also a shame that I didn't spot it before the kids welded the buggers in...  |

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

|

|

|

So, what to do about it? Well after spending 15 minutes explaining why a panel made in Taiwan (who I think drive on the left) for a British company (and we definitely drive on the left) is only available in LHD configuration, one of the lads removed the plate from the old pan half and one of the girls made a replacement one out of 2mm plate - the idea that the students have worked out is that if the original pressing was level with the bottom of the ribs, and the ribs are 3.5mm deep, with the plate being 5.5.mm thick that puts the top of the plate 2mm above the top of the pan. She also made a rather clever card template for a thicker plate that will weld onto the underside of the floorpan and curve around the ribs but still allow for a decent thickness of metal to strengthen the floorpan and tap into for those m8 bolts! Genius!

|

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

|

|

Photo as of the end of the day:  And view from my side door - the head teacher from the school next-door has just had his '71 painted - unusual two tone colour split, but it looks great! Our kids will be rebuilding that one too! |

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

|

|

|

|

|

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

oldisbetter

Part of things

If it has a ECU it's complicated :)

If it has a ECU it's complicated :)

Posts: 478

|

|

|

|

It looks like you are making some lovely progress Neil, I have managed a lot less progress on my 56 oval but the good news is the guy that the DVLA sent out to check the car is real and all the numbers are correct gave it the thumbs up and an age related number plate should be granted in 7 to 10 days.  |

| |

|

|

|

|

|

|

|

|

Nice one Rob! If you're going solid but patina, the black transport primer on the wings gets surface rust pretty quickly, so once it matches the body just give the whole thing a coat of wax to stop it all getting worse. Obviously paint underneath them though!

I don't know how complete the oval is, but I've got a pair of sloping headlamps off the '71 - we're going back to the proper upright ones so they're just sat in a cupboard at school. They've got Cibie lenses, which I've never seen before, and look complete although the rings are rusty. I suspect they're late 90's repro US-spec sealed beam ones that the lenses have been changed on.

|

| |

1968 Cal Look Beetle - 2007cc motor - 14.45@93mph in full street trim

1970-ish Karmann Beetle cabriolet - project soon to be re-started.

1986 Scirocco - big plans, one day!

|

|

|

|

I had a mate whose chainsaw kicked back out of an undercut and because of the tree above, had nowhere to go but backwards. Caught him straight in the lovespuds, though his kevlar aramid trousers did their job and snarled the chain to a stop before it cut anything he wanted to keep. But when a chain travelling about 60mph stops dead, there's a lot of kinetic energy that has to go somewhere and it had no choice but to go into forcing the saw the opposite way. Taking it where he did must have been like being kicked in the nuts by a shire horse

I had a mate whose chainsaw kicked back out of an undercut and because of the tree above, had nowhere to go but backwards. Caught him straight in the lovespuds, though his kevlar aramid trousers did their job and snarled the chain to a stop before it cut anything he wanted to keep. But when a chain travelling about 60mph stops dead, there's a lot of kinetic energy that has to go somewhere and it had no choice but to go into forcing the saw the opposite way. Taking it where he did must have been like being kicked in the nuts by a shire horse  We didn't laugh... until we realised he hadn't just disemboweled himself. Then we genuinely soiled ourselves laughing. Didn't get much out of him for the rest of the day

We didn't laugh... until we realised he hadn't just disemboweled himself. Then we genuinely soiled ourselves laughing. Didn't get much out of him for the rest of the day I had a mate whose chainsaw kicked back out of an undercut and because of the tree above, had nowhere to go but backwards. Caught him straight in the lovespuds, though his kevlar aramid trousers did their job and snarled the chain to a stop before it cut anything he wanted to keep. But when a chain travelling about 60mph stops dead, there's a lot of kinetic energy that has to go somewhere and it had no choice but to go into forcing the saw the opposite way. Taking it where he did must have been like being kicked in the nuts by a shire horse

I had a mate whose chainsaw kicked back out of an undercut and because of the tree above, had nowhere to go but backwards. Caught him straight in the lovespuds, though his kevlar aramid trousers did their job and snarled the chain to a stop before it cut anything he wanted to keep. But when a chain travelling about 60mph stops dead, there's a lot of kinetic energy that has to go somewhere and it had no choice but to go into forcing the saw the opposite way. Taking it where he did must have been like being kicked in the nuts by a shire horse  We didn't laugh... until we realised he hadn't just disemboweled himself. Then we genuinely soiled ourselves laughing. Didn't get much out of him for the rest of the day

We didn't laugh... until we realised he hadn't just disemboweled himself. Then we genuinely soiled ourselves laughing. Didn't get much out of him for the rest of the day